Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-40-700-001-B00 HP System Module - Check The Variable Inlet Guide Vane (VIGV) And Variable Stator Vane (VSV) Actuating Mechanism, Testing-001

General

This TASK gives the procedure to check the VIGV and VSV actuating mechanism. It includes the procedure to examine the system and also check the high speed rigging position.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of the threaded parts. Let the parts soak before removal.

Lubricate all threads and mating faces of the nuts and the bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Spring balance, 0 to 150 lbf (0 to 203.37 N) range | LOCAL | Spring balance, 0 to 150 lbf (0 to 203.37 N) range | ||

| Vernier caliper | LOCAL | Vernier caliper | ||

| Dial gauge | LOCAL | Dial gauge | ||

| IAE 1R18254 Rigging pin | 0AM53 | IAE 1R18254 | 1 | |

| IAE 1R18423 Rigging pin | 0AM53 | IAE 1R18423 | 1 | |

| IAE 1R18892 Rigging pin | 0AM53 | IAE 1R18892 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cotter pin | LOCAL | Cotter pin | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

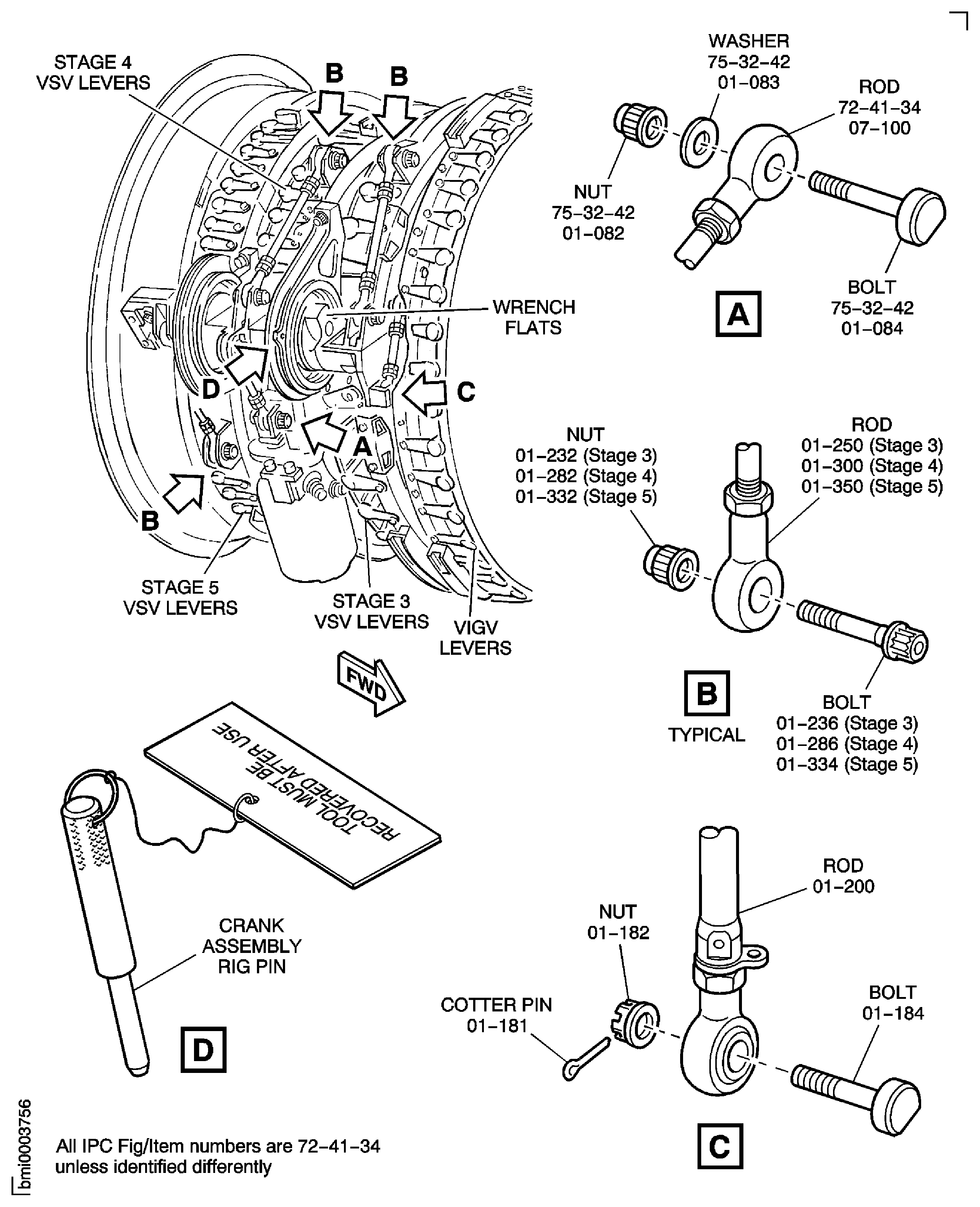

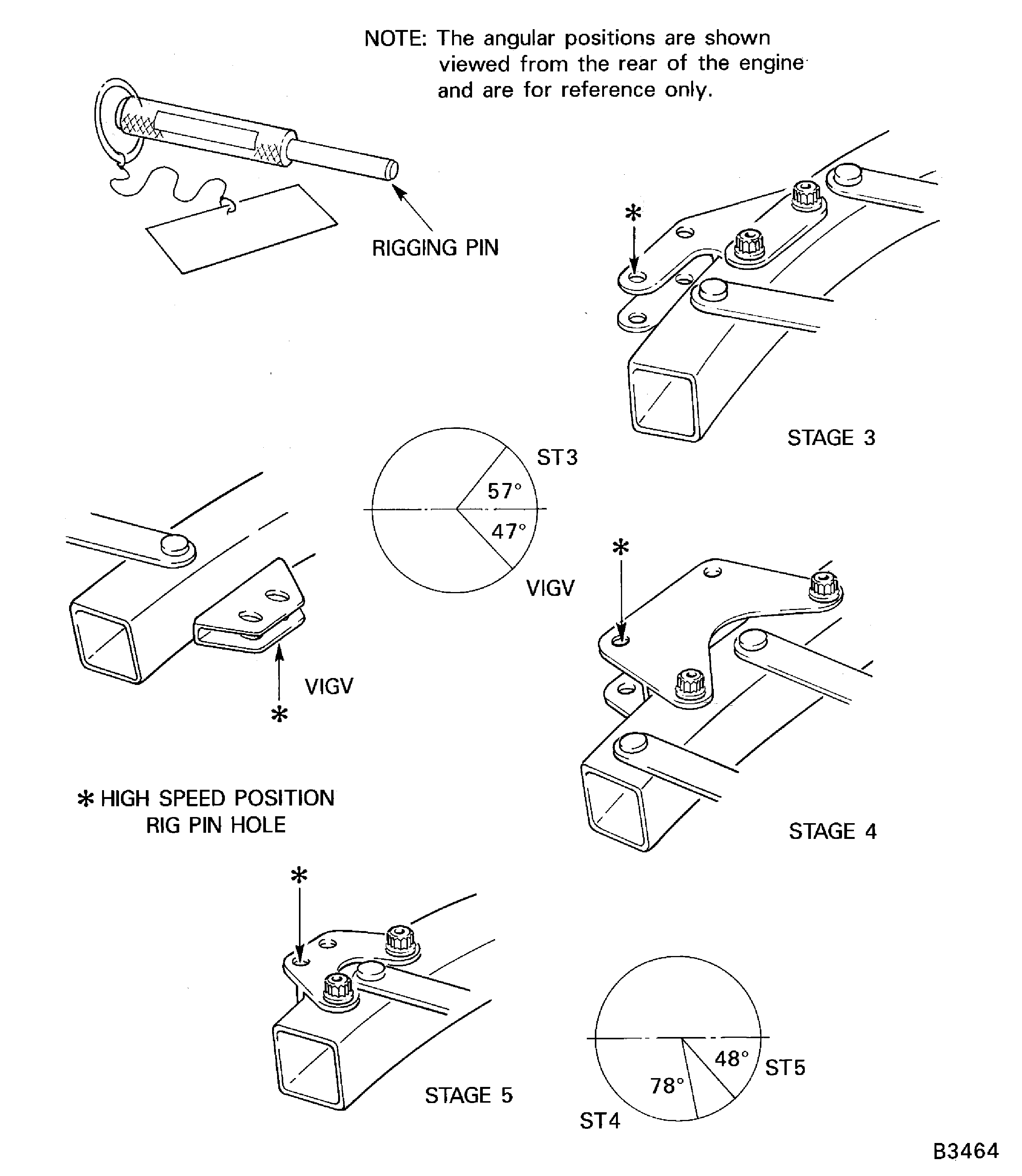

Install the IAE 1R18254 Rigging pin 1 off, through the rig pin holes in the crankshaft front bearing housing and the crankshaft.

Install the IAE 1R18423 Rigging pin 1 off or IAE 1R18892 Rigging pin 1 off in to the rig pin bracket on the VIGV unison ring and the VSV unison ring positions.

SUBTASK 72-00-40-220-114 Check the VIGV and VSV Actuating Mechanism

Put a torque wrench with an applicable wrench adapter on to the wrench flats of the crankshaft. Measure the torque necessary to turn the crankshaft from the low speed position to the high speed position. If the torque necessary is more than 350 lbfin. (39.5 Nm) then lubricate the VSV system, refer to TASK 72-41-00-440-002-B00 (ASSEMBLY-002, CONFIG-002). Measure the torque after lubrication, if it is still in excess of 350 lbfin., do steps Step through Step.

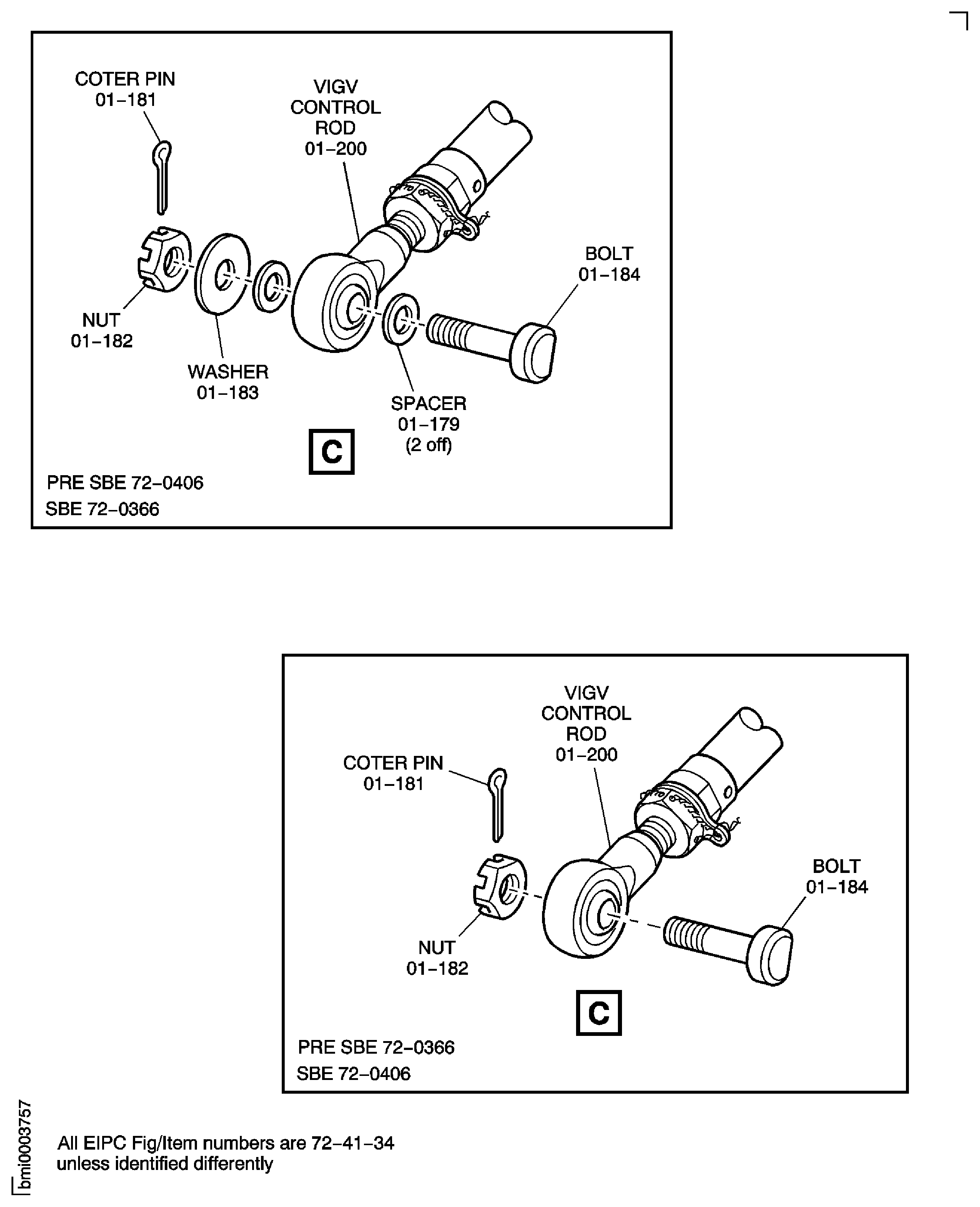

Pre SBE 72-0366, SBE 72-0406 and SBE 72-0426: Disconnect the VIGV control rod from the crank lever bracket on the VSV crankshaft. Refer to Figure, detail C.

SBE 72-0366, Pre SBE 72-0406 and Pre SBE 72-0426: Disconnect the VIGV control rod from the crank lever bracket on the VSV crankshaft. Refer to Figure, detail C.

SUBTASK 72-00-40-220-139 Check the Force Necessary to move the VIGV/VSV Actuating Mechanism (Pre SBE 72-0366, SBE 72-0366, Pre SBE 72-0406, Pre SBE 72-0426, SBE 72-0406 and SBE 72-0426)

SBE 72-0366: Actuating mechanism HPC variable vanes - introduction of a revised crankshaft assembly

SBE 72-0406: Actuating mechanism HPC variable vanes - introduction of a fully machined from bar crankshaft assembly

SBE 72-0426: Actuating mechanism HPC variable vanes - introduction of a revised crankshaft assembly with reduced front bearing interference

Install the cotter pin V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-181) through the nut and the bolt to safety the assembly. Refer to Step for the procedure to install the cotter pin.

Pre SBE 72-0366, SBE 72-0406 and SBE 72-0426: Connect the VIGV control rod to the crank lever bracket on the VSV crankshaft. Refer to Figure, detail C.

Install the bolt V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-184), two spacers V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-179), washer V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-183) and the nut V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-182) to attach right hand bearing to the integral VIGV crank lever of the VSV crankshaft.

Torque the nut to 170 lbfin. to 210 lbfin. (19 Nm to 24 Nm). Install the cotter pin V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-181) through the nut and bolt to safety the assembly. Refer to Step for the procedure to install the cotter pin.

SBE 72-0366, Pre SBE 72-0406 and Pre SBE 72-0426: Connect the VIGV control rod to the crank lever bracket on the VSV crankshaft, Figure, detail C.

SUBTASK 72-00-40-440-055 Connect the Control Rods (Pre SBE 72-0366, SBE 72-0366, Pre SBE 72-0406, Pre SBE 72-0426, SBE 72-0406 and SBE 72-0426)

SBE 72-0366: Actuating mechanism HPC variable vanes - introduction of a revised crankshaft assembly

SBE 72-0406: Actuating mechanism HPC variable vanes - introduction of a fully machined from bar crankshaft assembly

SBE 72-0426: Actuating mechanism HPC variable vanes - introduction of a revised crankshaft assembly with reduced front bearing interference

Align the control rod ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-100) to the Actuator.

Install the bolt HPC Variable Stator Vane Actuator (75-32-42, 01-084), the washer (75-32-42 01-083) and the nut HPC Variable Stator Vane Actuator (75-32-42, 01-082) to attach the control rod to the actuator.

SUBTASK 72-00-40-440-056 Connect the Control Rod to the VSV Actuator

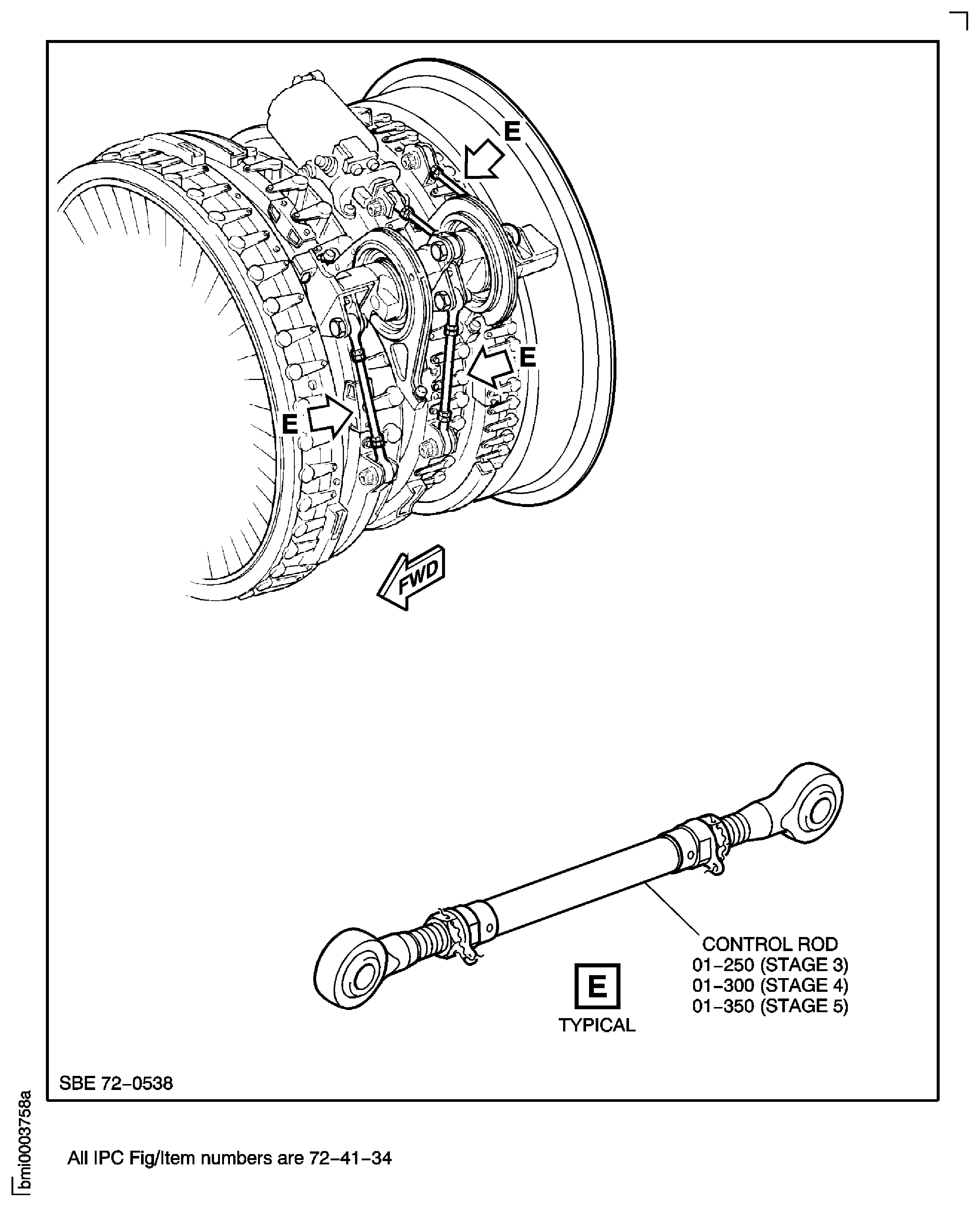

Figure: Pre SBE 72-0366, Pre SBE 72-0406 and Pre SBE 72-0538: VSV Crankshaft and Unison Rings

Pre SBE 72-0366, Pre SBE 72-0406 and Pre SBE 72-0538: VSV Crankshaft and Unison Rings

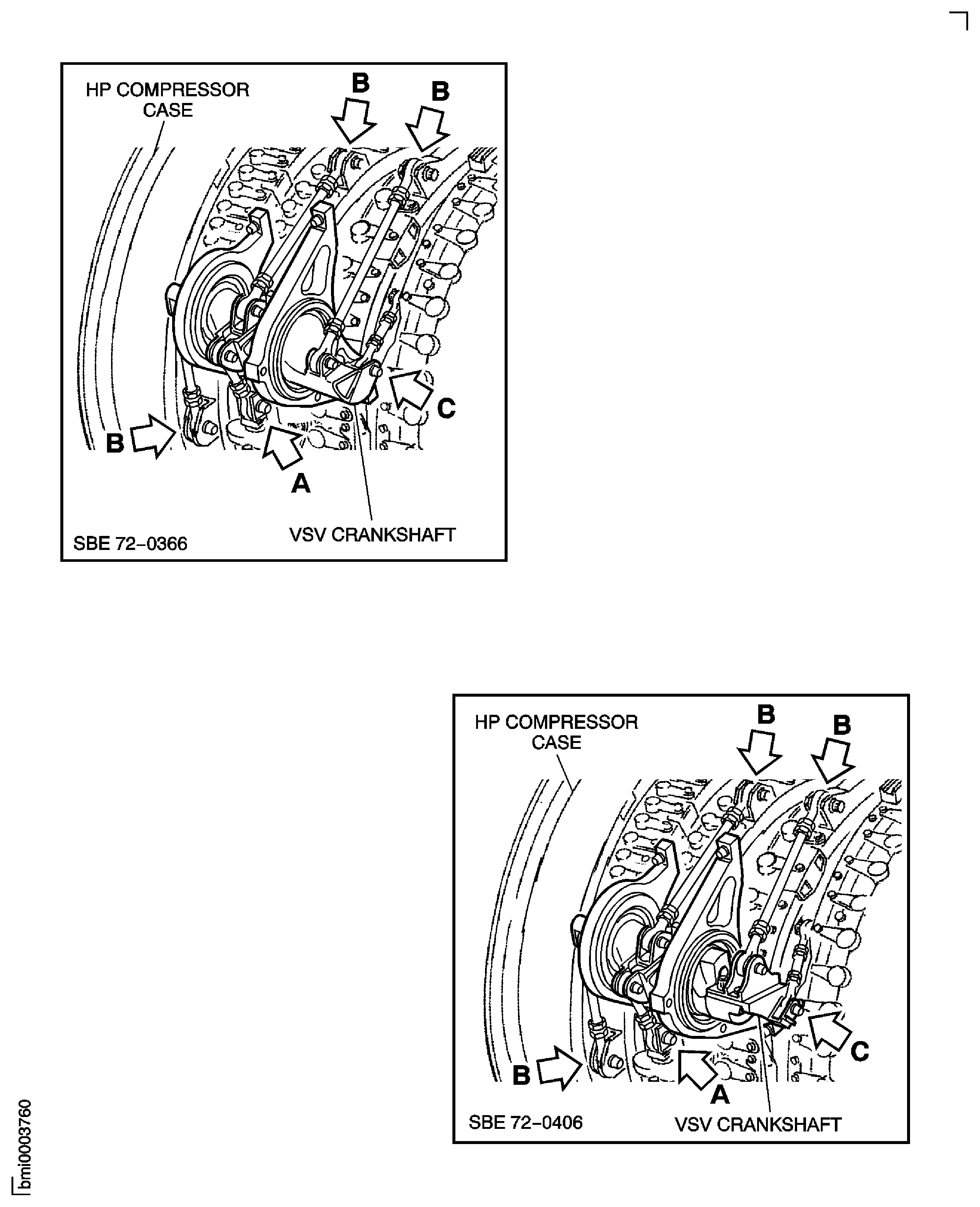

Figure: SBE 72-0366 and SBE 72-0406: VSV Crankshaft and Unison Rings

SBE 72-0366 and SBE 72-0406: VSV Crankshaft and Unison Rings

Figure: SBE 72-0366 and SBE 72-0406: VSV Crankshaft and Unison Rings

SBE 72-0366 and SBE 72-0406: VSV Crankshaft and Unison Rings

Figure: SBE 72-0538: VSV Crankshaft and Unison Rings

SBE 72-0538: VSV Crankshaft and Unison Rings

Figure: Install a Split Cotter Pin

Install a Split Cotter Pin

Figure: Unison ring rig pin brackets

Unison ring rig pin brackets

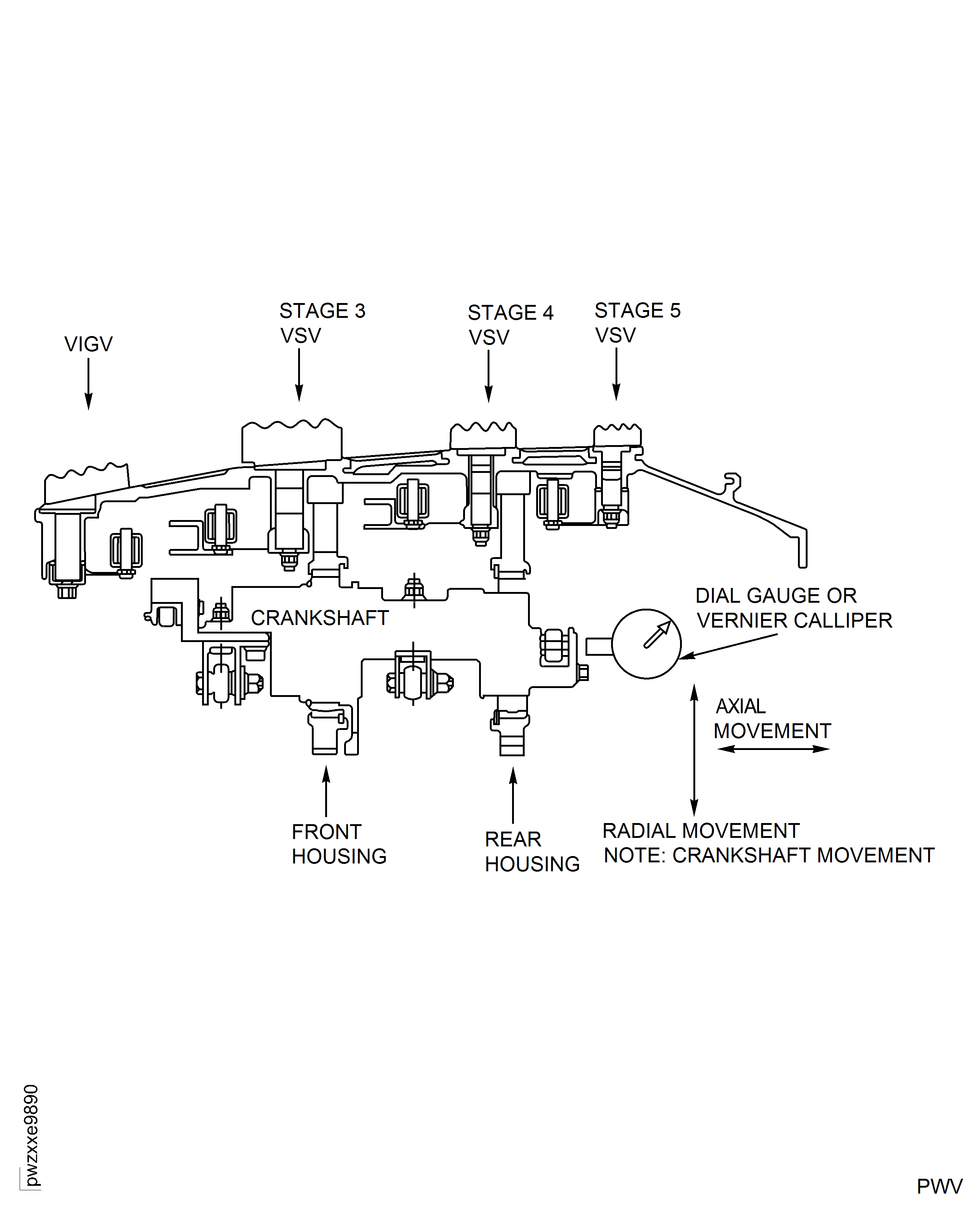

Figure: Crankshaft Movement Check

Crankshaft Movement Check