Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-85-300-058Fan Case - Repair The Damaged Bolt Hole At Flange FE By Bushing, Repair-058 (VRS1992)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-100 | 5W0149 |

01-100 | 5W0169 |

01-100 | 5W0172 |

01-100 | 5W0195 |

01-100 | 5W0197 |

01-100 | 5W0198 |

01-100 | 5W0218 |

01-100 | 5W0220 |

01-100 | 5W0221 |

01-100 | 5W0223 |

01-100 | 5W0225 |

01-100 | 5W0226 |

01-100 | 5W0307 |

01-100 | 5W0313 |

General

This Repair scheme gives the procedure for blending the Fan Case.

This repair is applicable to all of the bolt holes except four holes of 16 millimeters in diameter at 3 o'clock and 9 o'clock positions and the bushing hole at top position.

Price and Availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent penetrant inspection equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Vibro-engraving equipment | LOCAL | |||

| Machining equipment | LOCAL | |||

| Standard workshop equipment | LOCAL | |||

| Heat Protective Gloves | LOCAL | Protective Gloves, Heat |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

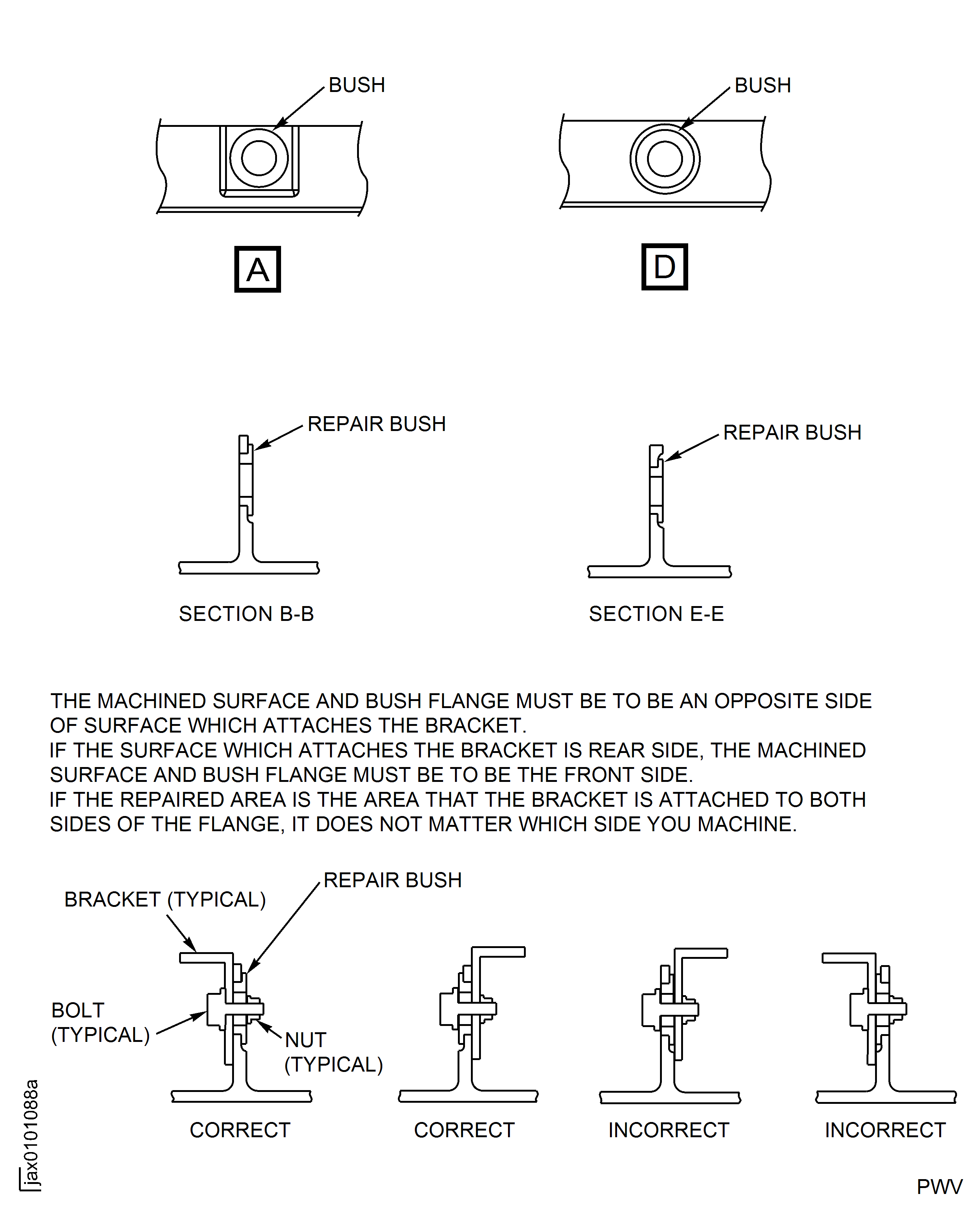

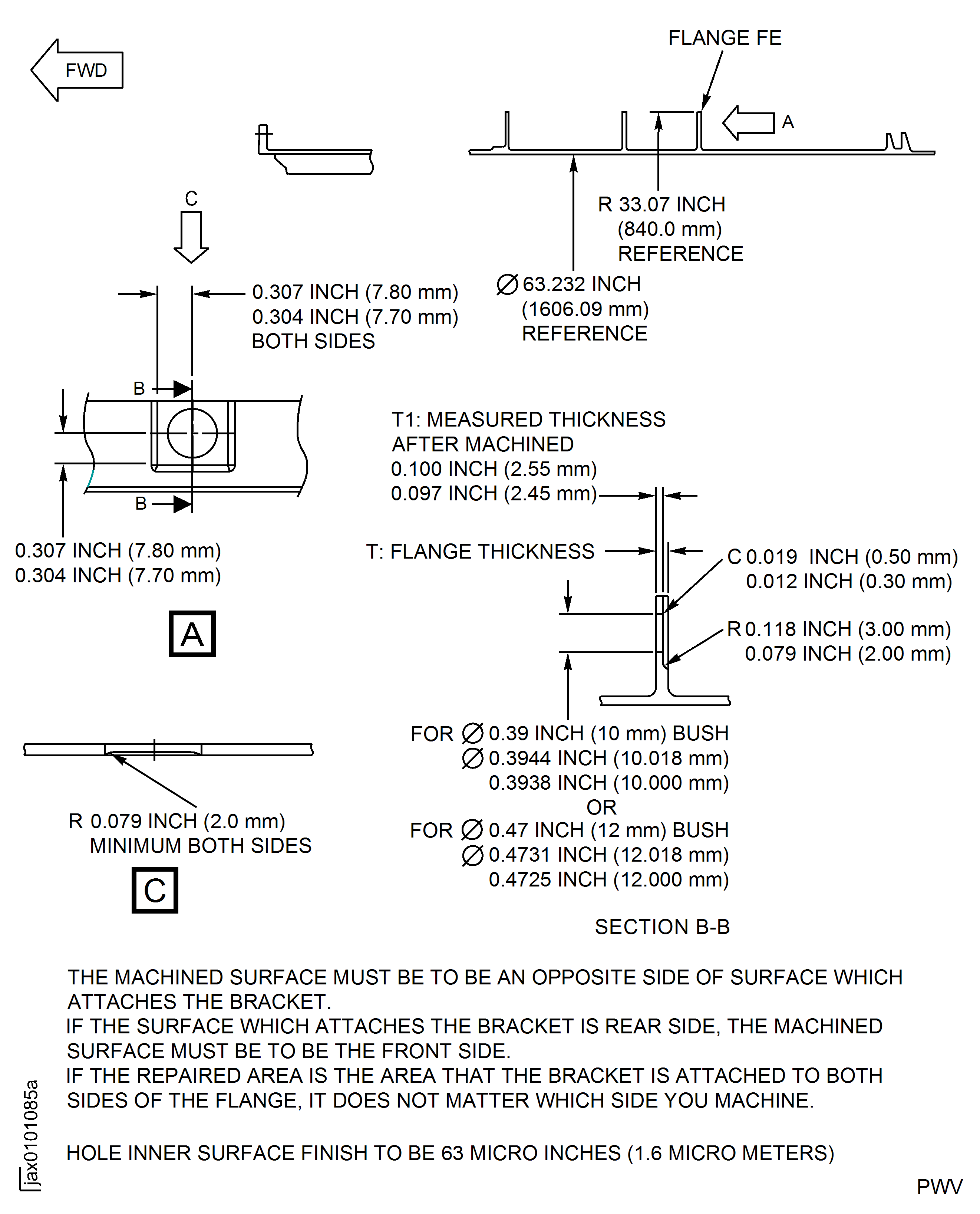

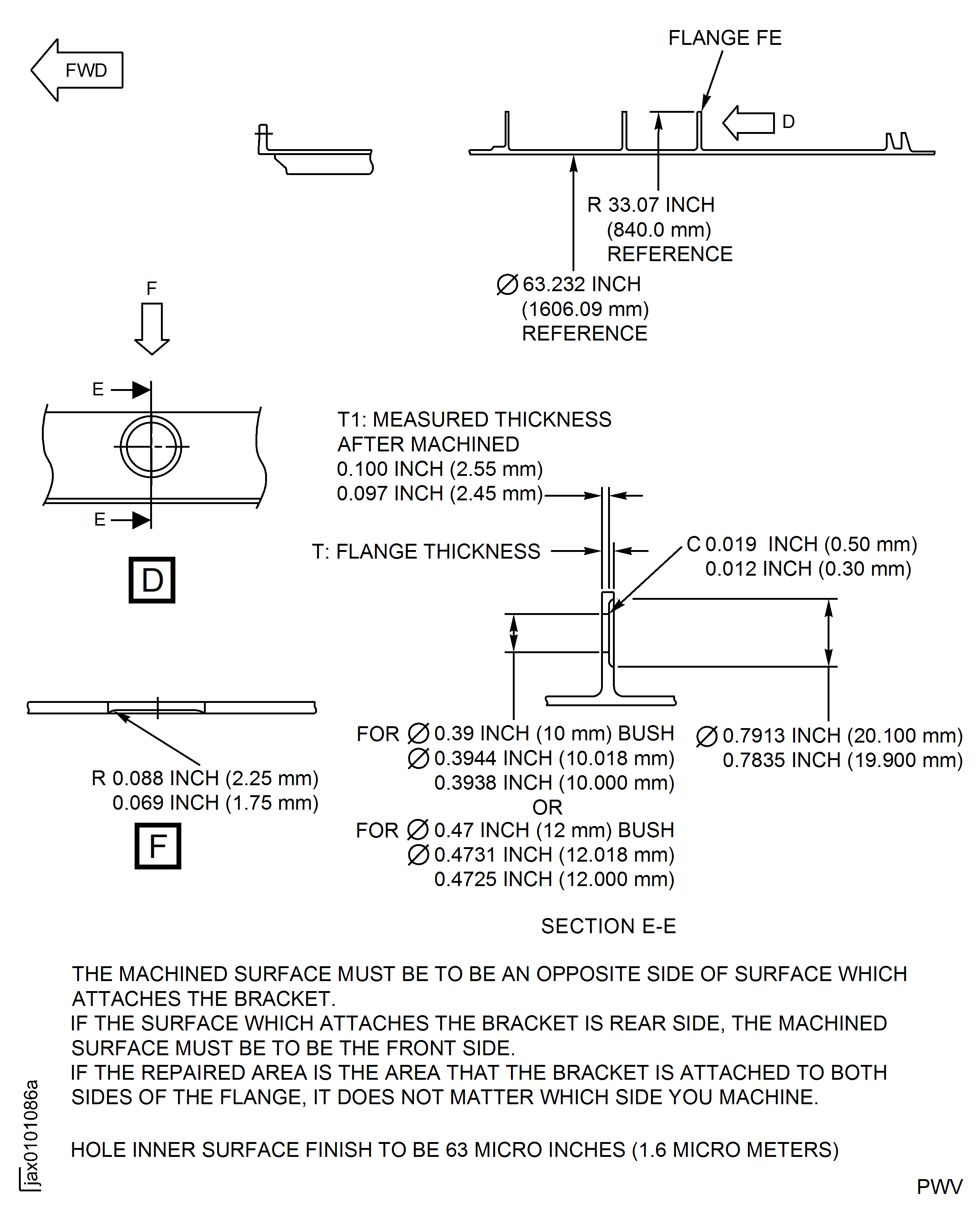

Machine the flange surface with either the round shape or the square shape. The machined surface must be to be an opposite side of surface which attaches the bracket. If the repaired area is the area that the bracket is attached to both sides of the flange, it does not matter which side you machine.

NOTE

You can select the round shape or square shape in consideration of the accessibility of machining equipment.

Machine the flange surface.

Make chamfer on the machined holes.

Remove the sharp edges and the raised materials from the repaired area.

SUBTASK 72-32-85-320-057 Machine the Damaged Hole and Flange Surface

Nicks, dents, scratches, galls, burrs, crack indications, spatter or a change in color to a darker than light straw color are not permitted.

Visually examine the repaired area.

SUBTASK 72-32-85-220-201 Examine the Repaired Area

Use chemical cleaning equipment.

Refer to the SPM TASK 70-11-26-300-503.

Clean the repaired area.

Use chemical etching equipment.

Refer to the SPM TASK 70-11-08-300-503.

Swab etch the repaired area.

SUBTASK 72-32-85-110-094 Do a Swab Etch to the Repaired Area

Refer to the SPM TASK 70-23-05-230-501.

No cracks are permitted.

Fluorescent penetrant examine the repaired area.

SUBTASK 72-32-85-230-072 Examine the Repaired Area for Cracks

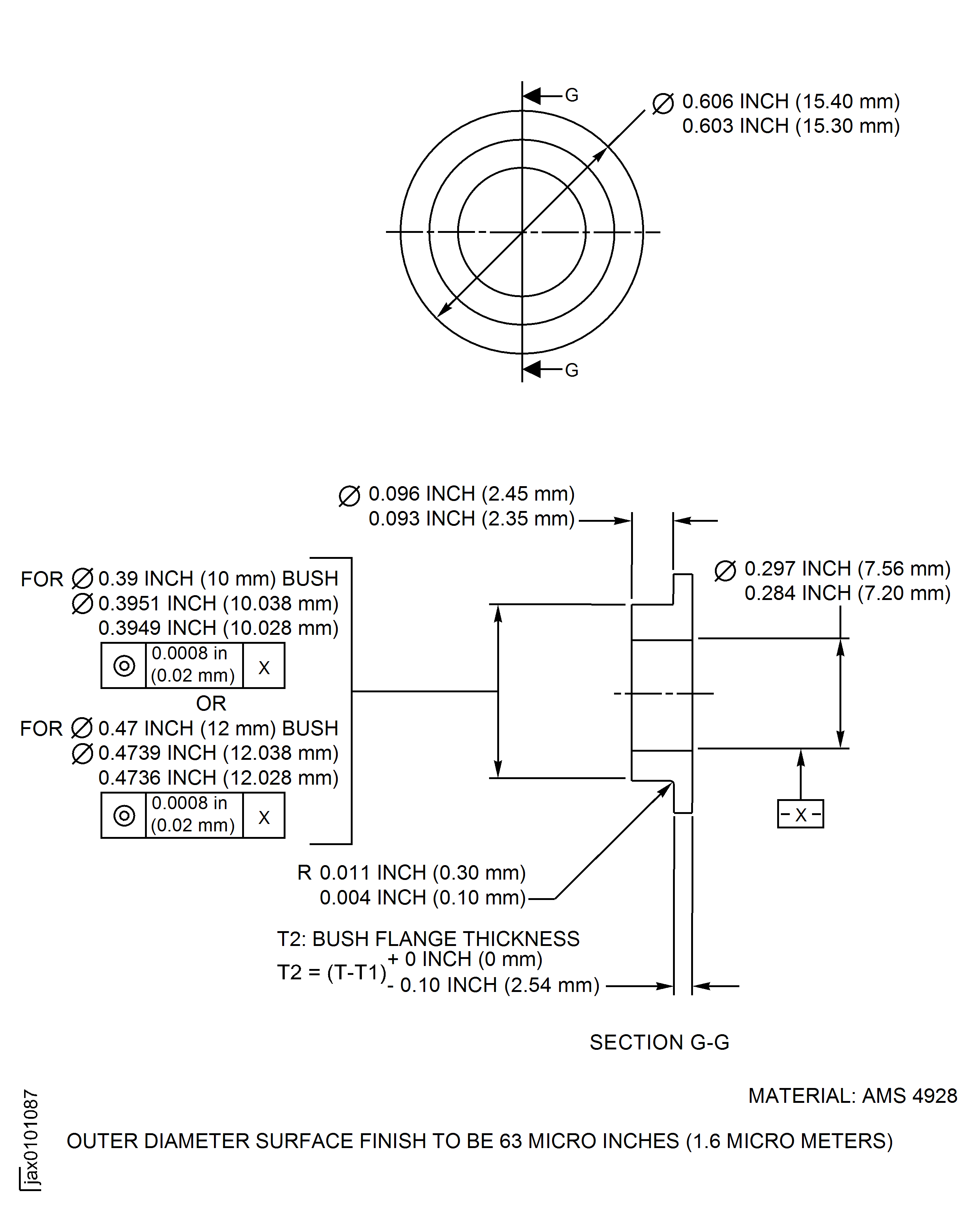

Fluorescent penetrant examine the manufactured bushes.

Refer to the SPM TASK 70-23-05-230-501.

No cracks are permitted.

SUBTASK 72-32-85-230-073 Examine the Manufactured Bush for Cracks

The bushes must be installed to the same side as machined surface.

Freeze and install the bushes.

SUBTASK 72-32-85-350-165 Install the Bush

Refer to Figure.

Make sure that the bush surface is to be flush with the surrounding flange surface.

Visually examine the bushes.

SUBTASK 72-32-85-220-202 Examine the Installed Bush

Use vibro-engraving equipment.

Refer to the SPM TASK 70-09-00-400-501.

Make a mark VRS1992 adjacent to the part number.

SUBTASK 72-32-85-350-166 Identify the Repair

Figure: Repair Details and Dimensions for Square Machining

Repair Details and Dimensions for Square Machining

Figure: Repair Details and Dimensions for Round Machining

Repair Details and Dimensions for Round Machining

Figure: Details of the Manufactured Bush

Details of the Manufactured Bush

Figure: After the Repair

After the Repair