Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-60-020-001-B00 External Gearbox Module - Remove The LPC/Intermediate Case Module Drains And Fire Detector, Removal-001

General

This TASK gives the procedure to remove the initial dressings from the external gearbox. Refer to TASK 72-00-60-020-002 for other related procedures. The engine must be on support pedestals for this procedure. Refer to TASK 71-00-00-560-001.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Seal all openings when tubes are disconnected, to prevent contamination from unwanted material.

Discard all rubber seal rings and cotter pins removed in this procedure.

Remove and discard the lockwire before the tube or connector is disconnected.

When electrical connectors are disconnected special plastic caps must be installed.

All tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | LOCAL | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

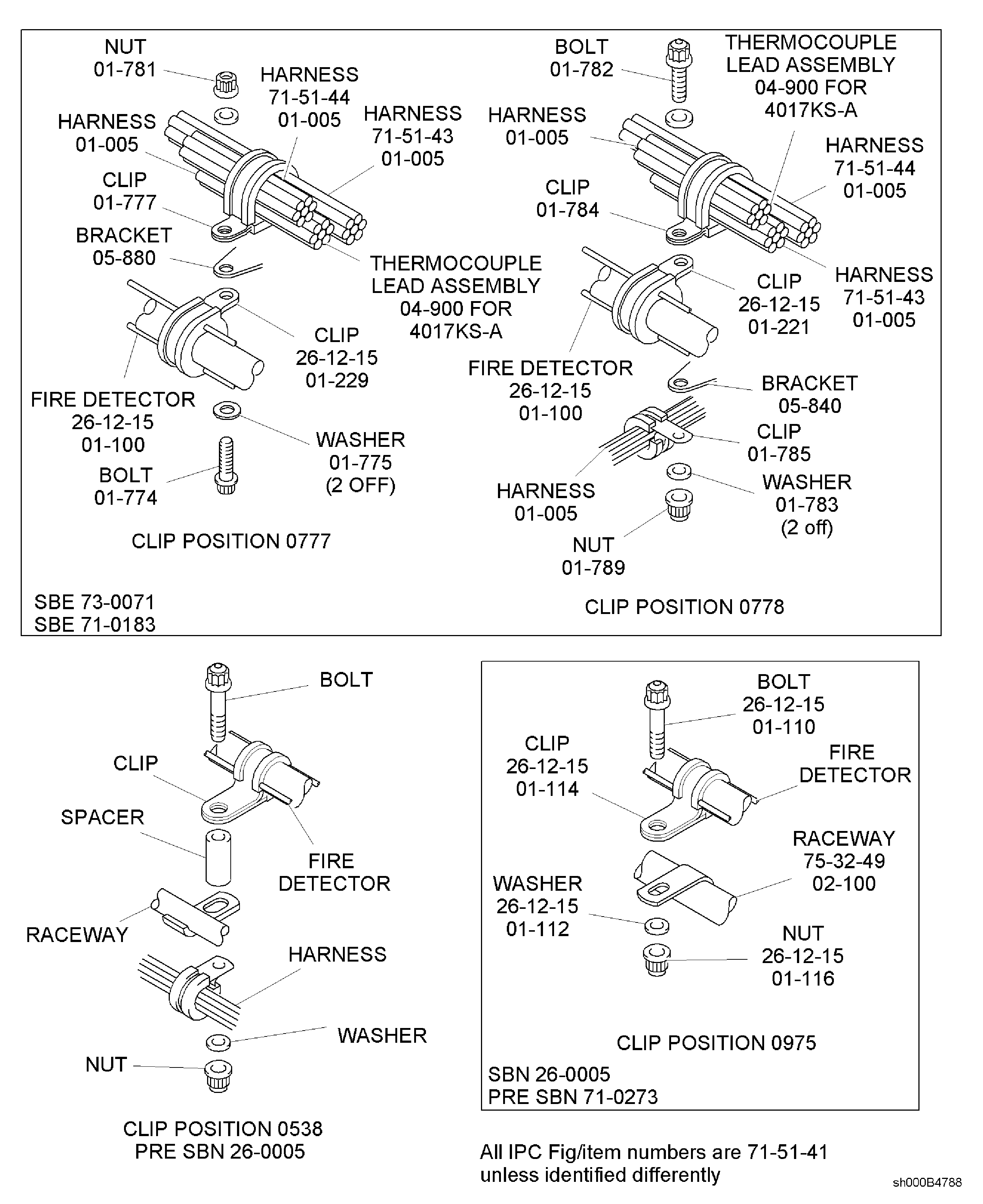

Disconnect the electrical connectors 4000WD1-A and 4000WD2-A from the responders ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 01-100).

1183, 1184, 0955, 0956, 0957, 0958, 0941, 0959, 0960, 0961, 0962, 0974, 0975 and 0976.

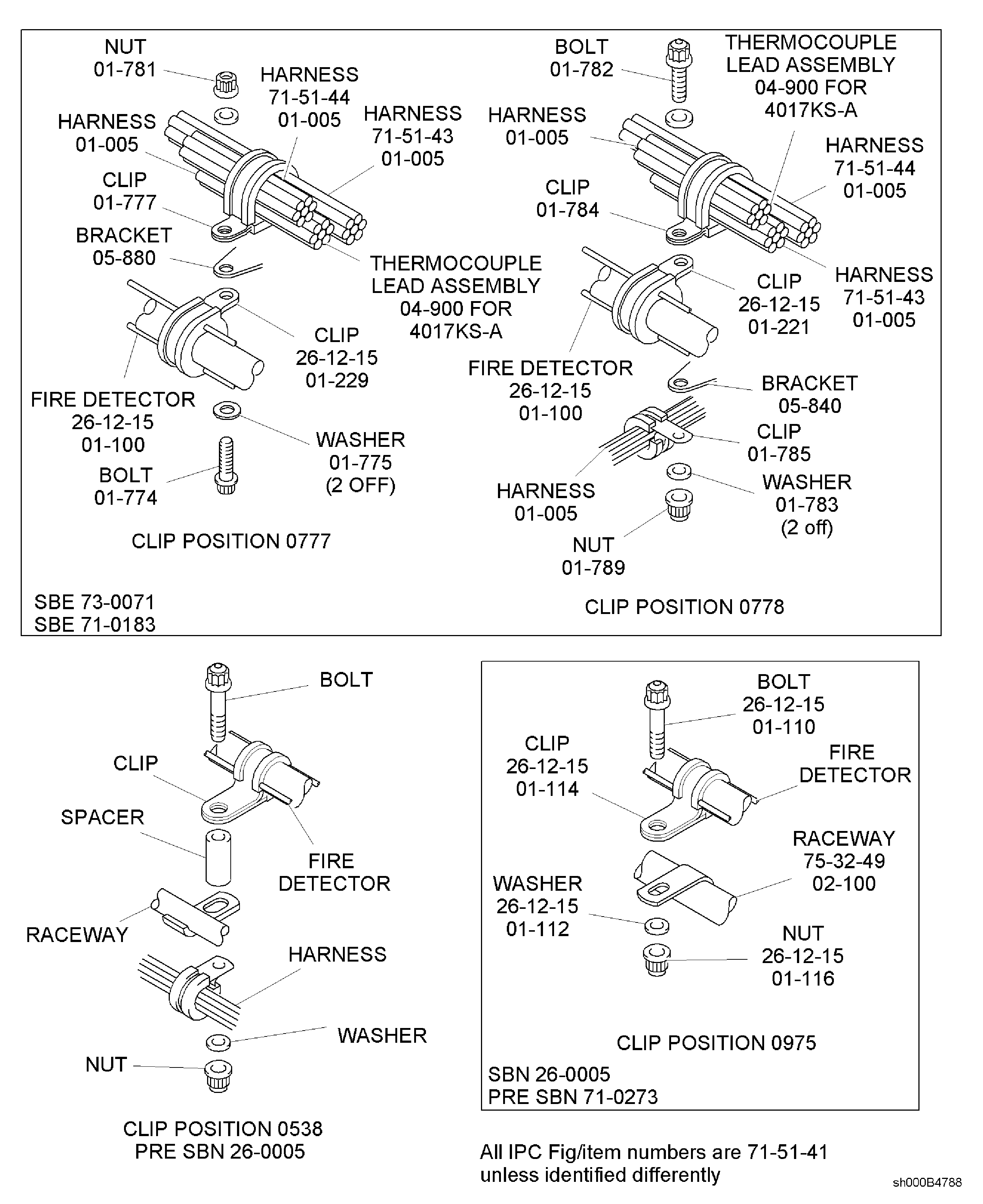

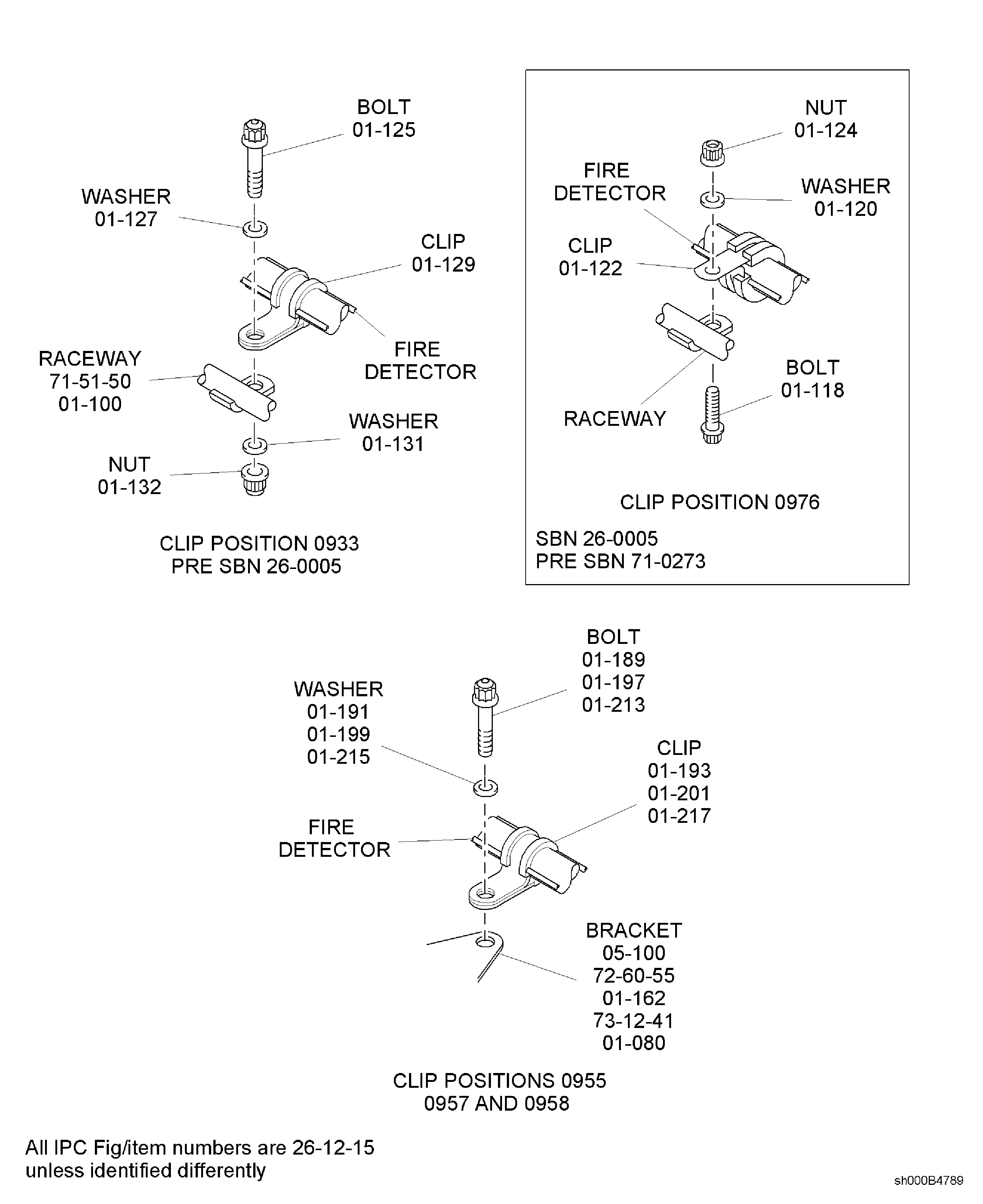

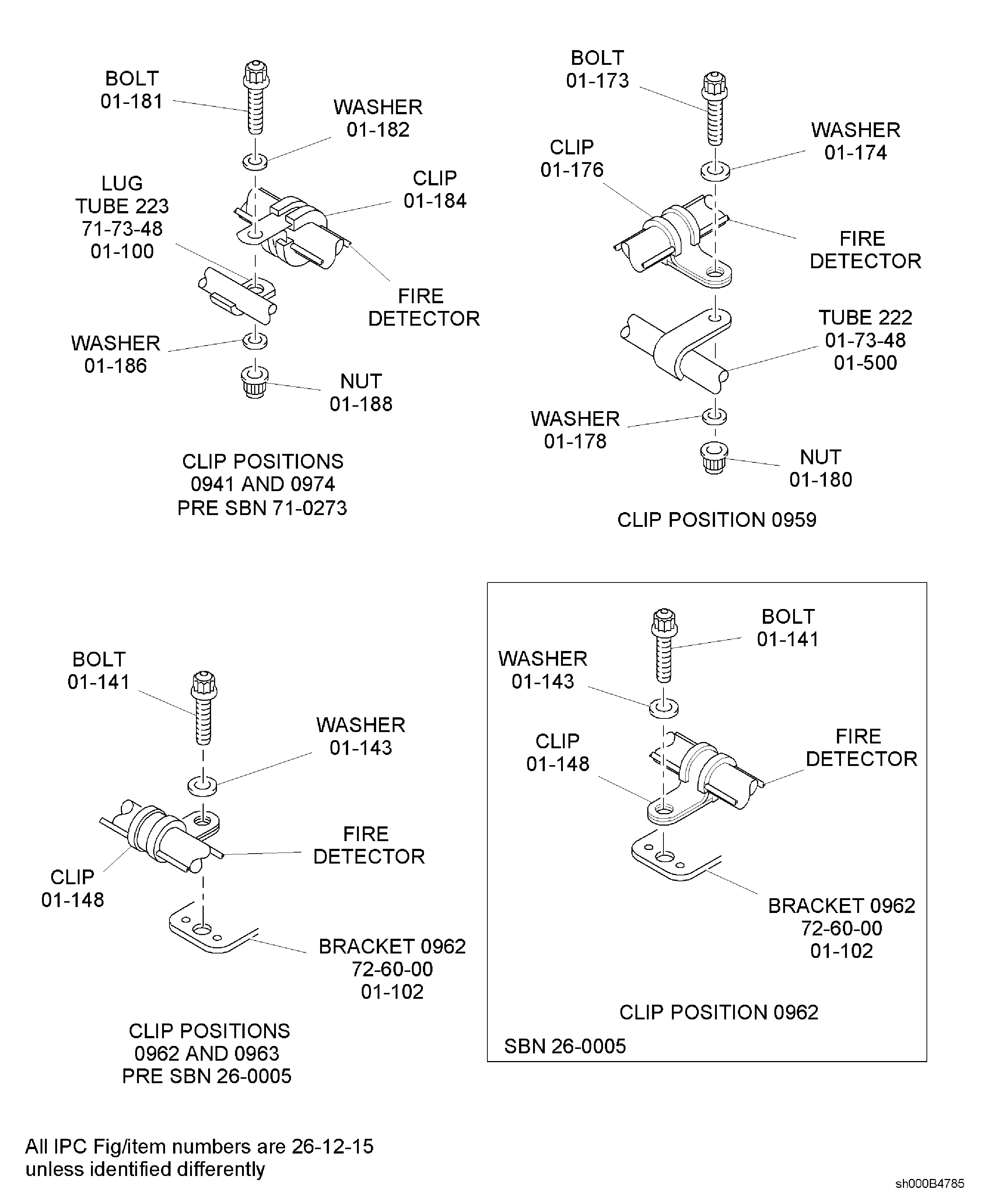

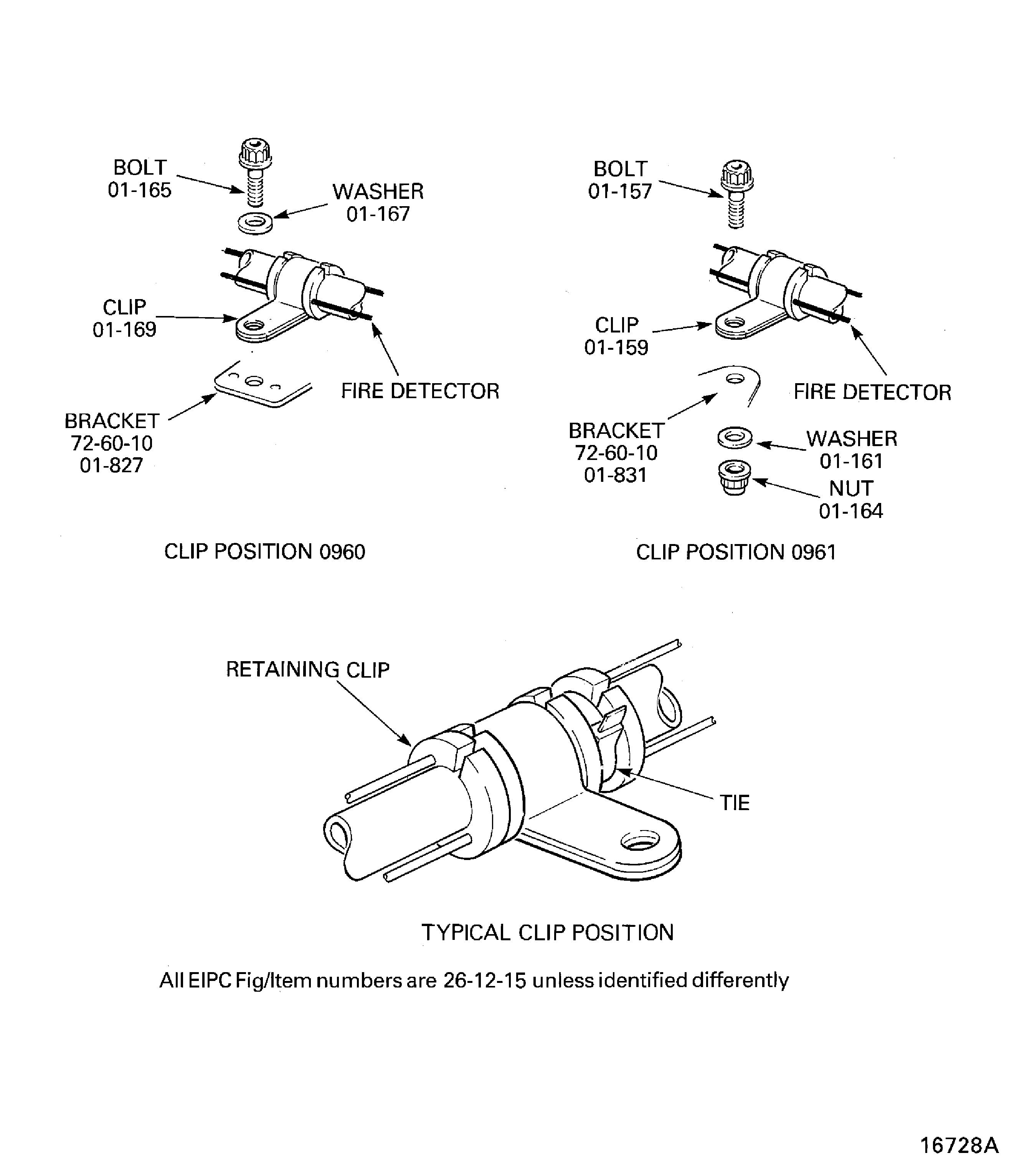

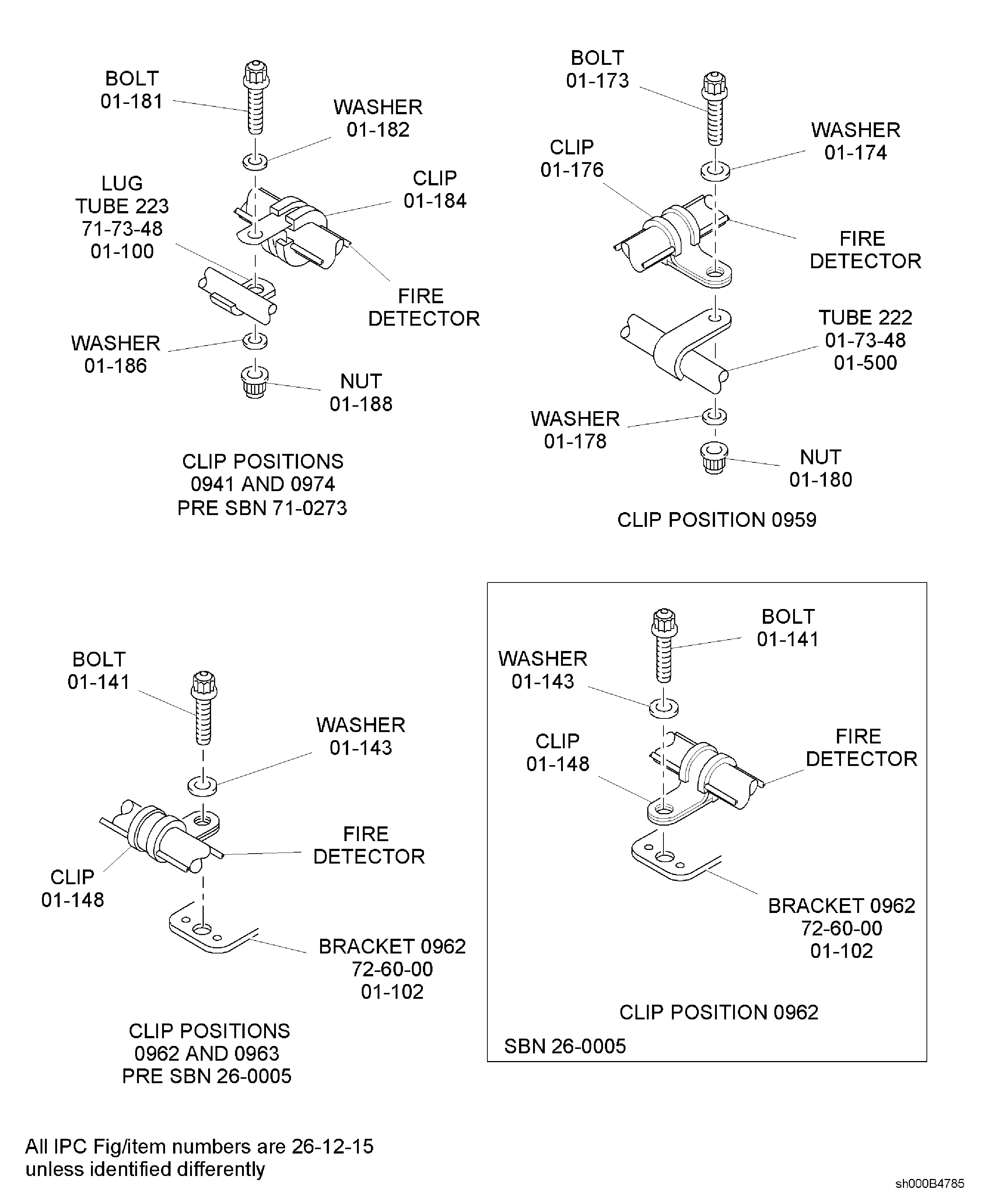

Pre SBN 71-0273: Remove the bolts, washers, clipnuts, nuts and clips from the clip positions that follow:

1183, 1184, 0955, 0956, 0957, 0958, 0941, 0959, 0960, 0961, 0962, 1437, 1423 and 1410.

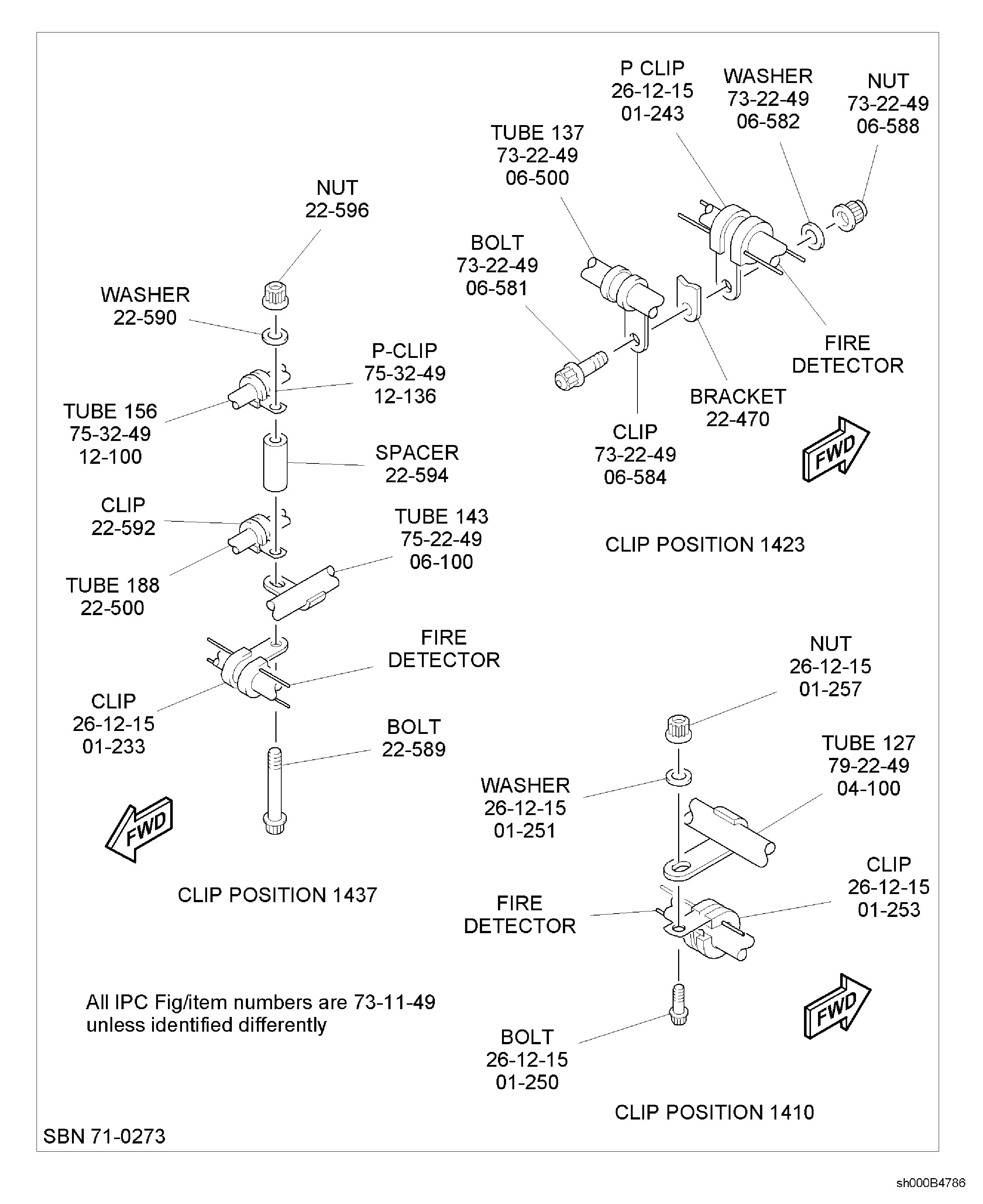

SBN 71-0273: Remove the bolts, washers, clipnuts, nuts and clips from the clip positions that follow:

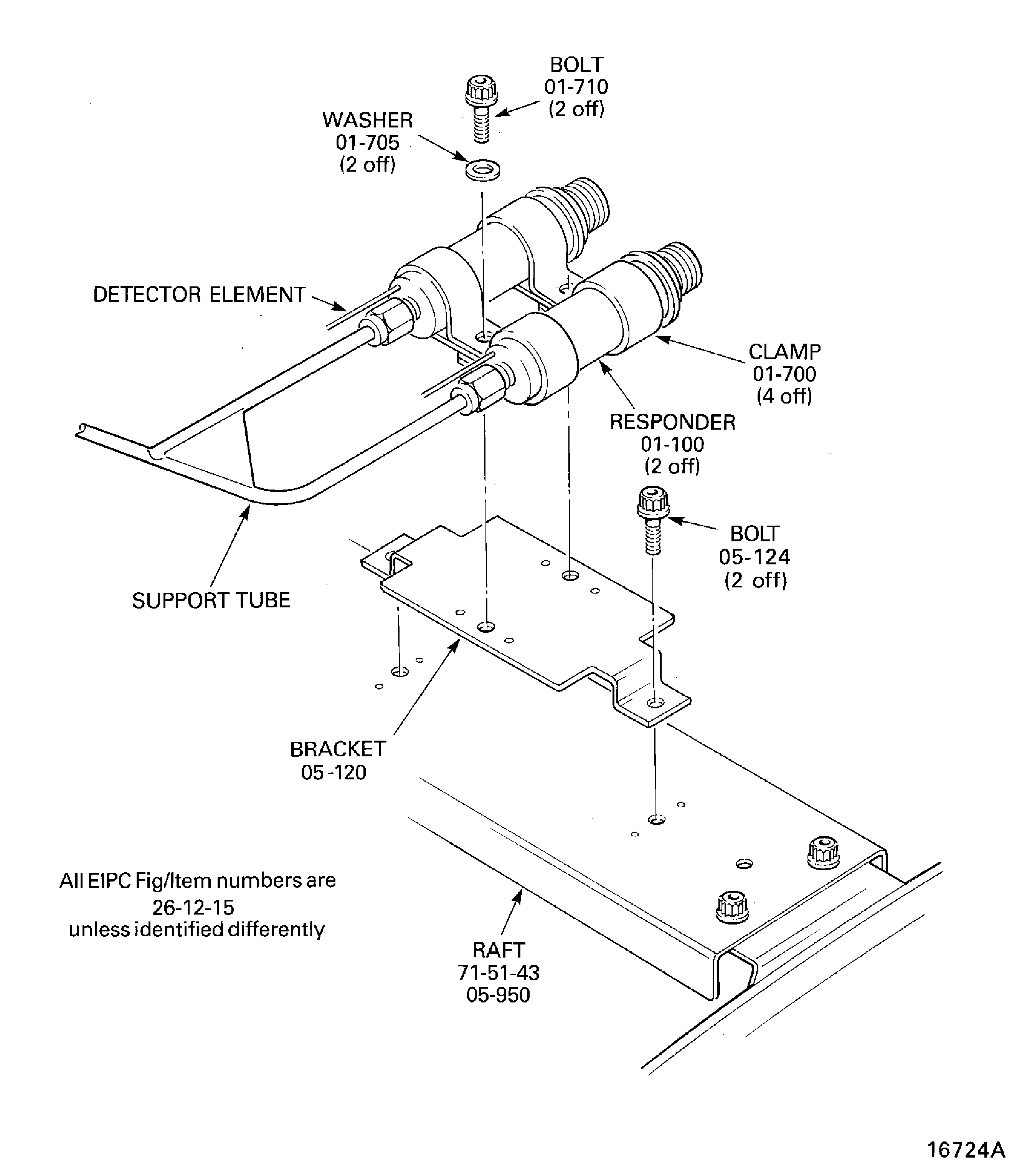

Remove the two bolts and washers that attach the two responders ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 01-100) to the bracket ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-120). Remove the bolts, washers, nut, clipnut and clips from clip positions 0933 and 0957 and remove the detector assembly.

NOTE

The accessory zone fire detector must have its maintenance completed, as given in the Systron Donner Component Maintenance Manual (26-12-15).Remove the two bolts that attach the bracket ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-120) to the raft General Services Harness (71-51-43, 05-950) and remove the bracket.

SUBTASK 72-00-60-020-172 Remove the Accessory Zone Fire Detector (Pre SBN 71-0273 and SBN 71-0273)

SBN 71-0273: Replacement and rerouting of several EBU systems to acommodate the rerouting of the oil scavenge tubes.

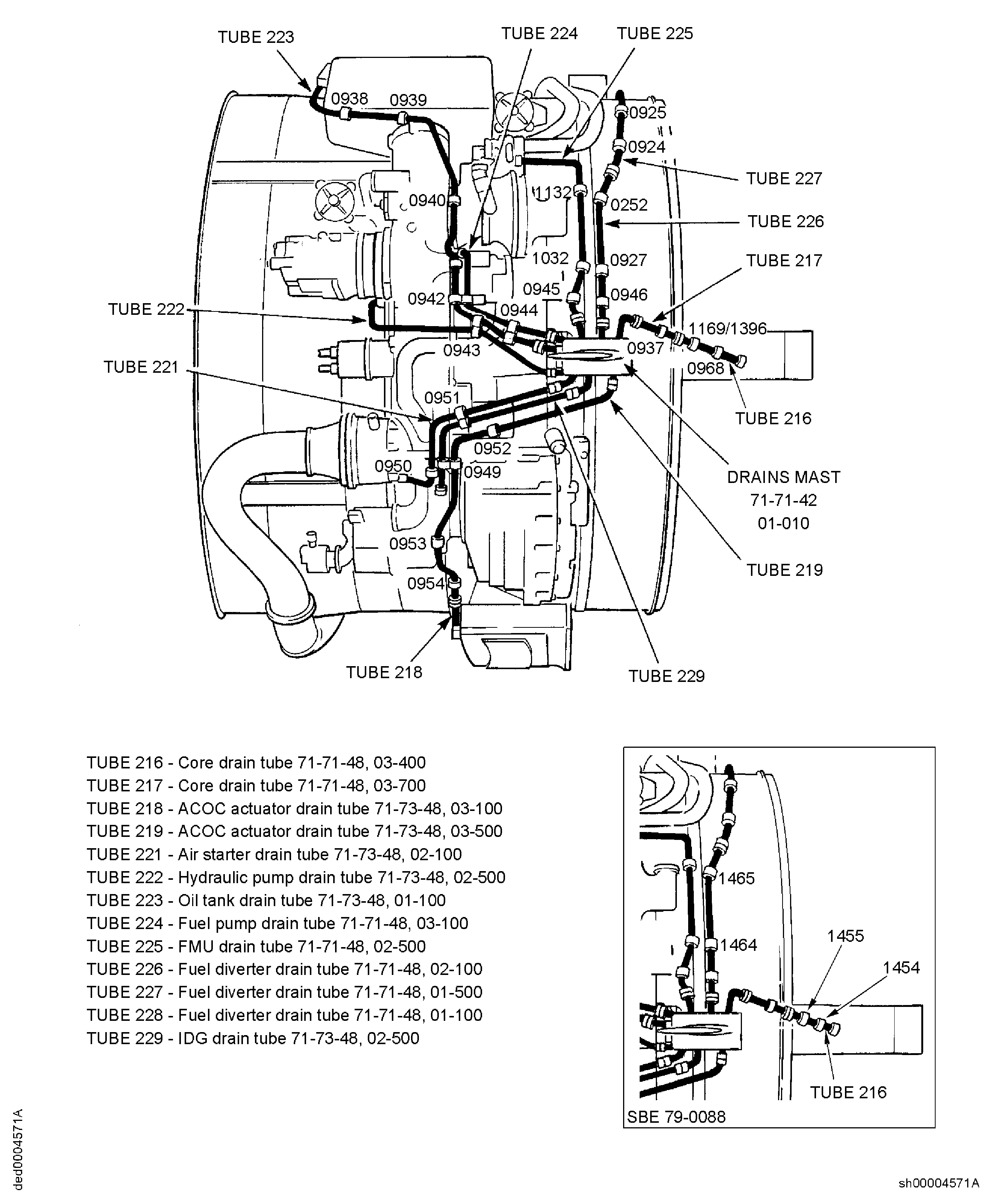

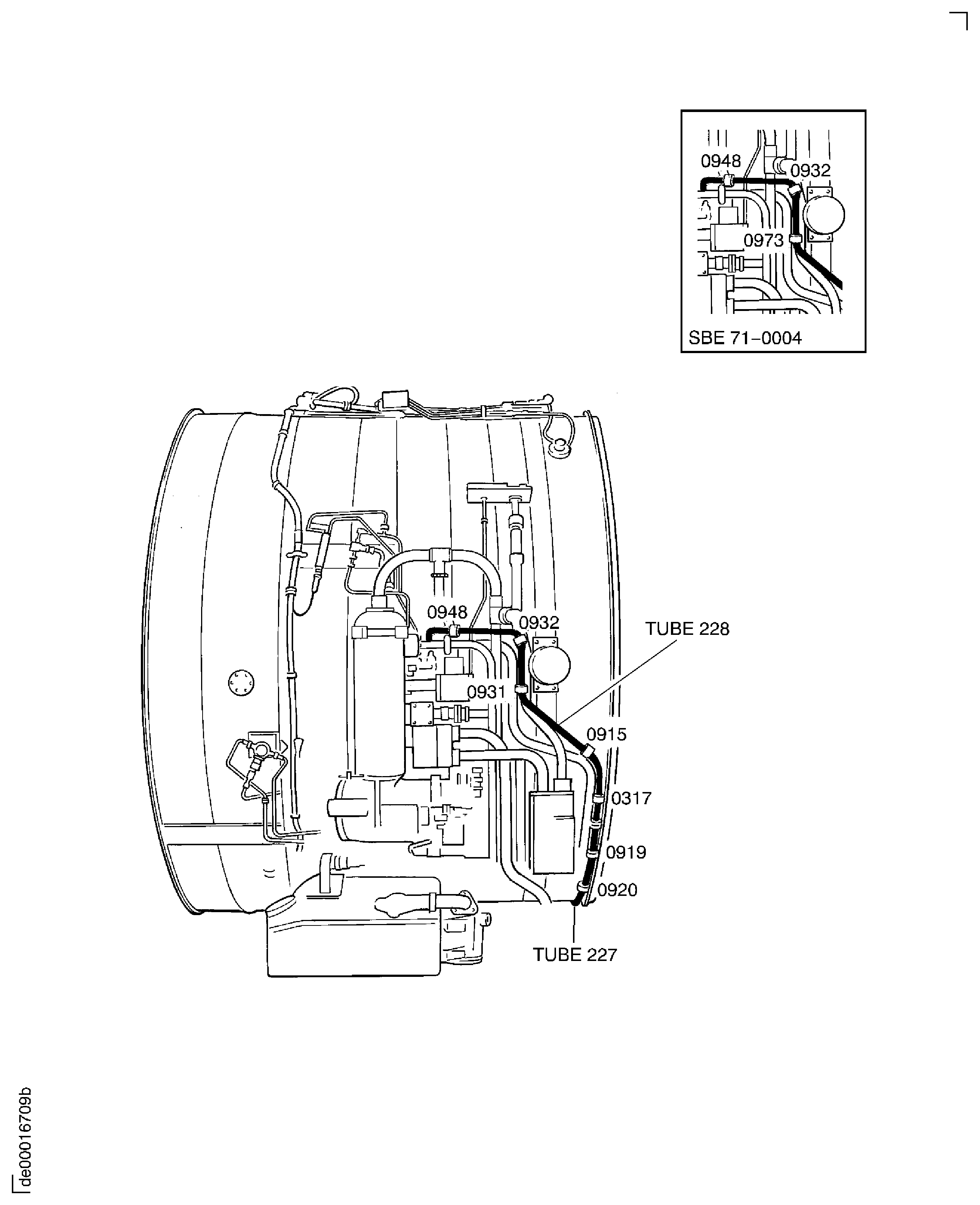

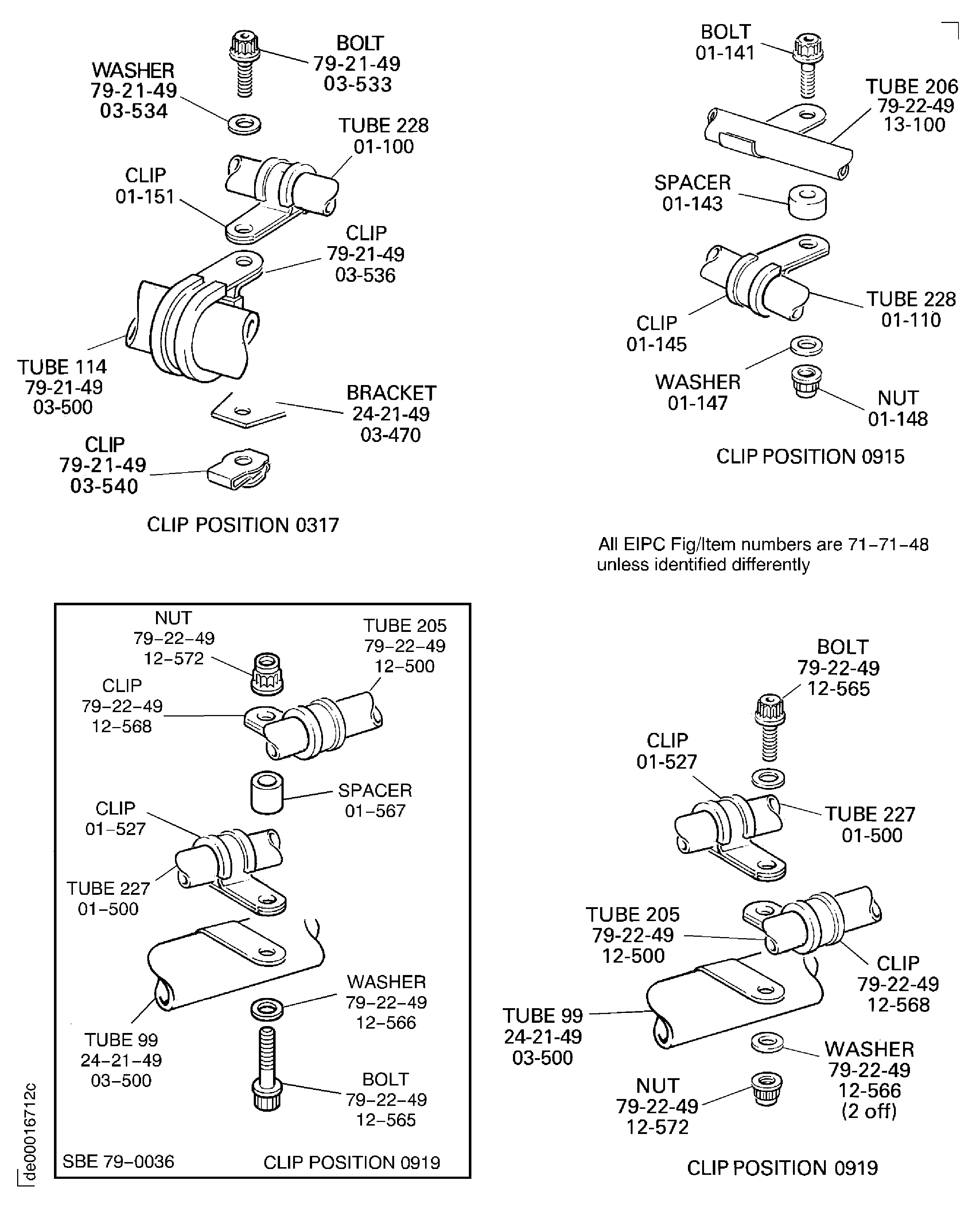

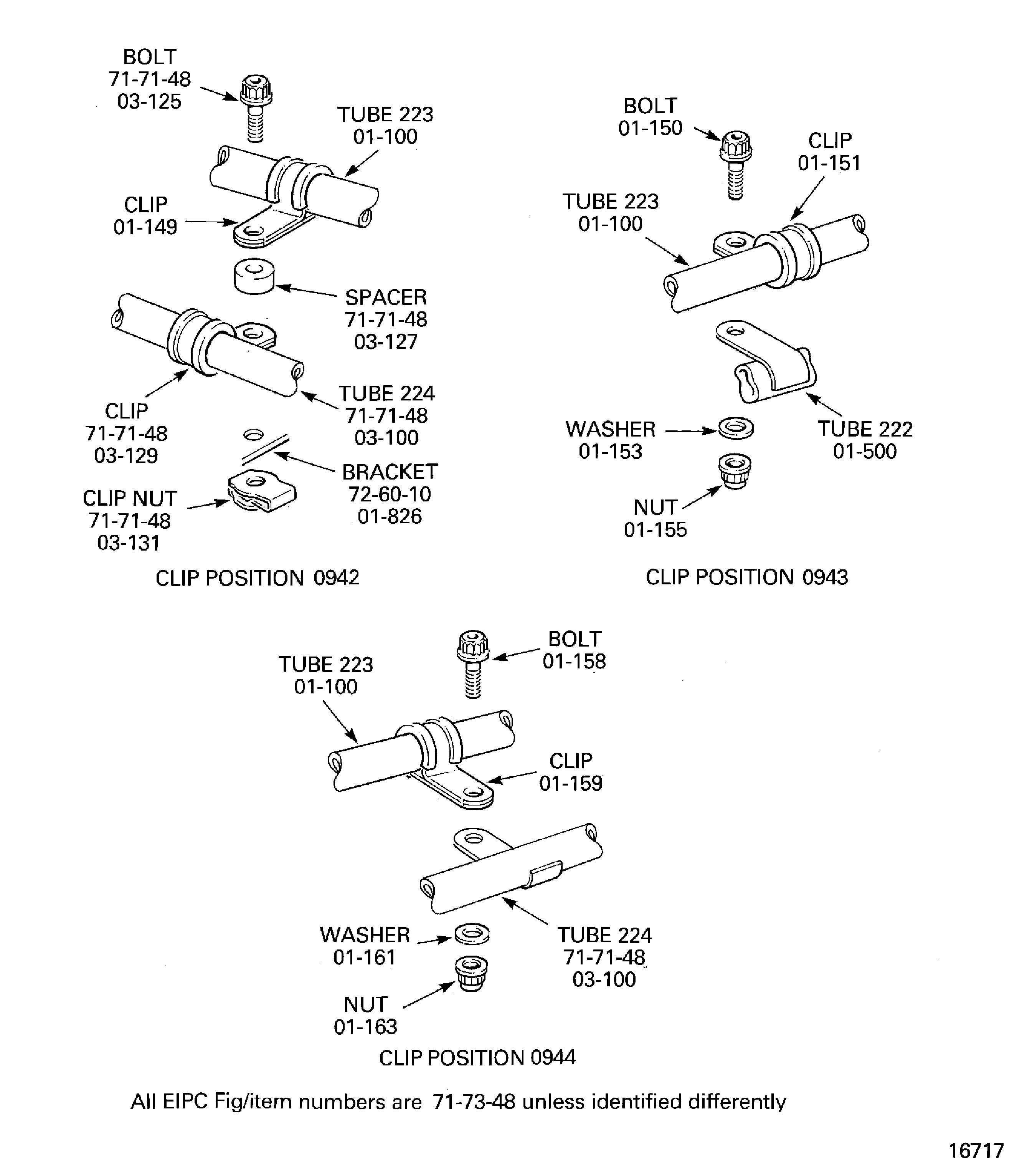

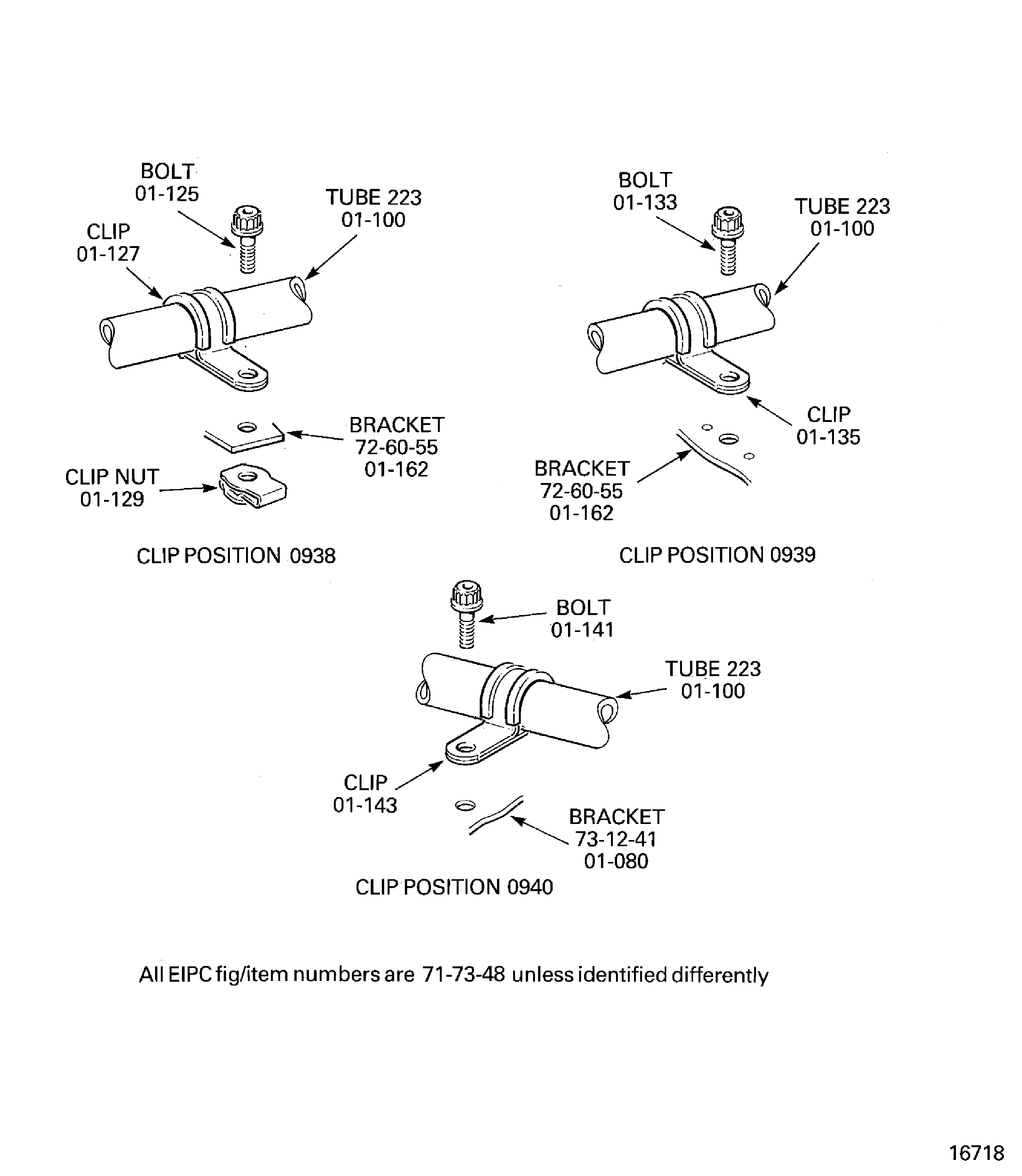

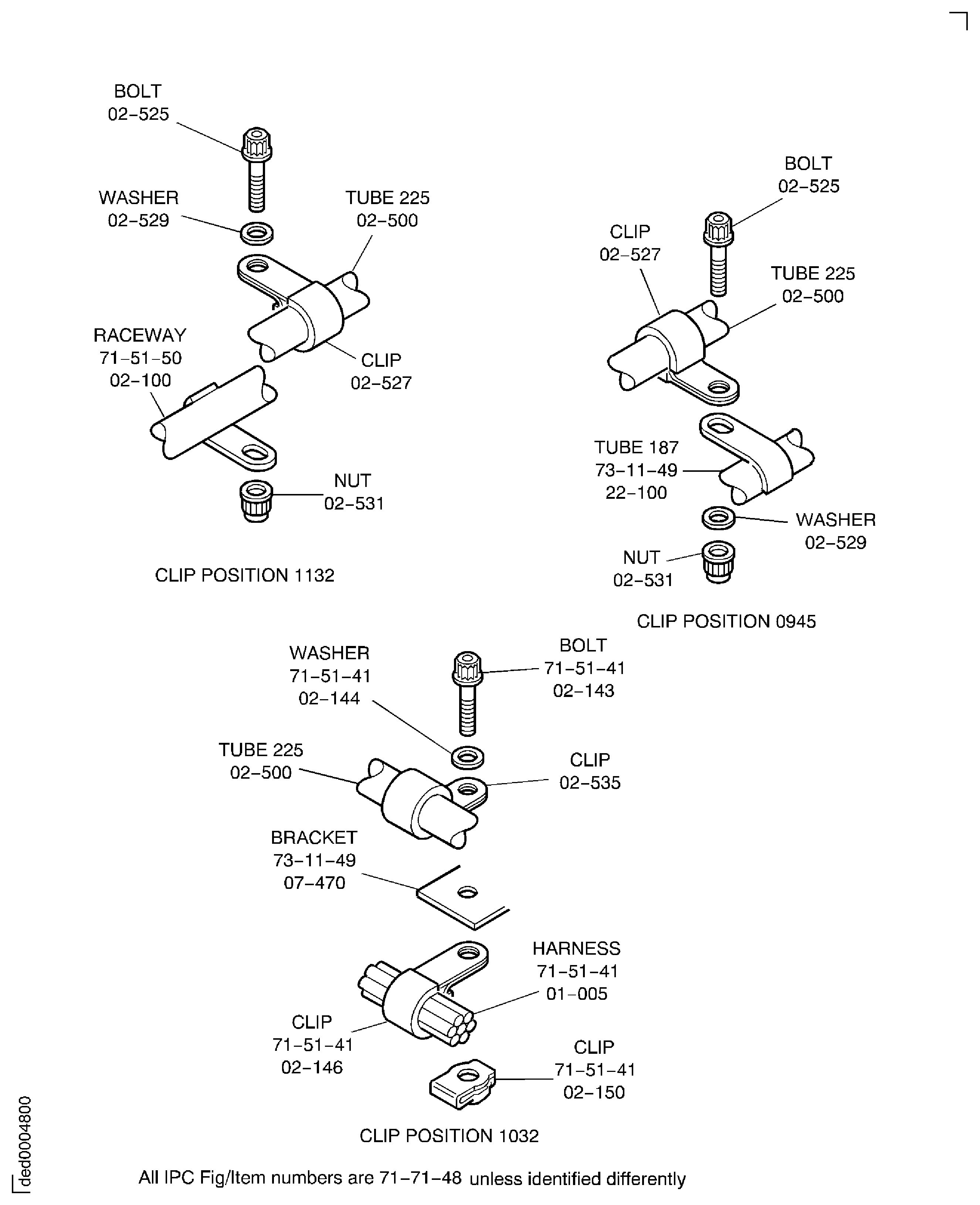

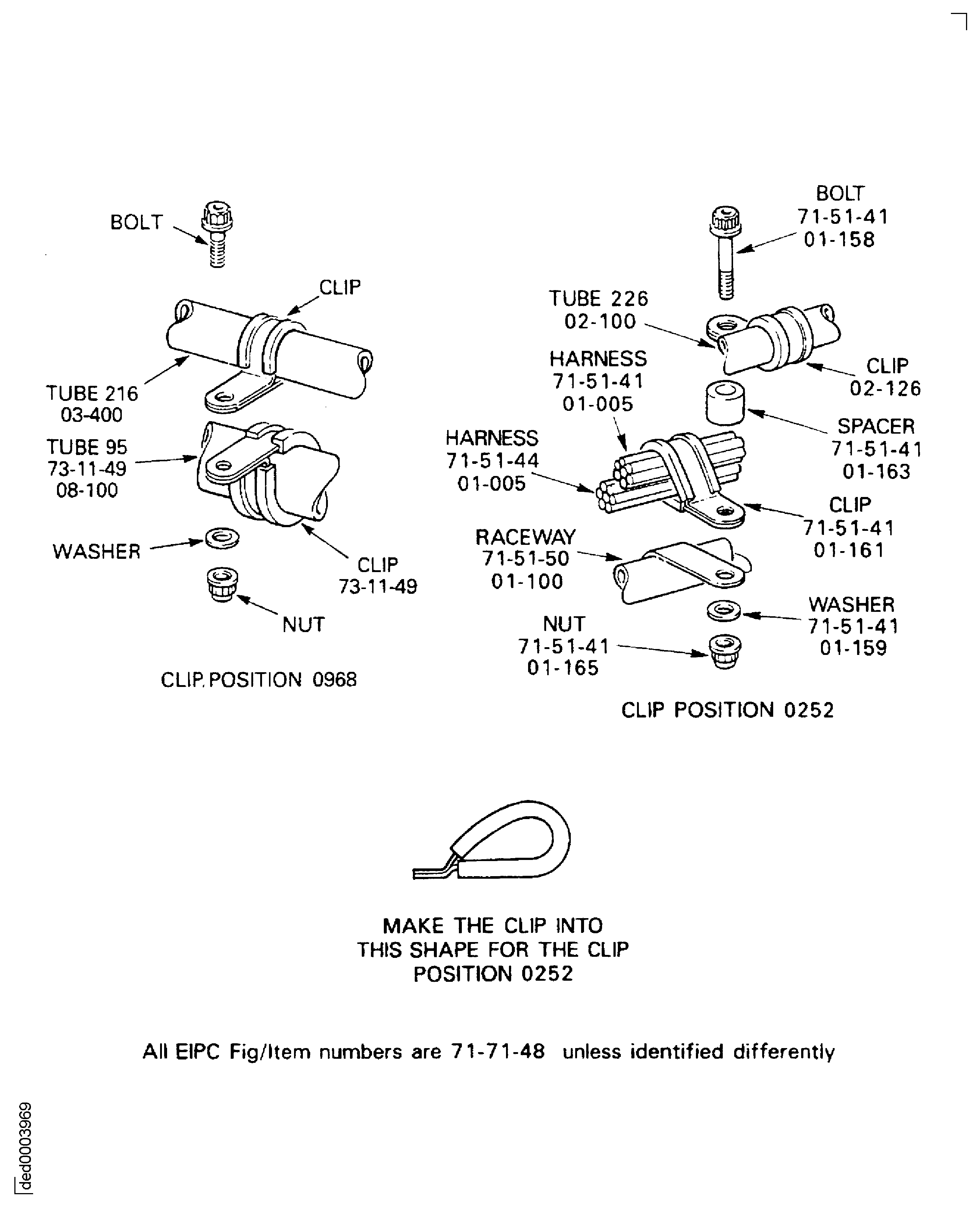

Pre SBE 71-004: 0948, 0932, 0931, 0915, 0317, 0919, 0920, 0925, 0924, 0252, 0927, 0946, 0937, 0952, 0949, 0953, 0954, 0951, 0950, 0968, 0943, 0942, 0940, 0939, 0945, 1032 and 1132.

SBE 71-004 and Pre SBE 79-0088: 0948, 0932, 0937, 0915, 0317, 0919, 0920, 0925, 0924, 0252, 0927, 0946, 0937, 0952, 0949, 0953, 0954, 0951, 0950, 0968, 0943, 0942, 0940, 0939, 0938, 0945, 1032 and 1132.

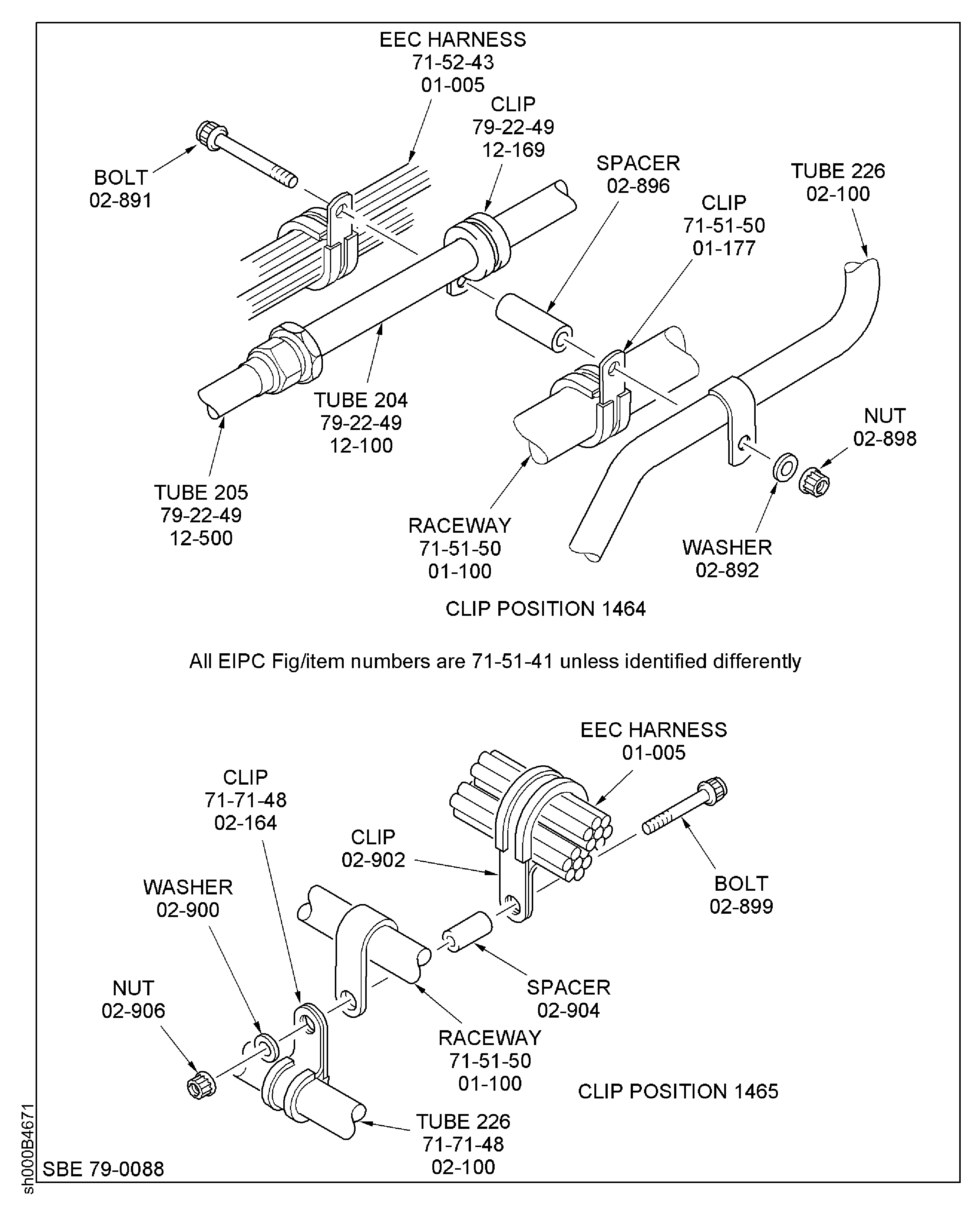

SBE 79-0088: 0948, 0932, 0973, 0915, 0317, 0919, 0920, 0925, 0924, 0252, 0927, 0946, 0937, 0952, 0949, 0953, 0954, 0951, 0950, 0968, 0943, 0942, 0940, 0939, 0945, 1032 and 1132.

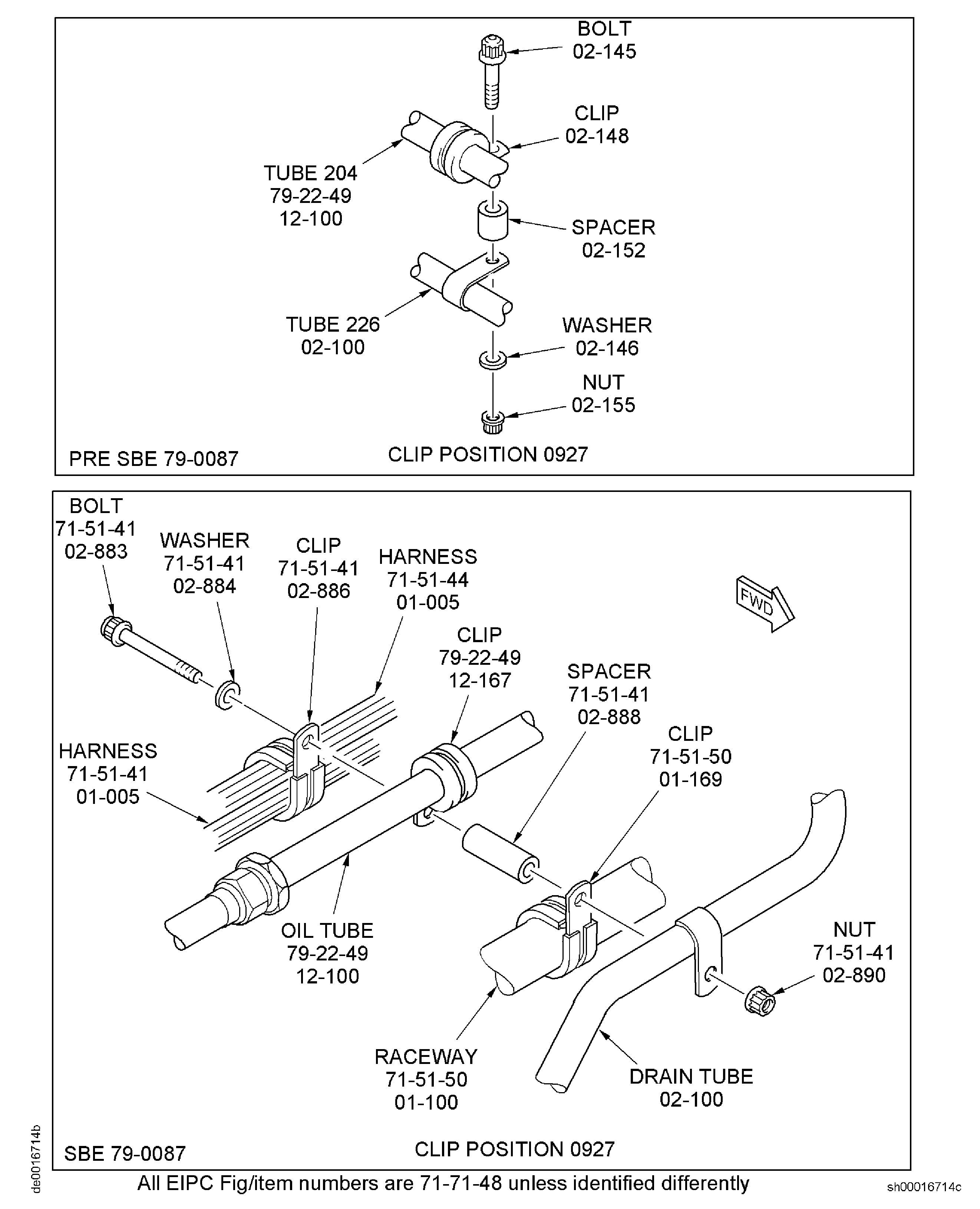

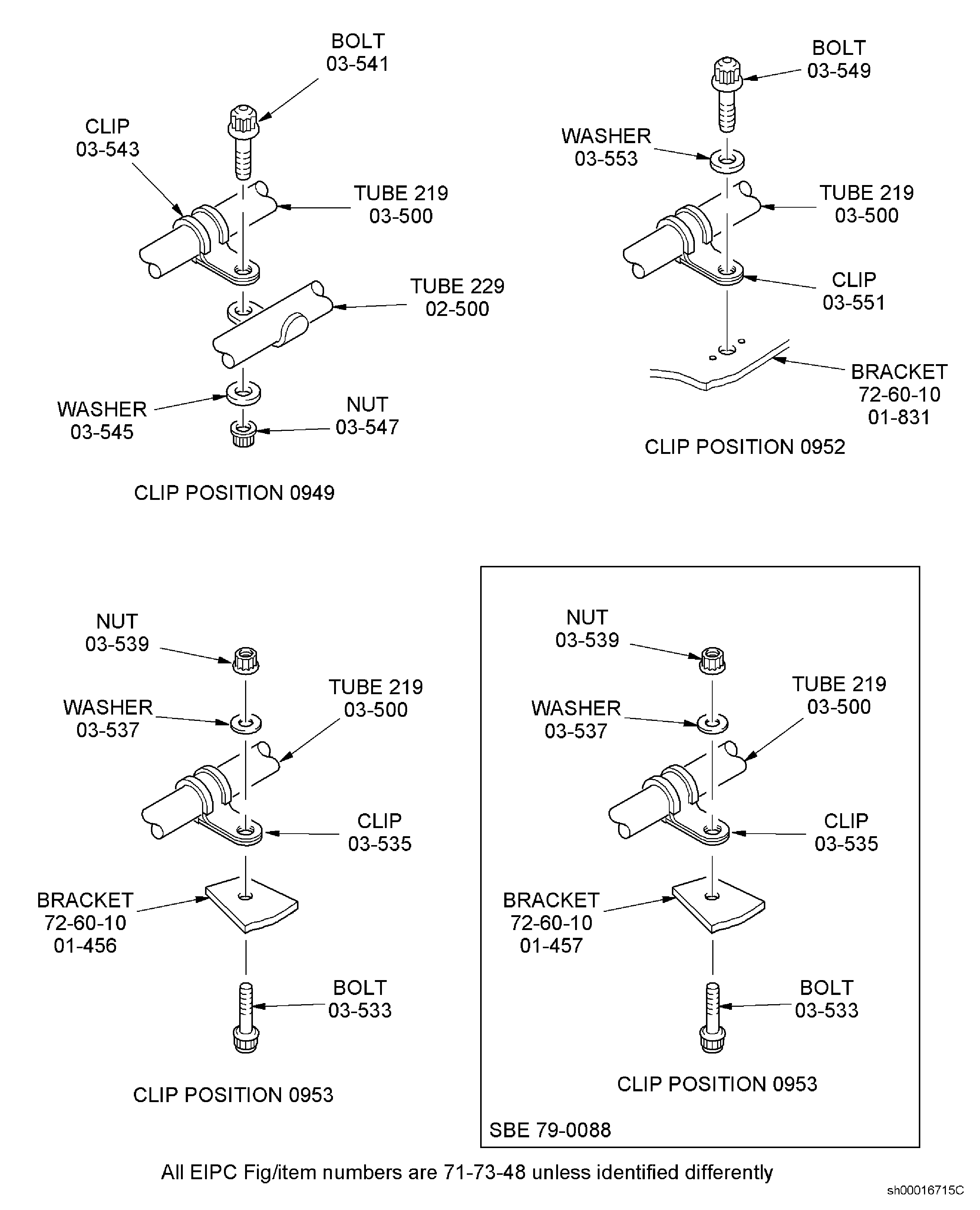

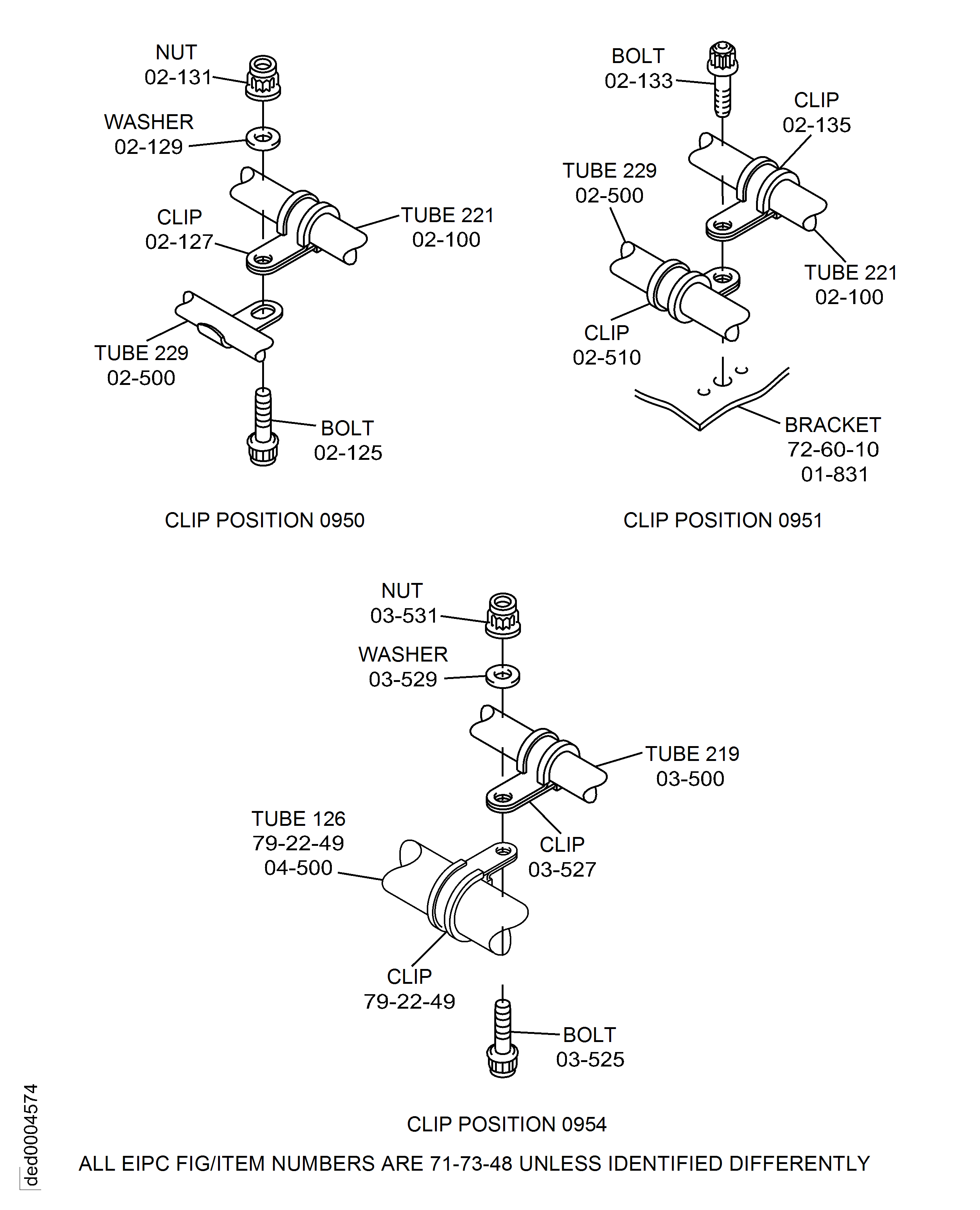

Remove the bolts, washers, spacers, clipnuts, nuts and clips from the clip positions that follow:

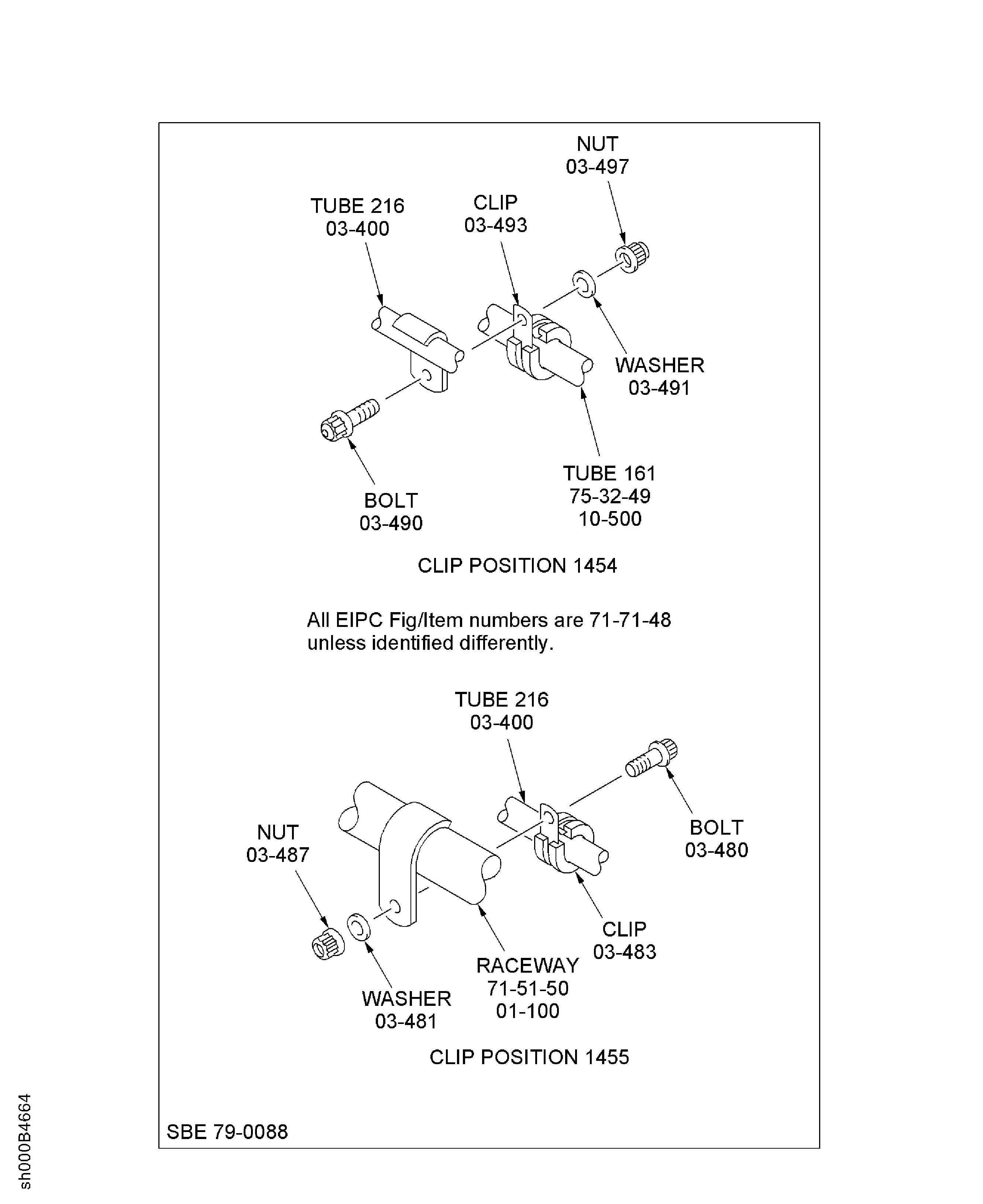

SUBTASK 72-00-60-020-173 Remove the LP Compressor/Intermediate Case Module Drains (Pre SBE 79-0088 and SBE 79-0088)

SBE 79-0088: Re-route of number 4 bearing scavenge tube.

Figure: Remove the Accessory Zone Fire Detector

Sheet 1

Figure: Remove the Accessory Zone Fire Detector

Sheet 2

Figure: Remove the Accessory Zone Fire Detector

Sheet 3

Figure: SBE 73-0071: Remove the Accessory Zone Fire Detector

Sheet 4

Figure: Remove the Accessory Zone Fire Detector

Sheet 5

Figure: Remove the Accessory Zone Fire Detector

Sheet 6

Figure: Remove the Accessory Zone Fire Detector

Sheet 7

Figure: Remove the Accessory Zone Fire Detector

Sheet 8

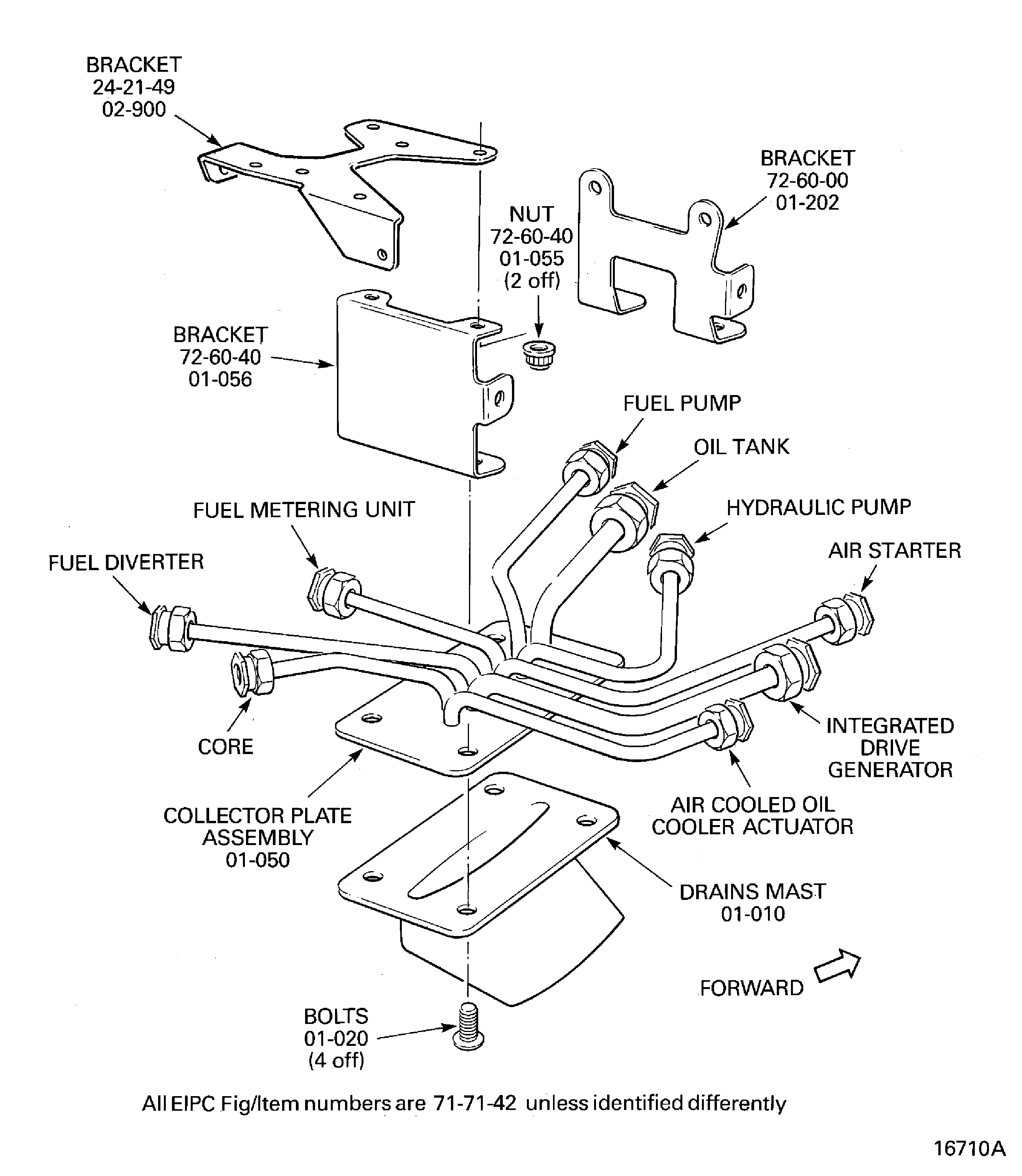

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 1

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 2

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 3

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 4

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 5

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 6

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 7

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 8

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 9

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 10

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 11

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 12

Figure: Remove the LP Compressor/Intermediate Case Module Drains

Sheet 13

Figure: Remove the LP Compressor/Iintermediate Case Module Drains

Sheet 14

Figure: Remove the LP Compressor/Iintermediate Case Module Drains

Sheet 15