Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-45-020-001-B02 HPT Assembly - Remove The HP Turbine Assembly (Vertical) - Method 2, Removal-002

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Remove and discard the lockwire before parts are disconnected or removed.

Discard all rubber seal rings, cotter pins and seal washers removed in this procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Torque wrench, range 0 to 100 lbfin (0 to 11.298 Nm) | LOCAL | Torque Wrench 0 to 100 | ||

| IAE 1F10015 Hydraulic wrench | 0AM53 | IAE 1F10015 | 1 | |

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1P16011 Wrench | 0AM53 | IAE 1P16011 | 1 | |

| IAE 1P16028 Build stand | 0AM53 | IAE 1P16028 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | 1 | |

| IAE 1P16048 Heater | 0AM53 | IAE 1P16048 | 1 | |

| IAE 1P16060 Protective cover | 0AM53 | IAE 1P16060 | 1 | |

| IAE 1P16109 cover | 0AM53 | IAE 1P16109 | 1 | |

| IAE 1P16125 Puller | 0AM53 | IAE 1P16125 | 1 | |

| IAE 1P16264 Dry ice fixture | 0AM53 | IAE 1P16264 | 1 | |

| IAE 1P16272 Adapter | 0AM53 | IAE 1P16272 | 1 | |

| IAE 1P16284 Hand wrench | 0AM53 | IAE 1P16284 | 1 | |

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | 1 | |

| IAE 1P16589 Retainer | 0AM53 | IAE 1P16589 | 1 | |

| IAE 1P17022 Removal/installation jaws assembly | 0AM53 | IAE 1P17022 | 1 | |

| IAE 1P17025 Adapter | 0AM53 | IAE 1P17025 | 1 | |

| IAE 1P17025 Adapter | 0AM53 | IAE 1P17025 | ||

| IAE 1P17047 Adapter | 0AM53 | IAE 1P17047 | 1 | |

| IAE 1P17509 Protective cover | 0AM53 | IAE 1P17509 | 1 | |

| IAE 1P17758 Protective cover | 0AM53 | IAE 1P17758 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Install the IAE 1P17509 Protective cover 1 off to the rear flange of the HP turbine rotor and stator assembly.

Loosen the wingnuts on the four clamp assemblies on the IAE 1P17025 Adapter or IAE 1P17047 Adapter.

Before positioning the teeth of the adapter, align slots of HPT stage 2 hub and HPT stage 2 Blade Retaining Plate. Use plastic or wooden rod and mallet.

Install the four straps (Detail 1) into the slots on the IAE 1P17047 Adapter.

Torque the two captured screws (Detail 2) to 20 lbfin (2.26 Nm) to attach the strap (Detail 1) to the IAE 1P17047 Adapter.

Do for each strap.

If you use IAE 1P17047 Adapter, install the IAE 1P16589 Retainer by the procedure that follows:

Install the IAE 1P16011 Wrench 1 off through the adapter to engage the retaining nut spline.

NOTE

You Can use IAE 1F10016 Mechanical wrench as an alternative to IAE 1F10015 Hydraulic wrench.Lift the IAE 1F10015 Hydraulic wrench 1 off with a hoist and install over the wrench and engage the anti-torque pins on the hydraulic wrench with the holes in the adapter.

Install the bearing retaining nut tools.

Remove the captured screws (Detail 3) from the four clamps (Detail 4) on IAE 1P16589 Retainer.

Remove the two captured screws (Detail 2) from the four straps (Detail 1) on IAE 1P16589 Retainer.

Remove the four straps (Detail 1) from the slots in the IAE 1P17047 Adapter.

Remove the IAE 1P16589 Retainer from the IAE 1P17047 Adapter and HPT Case.

If you use IAE 1P17047 Adapter then do the procedure that follows:

Remove the bearing retaining nut tools.

Remove the bearing retaining nut from the engine with the IAE 1P16284 Hand wrench 1 off.

SUBTASK 72-00-45-020-066 Remove the Bearing Retaining Nut

Disassemble, and then Repair. Refer to Repair, VRS3238 TASK 72-45-31-300-001 (REPAIR-001).

Dents, nicks and scratches.

Examine the Stage 2 Turbine Hub for dents, nicks and scratches that occurred during the disassembly process.

SUBTASK 72-00-45-220-262 Examine the Stage 2 Turbine Hub for Damage

Install the IAE 1P16048 Heater 1 off to the IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off before the fixture is installed to the engine.

Install the IAE 1P17022 Removal/installation jaws assembly 1 off.

Install the IAE 6F10027 Heater control unit 1 off to the heater installed on the fixture.

Install the IAE 1F10052 Two cables sling 1 off to a hoist and to the two lifting spools on the fixture.

SUBTASK 72-00-45-020-067 Install the Tooling to remove the HP Turbine Rotor and Stator Assembly

Refer to Figure.

Install the IAE 1P16264 Dry ice fixture 1 off into the inner diameter of the HP compressor rear shaft.

Attach the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder.

Install the IAE 1P16272 Adapter 1 off to the rear flange of the IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off.

Apply air to the IAE 1P16264 Dry ice fixture 1 off.

SUBTASK 72-00-45-020-068 Remove the HP Turbine Rotor and Stator Assembly from the Engine

Lower the HP turbine rotor and stator assembly (front and down) to the IAE 1P16028 Build stand 1 off, Figure.

Remove the adapter from the rear face of the fixture Figure.

SUBTASK 72-00-45-020-069 Remove the Tooling from the HP Turbine Rotor and Stator Assembly

Visually inspect front interface of HPT Rotor and Stator Assembly for soot and oil. If soot and oil found, perform oil ignition event inspection TASK 72-45-00-200-801. Report all findings to IAE Technical Services.

Visually inspect rear face of No. 4 Bearing Compartment for soot and oil. If soot and oil found, perform oil ignition event inspection TASK 72-45-00-200-801. Report all findings to IAE Technical Services.

SUBTASK 72-00-45-220-253 Inspect for Soot and Oil

Refer to Figure.

Install the IAE 1P16125 Puller 1 off to the No. 4 bearing spacer with the lip of the jaws on the puller grooves on the spacer.

Install the IAE 1P16109 cover 1 off (with the center flap open) over the stage 1 turbine nozzle assembly. Put hand pressure on the outer edge of the cover to hold in position.

Install the IAE 1P16060 Protective cover 1 off or the IAE 1P17758 Protective cover 1 off to the rear flange of the HP turbine rotor and stator assembly. Put equal hand pressure on the outer edge of the cover to hold in position.

SUBTASK 72-00-45-020-070 Remove the No. 4 Bearing Spacer

Figure: HP Turbine Rotor and Stator Assembly and Related Parts

HP Turbine Rotor and Stator Assembly and Related Parts

Figure: Release the Bearing Retaining Nut

Release the Bearing Retaining Nut

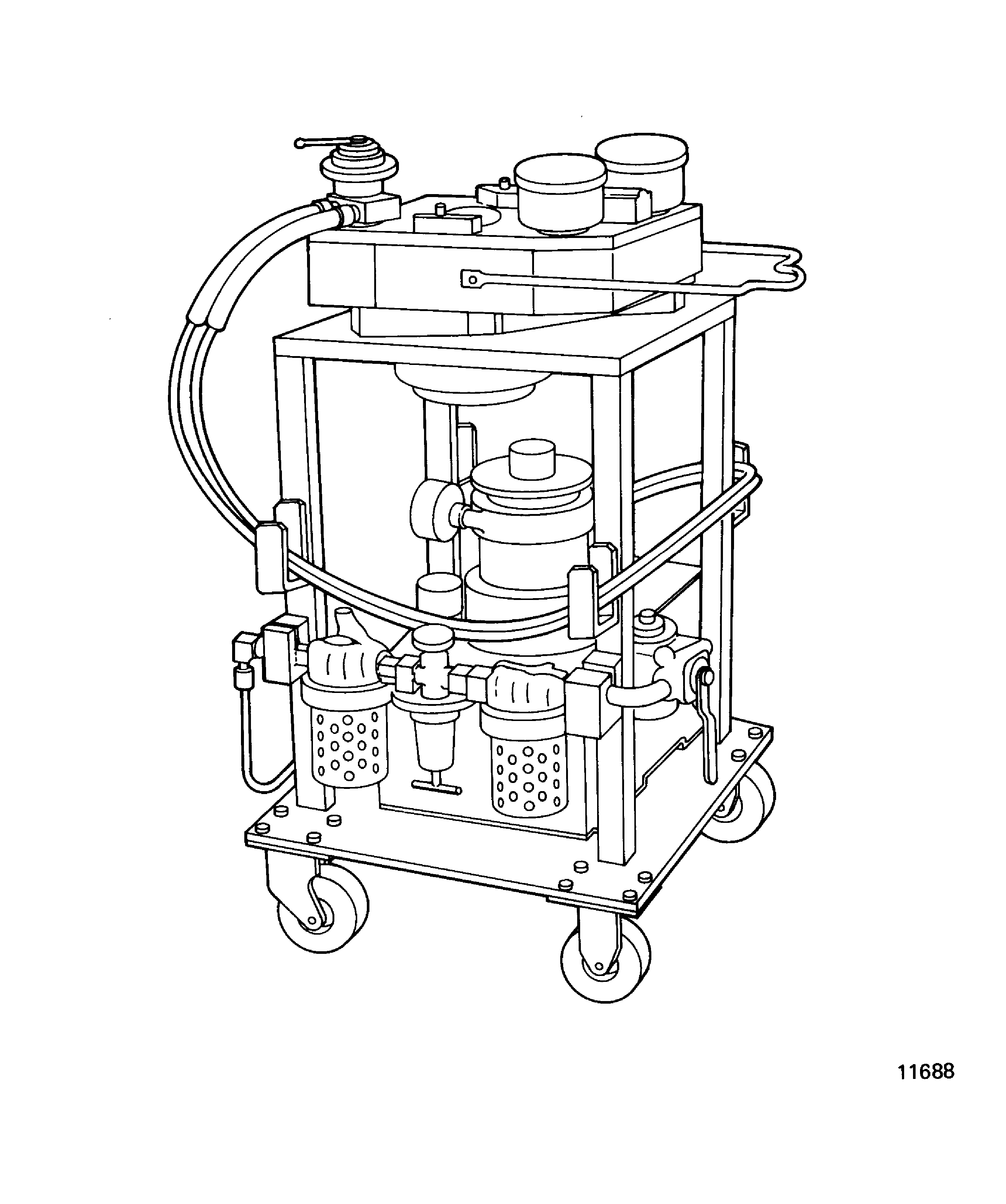

Figure: Hydraulic Wrench Package

Hydraulic Wrench Package

Figure: Remove the Bearing Retaining Nut

Remove the Bearing Retaining Nut

Figure: Removal Tooling for the HP Turbine Rotor and Stator Assembly

Removal Tooling for the HP Turbine Rotor and Stator Assembly

Figure: Removal Tooling for the HP Turbine Rotor and Stator Assembly

Removal Tooling for the HP Turbine Rotor and Stator Assembly

Figure: Install the HP Turbine Rotor and Stator Assembly to the Stand

Install the HP Turbine Rotor and Stator Assembly to the Stand

Figure: Remove the No. 4 Bearing Spacer

Remove the No. 4 Bearing Spacer

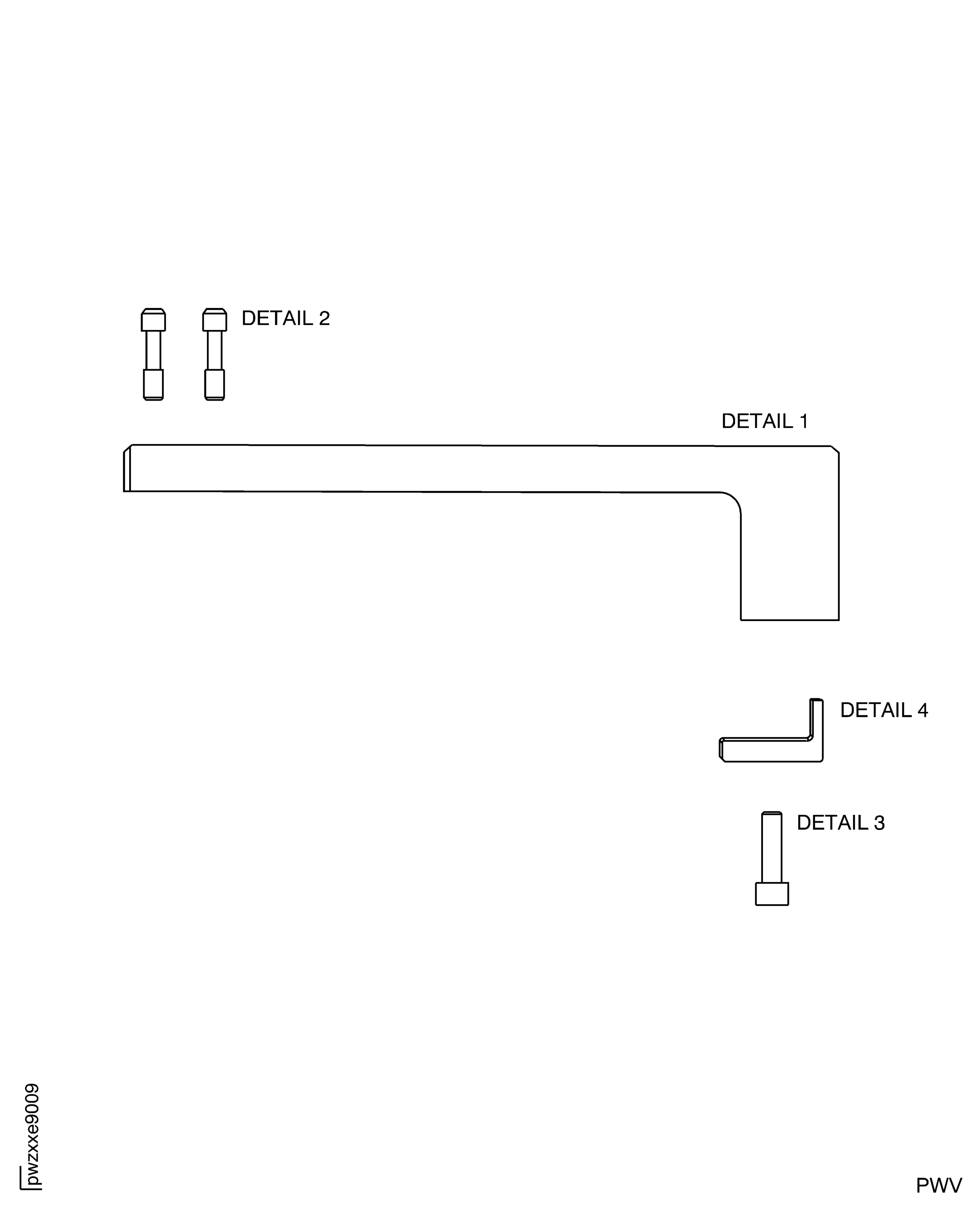

Figure: IAE 1P16589 Retainer Exploded View

IAE 1P16589 Retainer Exploded View

Figure: Misaligned Slot Between HPT Stage 2 Hub And HPT Stage 2 Blade Retaining Plate

Misaligned Slot Between HPT Stage 2 Hub And HPT Stage 2 Blade Retaining Plate