Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-50-10-030-007-B00 LPT Case And Rotor Assembly - Disassemble The LPT Stage 5 Stator Vanes From The LPT, Disassembly-007

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Discard all rubber seal rings, cotter pins and keywashers removed in this procedure.

Refer to TASK 72-50-00-990-501 for a sectional view of the LP turbine module.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Electronic balance crane | LOCAL | Electronic balance crane | ||

| Basket | LOCAL | Basket | For blades and vanes | |

| Lifting sling | LOCAL | Lifting sling | ||

| Rack pallet | LOCAL | Rack pallet | ||

| IAE 1M14042 Tilting plate | 0AM53 | IAE 1M14042 | 1 | |

| IAE 1M14056 Lifting shaft | 0AM53 | IAE 1M14056 | 1 | |

| IAE 1M14063 Guide fixture | 0AM53 | IAE 1M14063 | 1 | |

| IAE 1M14072 Mounting plate | 0AM53 | IAE 1M14072 | 1 | |

| IAE 1M14073 Lifting fixture | 0AM53 | IAE 1M14073 | 1 | |

| IAE 1M14119 Protector ring segment | 0AM53 | IAE 1M14119 | 3 | |

| IAE 1M14130 Removal puller | 0AM53 | IAE 1M14130 | 1 | |

| IAE 1M14010 Assembly/Disassembly fixture | 0AM53 | IAE 1M14010 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Install the IAE 1M14119 Protector ring segment 3 off between the stage 5 vane inner platforms and the stage 4 blade roots.

SUBTASK 72-50-10-030-161 Install the Protector Ring Segments

Refer to Figure.

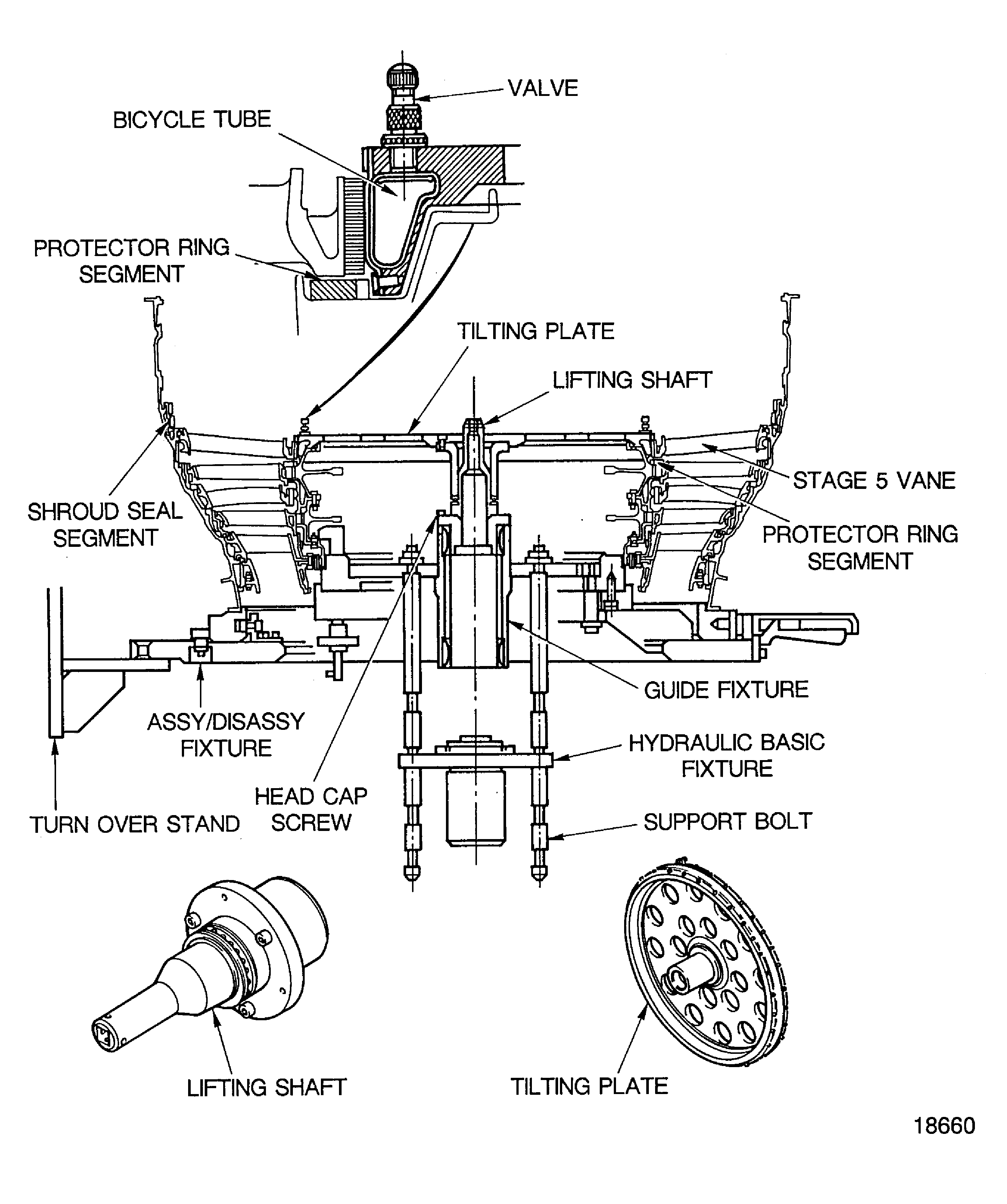

Install the IAE IAE 1M14056 Lifting shaft 1 off into the IAE 1M14063 Guide fixture 1 off.

Attach the bushing, part of the IAE 1M14056 Lifting shaft, with three head capscrews on to the IAE 1M14063 Guide fixture. Tighten the bolts.

SUBTASK 72-50-10-030-162 Install the Lifting Shaft in to the Guide Fixture

Refer to Figure.

Install the IAE IAE 1M14042 Tilting plate 1 off on to the IAE 1M14056 Lifting shaft.

Turn the IAE 1M14056 Lifting shaft. Lift the IAE 1M14042 Tilting plate until the protective rubber, part of the IAE 1M14042 Tilting plate, is on the same level as the Stage 5 vane honeycombs. Use an applicable wrench.

Carefully fill the bicycle tube, part of the IAE 1M14042 Tilting plate, with compressed air.

SUBTASK 72-50-10-030-163 Install the Tilting Plate on to the Lifting Shaft

Refer to Figure.

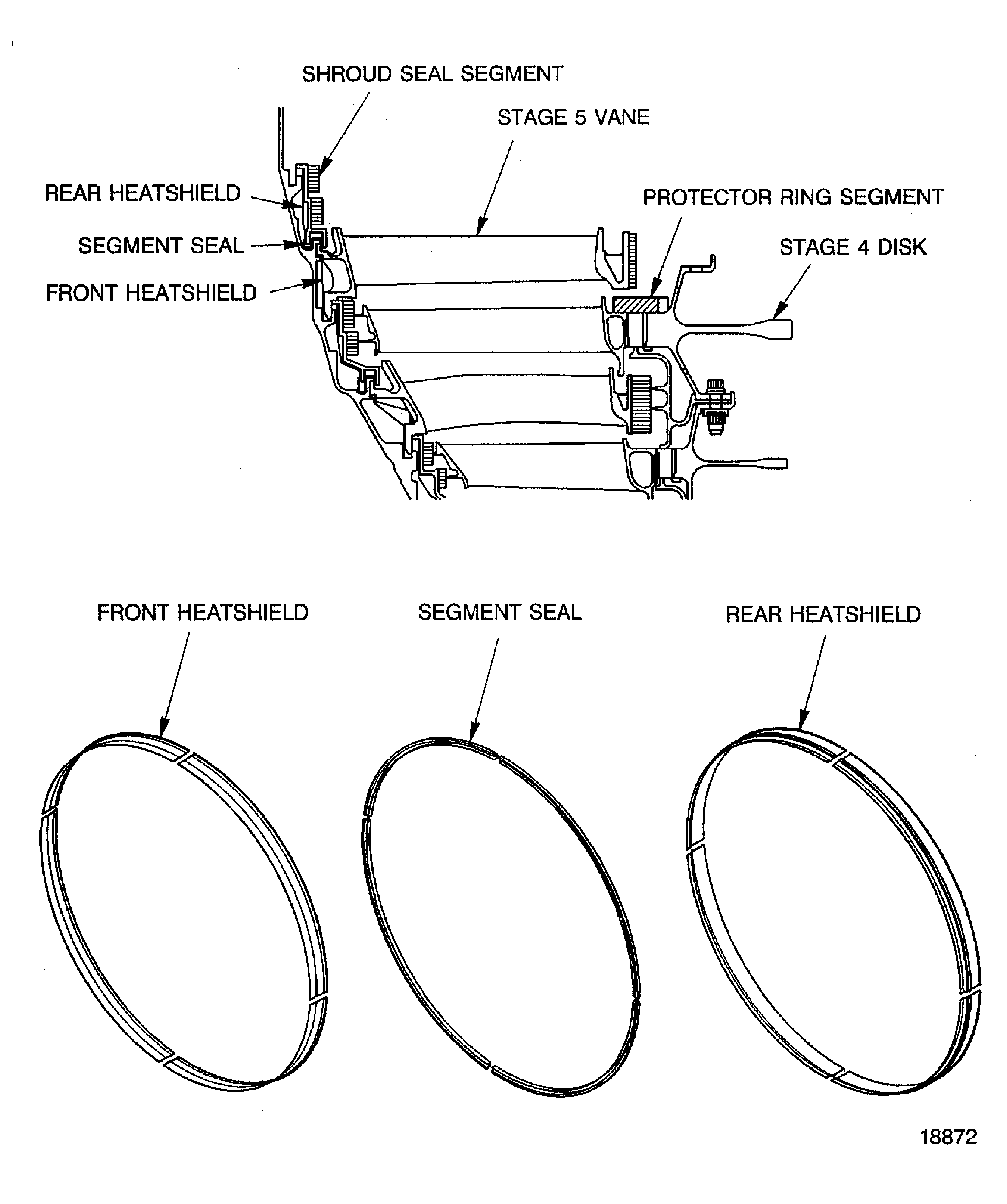

Loosen the shroud seal segments with the IAE 1M14130 Removal puller 1 off.

Put the shroud seal segments in a Basket.

SUBTASK 72-50-10-030-164 Remove the Shroud Seal Segments of the Stage 5

Refer to Figure.

Put the heatshields on a Rack pallet.

SUBTASK 72-50-10-030-165 Remove the Stage 5 Rear Heatshields

Refer to Figure.

NOTE

Make sure that the rear hub hooks from all vanes become free from the groove in the turbine case.Carefully lower the inner ends of the 31 vane segments. Turn the IAE 1M14056 Lifting shaft stepwise down. Use an applicable wrench. Push all 31 vane segments at the inner end down by hand if necessary.

SUBTASK 72-50-10-030-166 Prepare the Stage 5 Vane Assembly for Removal

Refer to Figure.

Release the pressure of the bicycle tube on the IAE 1M14042 Tilting plate.

Remove the IAE 1M14042 Tilting plate.

Loosen and remove the three head capscrews which attach the bushing to the IAE 1M14063 Guide fixture.

Remove the IAE 1M14056 Lifting shaft from the IAE 1M14063 Guide fixture.

SUBTASK 72-50-10-030-167 Remove the Tilting Plate and the Lifting Shaft

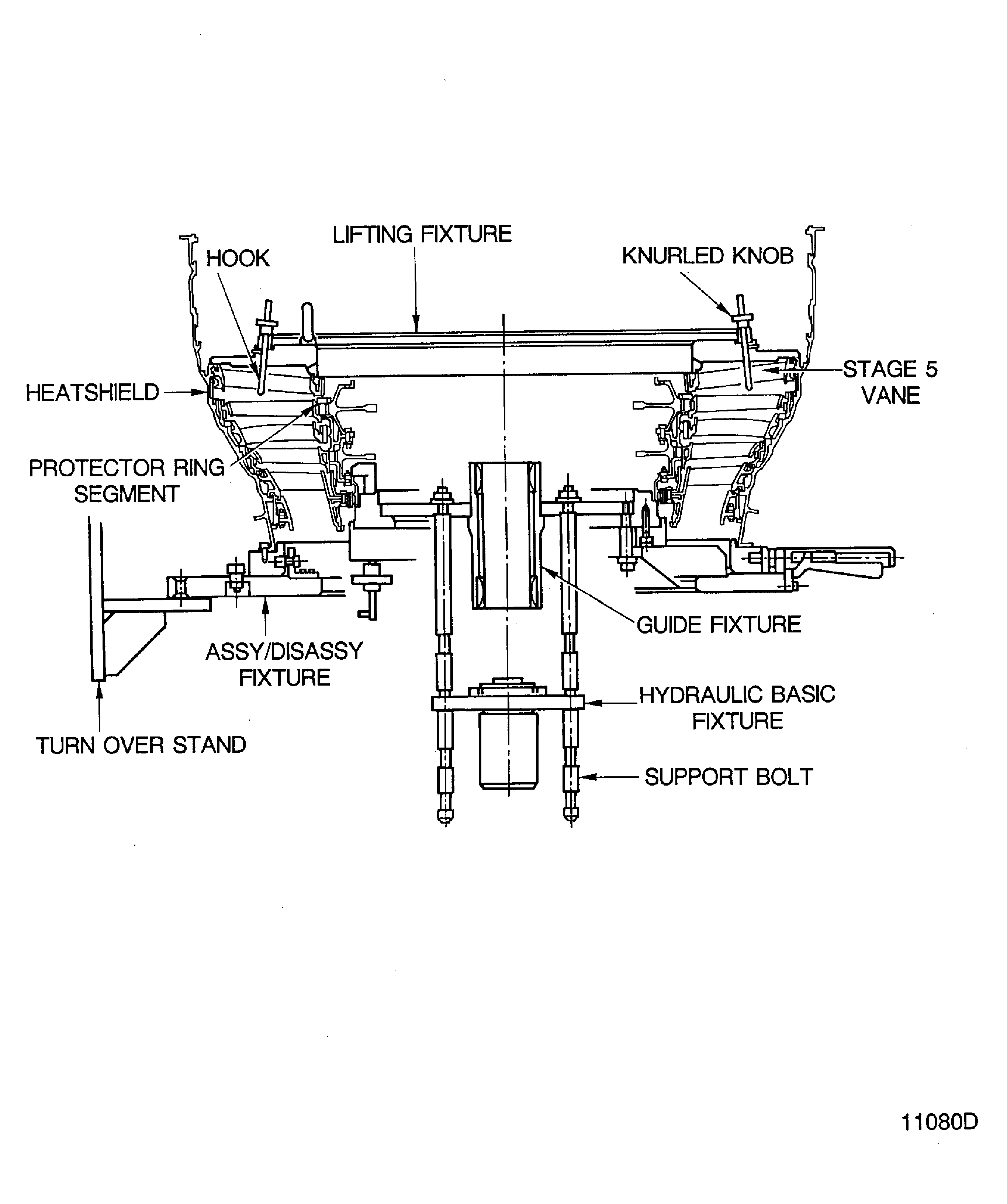

Use hoist equipment. Lift the IAE 1M14073 Lifting fixture 1 off above the LP turbine case and rotor.

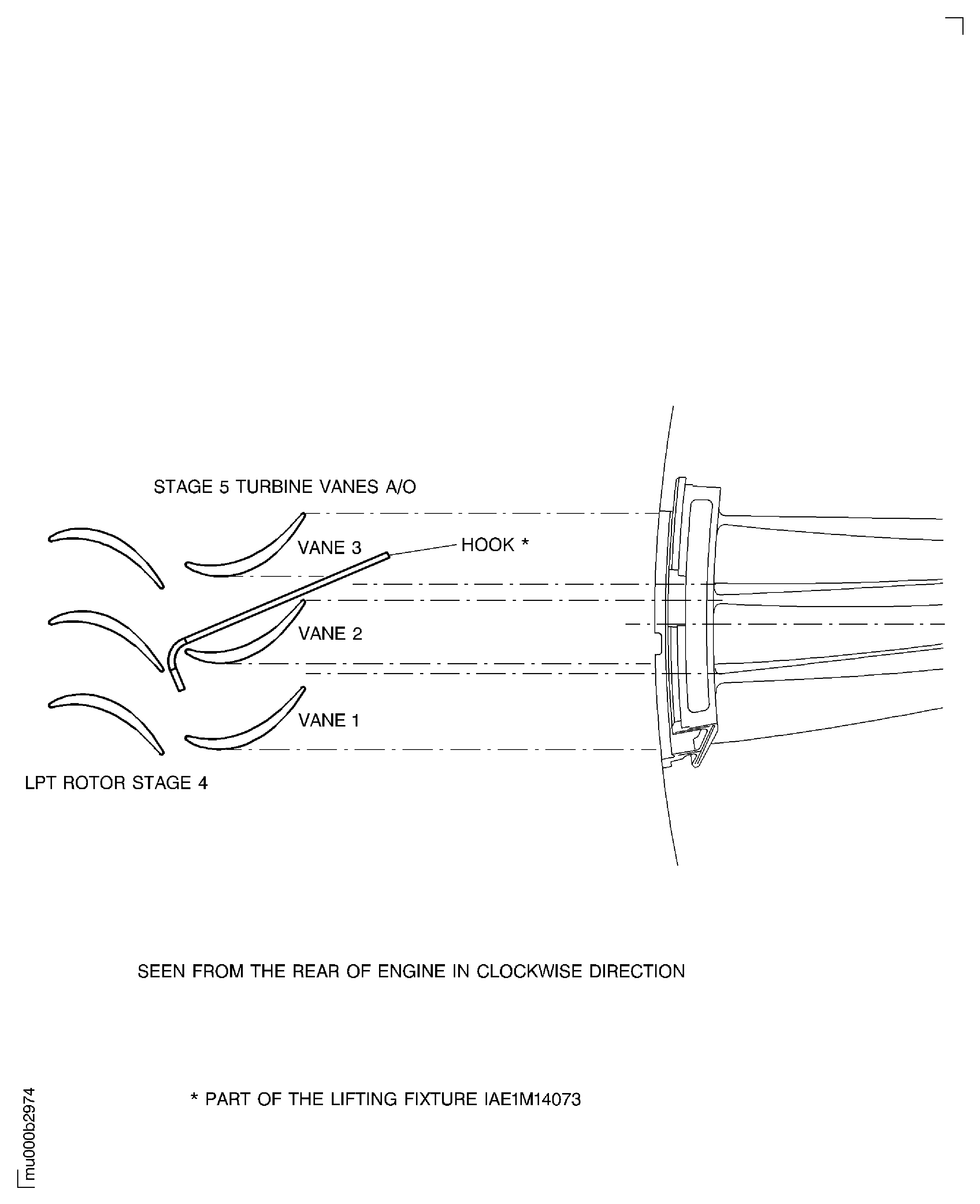

Carefully lower the IAE 1M14073 Lifting fixture on to the stage 5 vane assembly. Turn the IAE 1M14073 Lifting fixture to engage the hooks through the vane cluster. Each hook must engage through the second and third vane of the vane cluster.

SUBTASK 72-50-10-030-168 Install the Lifting Fixture

Refer to Figure.

Put the segment seals on a Rack pallet.

SUBTASK 72-50-10-030-169 Remove the Stage 5 Segment Seals

Refer to Figure.

Attach hoist equipment on to Electronic balance crane. Lift the Electronic balance crane above the LP turbine case and rotor. Attach the IAE 1M14073 Lifting fixture 1 off to the Electronic balance crane. Use a Lifting sling.

Lift the Electronic balance crane until the balance scale shows the value of approximately 85.0 lb (38.5 kg) plus the weight of the Lifting sling.

CAUTION

DURING REMOVAL OF THE STAGE 5 VANE ASSEMBLY, MAKE SURE THAT THE BALANCE SCALE KEEPS APPROXIMATELY AT THE SAME POSITION TO PREVENT DAMAGES.Compress the ropes of the Lifting sling while you disengage the vane assembly from the LP turbine case grooves.

Remove the stage 5 vane assembly carefully with hoist equipment, the Electronic balance crane and the installed IAE 1M14073 Lifting fixture out of the LP turbine case.

Put the stage 5 vane assembly on to the IAE 1M14072 Mounting plate 1 off.

Release the holders of the IAE 1M14073 Lifting fixture with the hand knobs. Remove the IAE 1M14073 Lifting fixture from the stage 5 vane assembly. Remove the Electronic balance crane from hoist equipment.

Disassemble the stage 5 vane assembly. Put the stage 5 vane segments and the sealing strips into a Basket.

SUBTASK 72-50-10-030-170 Remove the Stage 5 Vane Assembly

Refer to Figure.

Put the heatshields in to a Rack pallet.

SUBTASK 72-50-10-030-171 Remove the Stage 5 Front Heatshields

Refer to Figure.

Remove the three IAE 1M14119 Protector ring segment.

SUBTASK 72-50-10-030-172 Remove the Protector Ring Segments

Move the lifting ring of the IAE 1M14010 Assembly/Disassembly fixture 1 off from the 'lifting -position' into the 'zero-position' with the use of the lever.

SUBTASK 72-50-10-030-190 Move the Lifting Ring

Figure: Install the Lifting Shaft and Tilting Plate

Install the Lifting Shaft and Tilting Plate

Figure: Remove the Stage 5 Vanes

Remove the Stage 5 Vanes

Figure: Remove the Stage 5 Vane Assembly

Remove the Stage 5 Vane Assembly

Figure: Correct Installation of the Hooks of the Lifting Fixture

Correct Installation of the Hooks of the Lifting Fixture