Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-50-020-001-B00 LPT Module - Remove The LPT Module Components, External Harnesses, And Tubes, Removal-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Discard all the rubber seal rings, split cotter pins, keywashers and gaskets removed in the procedure.

Remove and discard the lockwire before the tube or connector is disconnected.

Refer to the V2500 Illustrated Tool and Equipment Manual Pub.ref. ITE-V2500-1IA, for the illustrations of the special tools given in this procedure.

All the electrical harnesses and cables removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual, Pub.ref. CMM-EHC-V2500-1IA.

All the tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual, Pub.ref. CMM-THD-V2500-1IA.

During the removal procedure make sure that the harnesses are held temporarily along their different lengths. This is to prevent too much strain on the harnesses, cables and electrical connectors.

During the removal procedure put the special plastic caps on the electrical connectors. This is to give protection from unwanted fluids or materials.

During the removal procedure put the transportation covers/blanks on all openings. This is to give protection from unwanted fluids or materials.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1M14084 Support fixture | 0AM53 | IAE 1M14084 | 2 | |

| IAE 1M14077 Protective plug | 0AM53 | IAE 1M14077 | 1 | |

| IAE 1M14083 Protective plug | 0AM53 | IAE 1M14083 | 2 | |

| IAE 1N20015 Aft engine mount sling | 0AM53 | IAE 1N20015 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Pre SBE 75-0049: Remove the nut, the bolt, the spacer, the washer and the clip from the clip position 5723.

SBE 75-0049: Remove the nut, the bolt, the two spacers and the two clips at the clip position 5723.

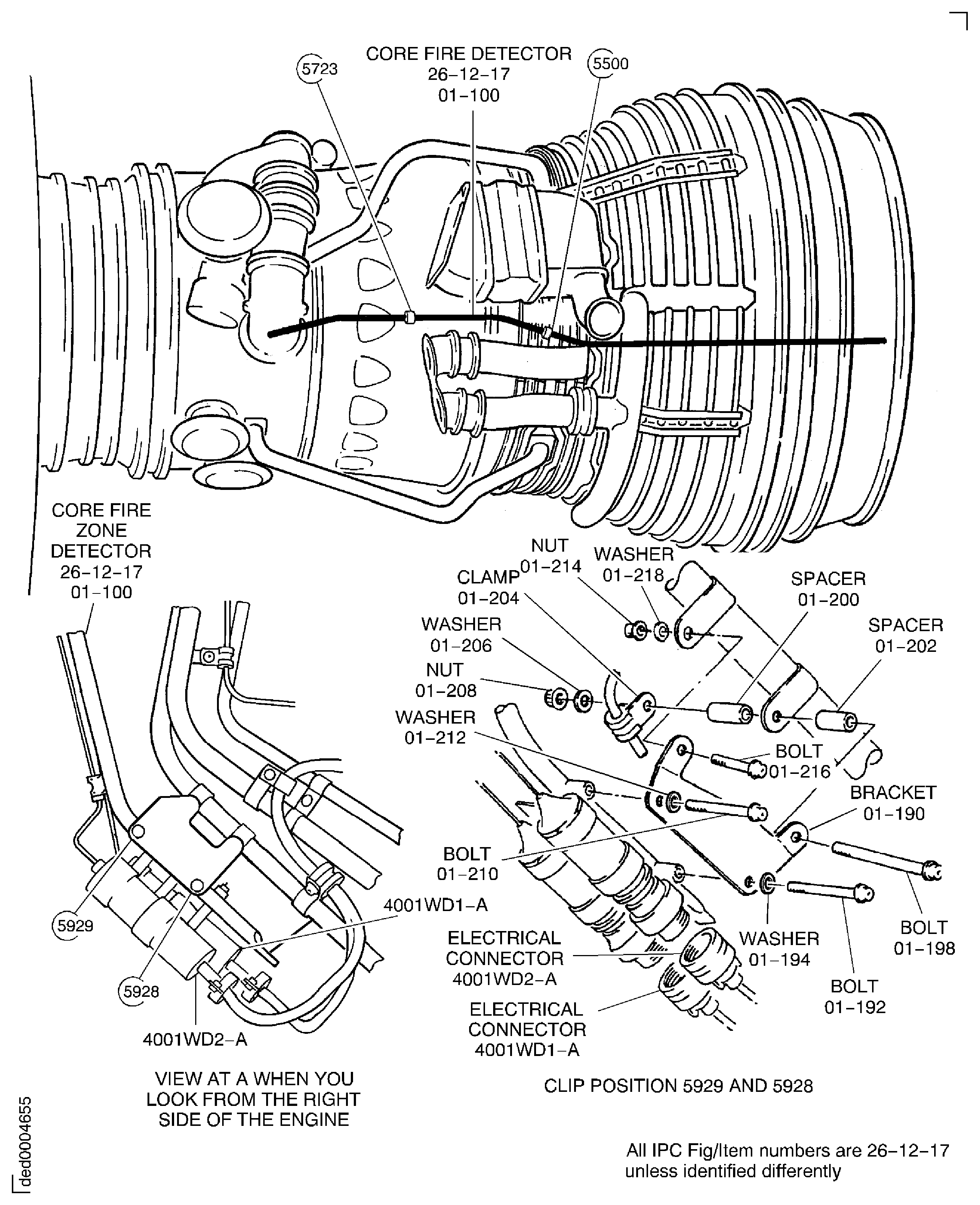

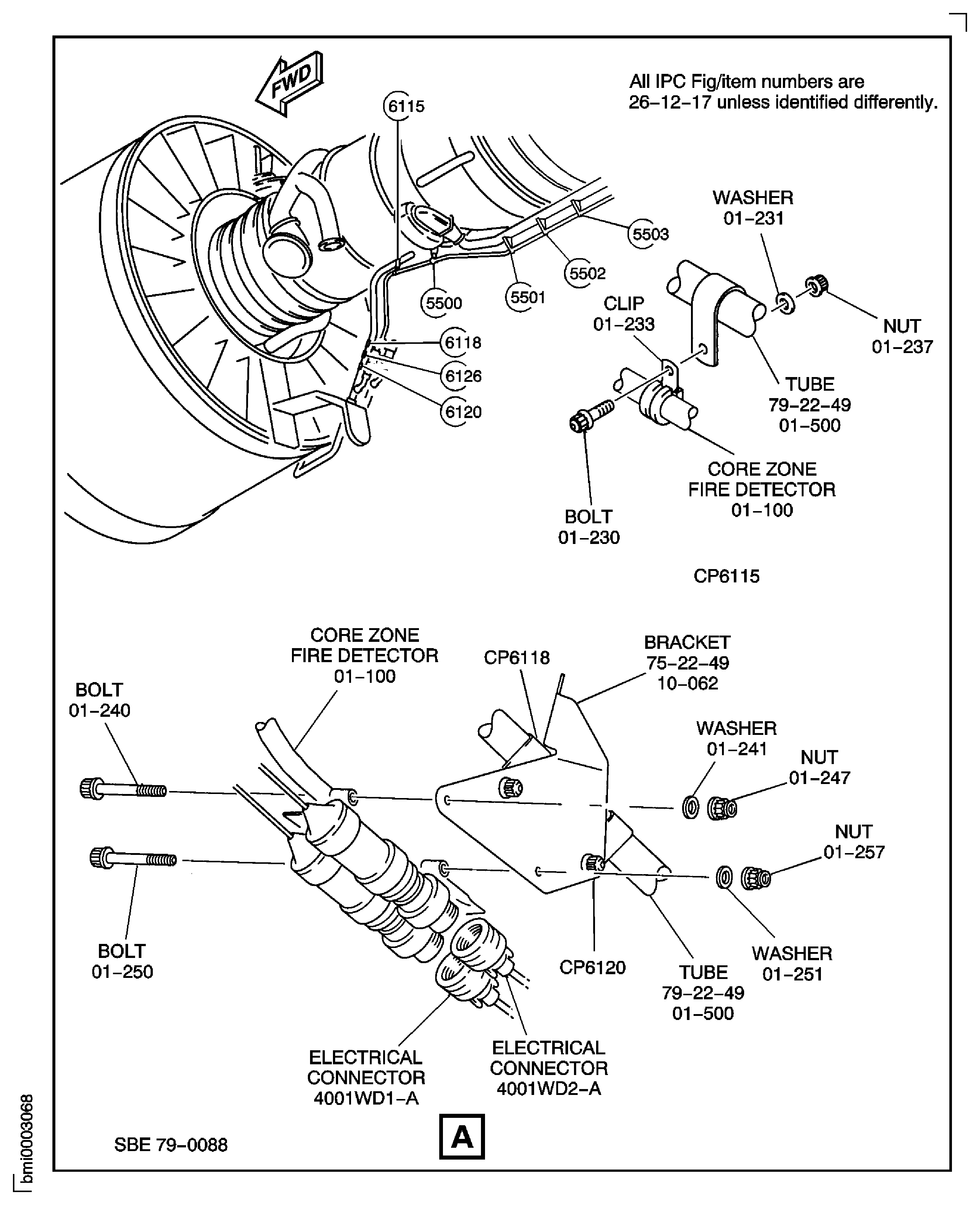

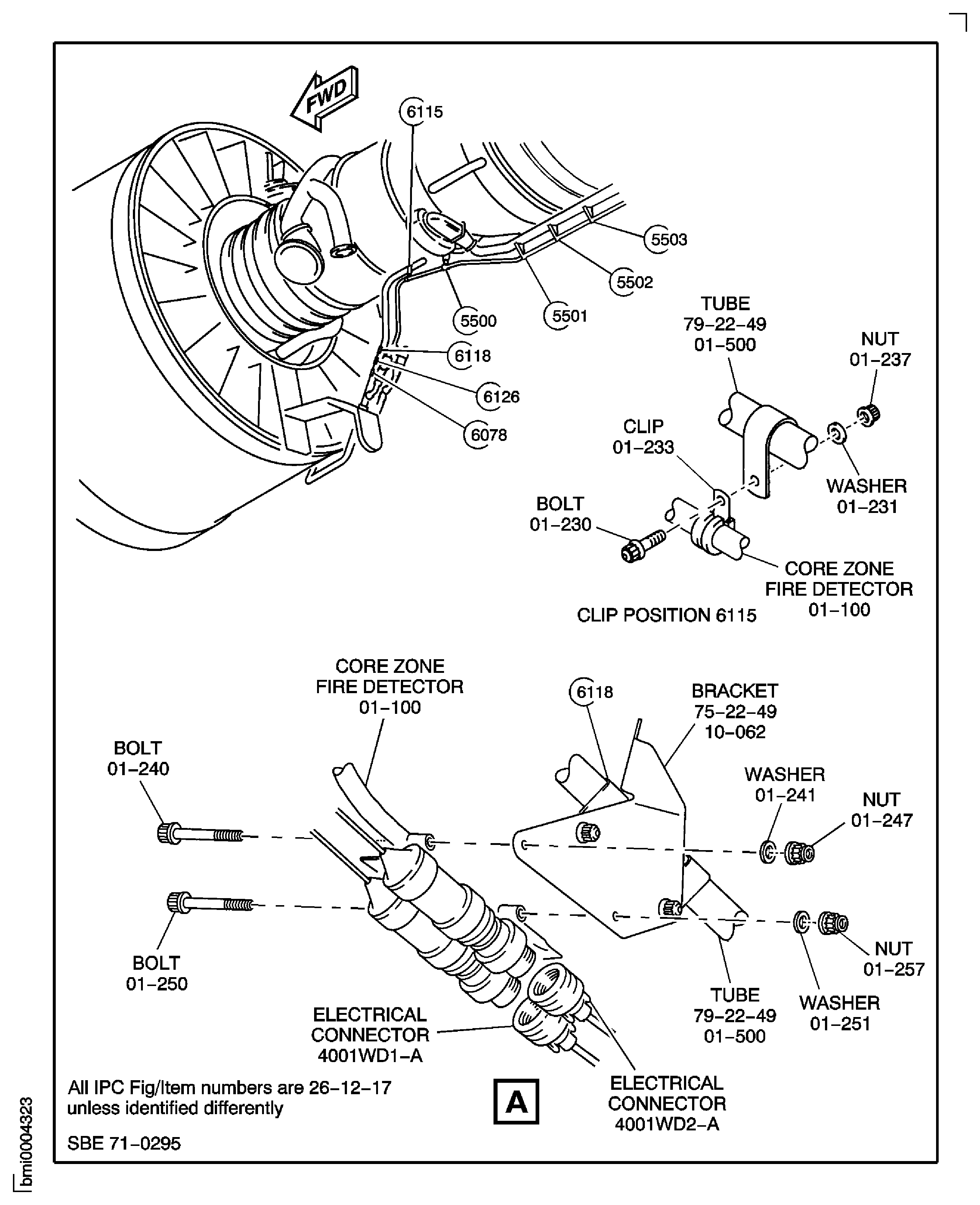

SUBTASK 72-00-50-020-123-A00 Remove the Core Zone Fire Detector (Pre SBE 79-0088)

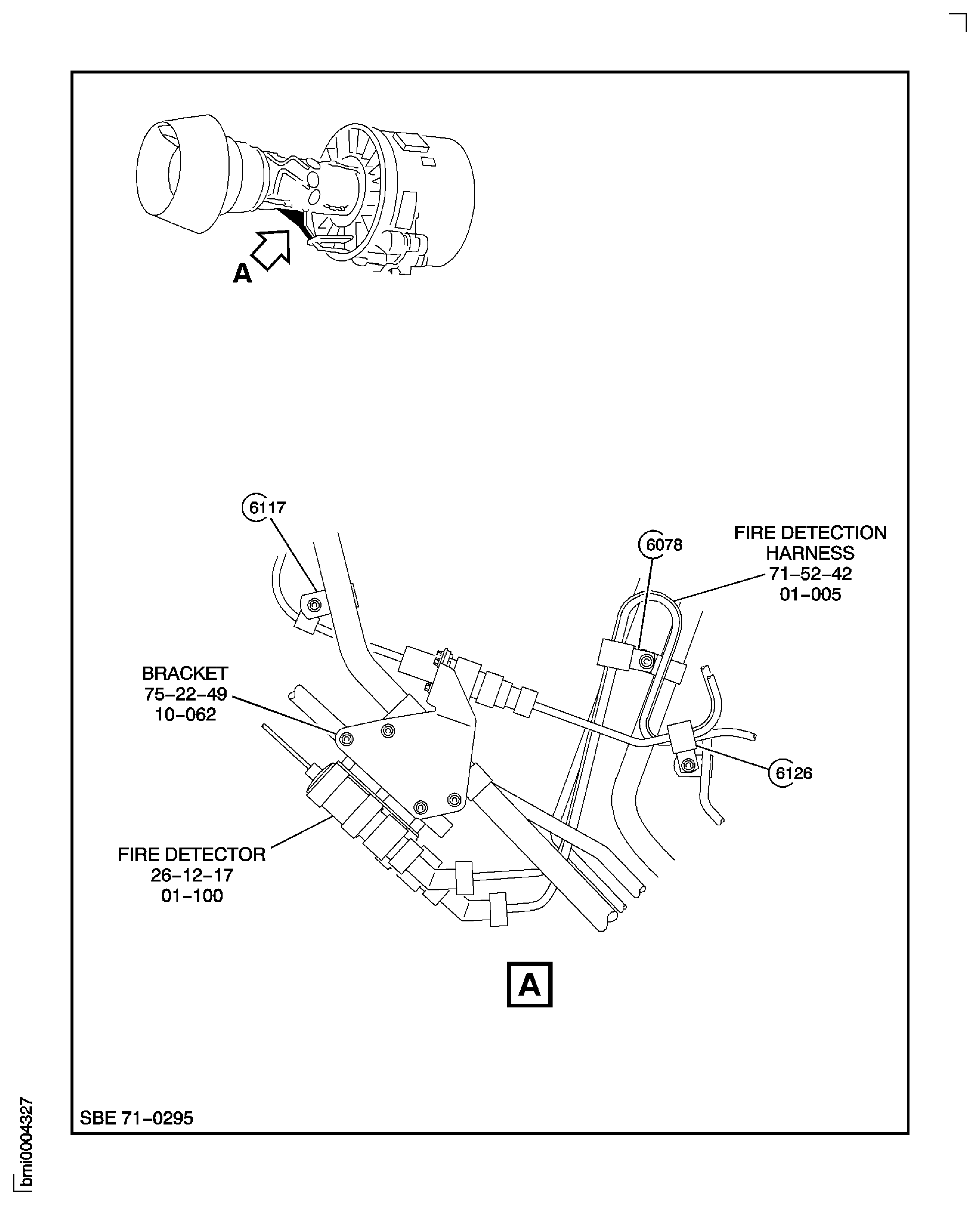

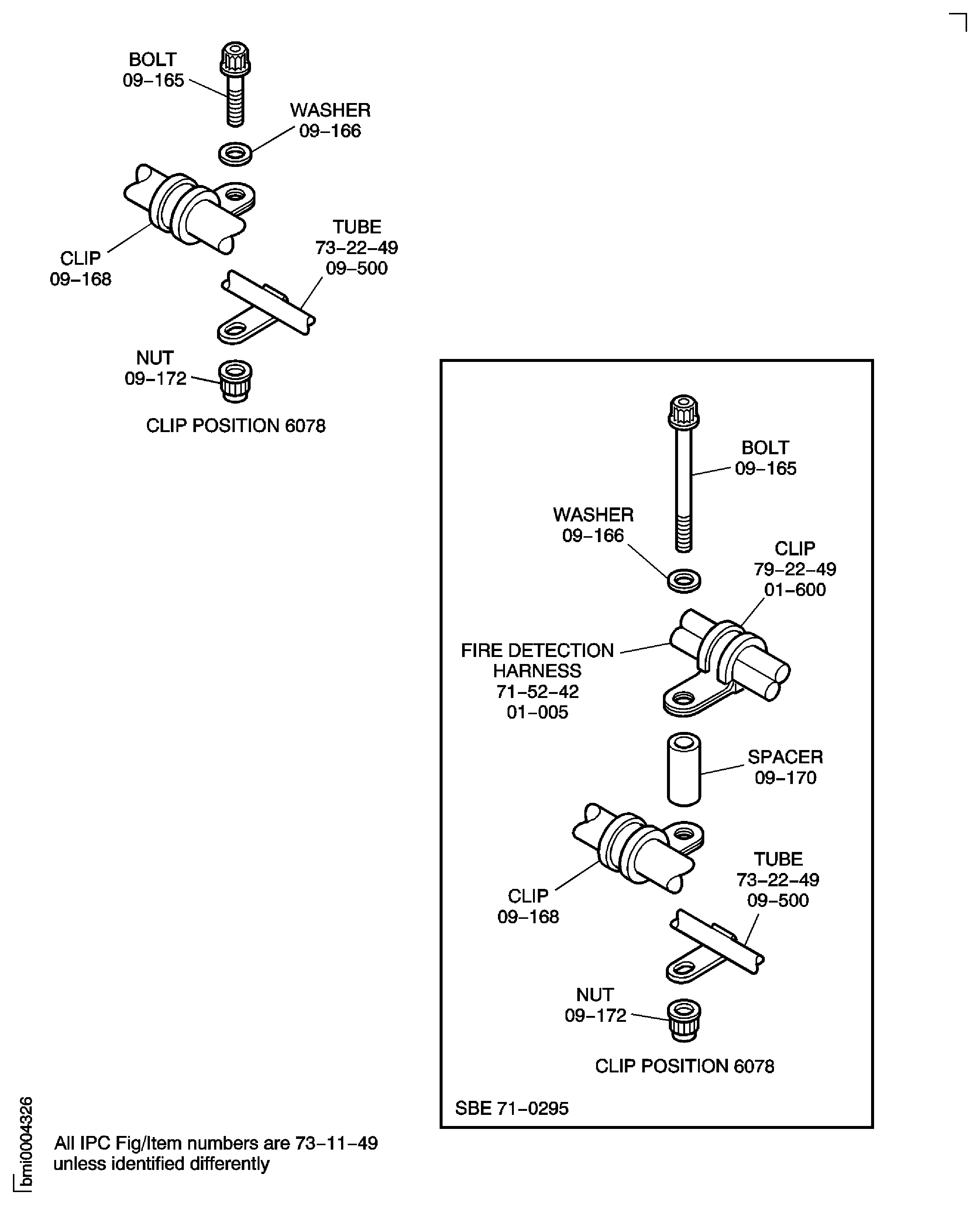

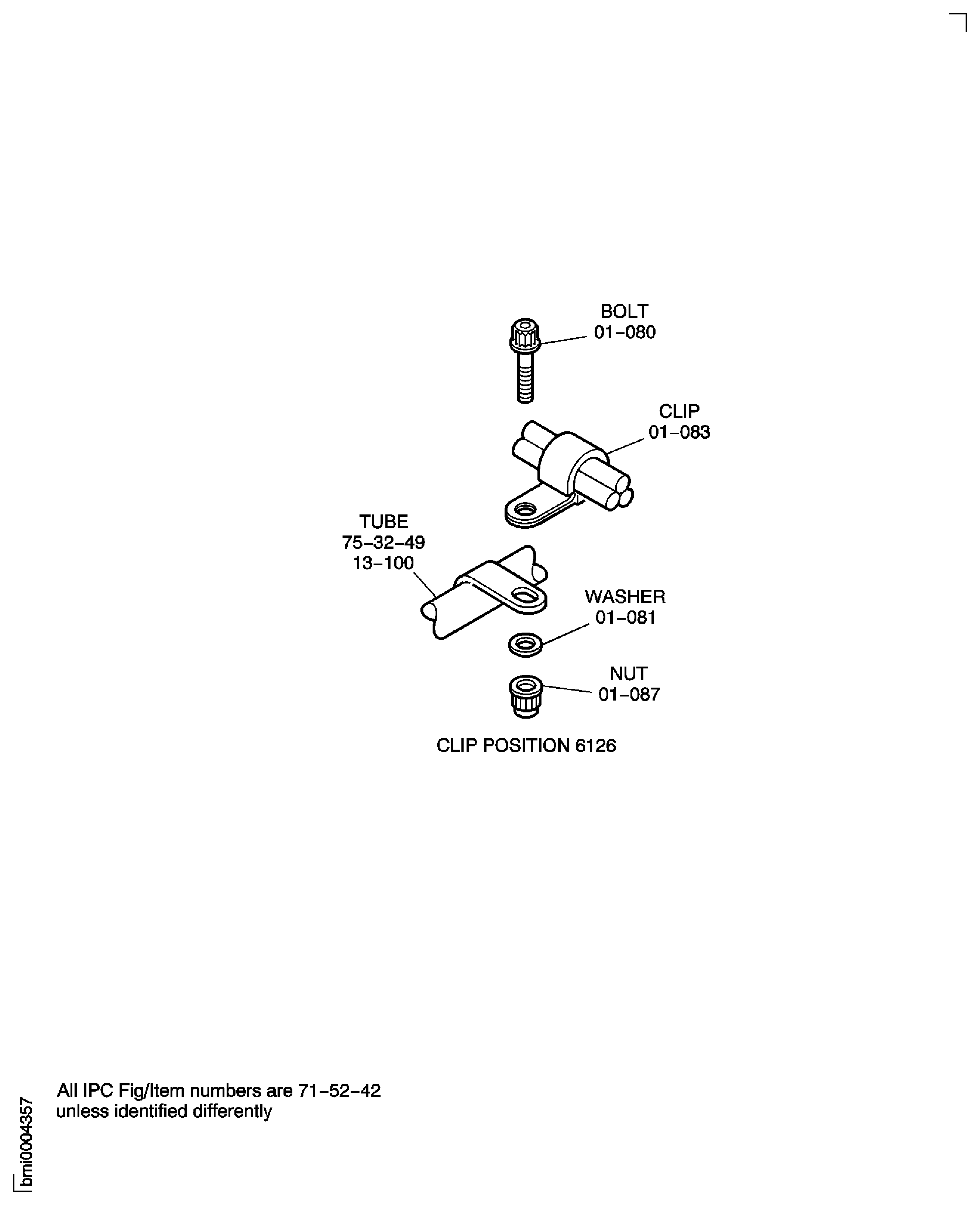

Pre SBE 71-0295: Remove the bolts, the washers and the nuts from the clip positions 6120 and 6126.

SBE 71-0295: Remove the bolts, the washers and the nuts from the clip positions 6078 and 6126.

SUBTASK 72-00-50-020-123-B00 Remove the Core Zone Fire Detector (SBE 79-0088, Pre SBN 71-0295 and SBN 71-0295)

WARNING

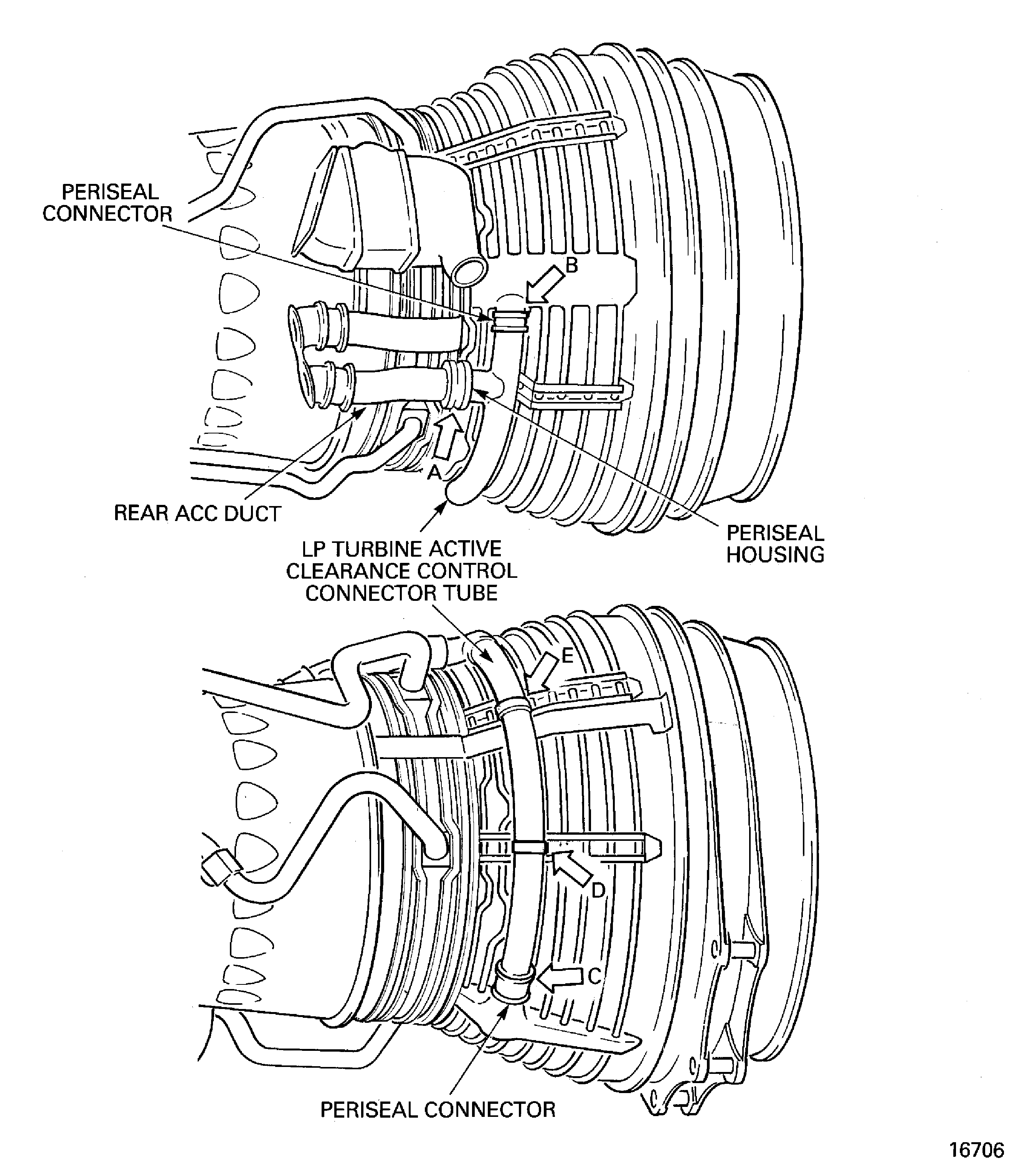

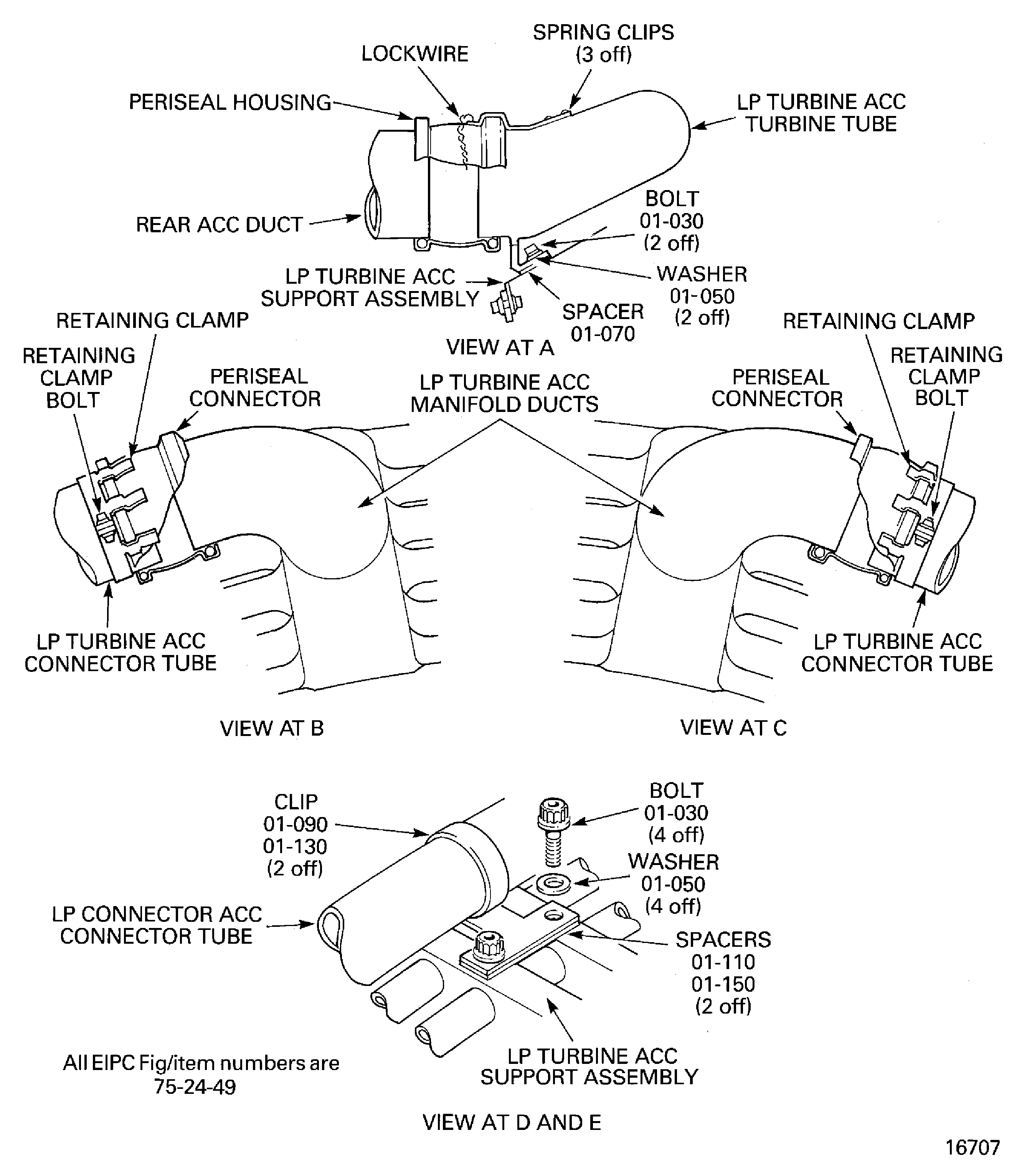

DURING DISASSEMBLY DO NOT BREATHE DUST OF THE LOOSENED BOLTS. PREVENT SKIN AND EYE CONTACT WITH RELEASED DUST. THE DUST CONTAINS NICKEL PARTICLES WHICH CAN POSE A HEALTH HAZARD. BEFORE DISASSEMBLY LUBRICATE ACCESSIBLE BOLTS AND BOLT HEADS, NUTS AND EXPOSED THREADS WITH AN APPROVED, SUITABLE PENETRANT OIL. WEAR A FACE MASK AND GOGGLES. DO NOT REMOVE DUST DEPOSITS WITH COMPRESSED AIR. REMOVE ANY SURFACE DUST PARTICLES WITH A DISPOSABLE DAMP RAG OR SIMILAR. AFTER END OF THIS PROCEDURE CLEAN YOUR HANDS AND EXPOSED SKIN WHERE POSSIBLE.Disengage the periseal housing LPT ACC Air Ducts And Tubes (75-24-49, 01-540) from the three spring clips and retract it from the T-piece above the ACC rear duct.

SBE 75-0051: Loosen the two bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-490) of the T-piece of the connector tube.

Remove the bolts and the two periseal clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-480).

Remove the nuts and bolts from the two retainig clamps LPT ACC Air Ducts And Tubes (75-24-49, 01-670) and LPT ACC Air Ducts And Tubes (75-24-49, 01-570) which safety the periseal connectors LPT ACC Air Ducts And Tubes (75-24-49, 01-730) and LPT ACC Air Ducts And Tubes (75-24-49, 01-630) to the connector tube.

Remove the bolts LPT ACC Air Ducts And Tubes (75-24-49, 01-030) and the washers LPT ACC Air Ducts And Tubes (75-24-49, 01-050) that attach the connector tube to the supports.

Removet the two periseal connectors, the two retaining clamps and the two clamps LPT ACC Air Ducts And Tubes(75-24-49,01-130) and LPT ACC Air Ducts And Tubes (75-24-49, 01-090) from the connector tube.

Remove the bolt, the washer and the spacer LPT ACC Air Ducts And Tubes (75-24-49, 01-070) from the T-piece angle bracket.

Install the IAE 1M14077 Protective plug protective plug 1 off, on to the LP turbine ACC connector tube.

Install the IAE 1M14083 Protective plug protective plug 2 off, on to the LP turbine ACC connector tube.

SUBTASK 72-00-50-020-124 Remove the LP Turbine Active Clearance Control (ACC) Connector Tube (Pre SBE 75-0051 and SBE 75-0051)

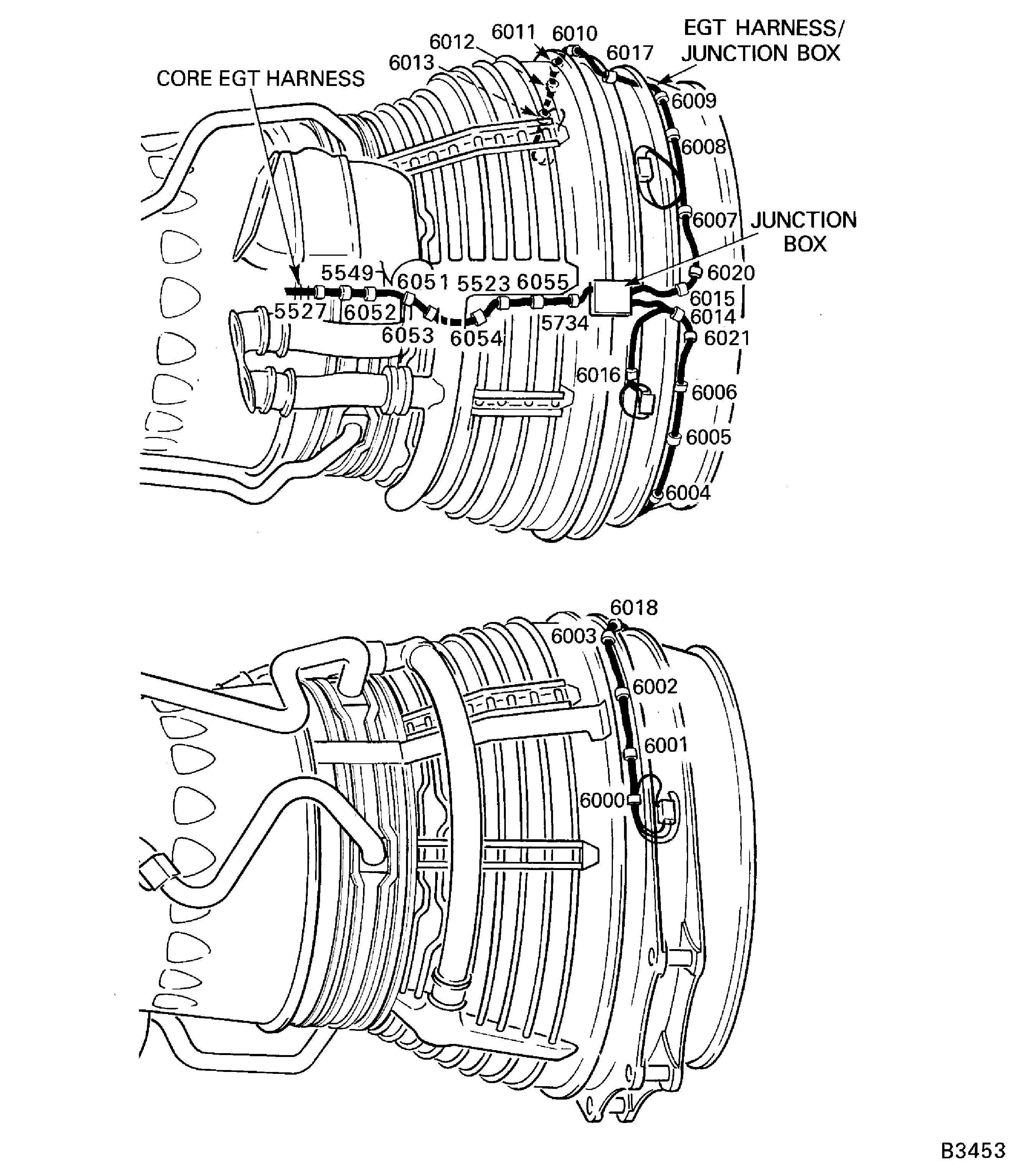

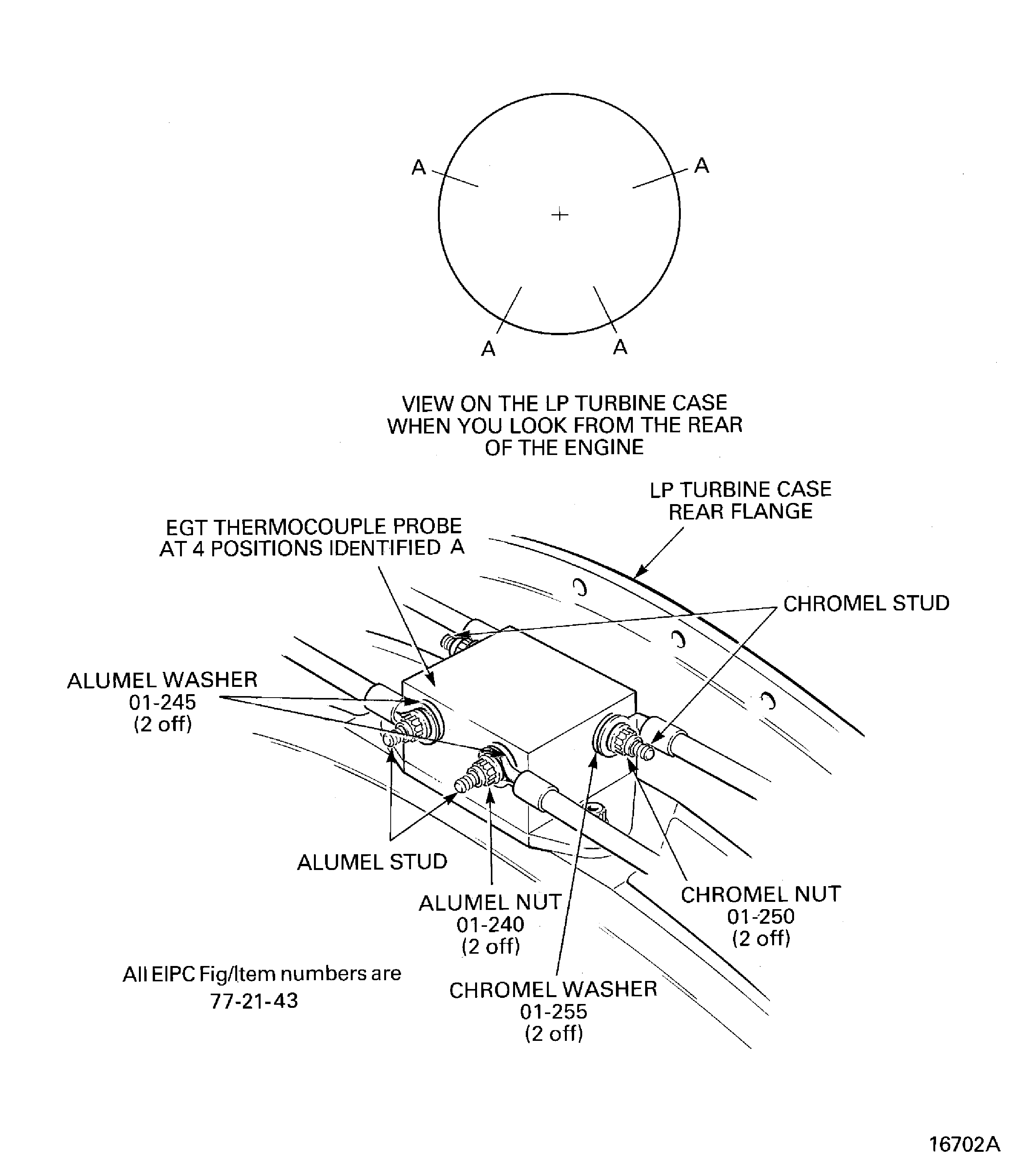

Pre SBE 77-0009 : Put the four nuts back on to the applicable studs.

CAUTION

ONCE A NEW STYLE NUT IS INSTALLED ON TO THE MATING STUD YOU MUST NOT INSTALL AN OLD NUT ON THAT STUD.SBE 77-0009 : Put the four self locking nuts back on to the applicable studs.

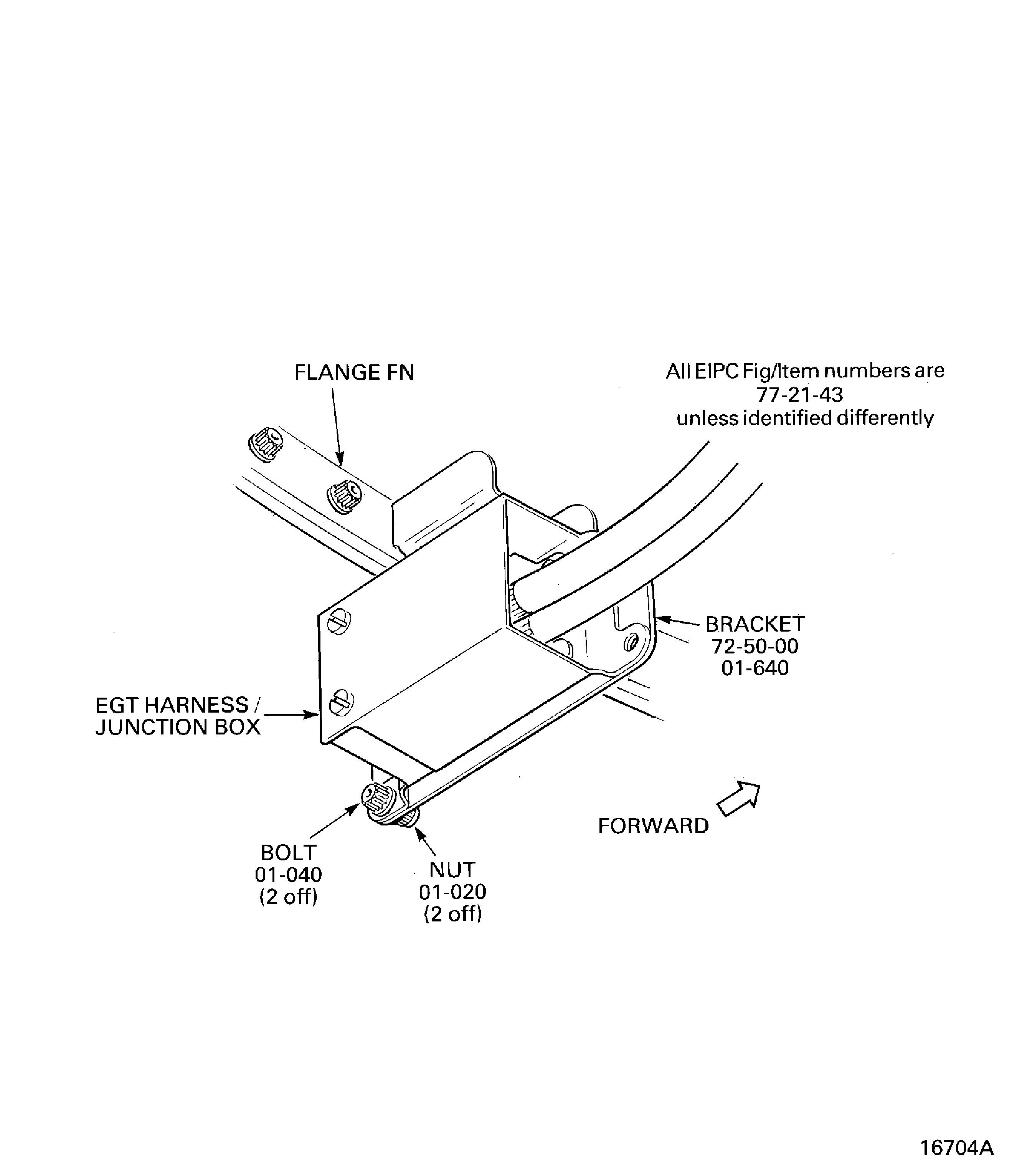

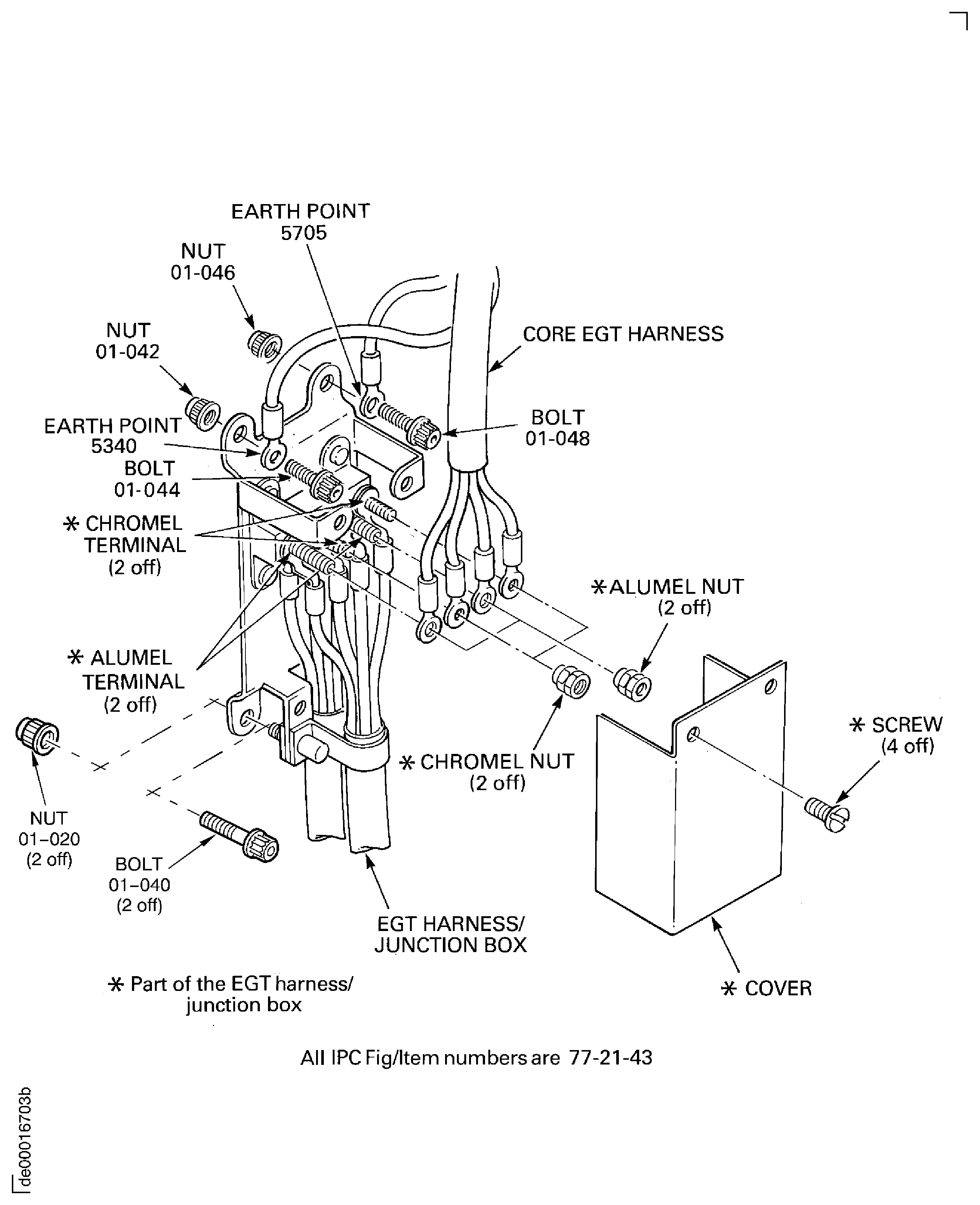

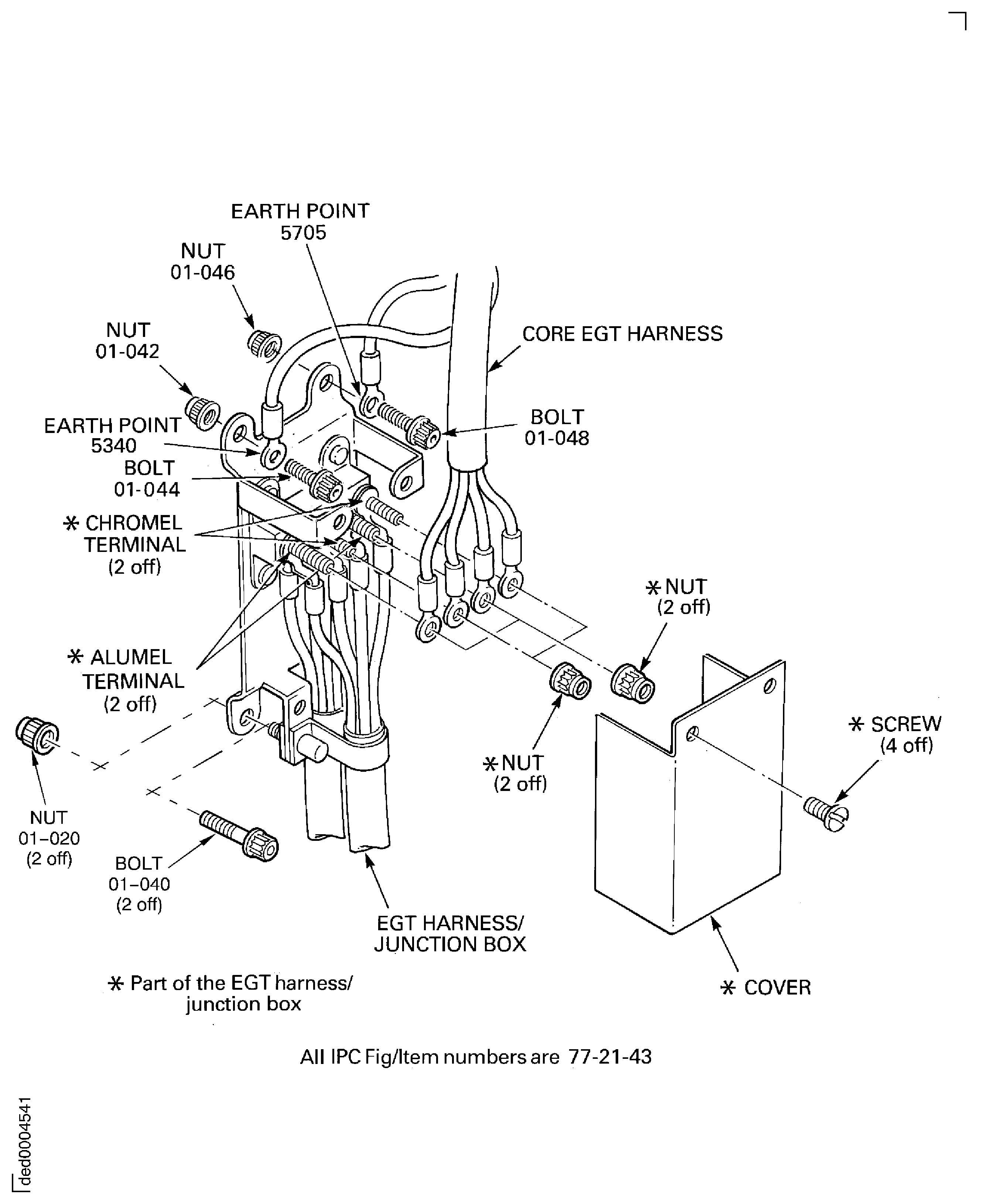

Disconnect the Core EGT harness from the EGT harness/junction box.

Remove the two bolts and the two nuts that secure the junction box to the bracket LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00, 01-640).

Remove the EGT harness/junction box.

SUBTASK 72-00-50-020-125Remove the Core Exhaust Gas Thermocouple (EGT) Harness, and the Exhaust Gas Thermocouple Harness/Junction Box (Pre SBE 77-0009 and SBE 77-0009)

SBE 77-0009: Provide new EGT harness junction box terminal nuts

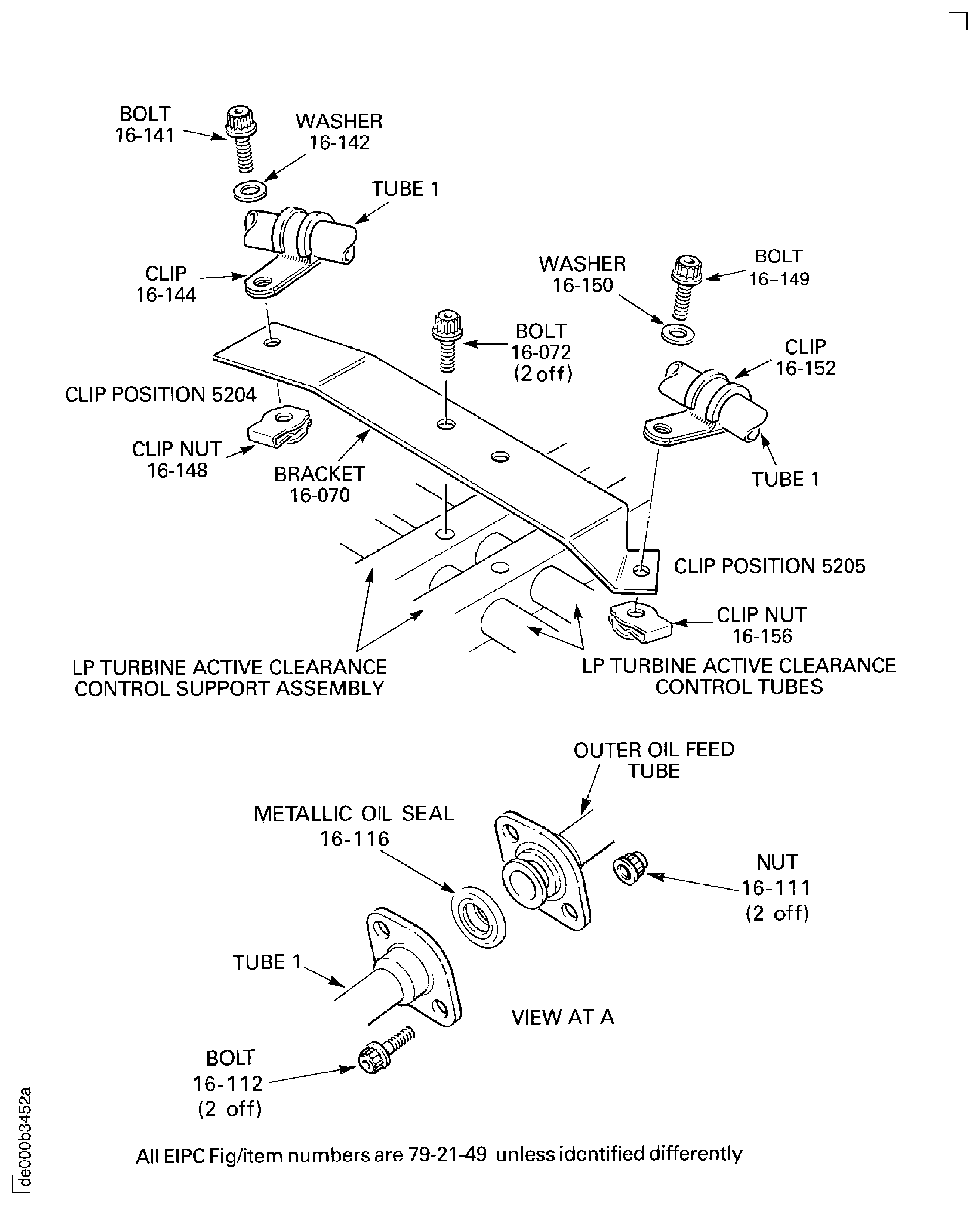

Remove the two bolts that secure the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-070) on the the LP turbine active clearance control at the seven o'clock position. Remove the bracket from the engine.

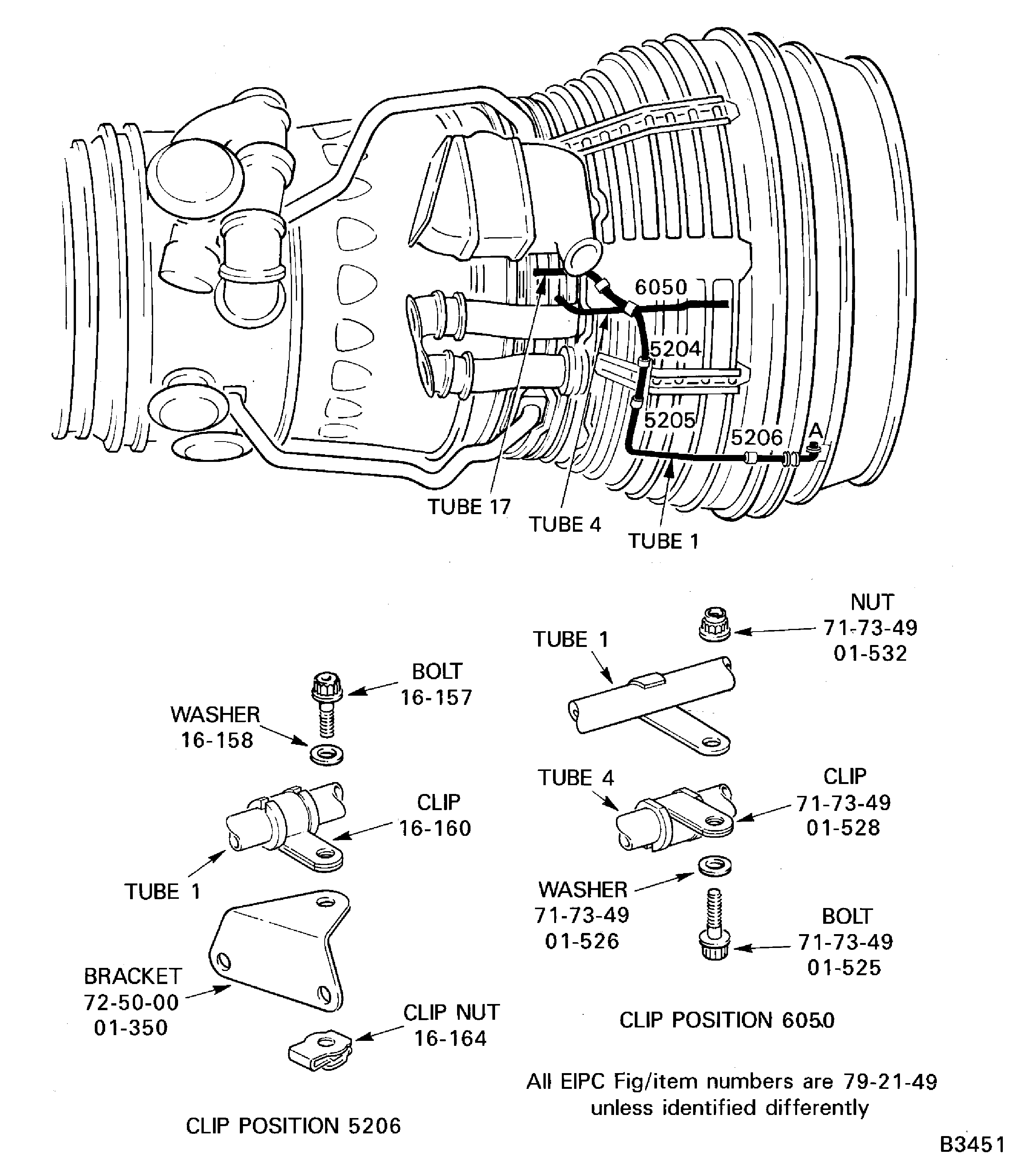

SUBTASK 72-00-50-020-126 Remove the Tube 1, Number 5 Bearing Oil Feed Tube

Refer to Figure.

SUBTASK 72-00-50-020-128 Remove the Tube 4, Number 4 Bearing Oil Weep Tube

WARNING

DURING DISASSEMBLY DO NOT BREATHE DUST OF THE LOOSENED BOLTS. PREVENT SKIN AND EYE CONTACT WITH RELEASED DUST. THE DUST CONTAINS NICKEL PARTICLES WHICH CAN POSE A HEALTH HAZARD. BEFORE DISASSEMBLY LUBRICATE ACCESSIBLE BOLTS AND BOLT HEADS, NUTS AND EXPOSED THREADS WITH AN APPROVED, SUITABLE PENETRANT OIL. WEAR A FACE MASK AND GOGGLES. DO NOT REMOVE DUST DEPOSITS WITH COMPRESSED AIR. REMOVE ANY SURFACE DUST PARTICLES WITH A DISPOSABLE DAMP RAG OR SIMILAR. AFTER END OF THIS PROCEDURE CLEAN YOUR HANDS AND EXPOSED SKIN WHERE POSSIBLE.Loosen all the bolts on the support assemblies C and G.

PRE SBE 75-0095: Remove the bolts, the washers, the spacers LPT ACC Air Ducts And Tubes (75-24-49, 04-440) and the nuts that attach the support assembly C. Discard the spacers.

SBE 75-0095: Remove the bolts, the washers, the spacers and the nuts that attach the support assembly C.

Put the lower ACC manifold in to one of IAE 1M14084 Support fixture (support fixture) 2 off.

Remove all the bolts, the washers, the spacers LPT ACC Air Ducts And Tubes (75-24-49, 04-040) and the nuts that attach the upper ACC duct to the front flange and the rear bosses.

PRE SBE 75-0095: Remove the bolts, the washers, the spacer LPT ACC Air Ducts And Tubes (75-24-49, 04-040) and the nuts that attach the support assembly G. Discard the spacers.

SBE 75-0095: Remove the bolts, the washers, the spacers and the nuts that attach the support assembly G.

SUBTASK 72-00-50-020-132 Remove the LP Turbine Active Clearance Control (ACC) Manifold (SBE 75-0095PRE and SBE 75-0095)

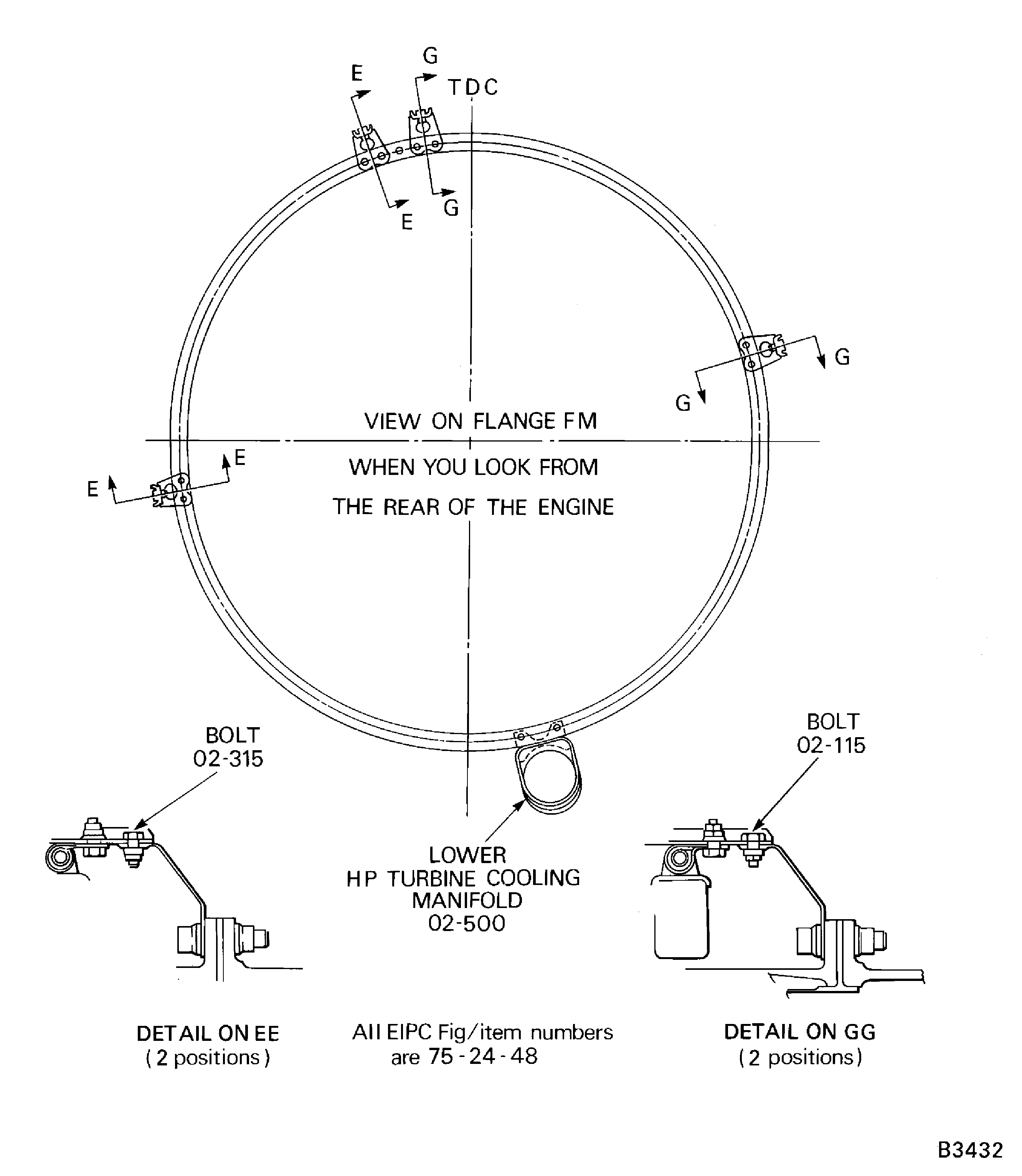

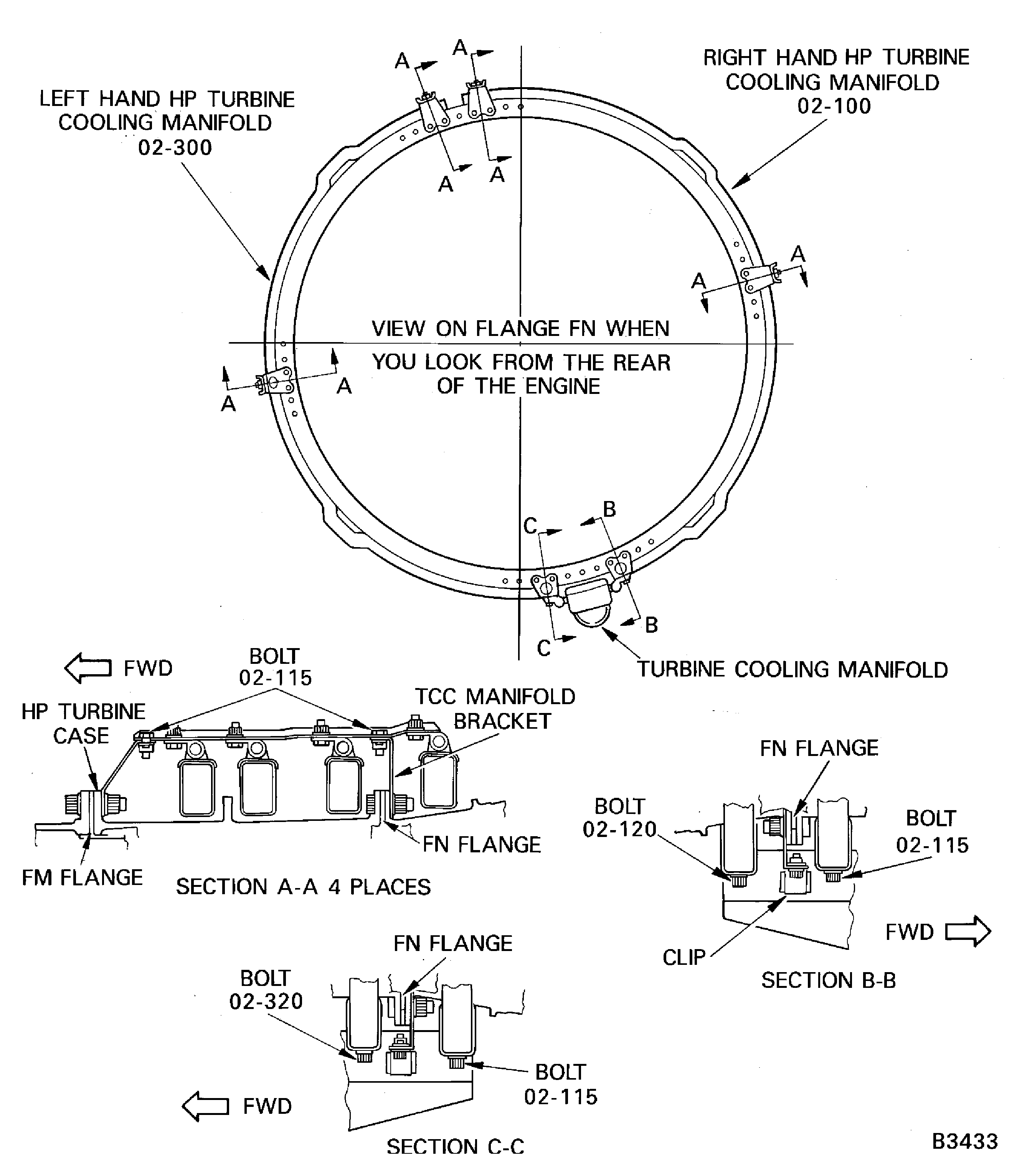

Remove the four bolts from the lower turbine cooling manifold and the left hand turbine cooling manifold.

Loosely install the bolts and the nuts removed in Step on to the left hand turbine cooling manifold.

Remove the left hand turbine cooling manifold.

Remove the four bolts from the lower turbine cooling manifold and the right hand turbine cooling manifold.

Loosely install the bolts and nuts removed in Step on to the right hand turbine cooling manifold.

Remove the right hand turbine cooling manifold.

Loosely install the bolts and nuts removed in Step on to the flange FM.

Remove the lower turbine cooling manifold.

SUBTASK 72-00-50-020-133 Remove the HP Turbine Active Clearance Control Manifolds

Refer to Figure.

NOTE

The EGT probes removed in this procedure must have their maintenance completed as given in the Weston Component Maintenance Manual (77-21-15).

The piston rings must be examined before installation. Refer to TASK 72-00-50-200-000.

Remove the two piston ring from the EGT probe.

SUBTASK 72-00-50-020-134 Remove the Exhaust Gas Thermocouple (EGT) Probes from the LP Turbine Module

WARNING

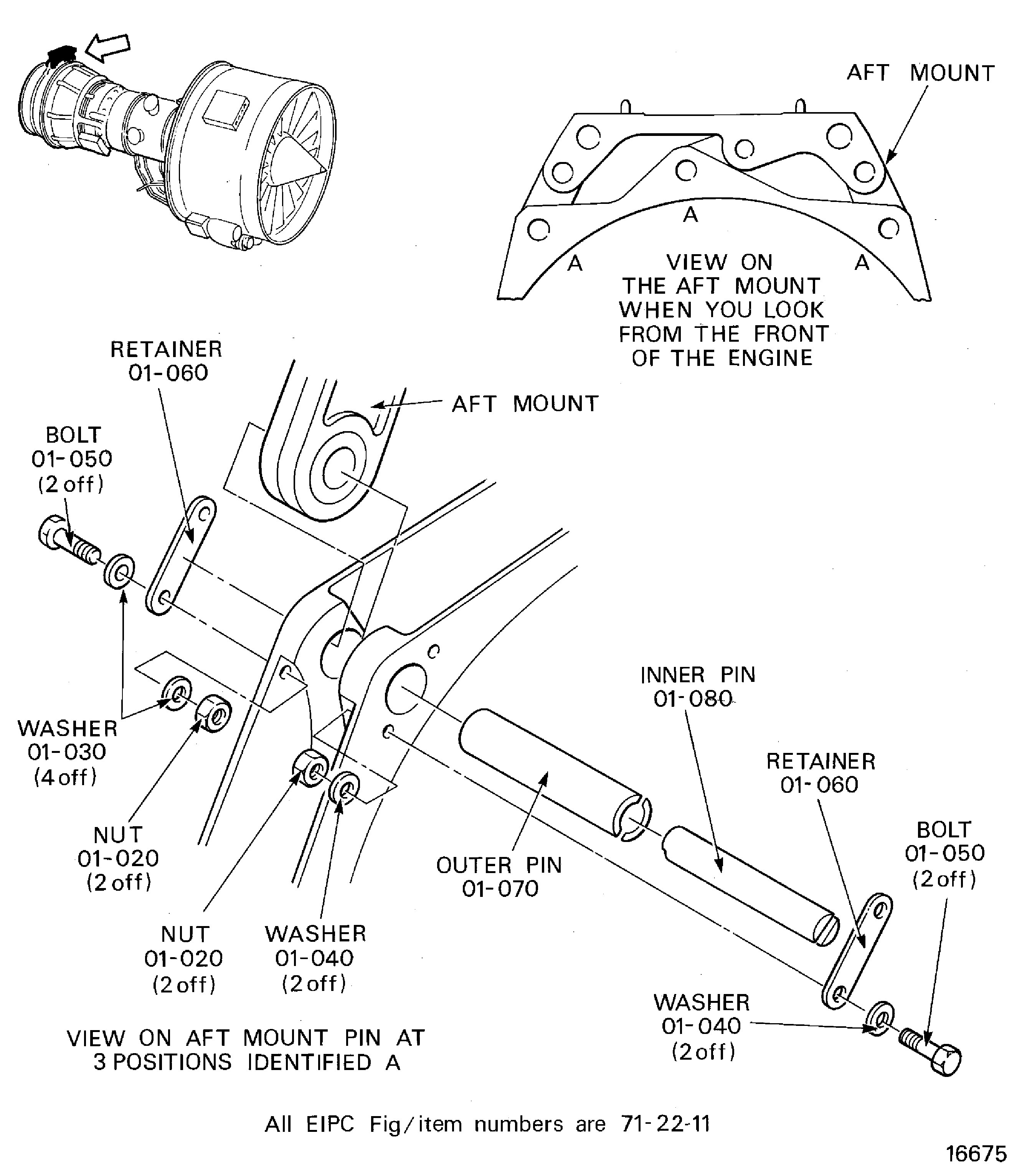

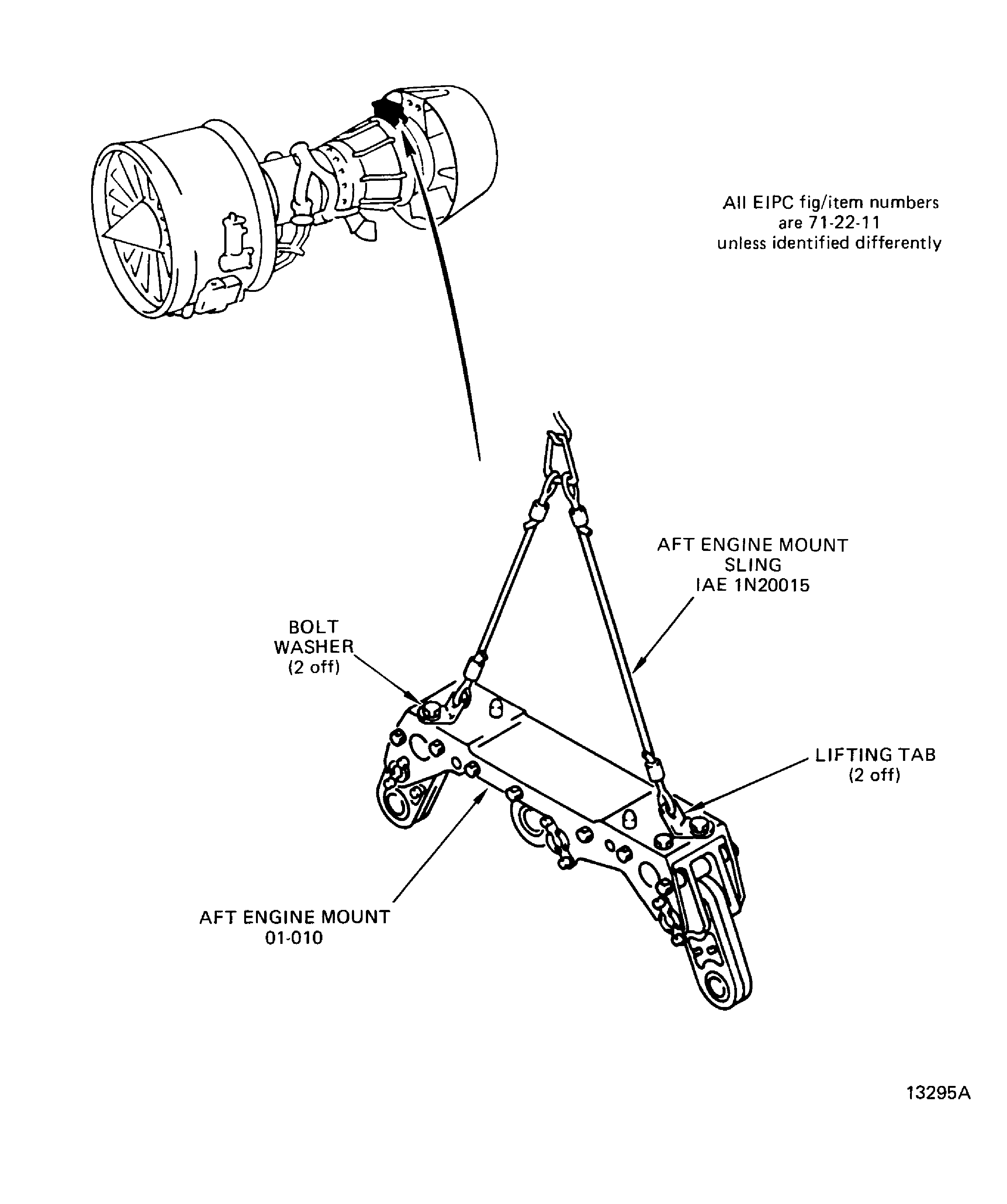

BE CAREFUL WHEN YOU REMOVE THE AFT MOUNT BECAUSE IT WEIGHS 64 LBS (29 KG).Attach IAE 1N20015 Aft engine mount sling 1 off to a hoist.

SUBTASK 72-00-50-020-135 Remove the Aft Mount

Figure: Pre SBE 79-0088: Remove the Core Zone Fire Detector

Sheet 1

Figure: SBE 71-0295: Remove the Core Zone Fire Detector

Sheet 2

Figure: Pre SBE 71-0295 and SBE 71-0295: Remove the Core Zone Fire Detector

Sheet 3

Figure: SBE 71-0295: Remove the Core Zone Fire Detector

Sheet 4

Figure: SBE 79-0088 and Pre SBE 71-0295: Remove the Core Zone Fire Detector

Sheet 5

Figure: SBE 71-0295: Remove the Core Zone Fire Detector

Sheet 6

Figure: Remove the LP Turbine Active Clearance Control Connector Tube

Sheet 1

Figure: Remove the LP Turbine Active Clearance Control Connector Tube

Sheet 2

Figure: Remove the LP Turbine Active Clearance Control Connector Tube

Sheet 3

Figure: Remove the LP Turbine Active Clearance Control Connector Tube

Sheet 4

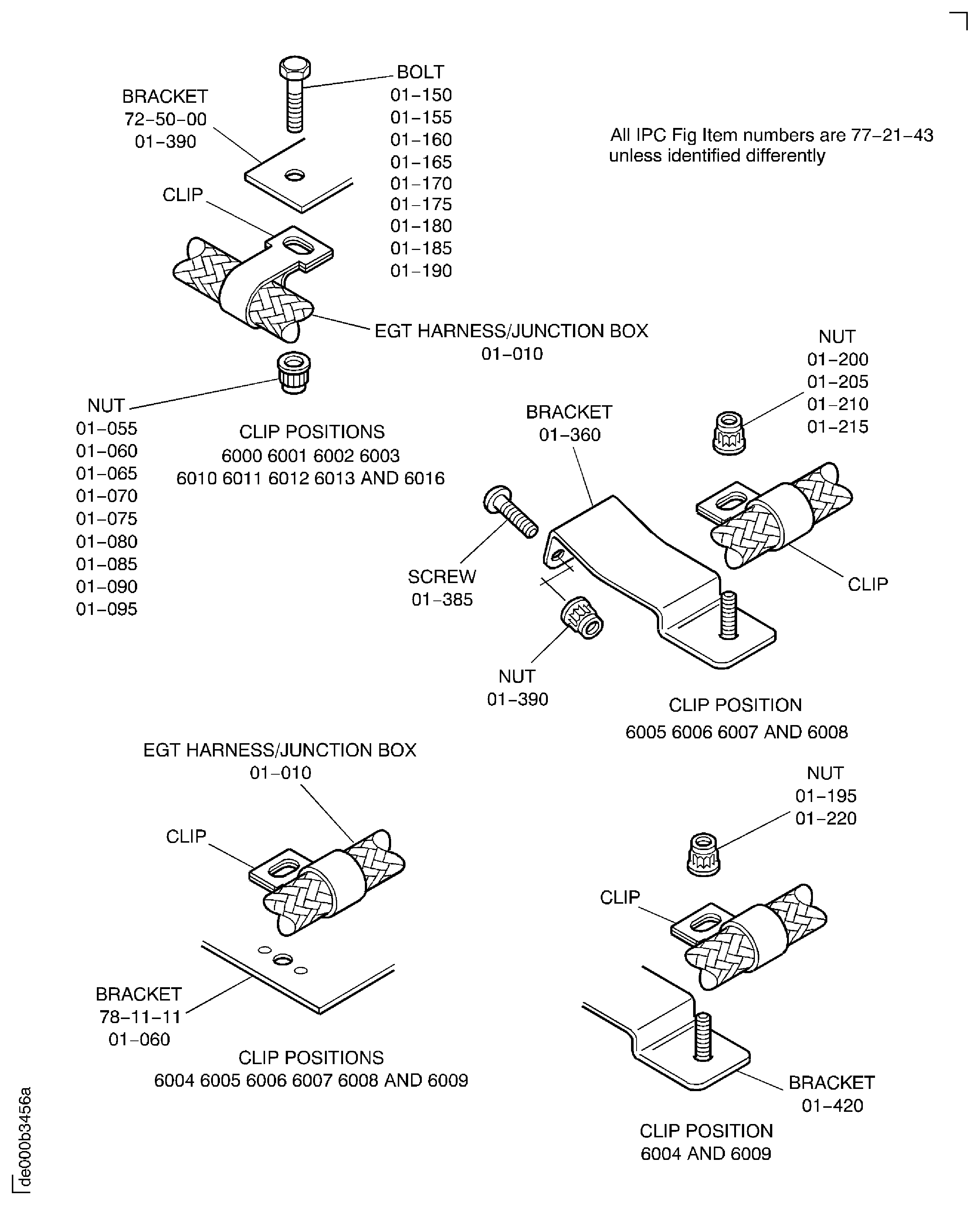

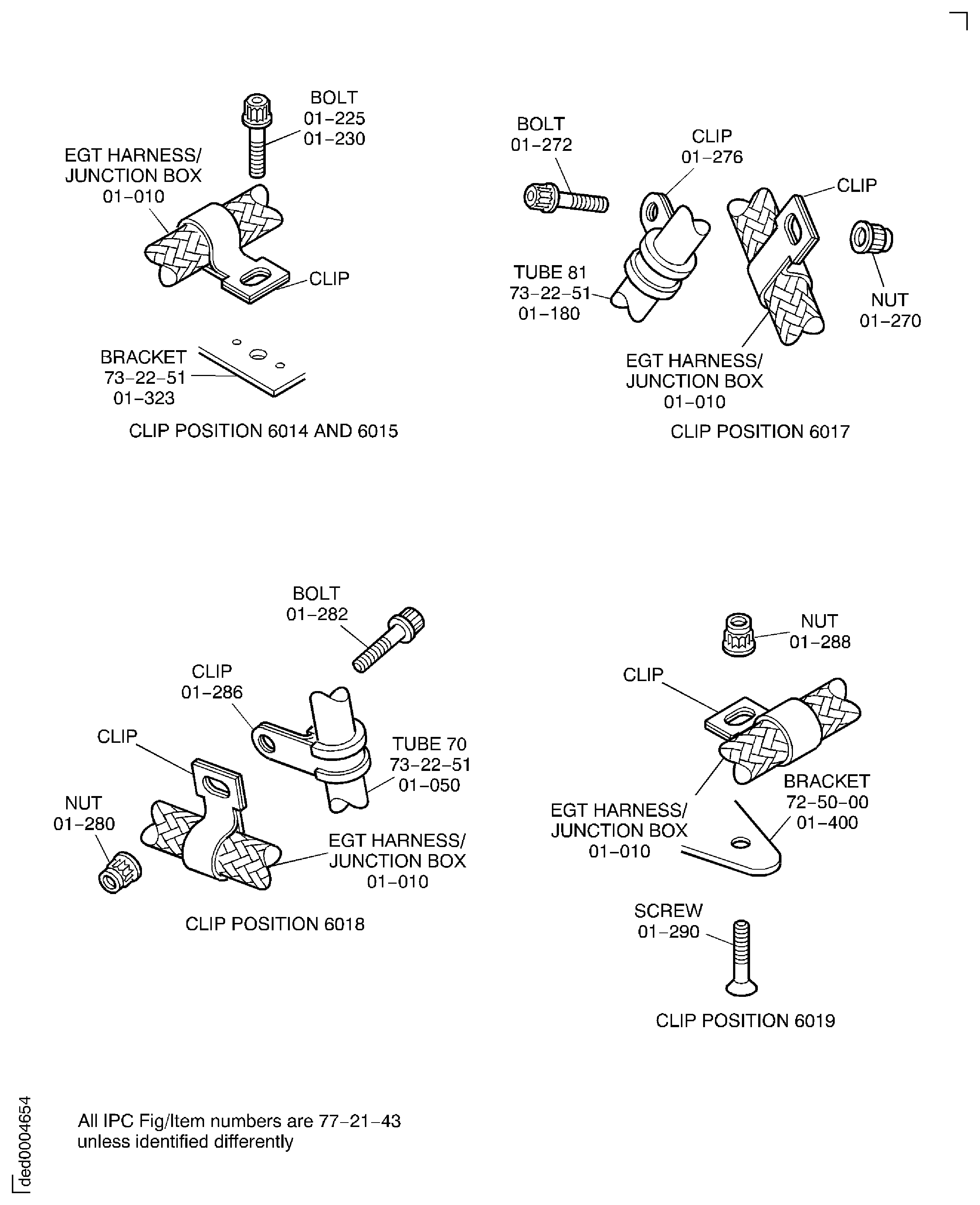

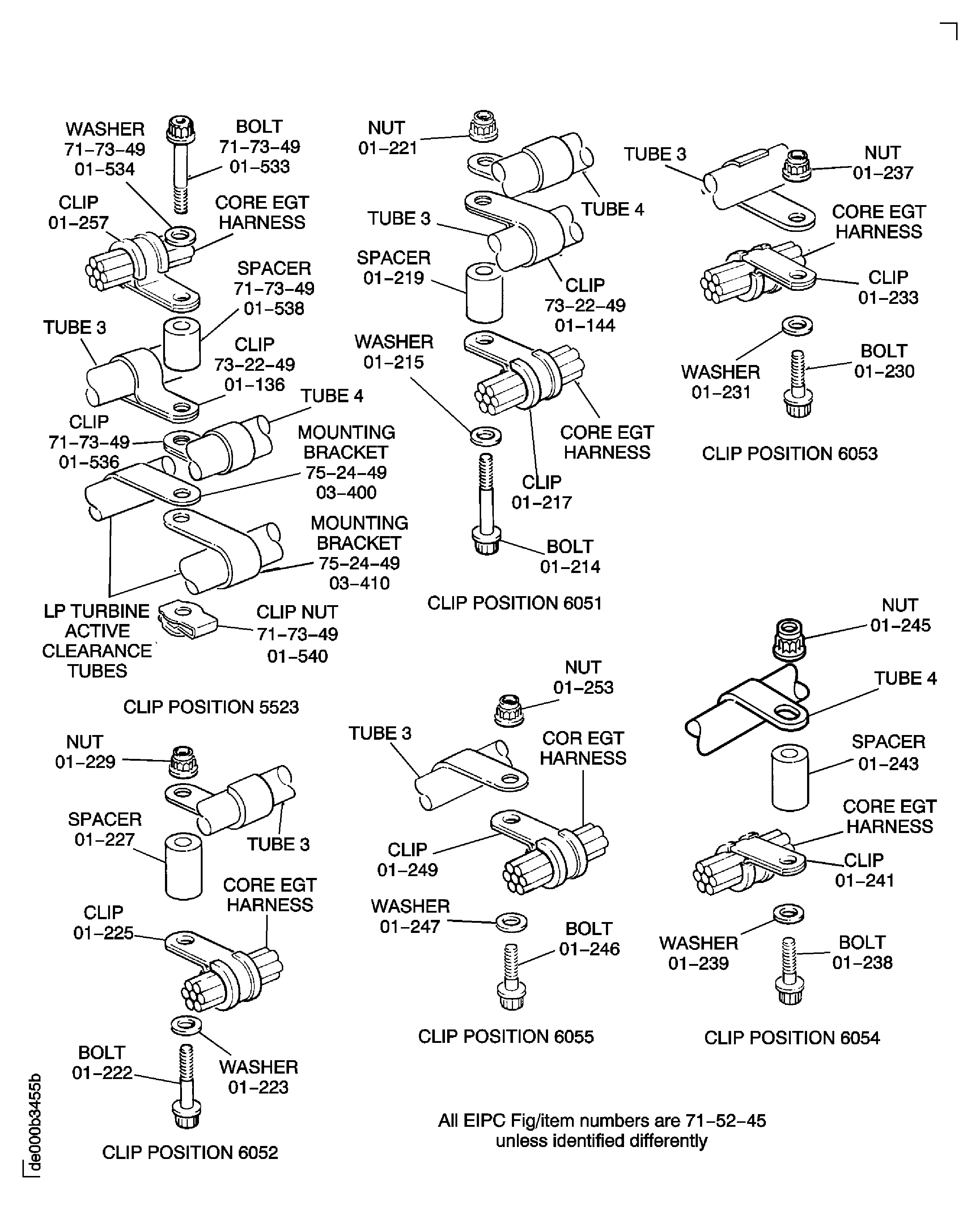

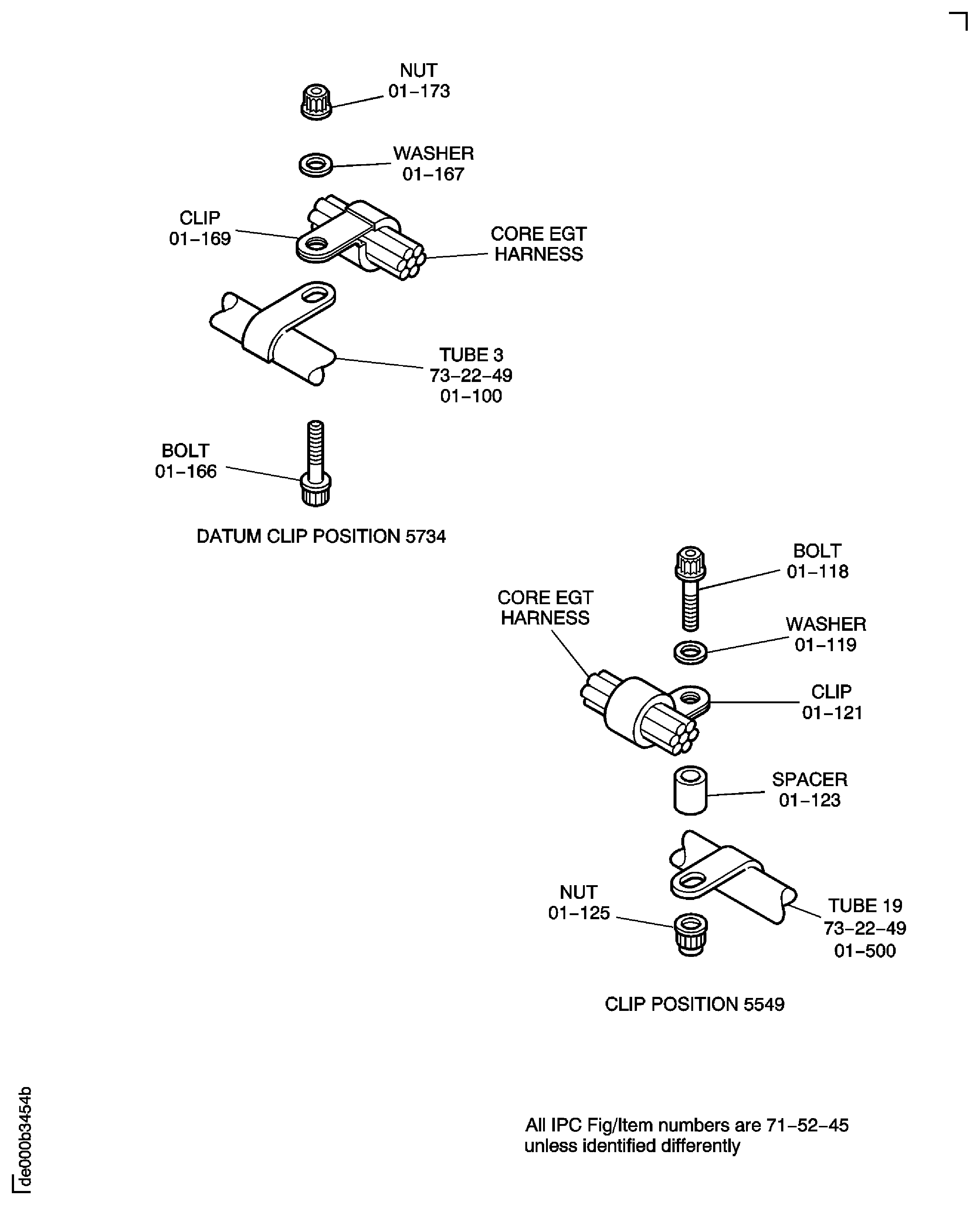

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 1

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 2

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 3

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 4

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 5

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 6

Figure: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 7

Figure: Pre SBE 77-0009: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 8

Figure: SBE 77-0009: Remove the EGT Harness/Junction Box and the Core EGT Harness

Sheet 9

Figure: Remove the No.5 Bearing Oil Feed Tube

Sheet 1

Figure: Remove the No.5 Bearing Oil Feed Tube

Sheet 2

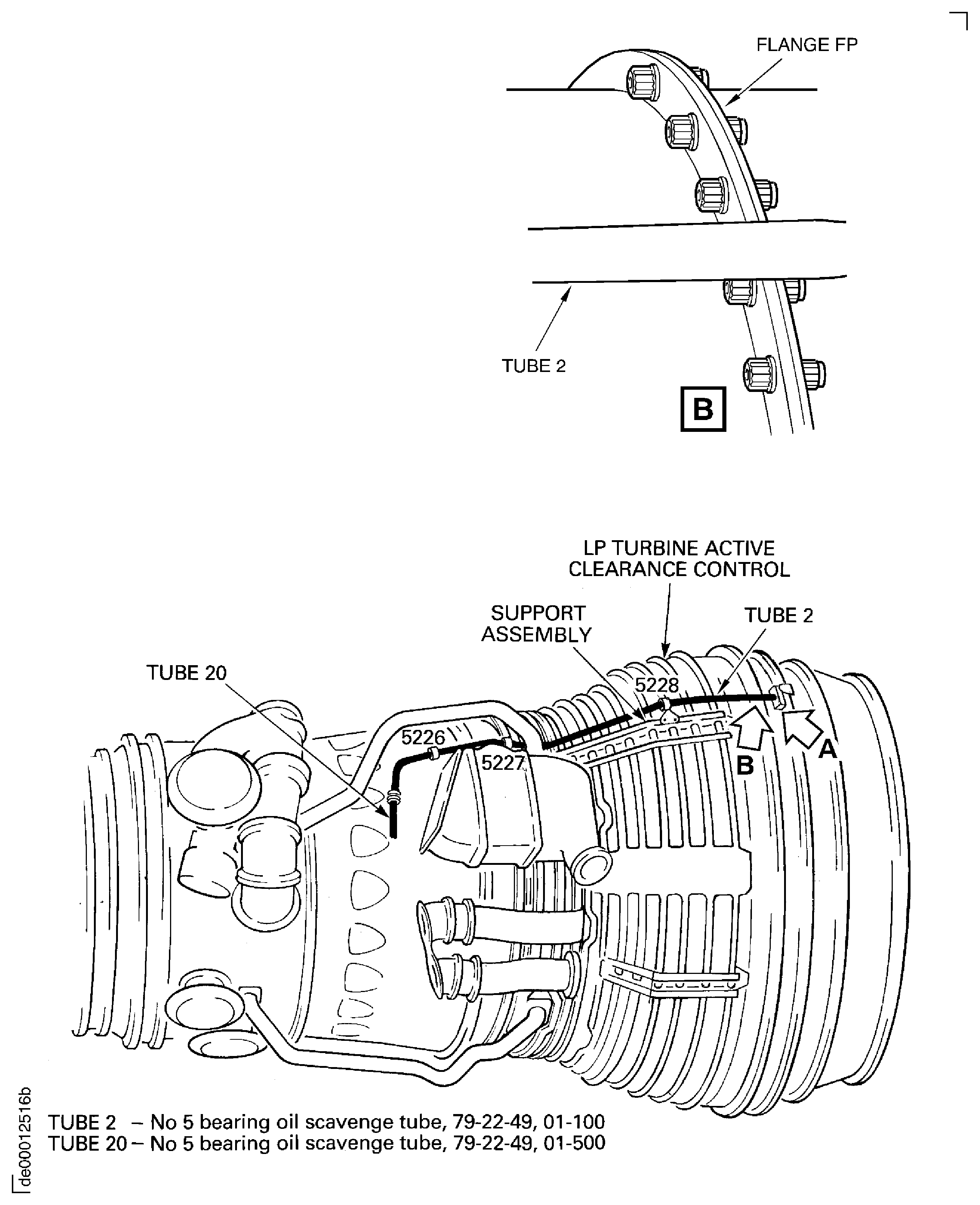

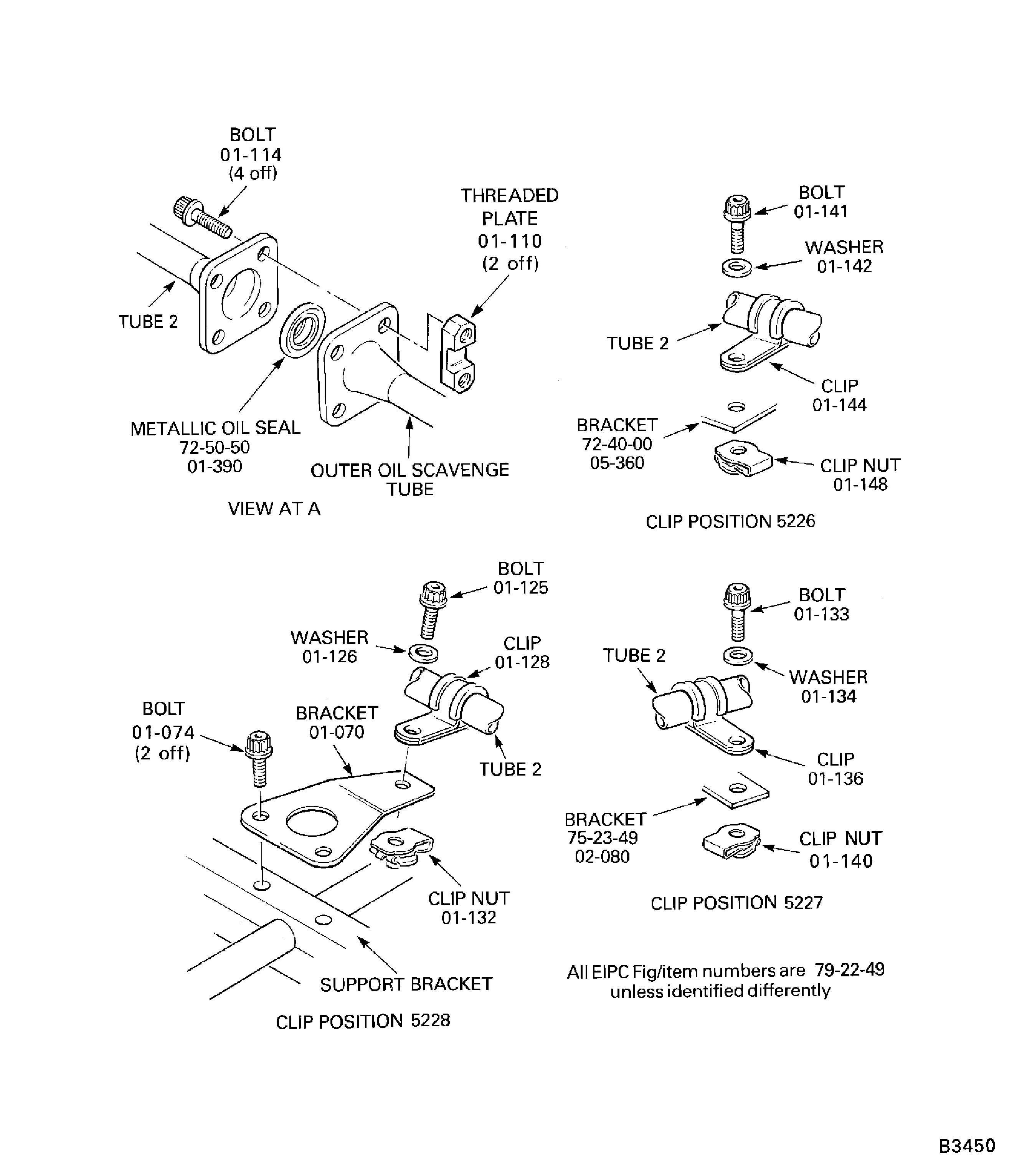

Figure: Remove the No.5 Bearing Oil Scavenge Tube

Sheet 1

Figure: Remove the No.5 Bearing Oil Scavenge Tube

Sheet 2

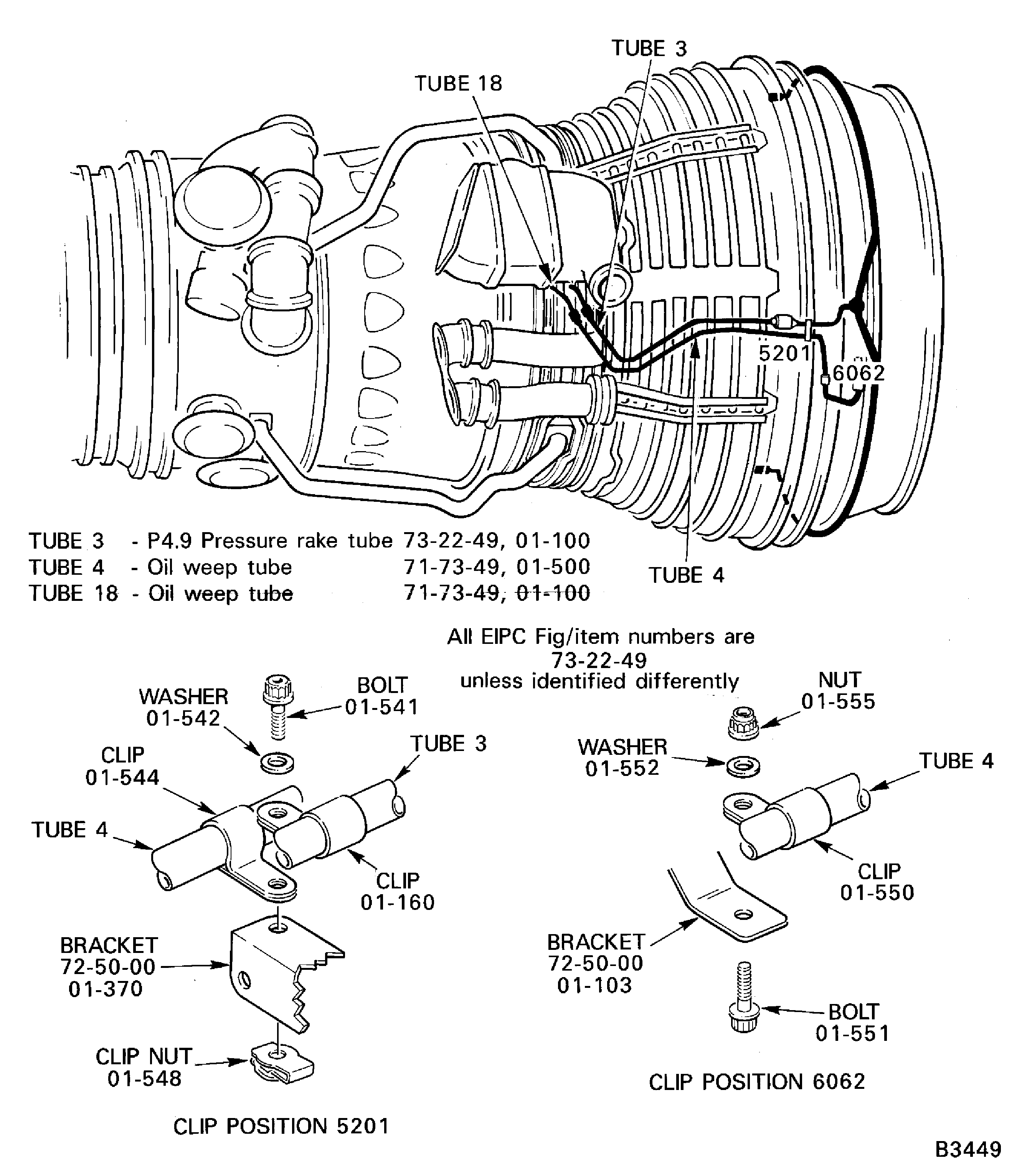

Figure: Remove the No. 4 Bearing Oil Weep Tube

Remove the No. 4 Bearing Oil Weep Tube

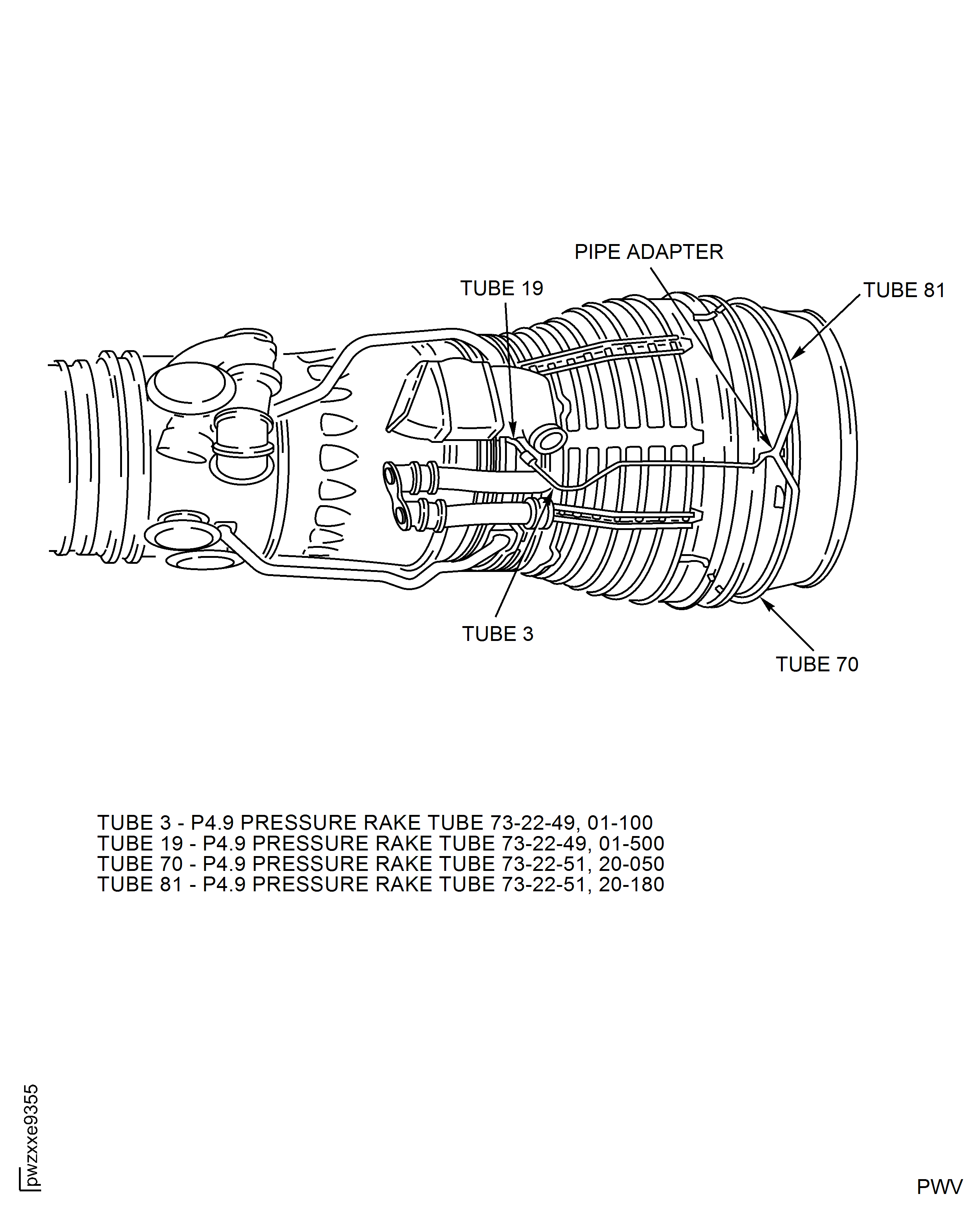

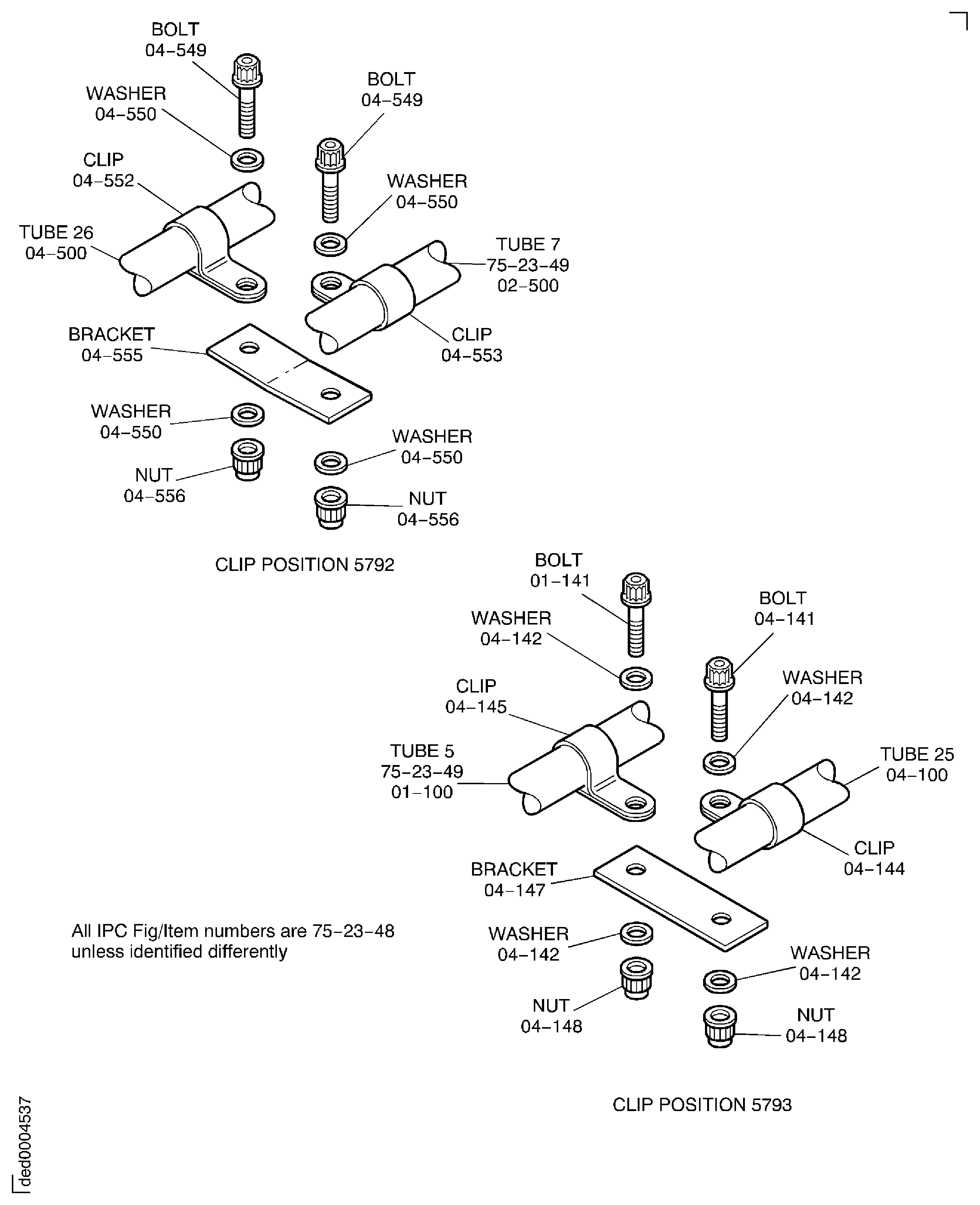

Figure: Remove the P4.9 Pressure Rake Tubes

Sheet 1

Figure: Remove the P4.9 Pressure Rake Tubes

Sheet 2

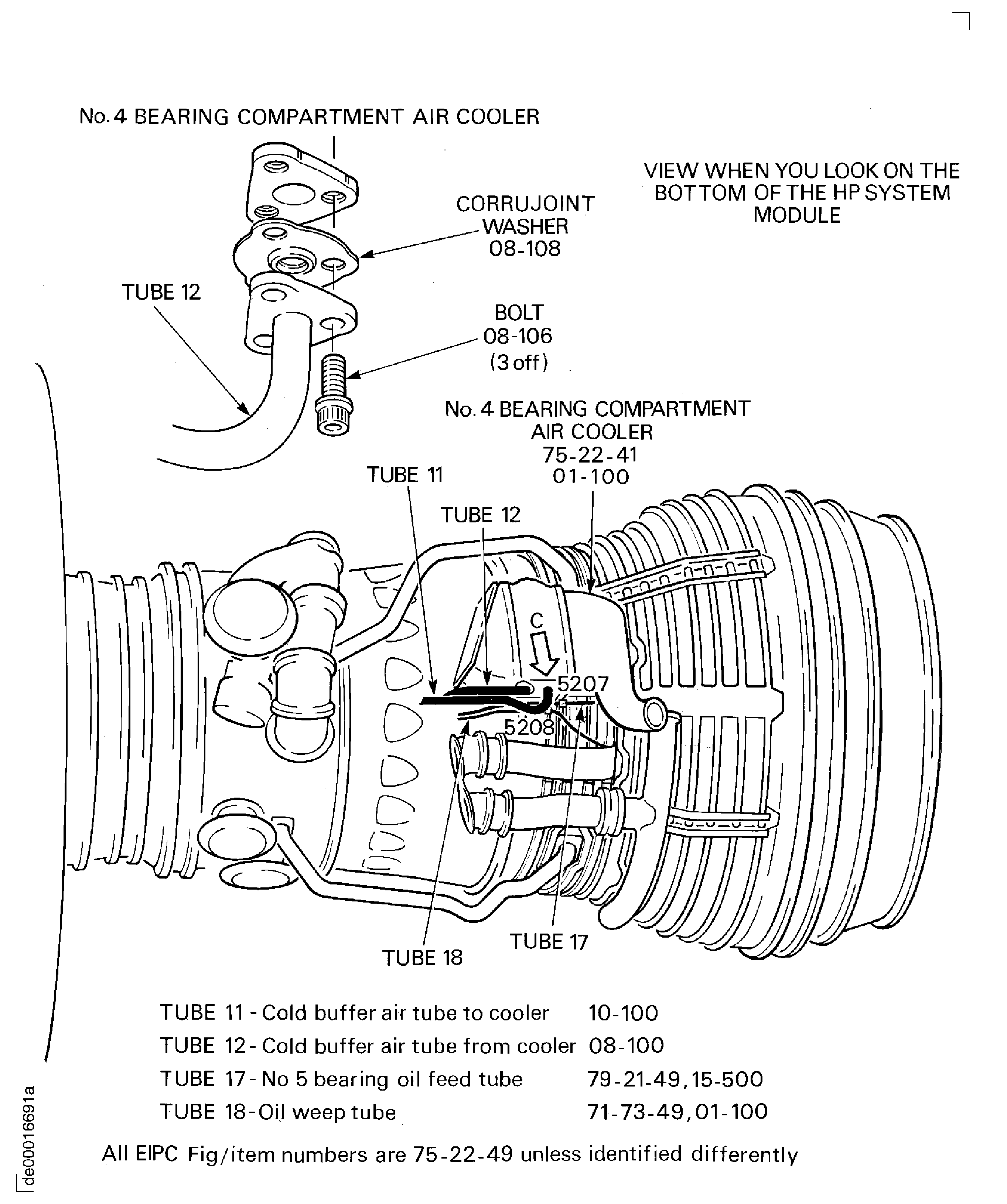

Figure: Remove the No.4 Bearing Compartment Air Cooler

Sheet 1

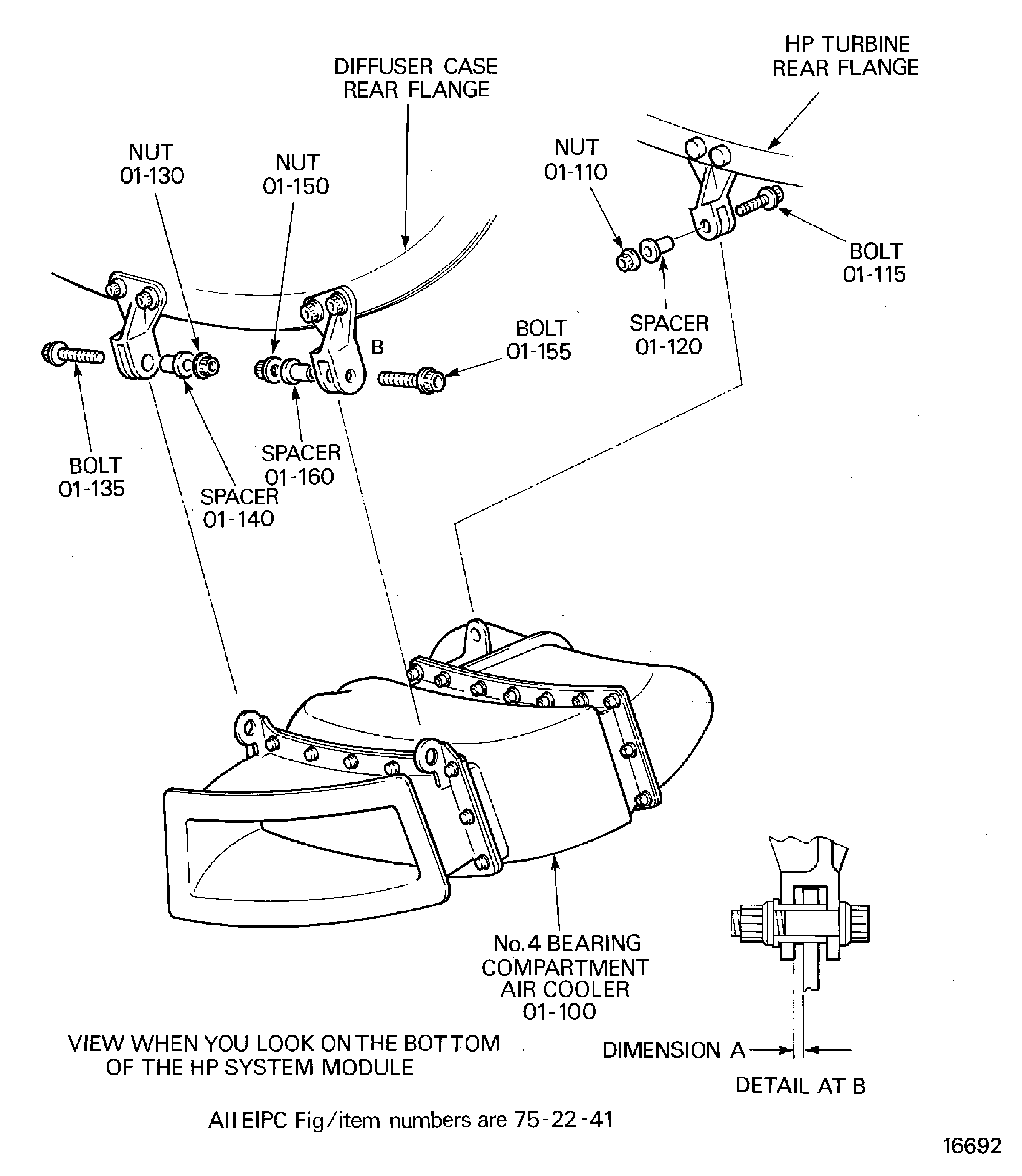

Figure: Remove the No.4 Bearing Compartment Air Cooler

Sheet 2

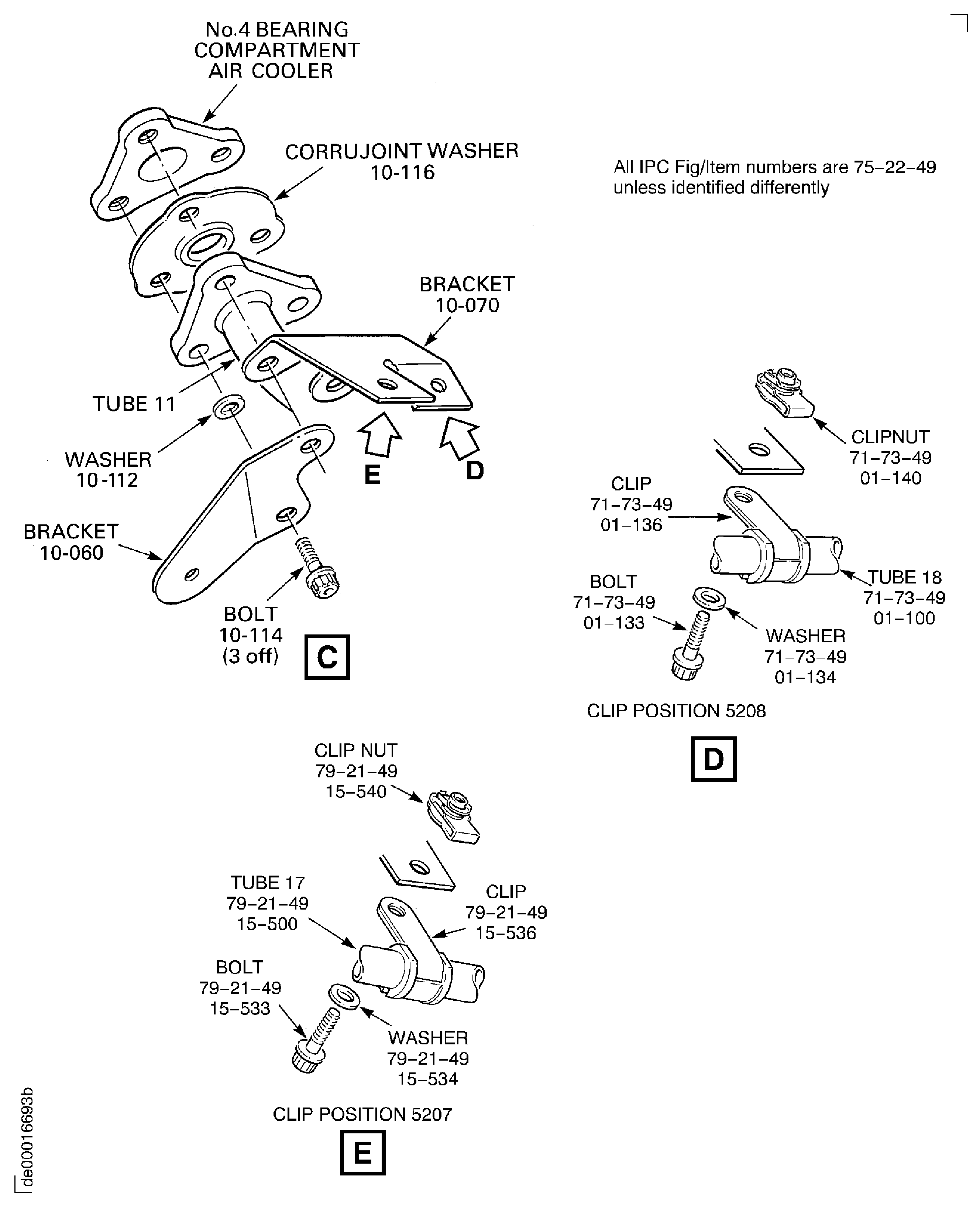

Figure: Remove the No.4 Bearing Compartment Air Cooler

Sheet 3

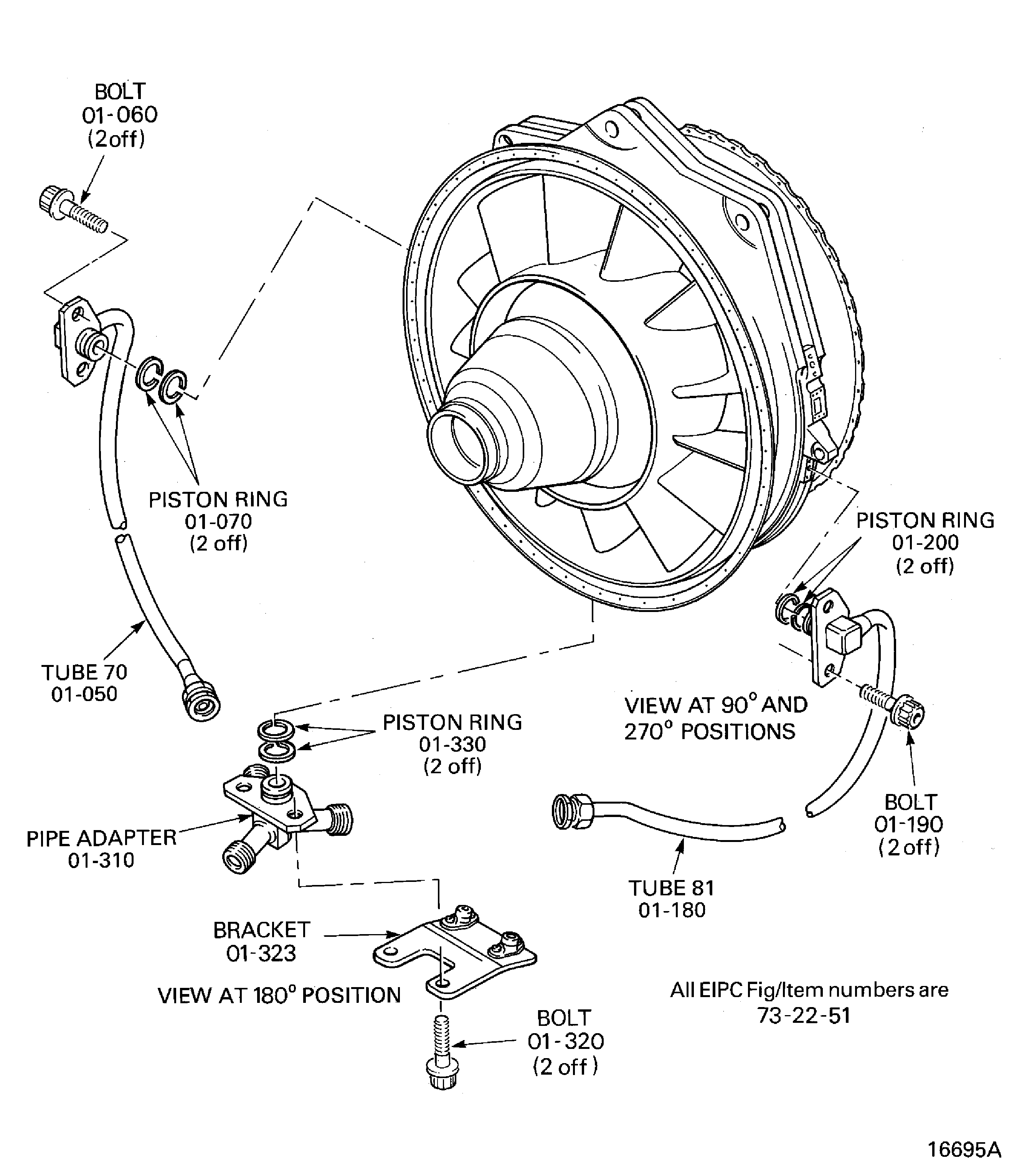

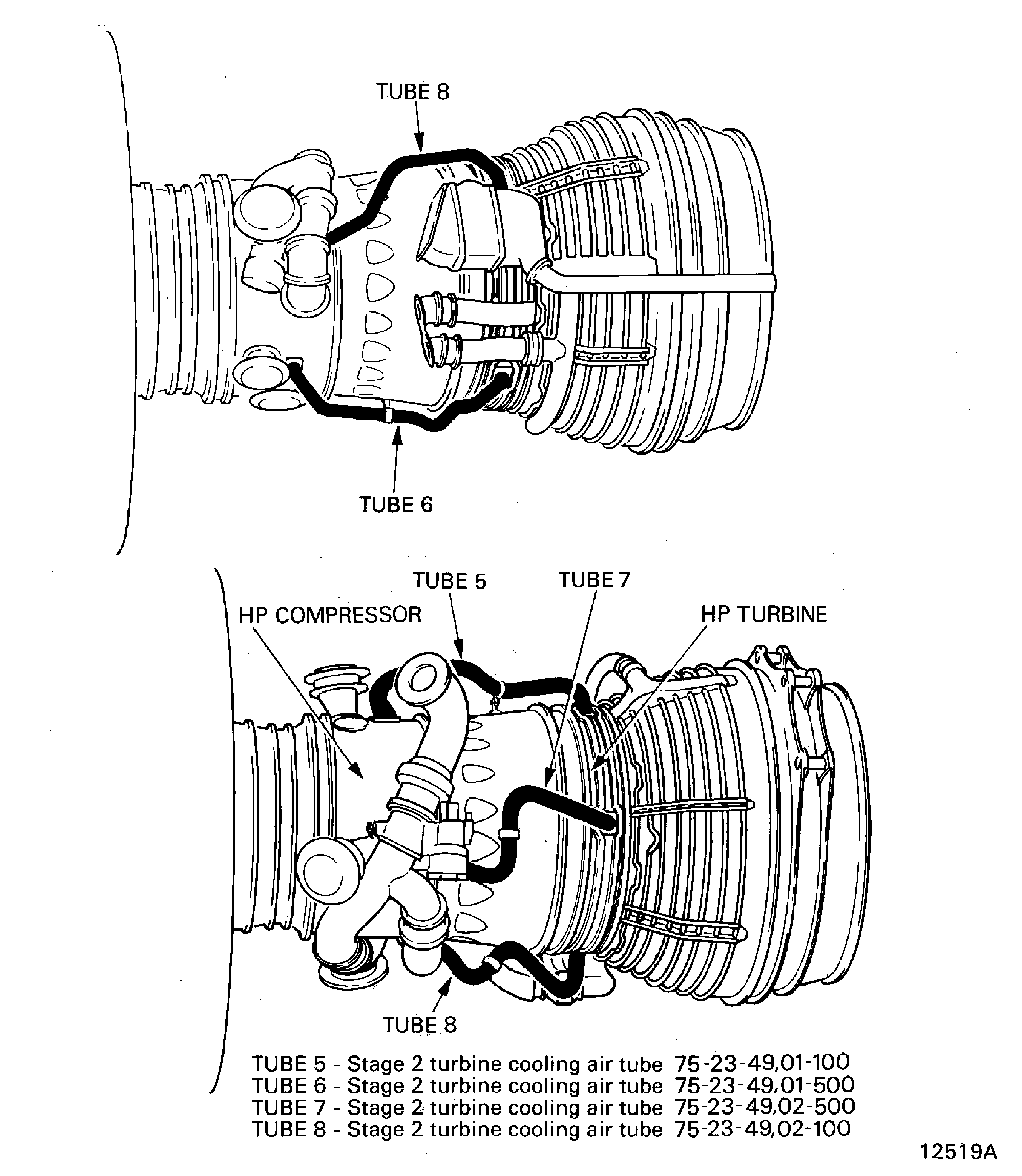

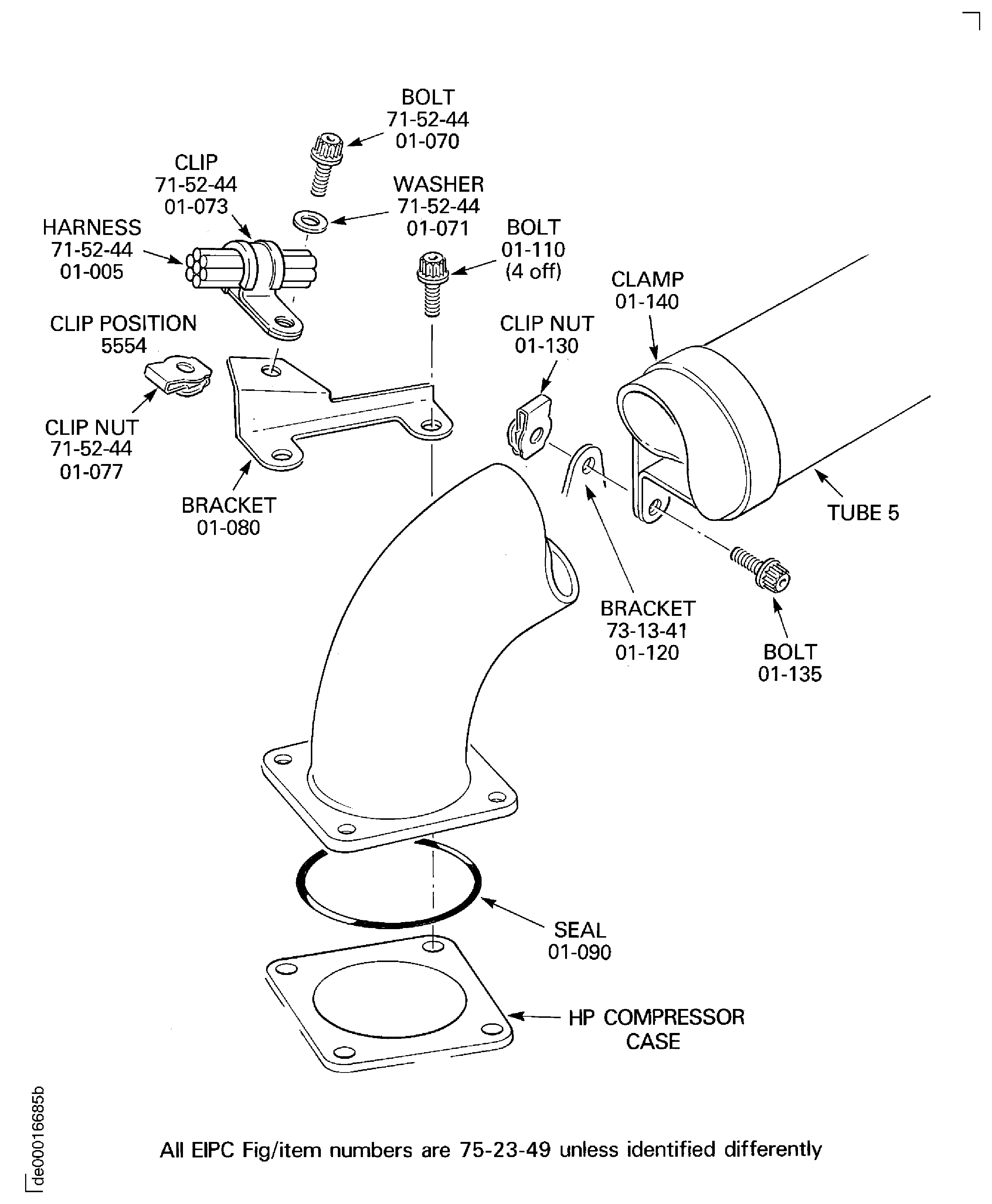

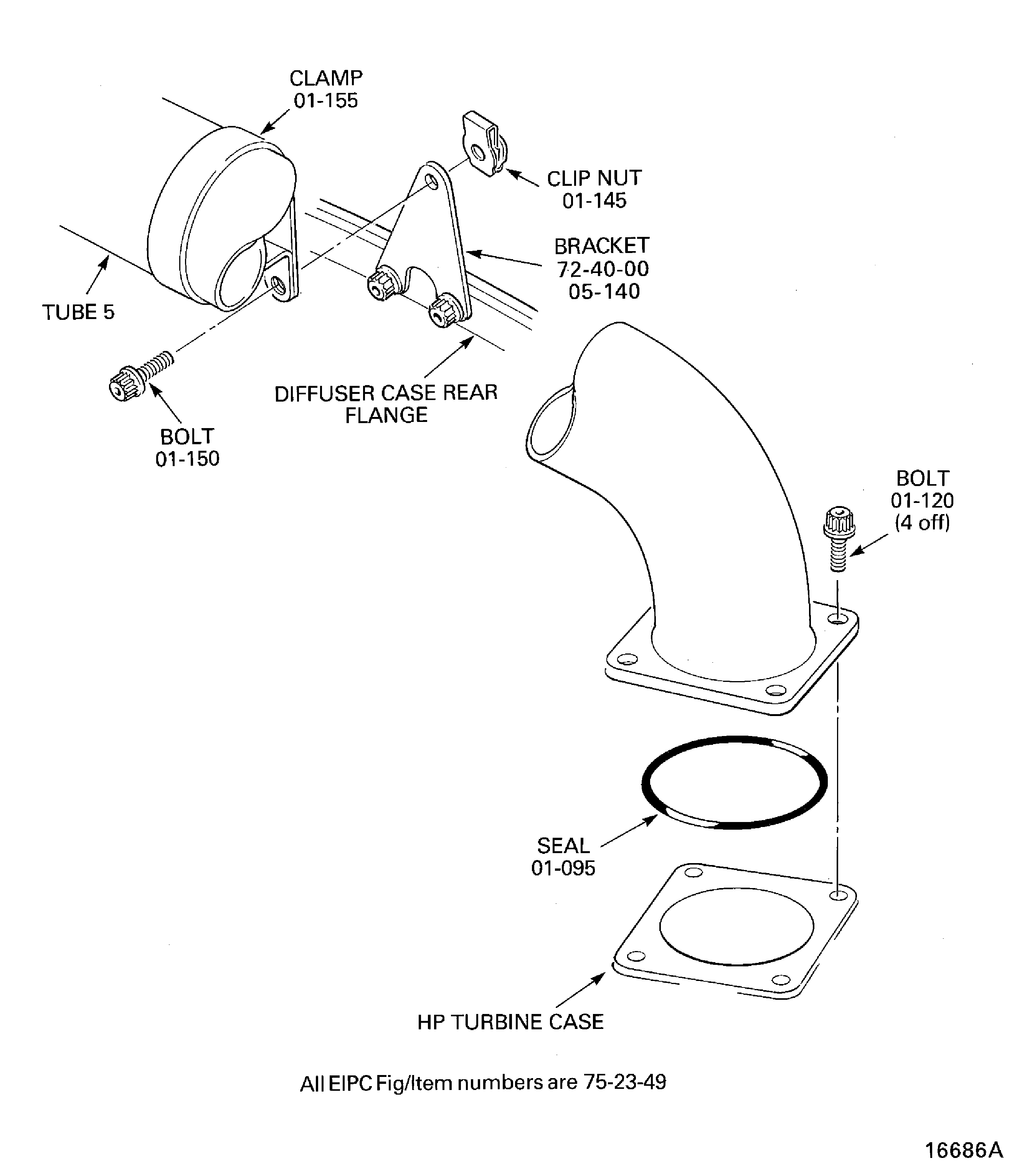

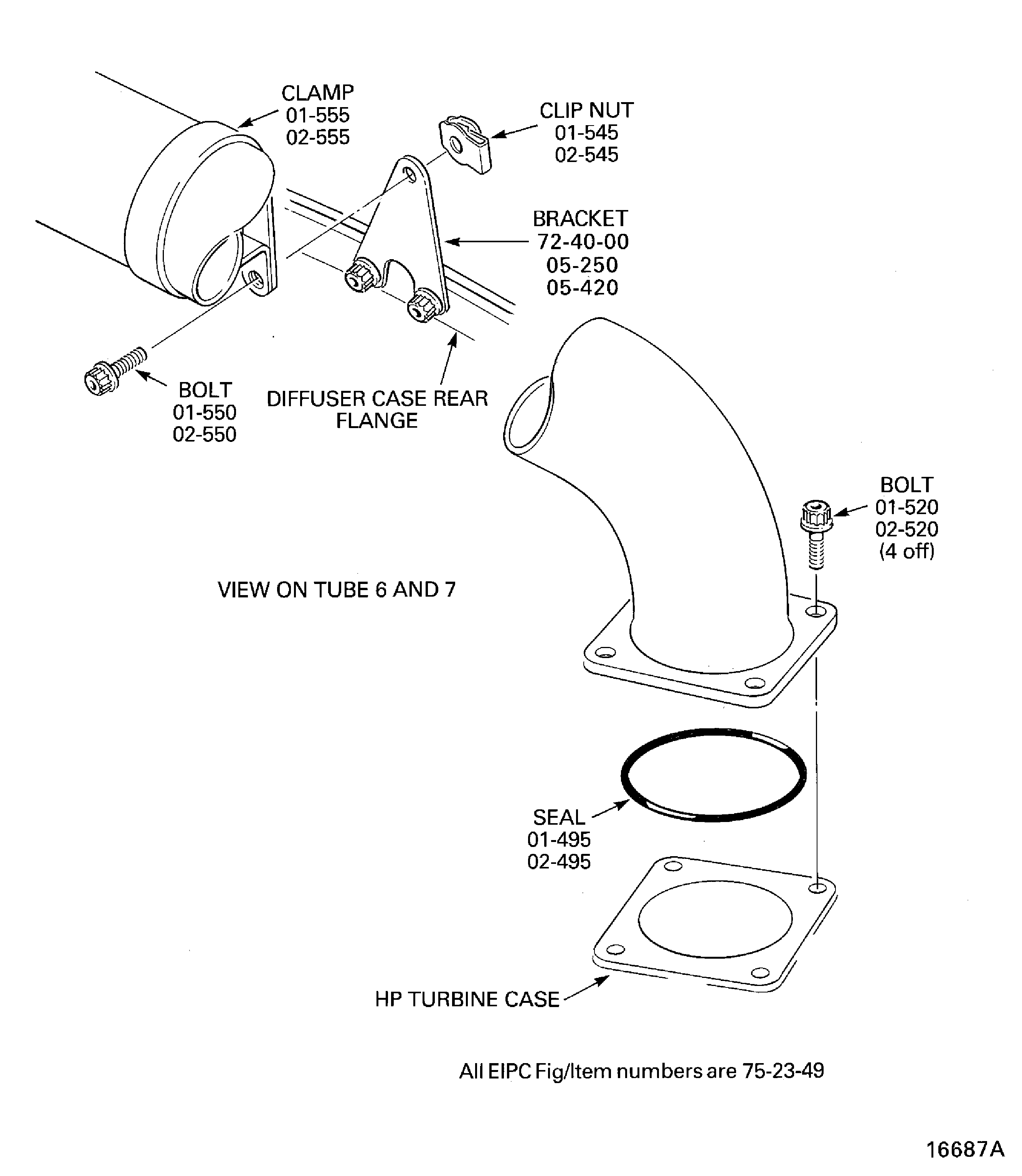

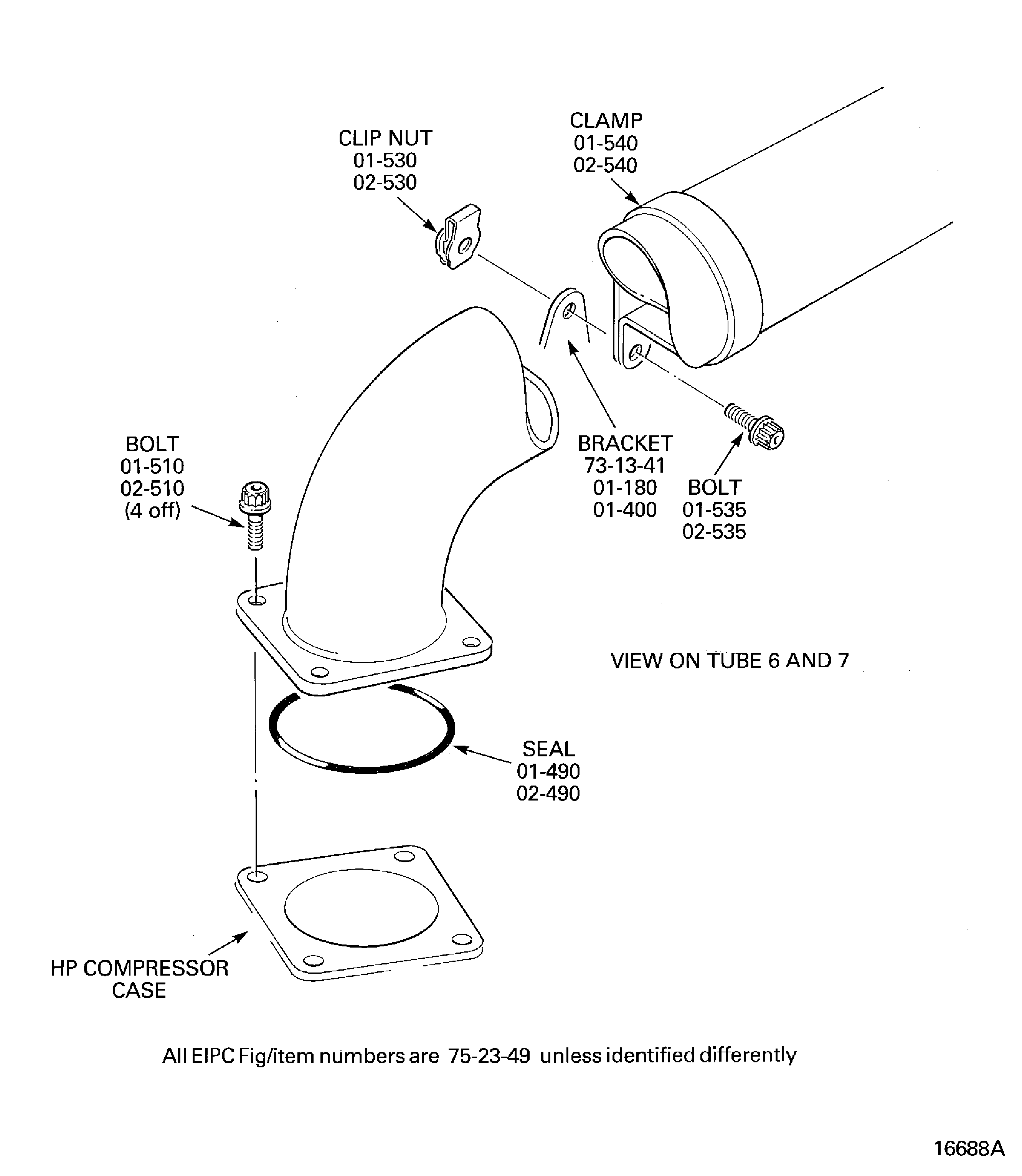

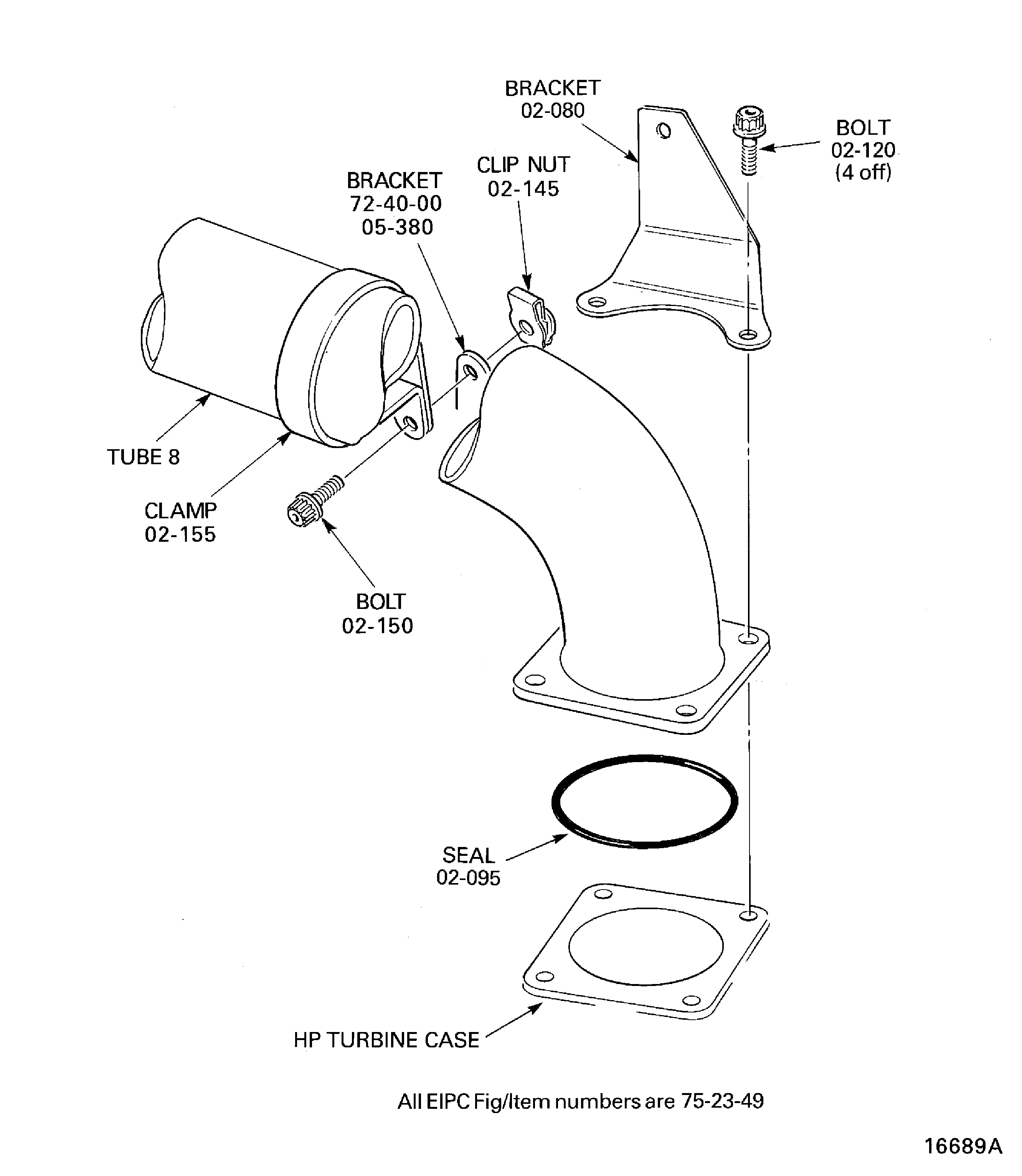

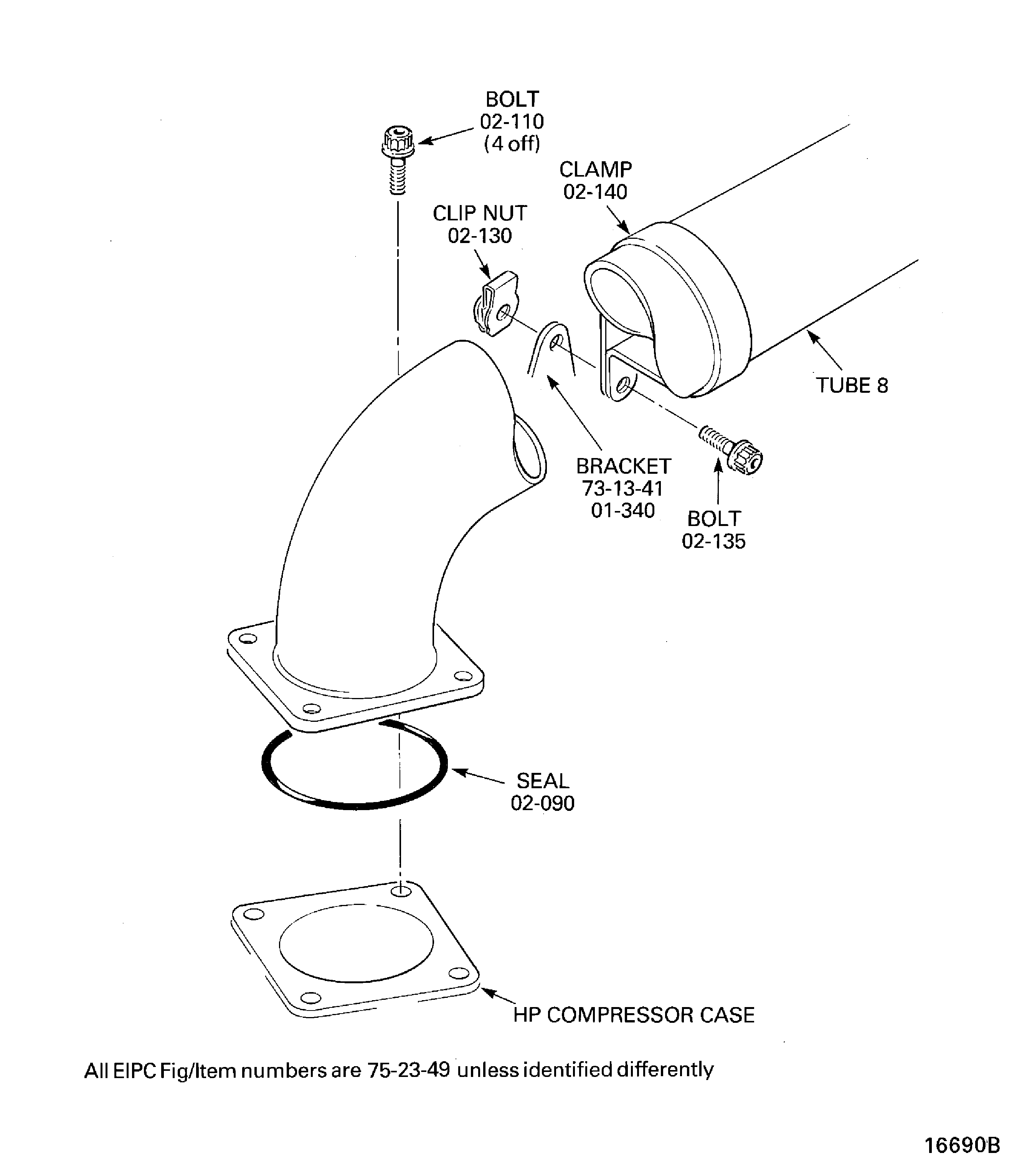

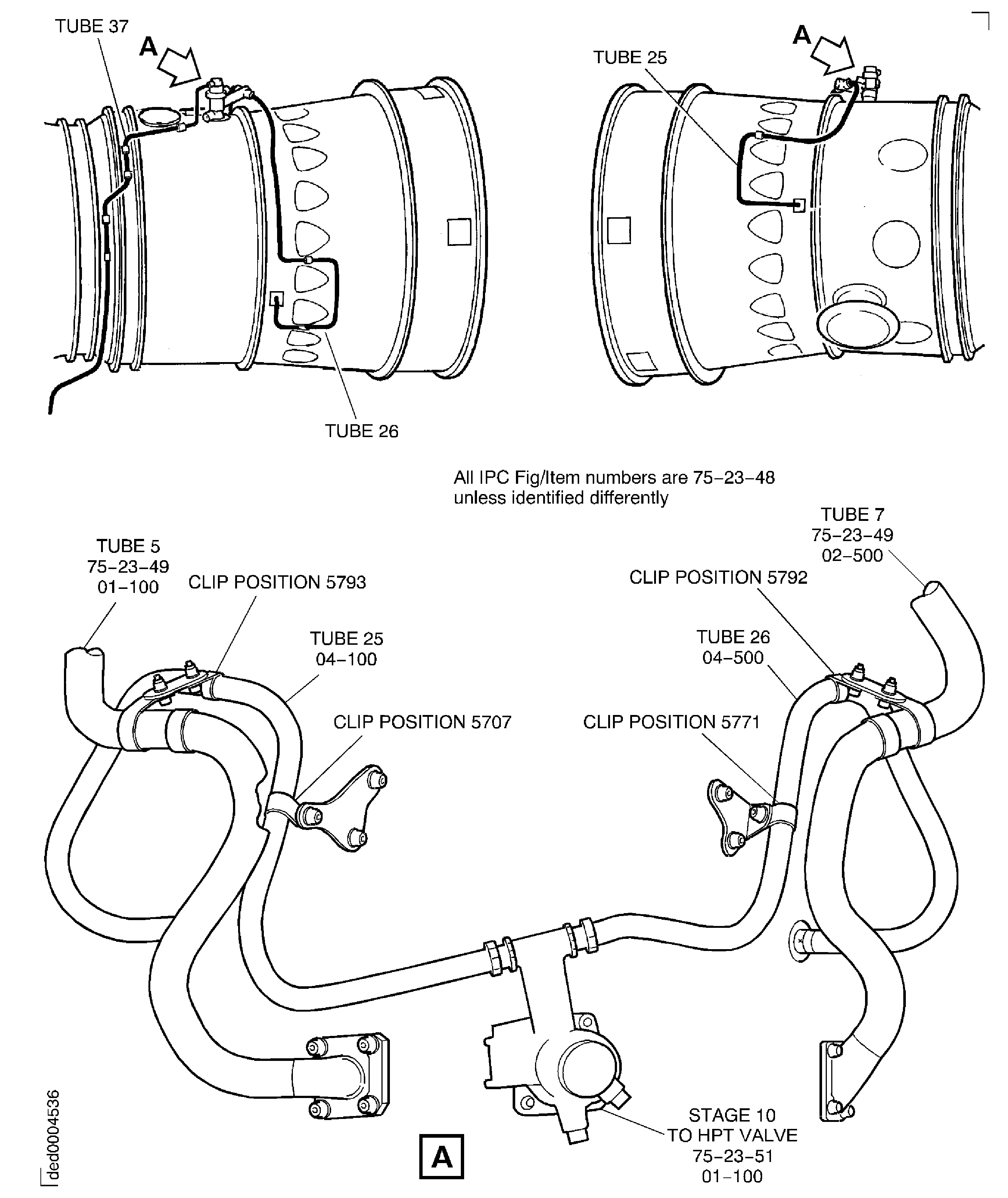

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 1

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 2

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 3

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 4

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 5

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 6

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 7

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 8

Figure: Remove the Stage 2 Turbine Cooling Air Tubes

Sheet 9

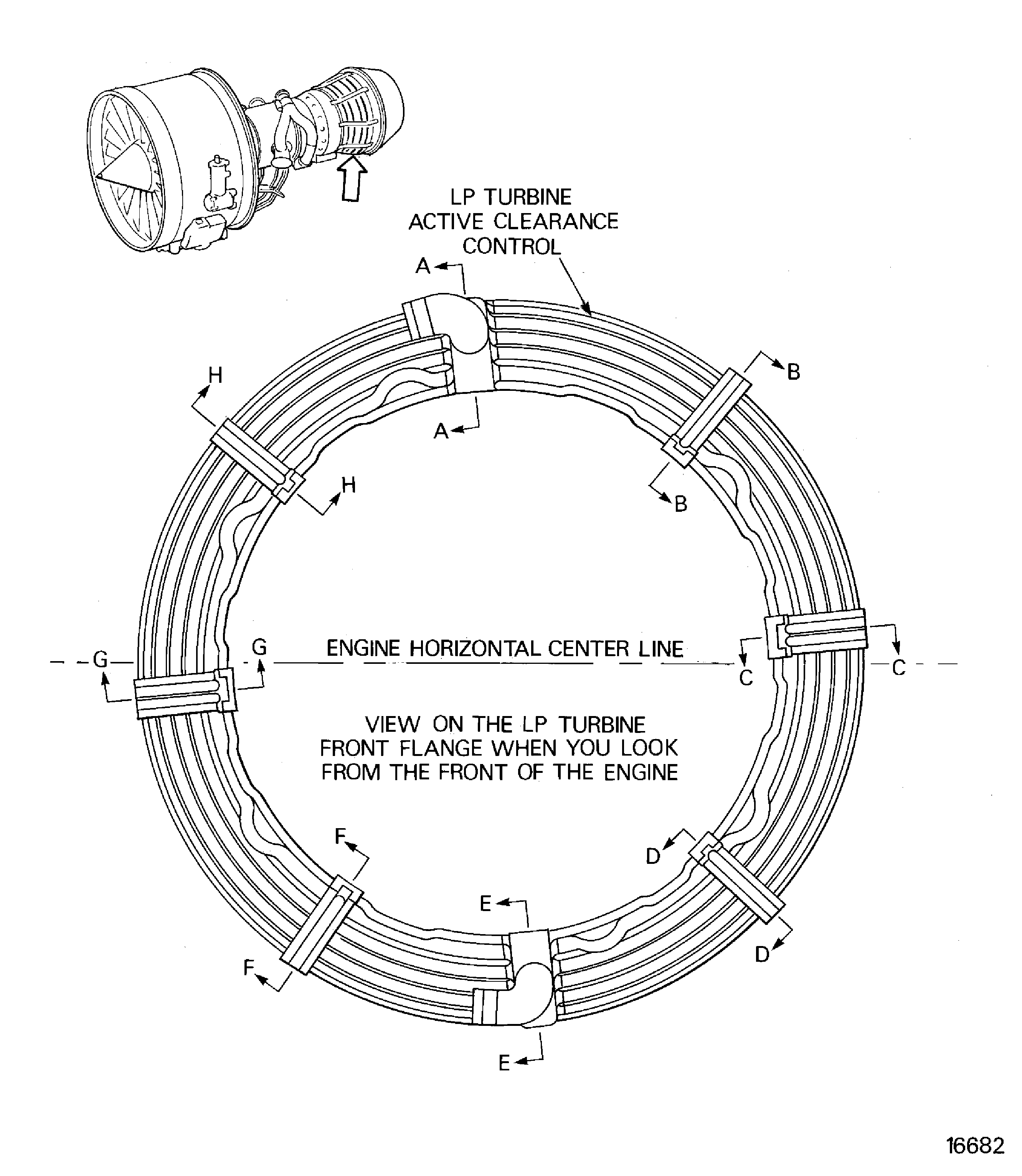

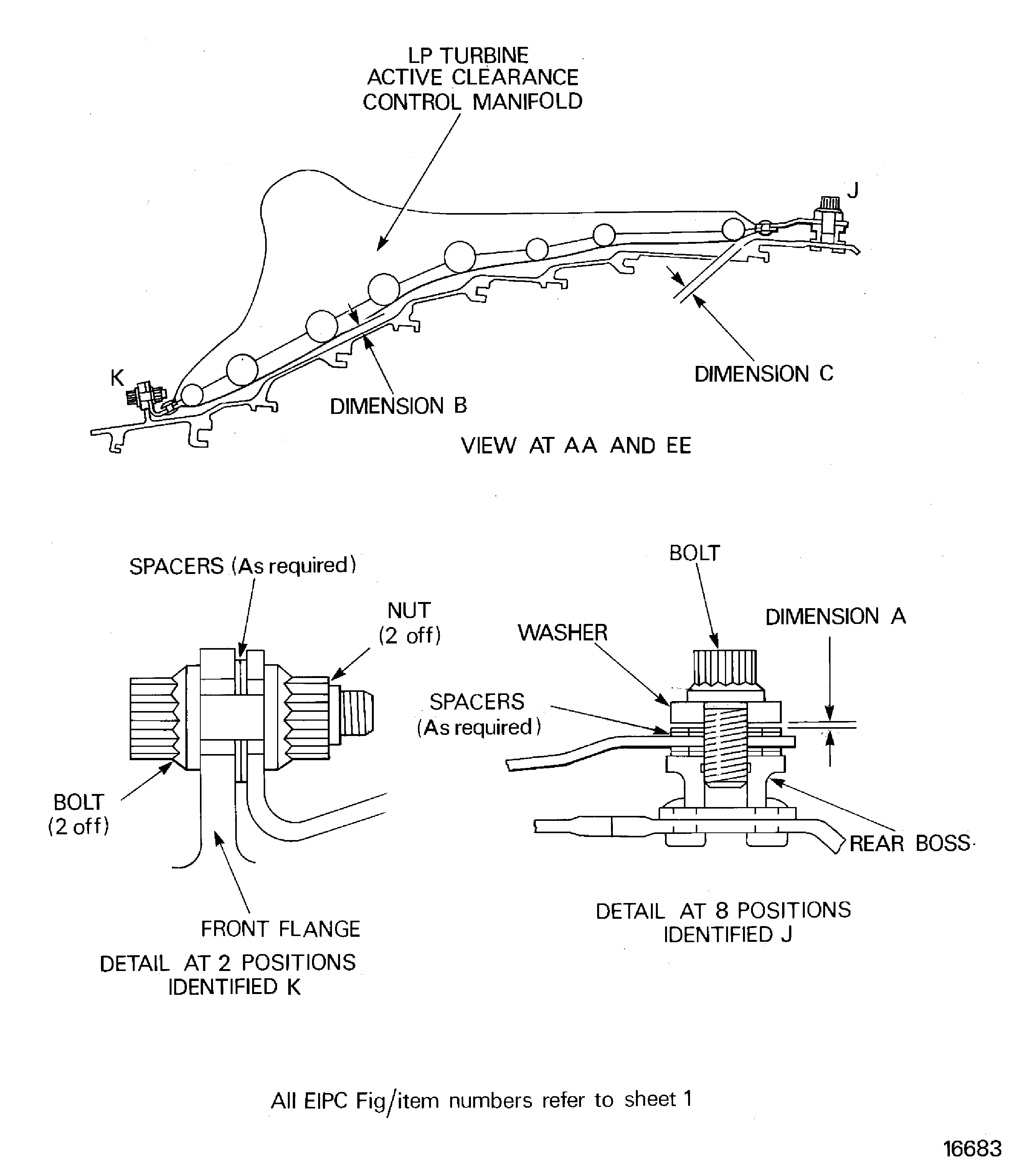

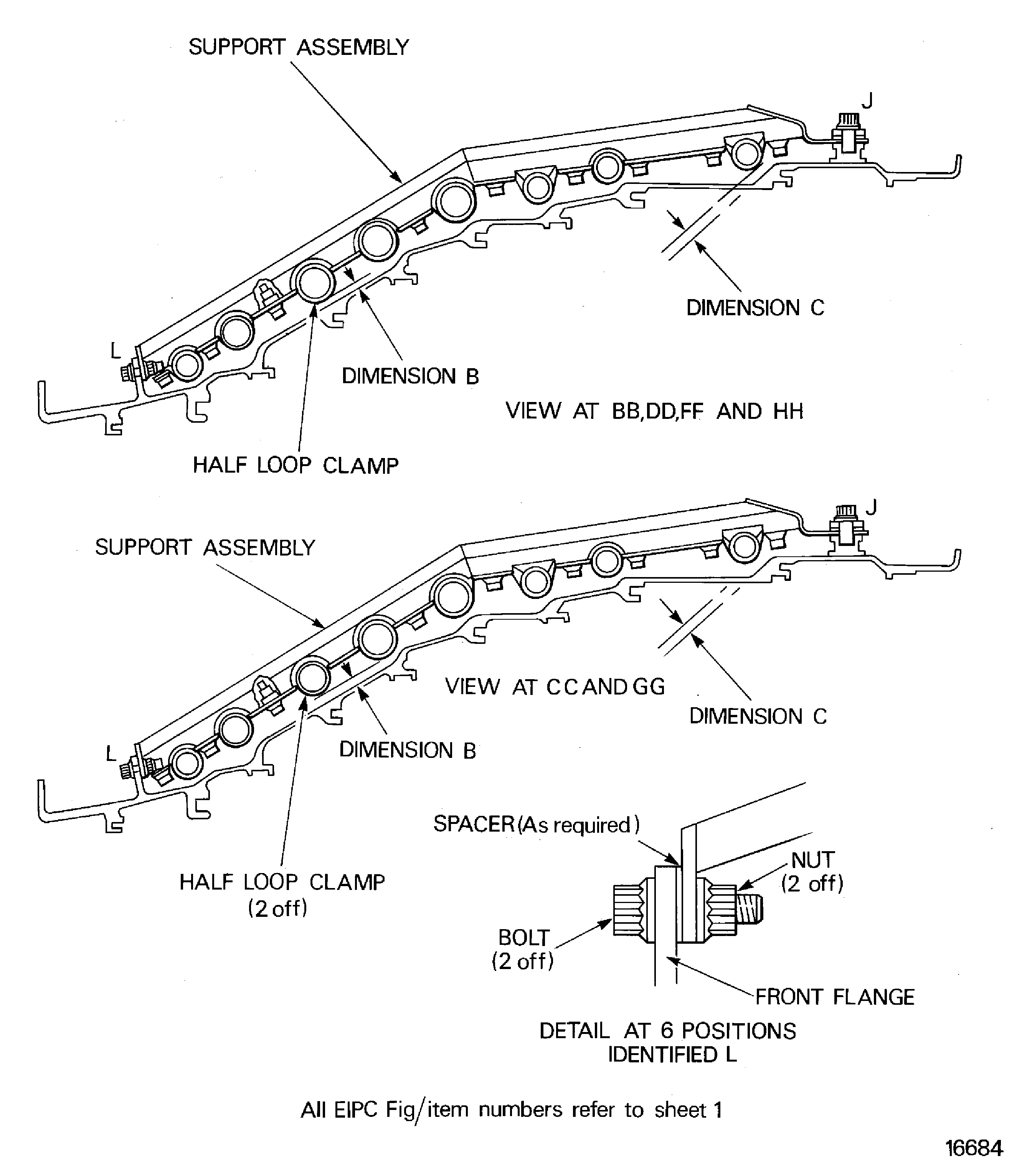

Figure: Remove the LP Turbine Active Clearance Control

Sheet 1

Figure: Remove the LP Turbine Active Clearance Control

Sheet 2

Figure: Remove the LP Turbine Active Clearance Control

Sheet 3

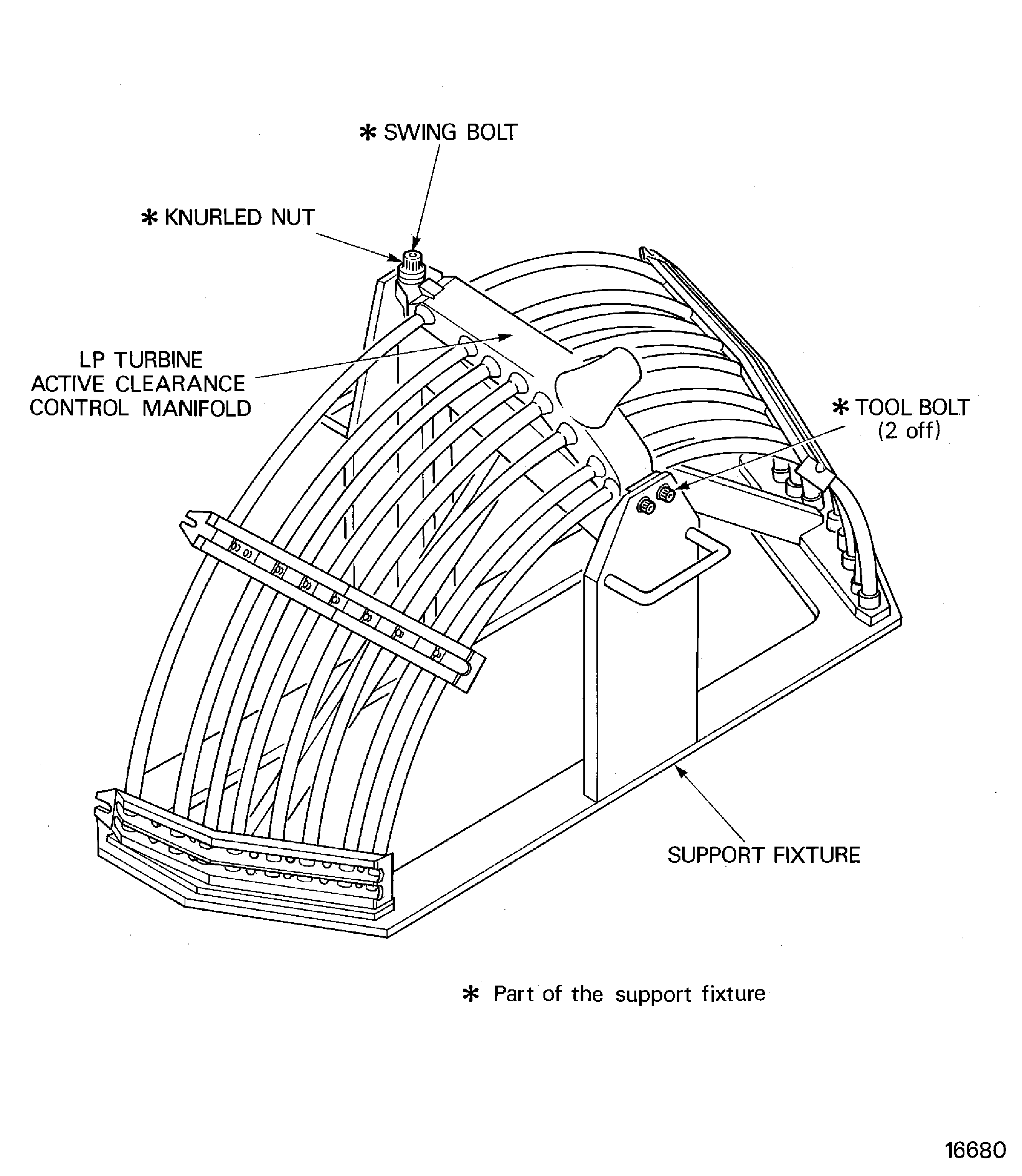

Figure: Install the LP Turbine Active Clearance Control Manifold in to the Support Fixture

Install the LP Turbine Active Clearance Control Manifold in to the Support Fixture

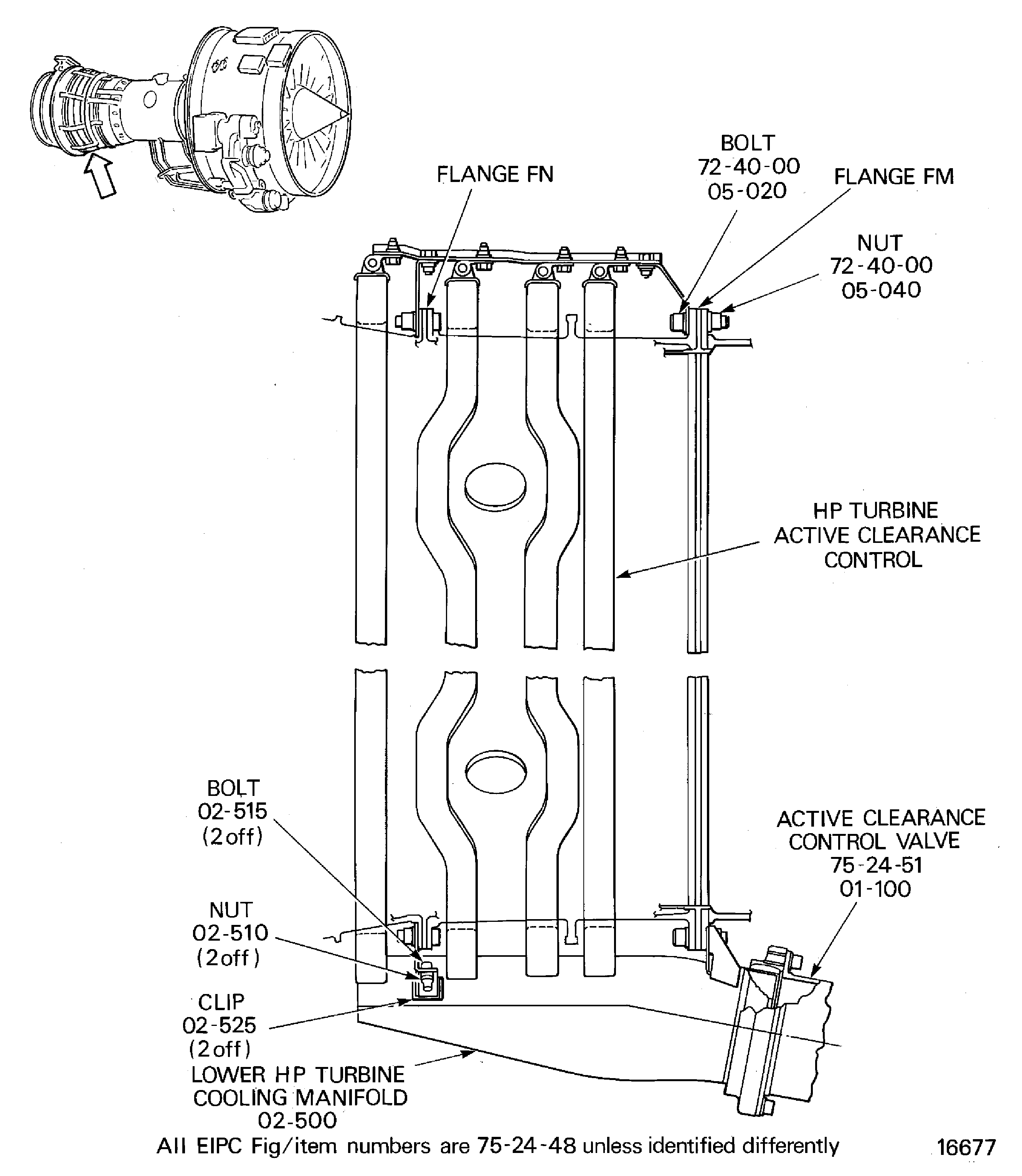

Figure: Remove the HP Turbine Active Clearance Control Manifolds

Sheet 1

Figure: Remove the HP Turbine Active Clearance Control Manifolds

Sheet 2

Figure: Remove the HP Turbine Active Clearance Control Manifolds

Sheet 3

Figure: Remove the EGT Probes

Remove the EGT Probes

Figure: Remove the Aft Mount

Sheet 1

Figure: Remove the Aft Mount

Sheet 2