Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-062 LPC Rear Case - Replace The Sleeve and Sleeve Hole Bushing Repair, Repair-062 (VRS1615)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

For the method to clean the parts, refer to TASK 72-32-83-100-000.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Boring machine | LOCAL | Boring machine | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SLEEVE | 81349 | M81934-1-05C014 | 40 |

Safety Requirements

NONEProcedure

Extract the loosened sleeve.

SUBTASK 72-32-83-350-152 Remove the Loosened Sleeve

Refer to TASK 72-32-83-100-000.

Clean the LPC rear case assembly.

SUBTASK 72-32-83-110-001 Clean the LPC Rear Case Assembly

Use a boring machine.

Install the LPC rear case assembly on to the machine. Secure in position for safe machining.

Use standard workshop equipment.

Diameter of the bush hole is 0.5652 to 0.5659 in. (14.355 to 14.373 mm).

Machine the bush holes.

Use standard workshop equipment.

Remove the sharp edges.

SUBTASK 72-32-83-350-155 Machine the Bush Hole

Refer to the SPM TASK 70-23-05-230-501. No cracks are permitted.

Examine the machined area for cracks.

Make sure the bush hole diameter is between 0.5652 to 0.5659 in. (14.355 to 14.373 mm).

Dimensionally inspect the machined hole.

SUBTASK 72-32-83-220-001 Examine the Machined Area

Refer to SPM TASK 70-38-02-300-503.

Do a chemical touch-up to the repaired area with a brush.

SUBTASK 72-32-83-380-001 Surface Treat the Machined Area

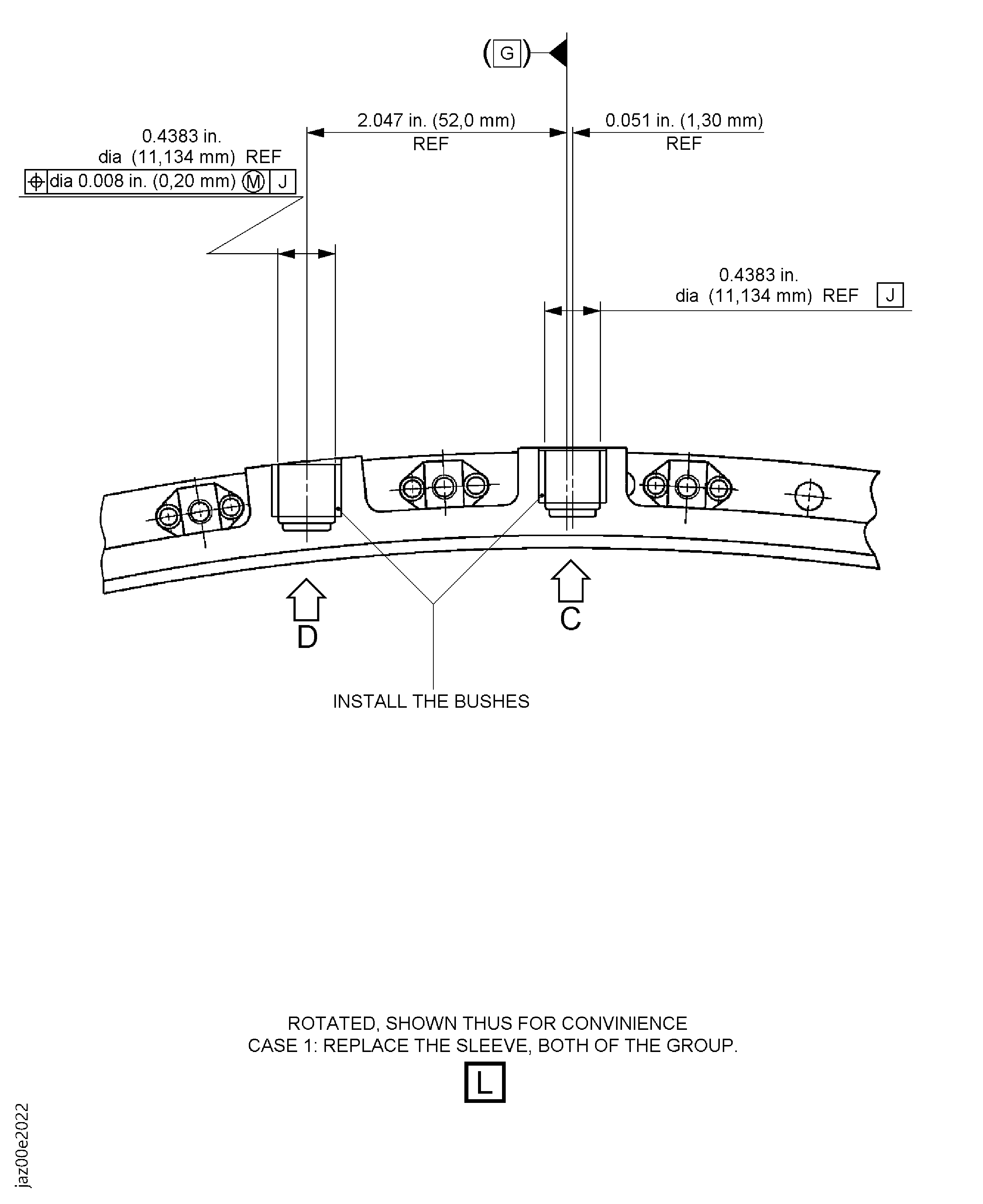

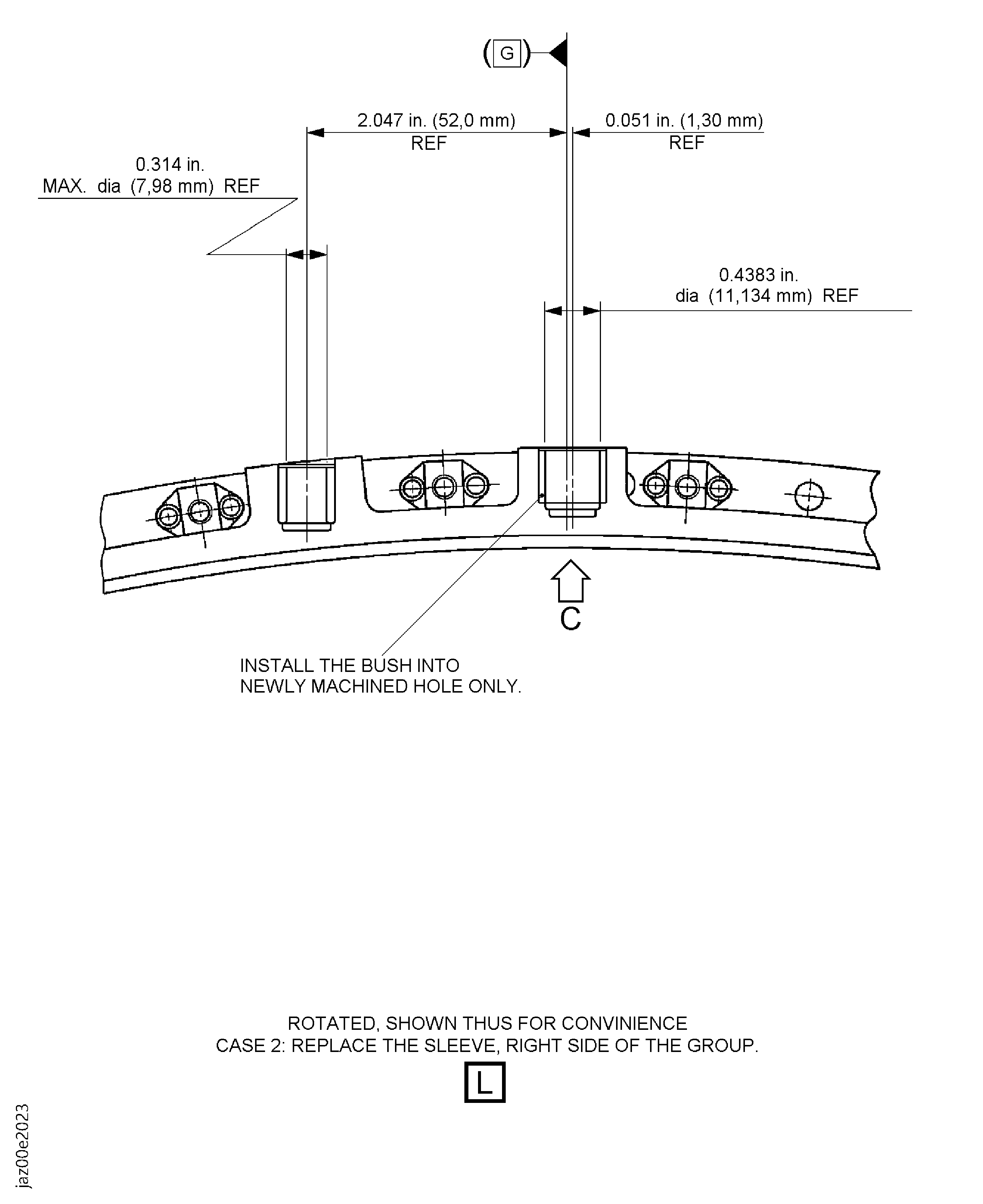

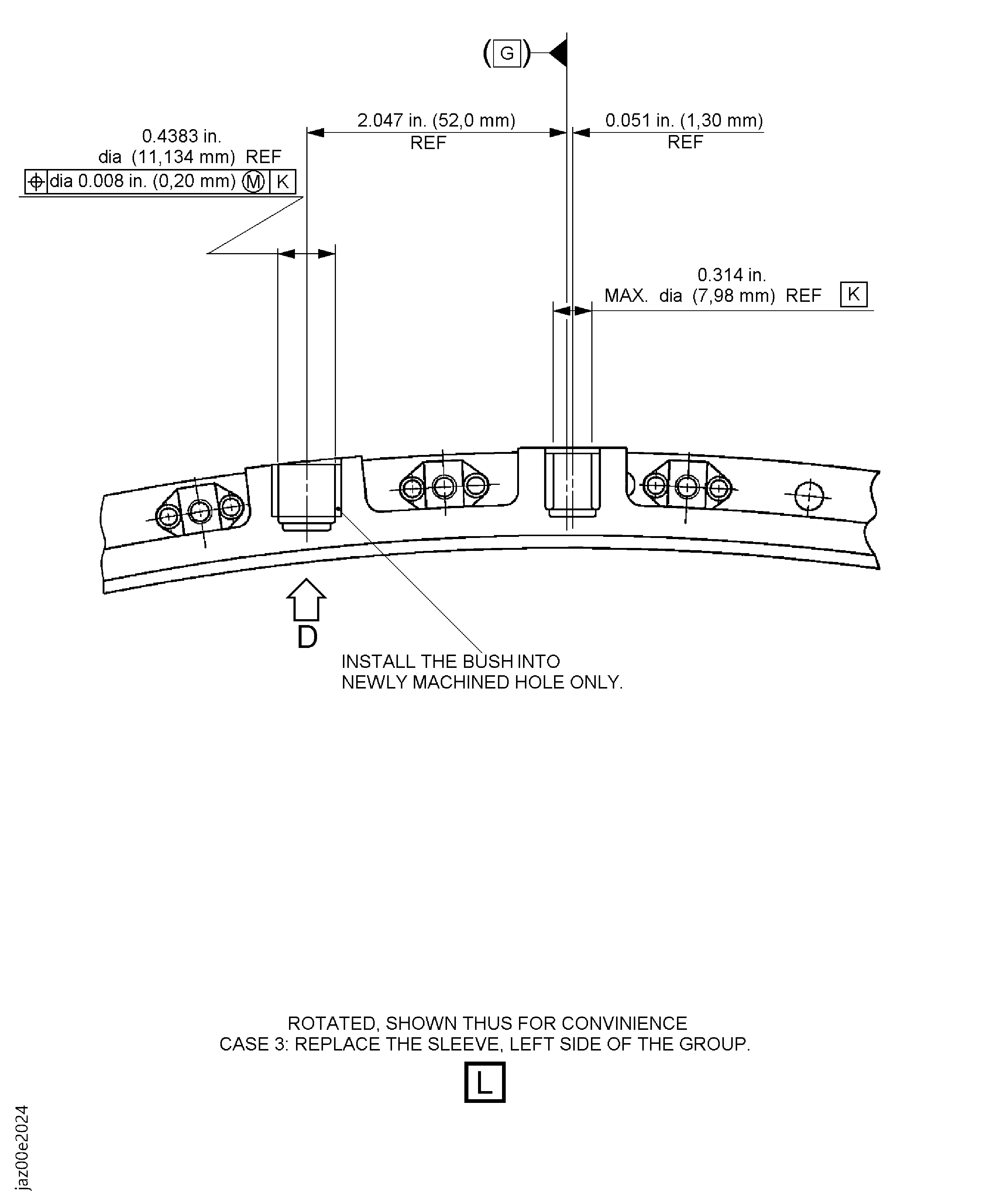

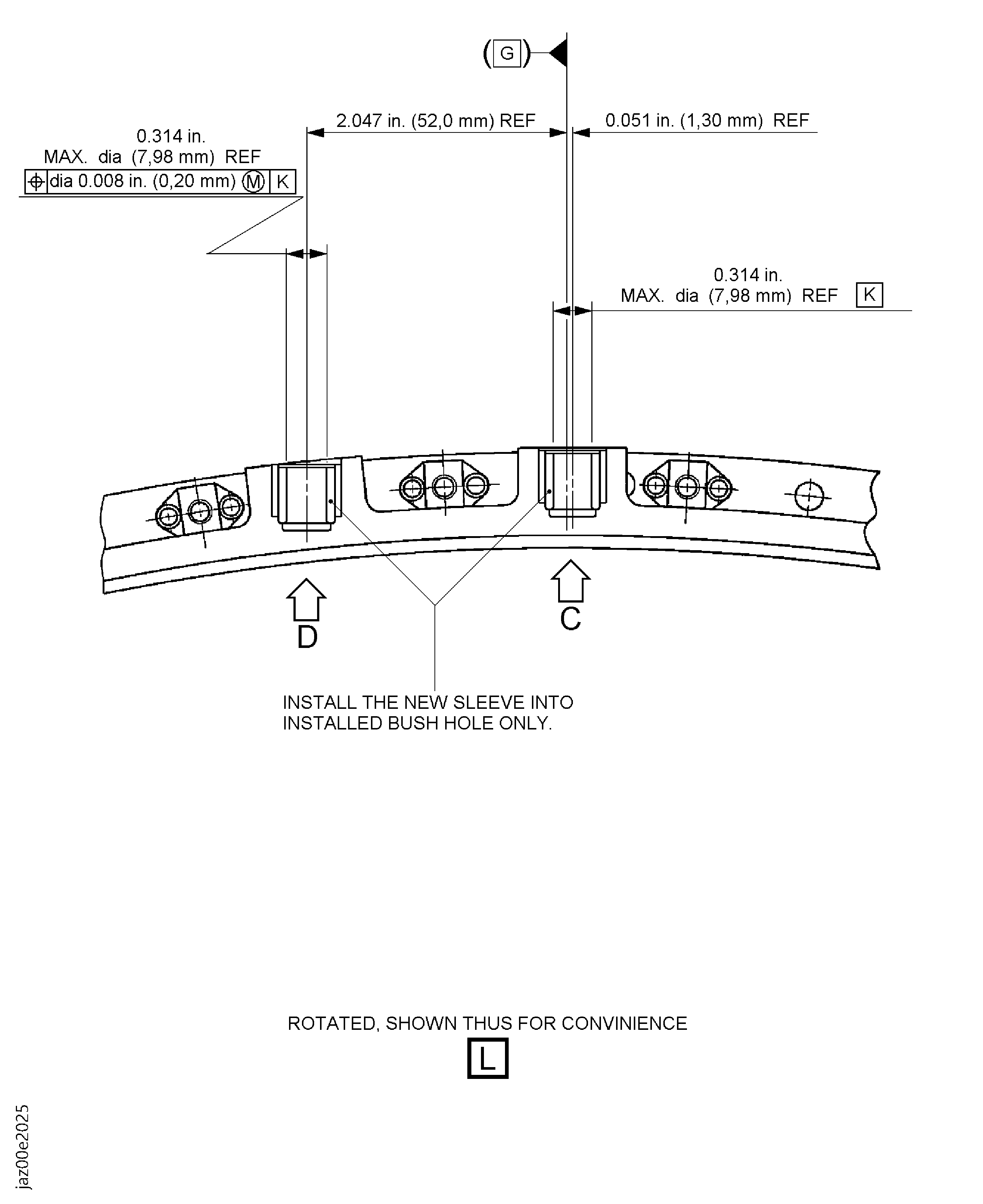

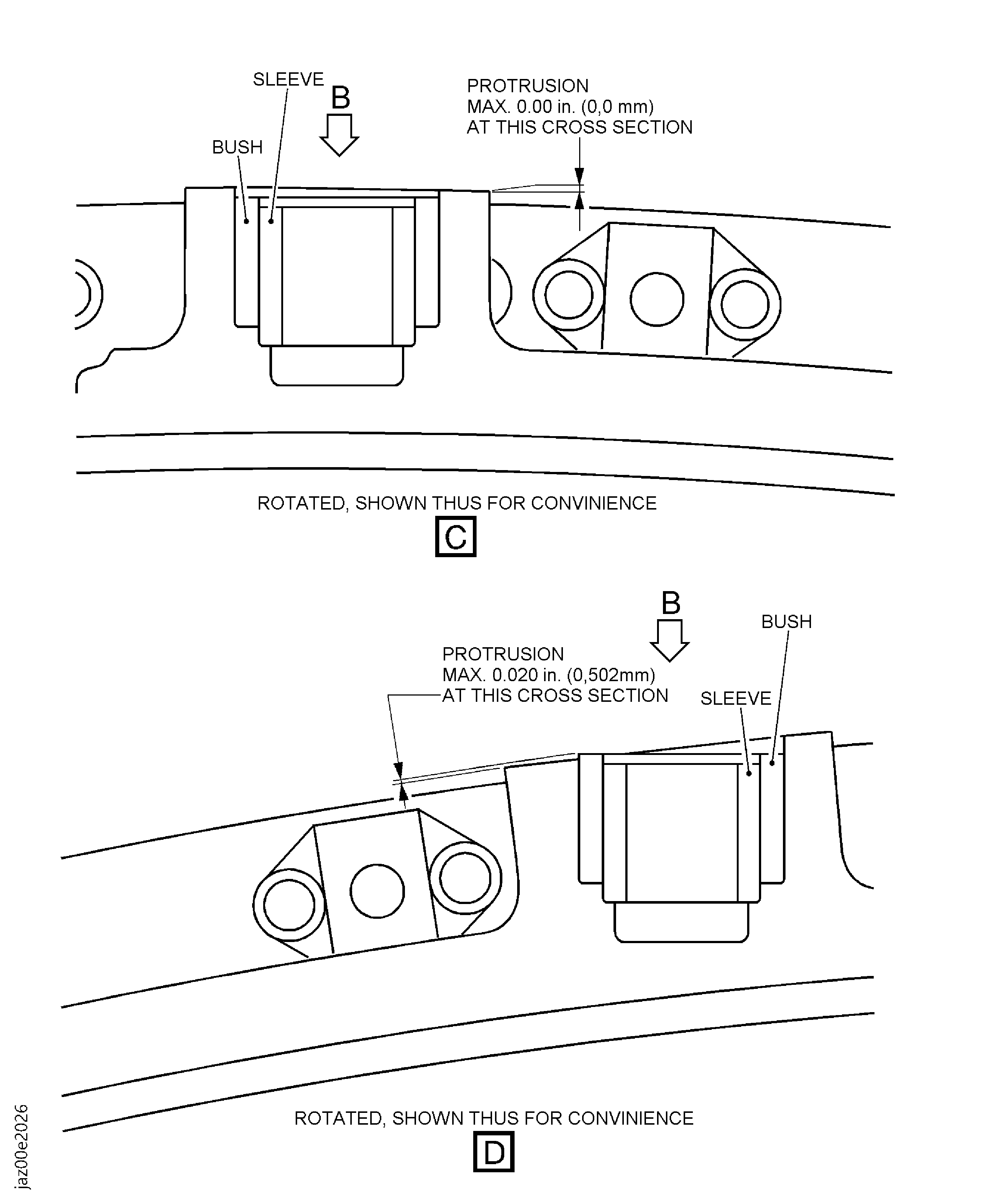

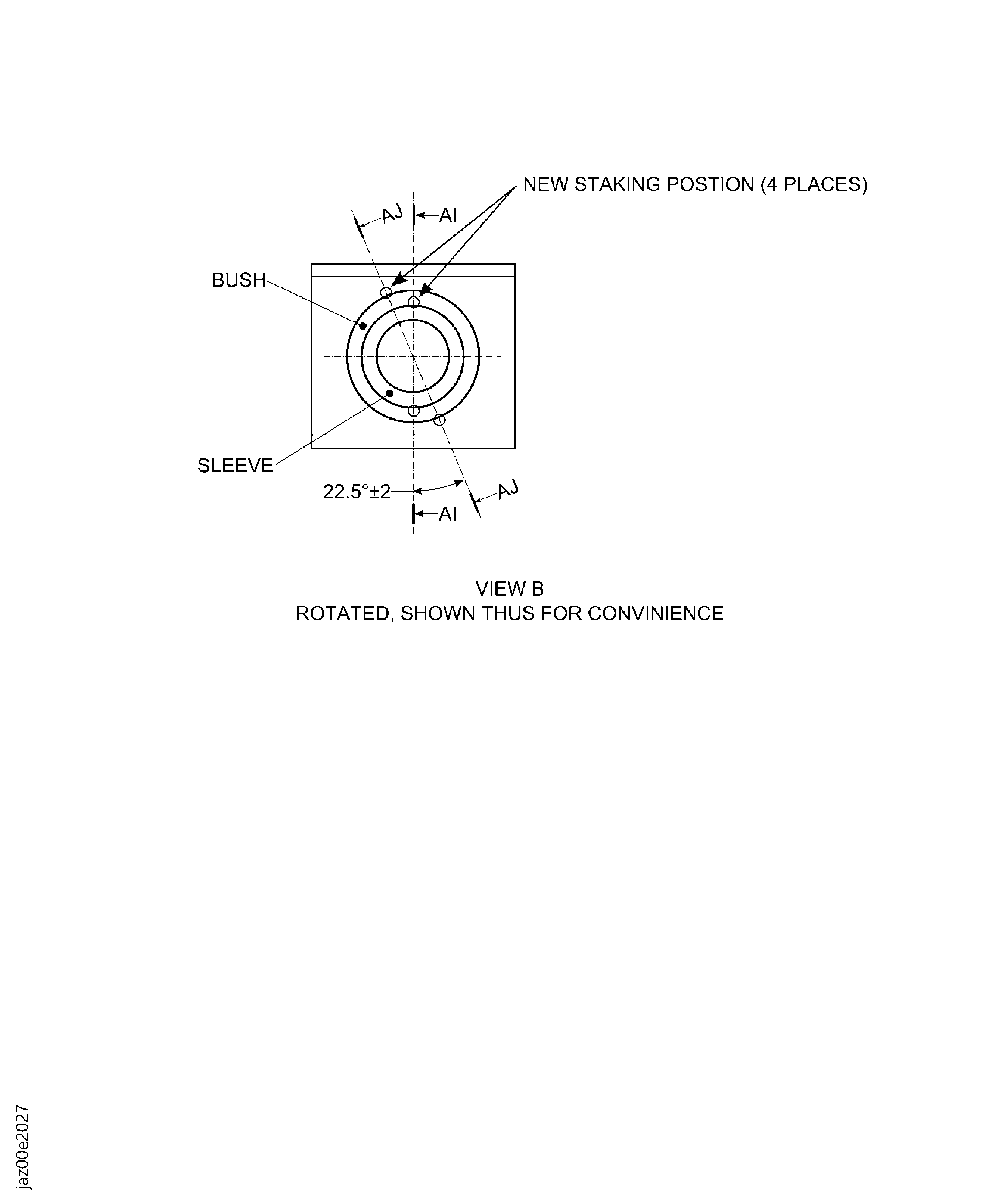

Refer to Figure.

Prepare the bush.

Refer to TASK 70-38-02-300-503.

Do a chemical touch-up to the bush with a brush.

SUBTASK 72-32-83-350-156 Prepare the Bush

Chill the bush in dry ice for minimum 15 minutes.

Chill the bush.

Heat the LPC Rear Case to a temperature of maximum 212 deg F (100 deg C).

Install the bush into the machined hole.

Refer to SPM TASK 70-42-06-400-501.

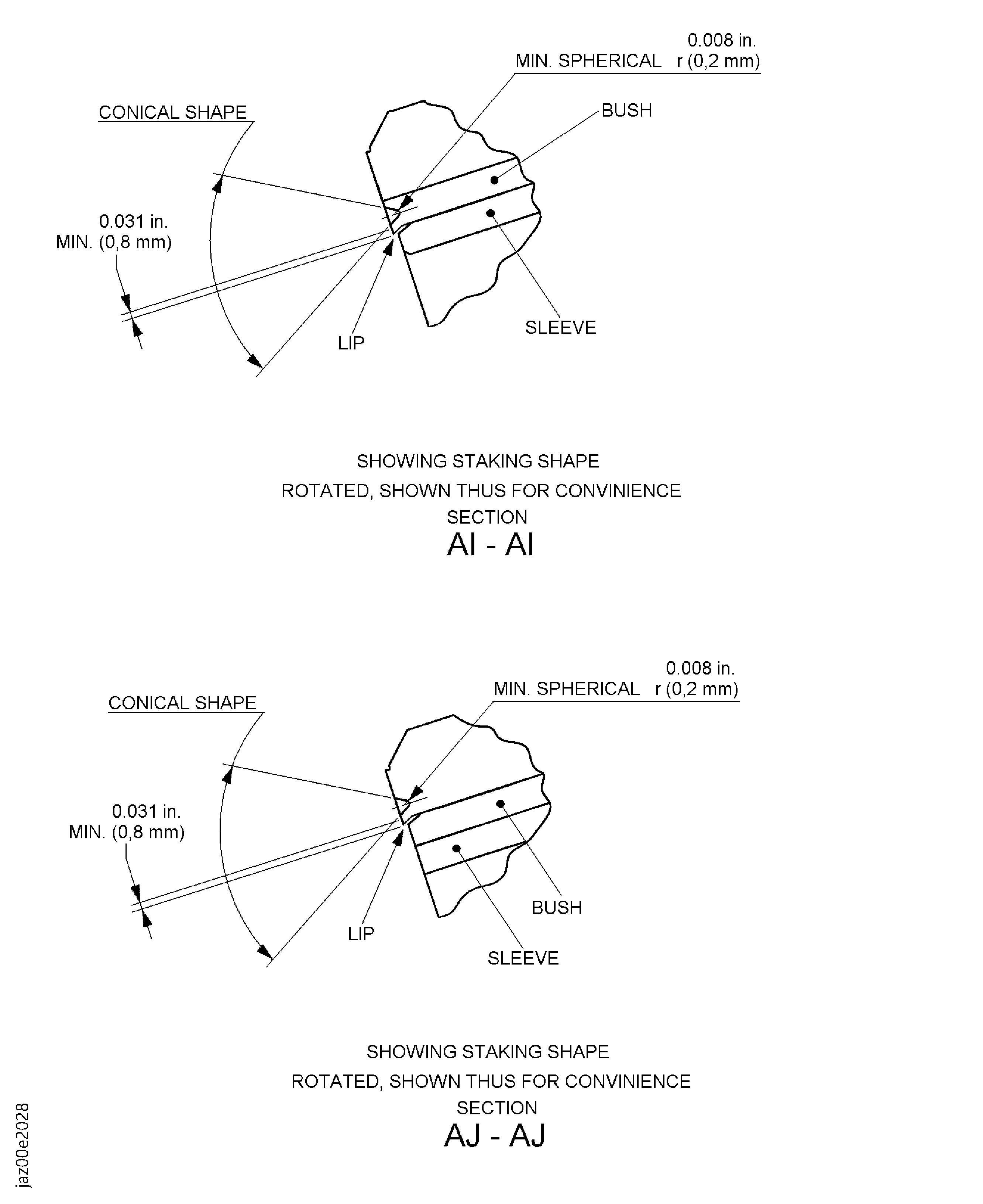

Adjust the position of the new staking.

Do a staking.

SUBTASK 72-32-83-350-157 Install the Bush

Chill the sleeve in dry ice for minimum 15 minutes.

Chill the new sleeve.

Install the sleeve into the bush hole.

Refer to SPM TASK 70-42-06-400-501.

Adjust the position of the new staking.

Do a staking.

SUBTASK 72-32-83-350-158 Install the New Sleeve

Refer to SPM TASK 70-09-00-400-501.

Mark VRS1615 next to the part number.

SUBTASK 72-32-83-350-159 Identify the Repair

Refer to SPM TASK 70-38-02-300-503.

Do a chemical touch-up to the marking area with a brush.

SUBTASK 72-32-83-350-160 Surface Treat the Marking Area

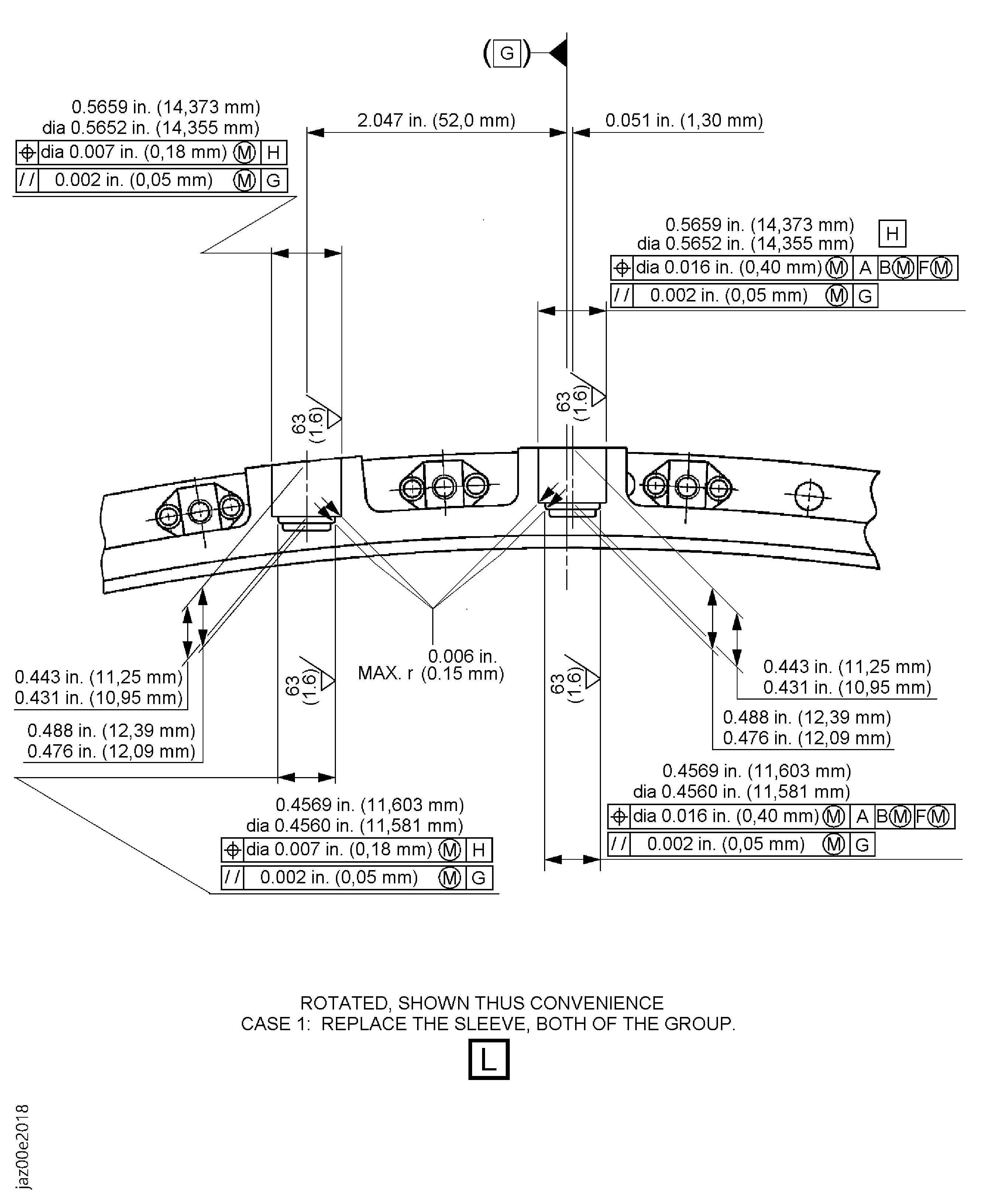

Figure: Repair details and dimensions

Repair details and dimensions

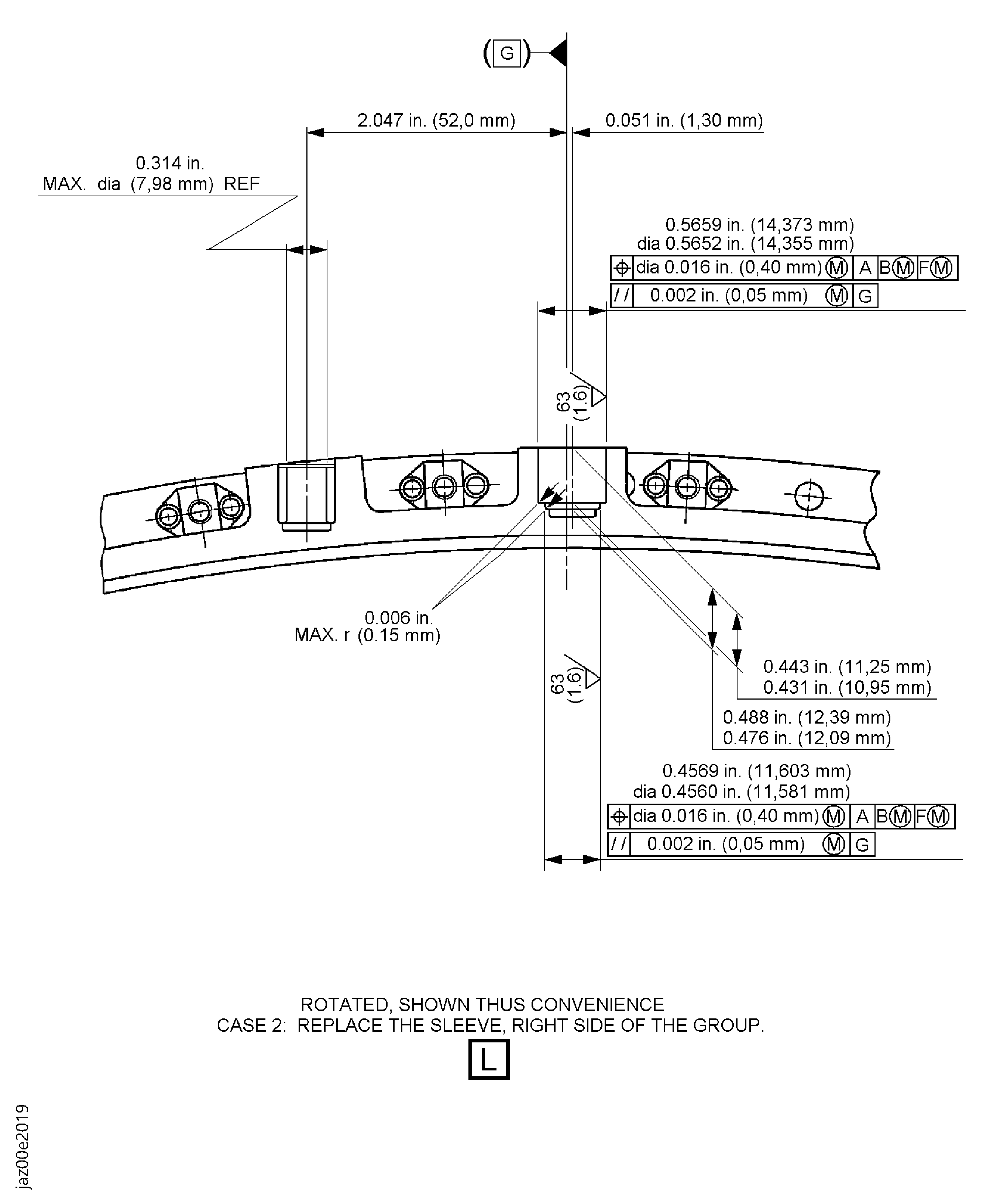

Figure: Repair details and dimensions

Repair details and dimensions

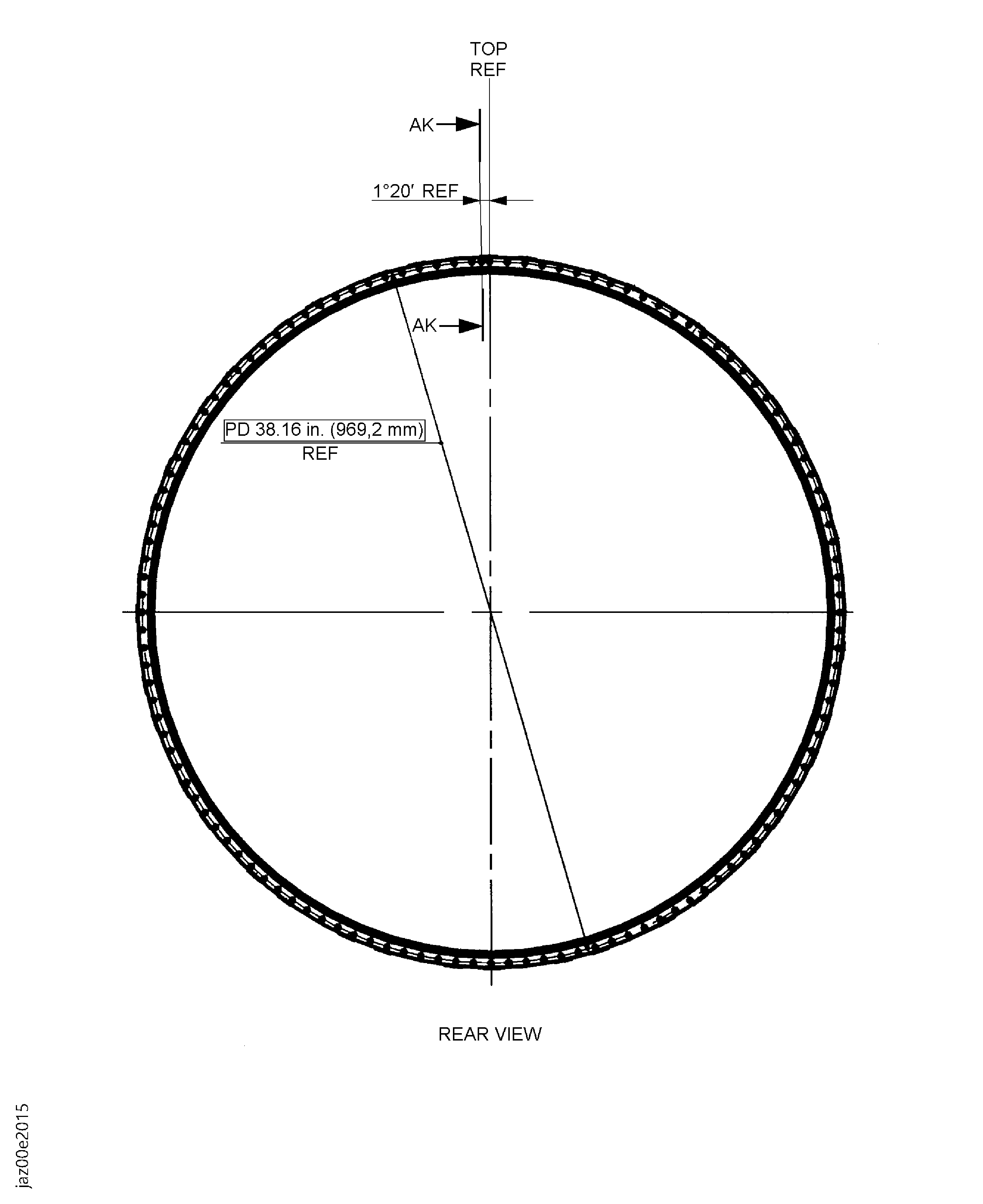

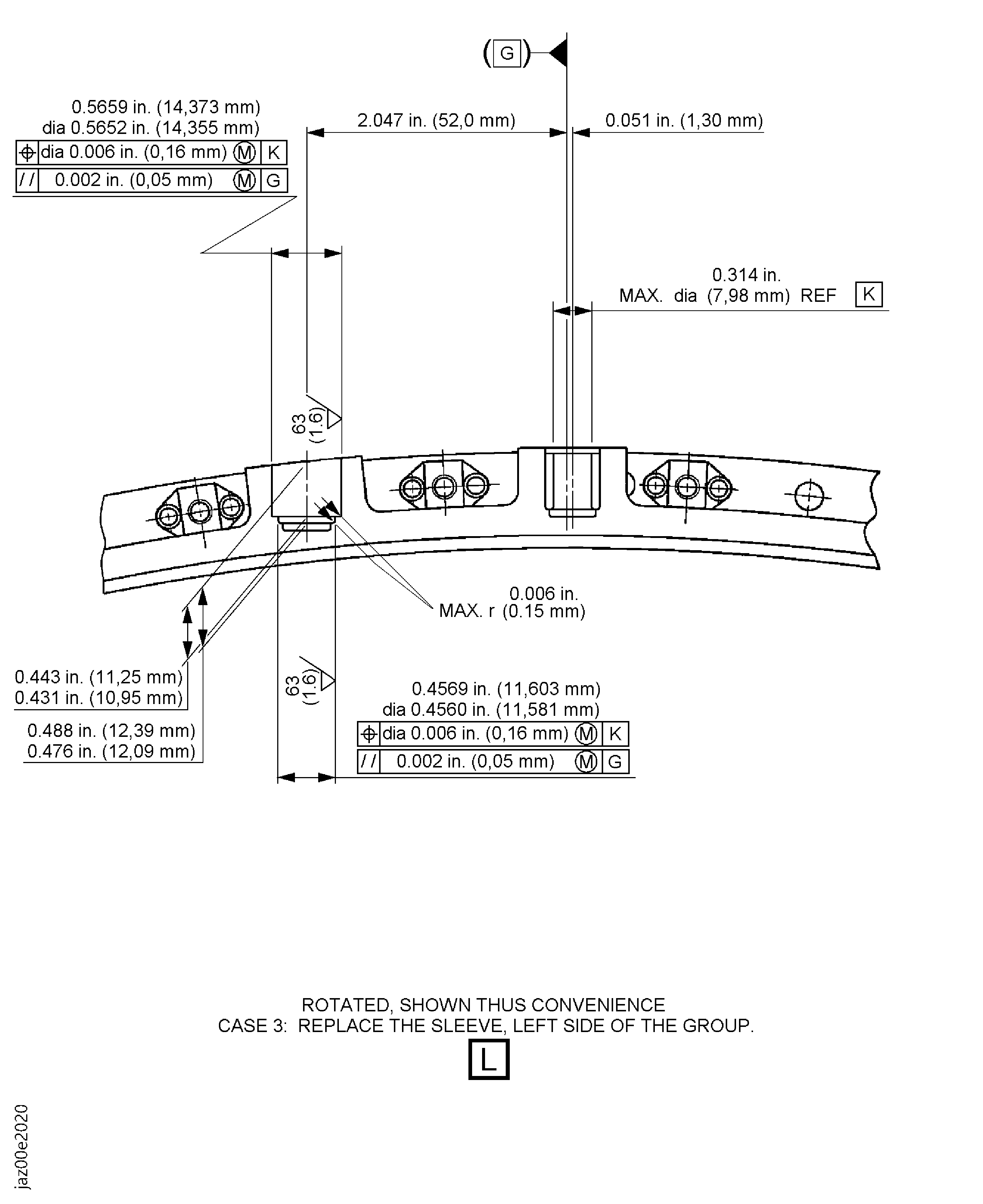

Figure: Repair details and dimensions

Repair details and dimensions

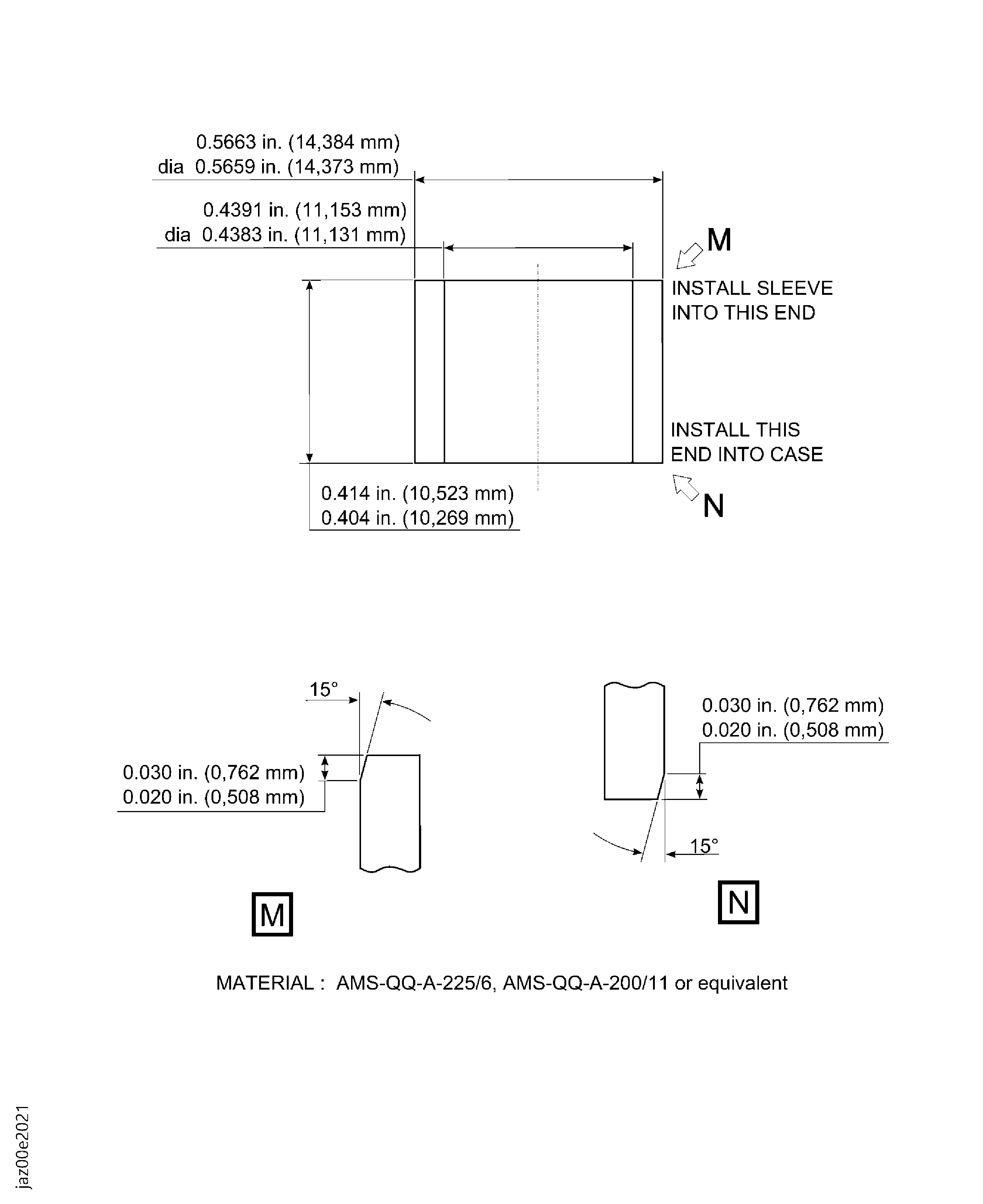

Figure: Repair details and dimensions

Repair details and dimensions

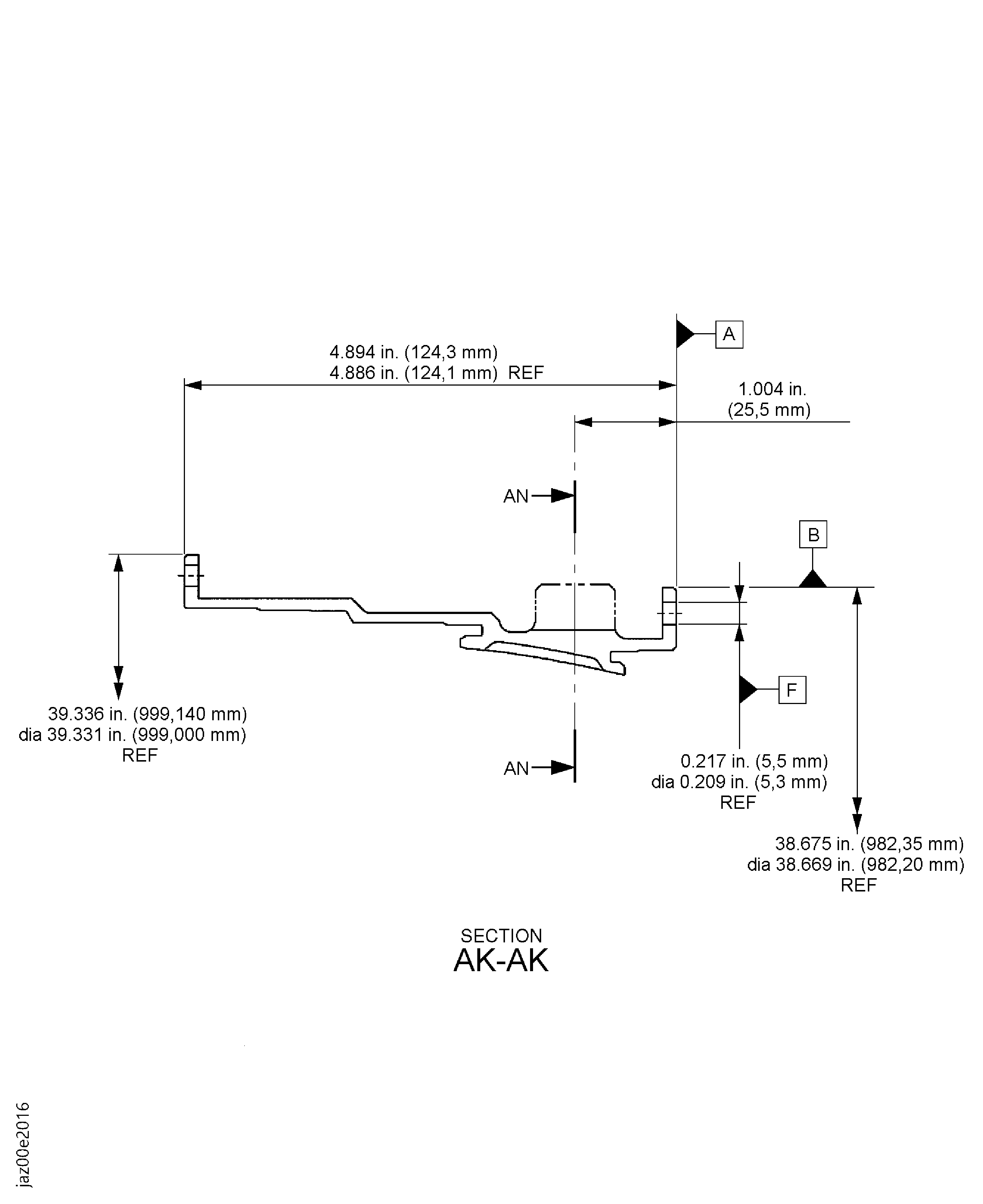

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

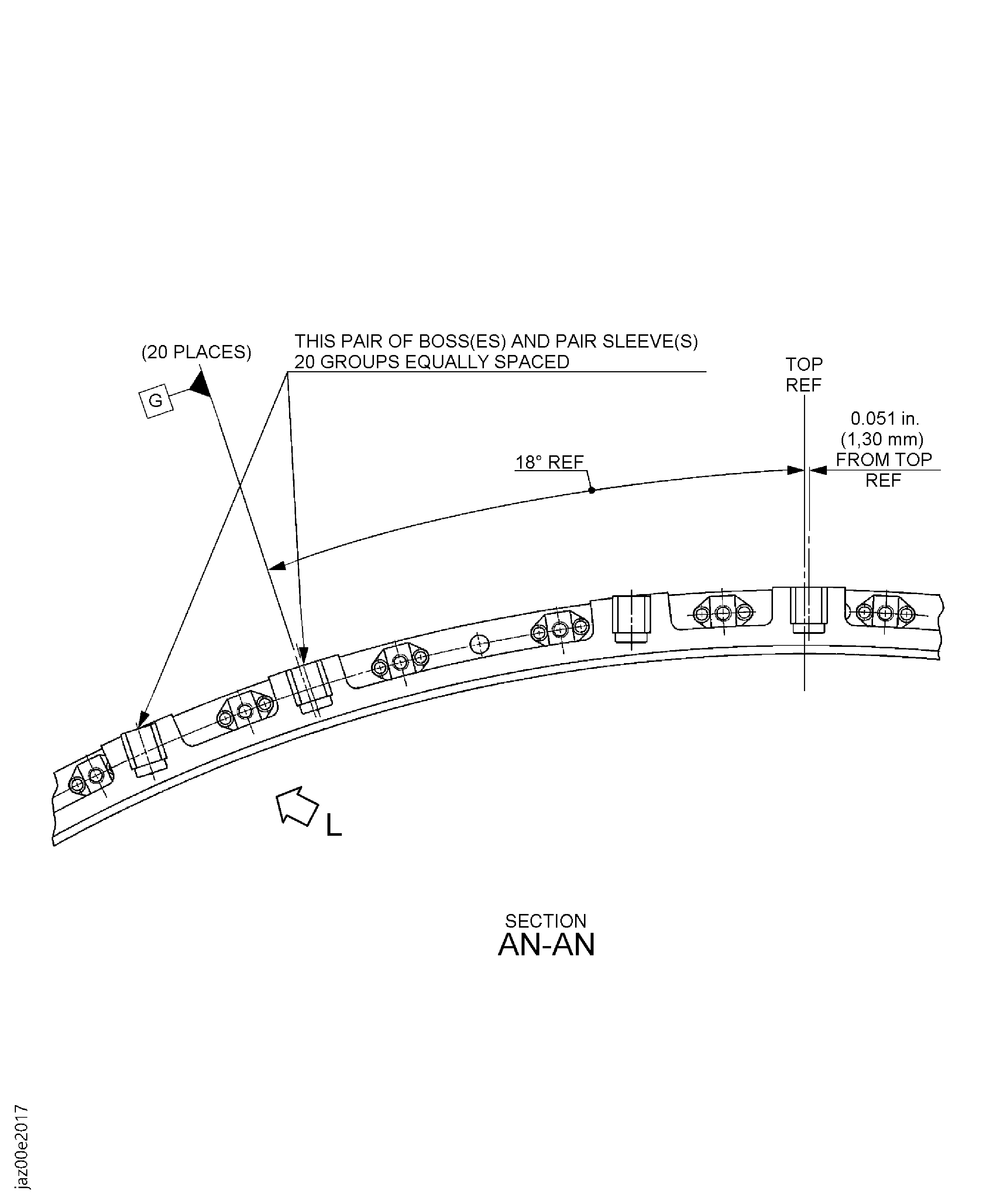

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions