Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-21-11-300-007 Thrust Mount Brackets - Replace The Damaged Bush, Repair-007 (VRS1105)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-500 | 5A0390 | Assembly A |

01-500 | 5A1422 | Assembly B |

01-500 | 5A1431 | Assembly B |

01-700 | 5A0391 | Assembly C |

01-700 | 5A1423 | Assembly D |

01-700 | 5A1432 | Assembly D |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Thrust mount bracket | - | Titanium alloy |

Bush | - | Corrosion resistance steel |

General

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Horizontal Boring Mill | LOCAL | Horizontal Boring Mill | ||

| Boring Head | LOCAL | Boring Head | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Inside Micrometer | LOCAL | Inside Micrometer | ||

| Bore Gage | LOCAL | Bore Gage | ||

| Heat Protective Gloves | LOCAL | Protective Gloves, Heat | ||

| Hand Tools | LOCAL | Tools, Hand | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| IAE 3J12837 Machining fixture | 0AM53 | IAE 3J12837 | 1 | |

| IAE 3J12859 Machining fixture | 0AM53 | IAE 3J12859 | 1 | |

| IAE 3J12832 Installation fixture | 0AM53 | IAE 3J12832 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) | 37676 | CoMat 06-018 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bush, pin thrust | 5A0994 | AR | ||

| Bush, pin thrust | 5A0994 | AR |

Safety Requirements

NONEProcedure

Use Horizontal Boring Mill 1 off and Boring Head 1 off.

Use IAE 3J12837 Machining fixture 1 off.

Set up and machine the damaged bush.

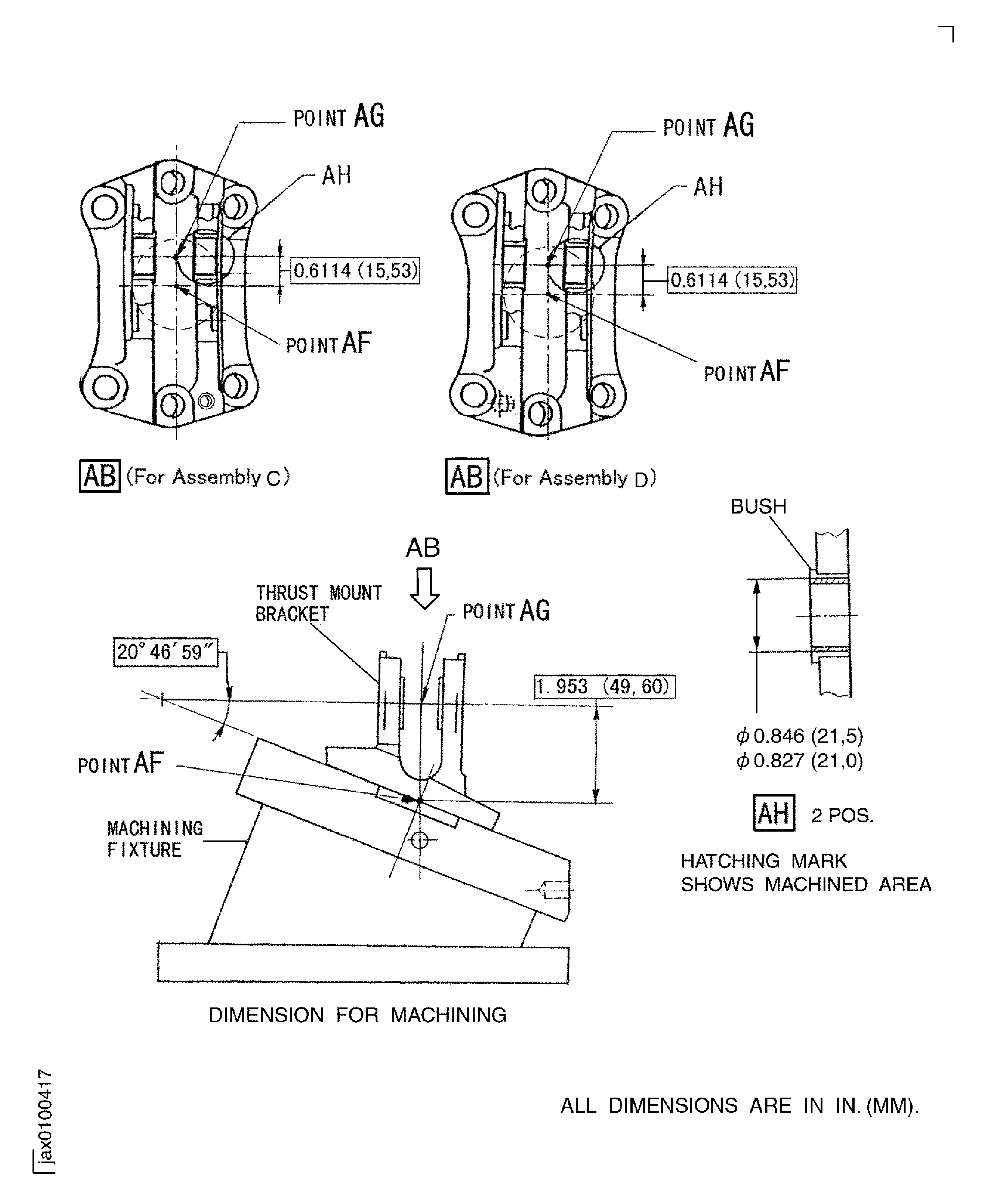

SUBTASK 71-21-11-322-003-A00 Machine the Thrust Pin Bush of the Thrust Mount Bracket Assembly for removing Damaged Bush, Assembly B and Assembly D

Use Horizontal Boring Mill 1 off and Boring Head 1 off.

Use IAE 3J12859 Machining fixture 1 off.

Set up and machine the damaged bush.

SUBTASK 71-21-11-322-004-B00 Machine the Thrust Pin Bush of the Thrust Mount Bracket Assembly for removing Damaged Bush, Assembly A and Assembly C

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine the bush holes.

SUBTASK 71-21-11-230-059 Examine the Bush Holes of the Thrust Mount Bracket Assembly for Cracks

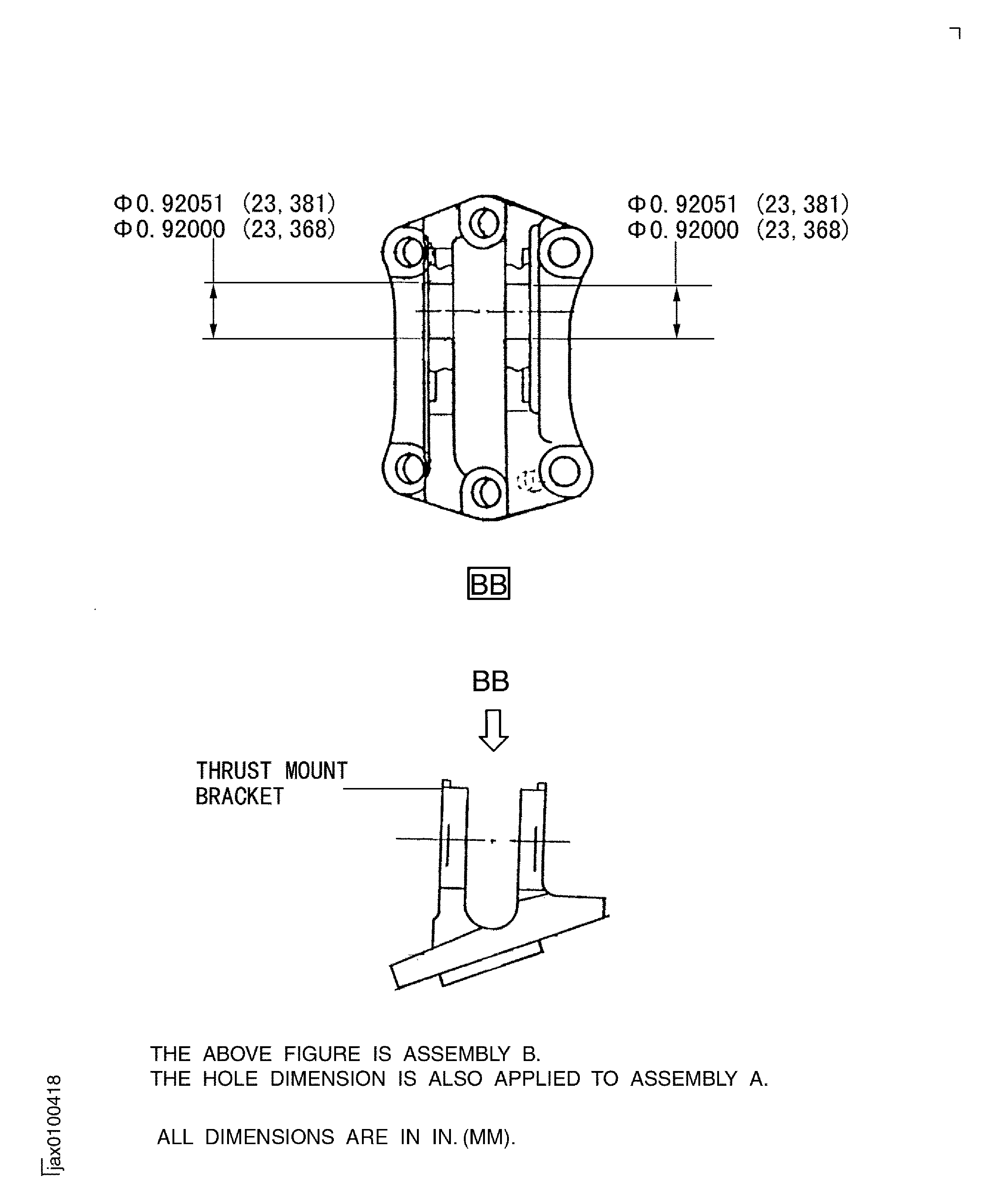

Refer to Figure.

Do the cleaning procedure in accordance with the SPM TASK 70-11-26-300-503.

WARNING

DO NOT GET LIQUID NITROGEN ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. LIQUID NITROGEN IS AN ASPHYXIATOR. USE THE LIQUID IN A WELL VENTILATED AREA. IF YOU GET THE LIQUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL HELP IF YOUR SKIN OR EYES BECOME IRRITATED.Clean the bush and bush hole of the thrust mount bracket.

Use IAE 3J12832 Installation fixture 1 off and Heat Protective Gloves 1 off.

Install and press the bush into the bush hole of the thrust mount bracket.

SUBTASK 71-21-11-420-054 Install the Bush to the Thrust Mount Bracket Assembly

Refer to Figure.

SUBTASK 71-21-11-220-005 Examine the Bush of the Thrust Mount Bracket Assembly

Use Horizontal Boring Mill 1 off and Boring Head 1 off.

Use IAE 3J12837 Machining fixture 1 off.

Set up and machine the bush.

SUBTASK 71-21-11-322-005-A00 Machine the Bush of the Thrust Mount Bracket Assembly, Assembly B and Assembly D

Use Horizontal Boring Mill 1 off and Boring Head 1 off.

Use IAE 3J12859 Machining fixture 1 off.

Set up and machine the bush.

SUBTASK 71-21-11-322-006-B00 Machine the Bush of the Thrust Mount Bracket Assembly, Assembly A and Assembly C

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine the machined surface of the bush.

SUBTASK 71-21-11-230-060 Examine the Bush of the Thrust Mount Bracket Assembly for Cracks

Refer to VRS1104, EM TASK 71-21-11-300-001.

Apply the dry film lubricant to the bush.

SUBTASK 71-21-11-380-003 Apply the Dry Film Lubricant to the Bush of the Thrust Mount Bracket Assembly

Use Vibrating Marking Pencil 1 off.

Refer to SPM TASK 70-09-00-400-501.

Make a mark VRS1105 adjacent to the part number.

Use the vibration peening method.

SUBTASK 71-21-11-350-005 Mark Repair Number on the Thrust Mount Bracket

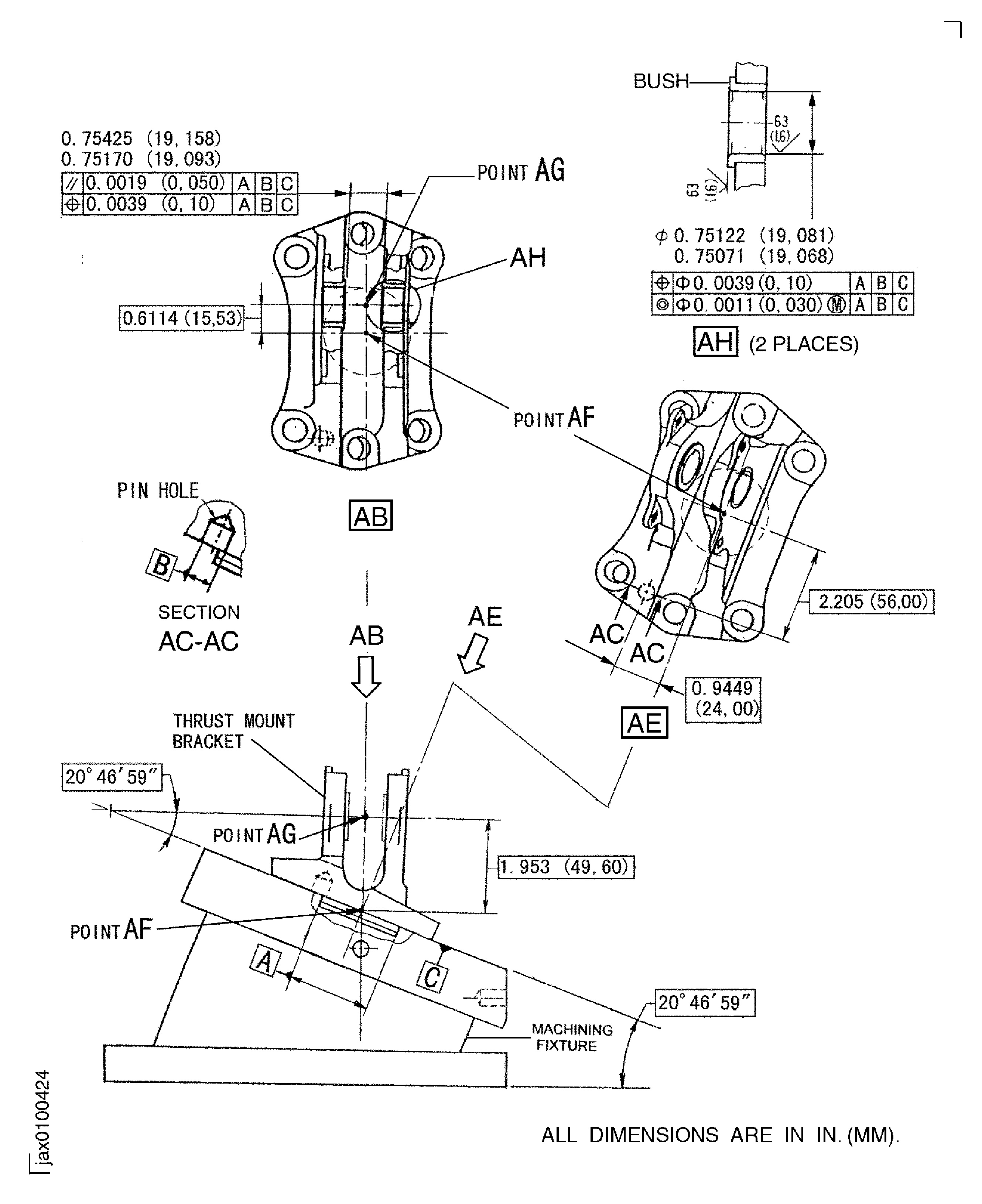

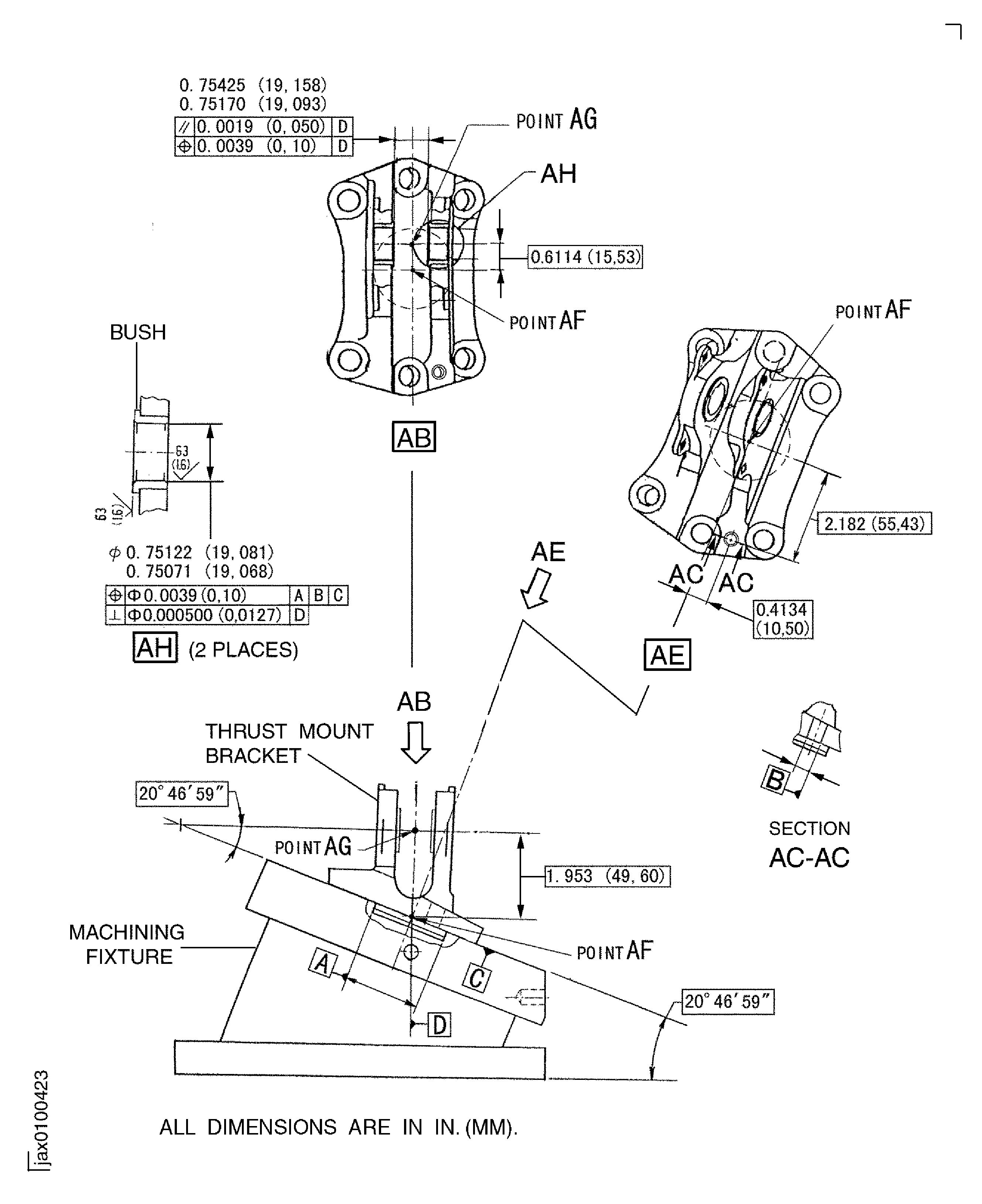

Figure: Machine the bore of the bush - Assembly A and Assembly B

Machine the bore of the bush - Assembly A and Assembly B

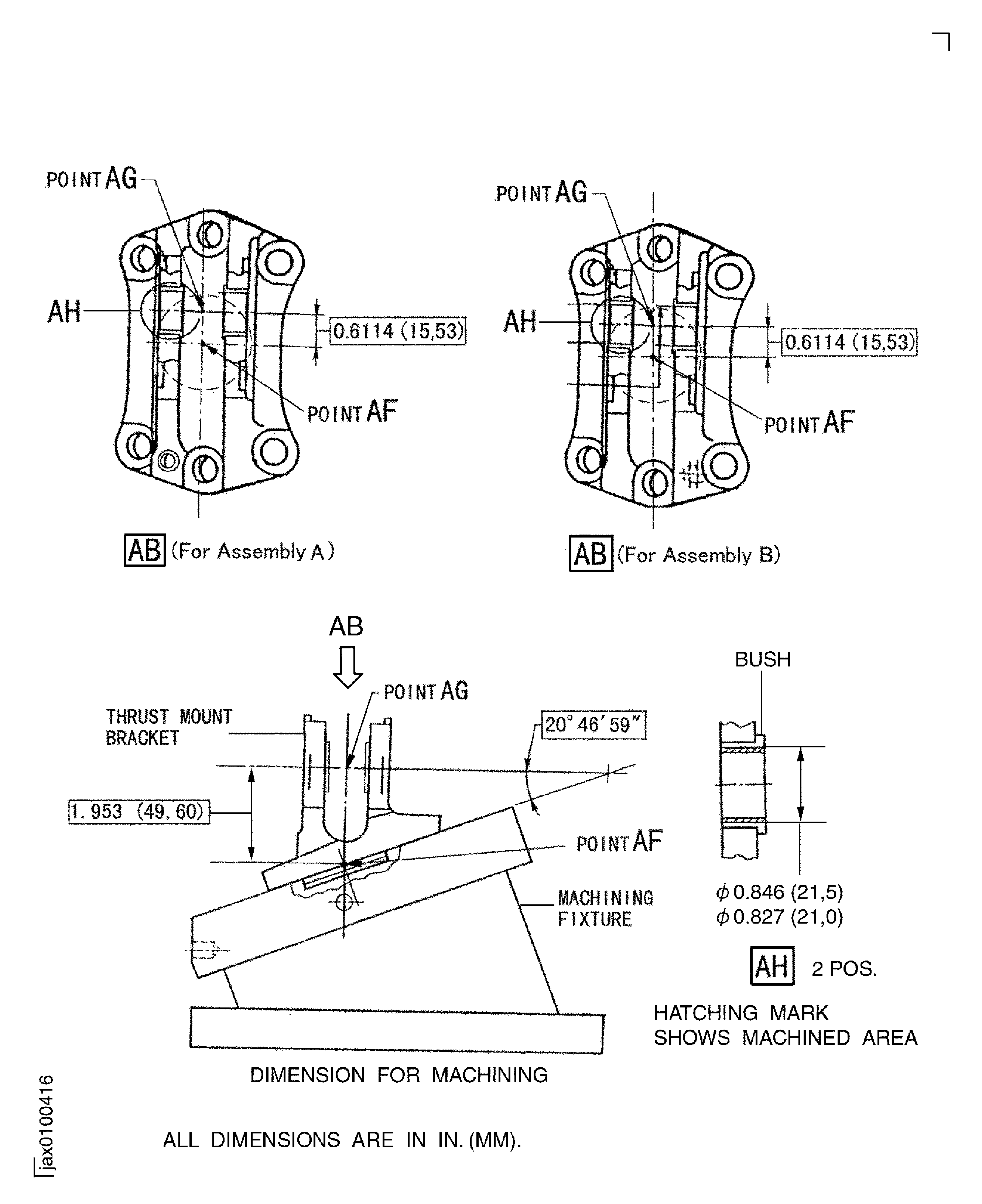

Figure: Machine the bore of the bush - Assembly C and Assembly D

Machine the bore of the bush - Assembly C and Assembly D

Figure: Dimension requirement without bush - Assembly A and Assembly B

Dimension requirement without bush - Assembly A and Assembly B

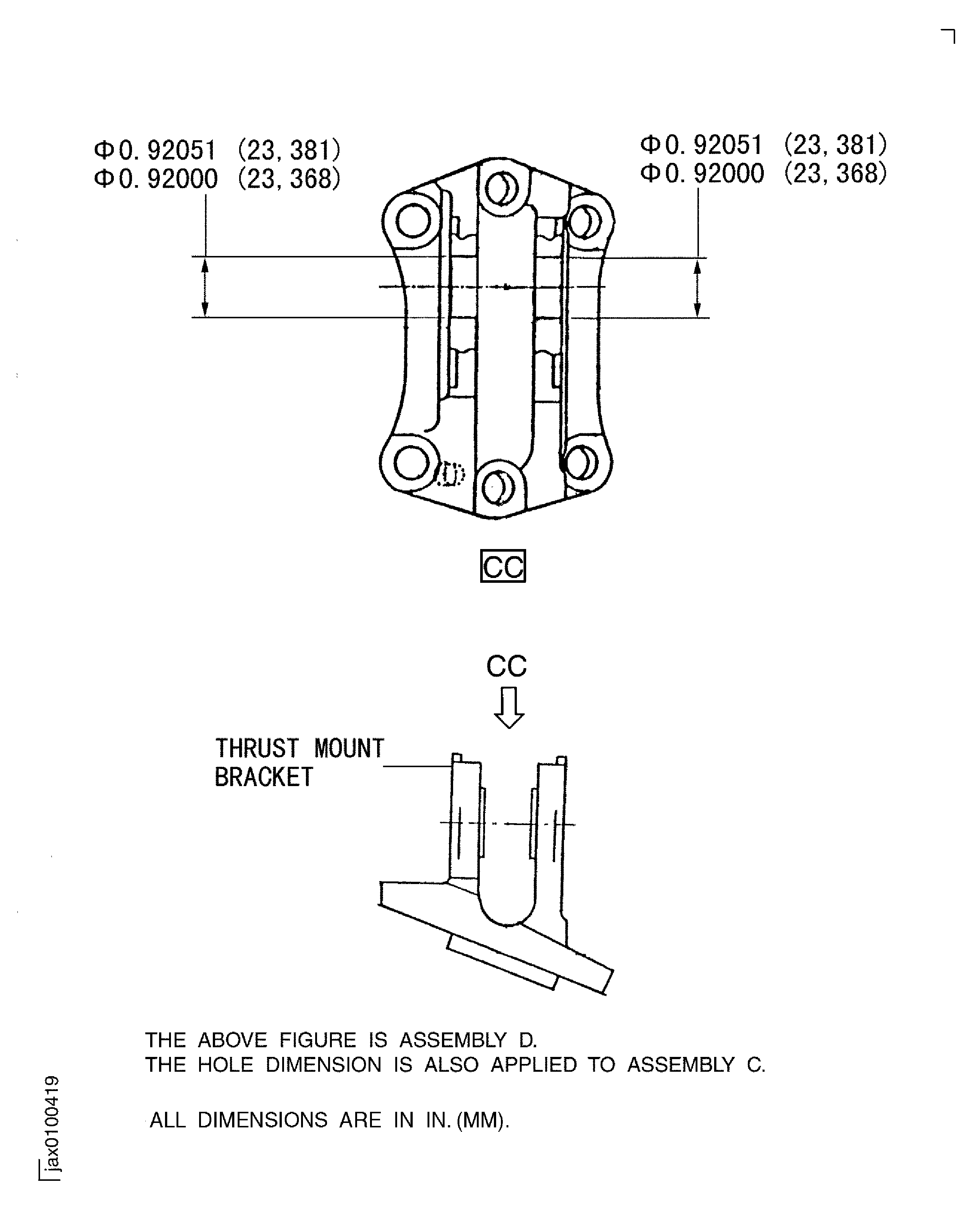

Figure: Dimension requirement without bush - Assembly C and Assembly D

Dimension requirement without bush - Assembly C and Assembly D

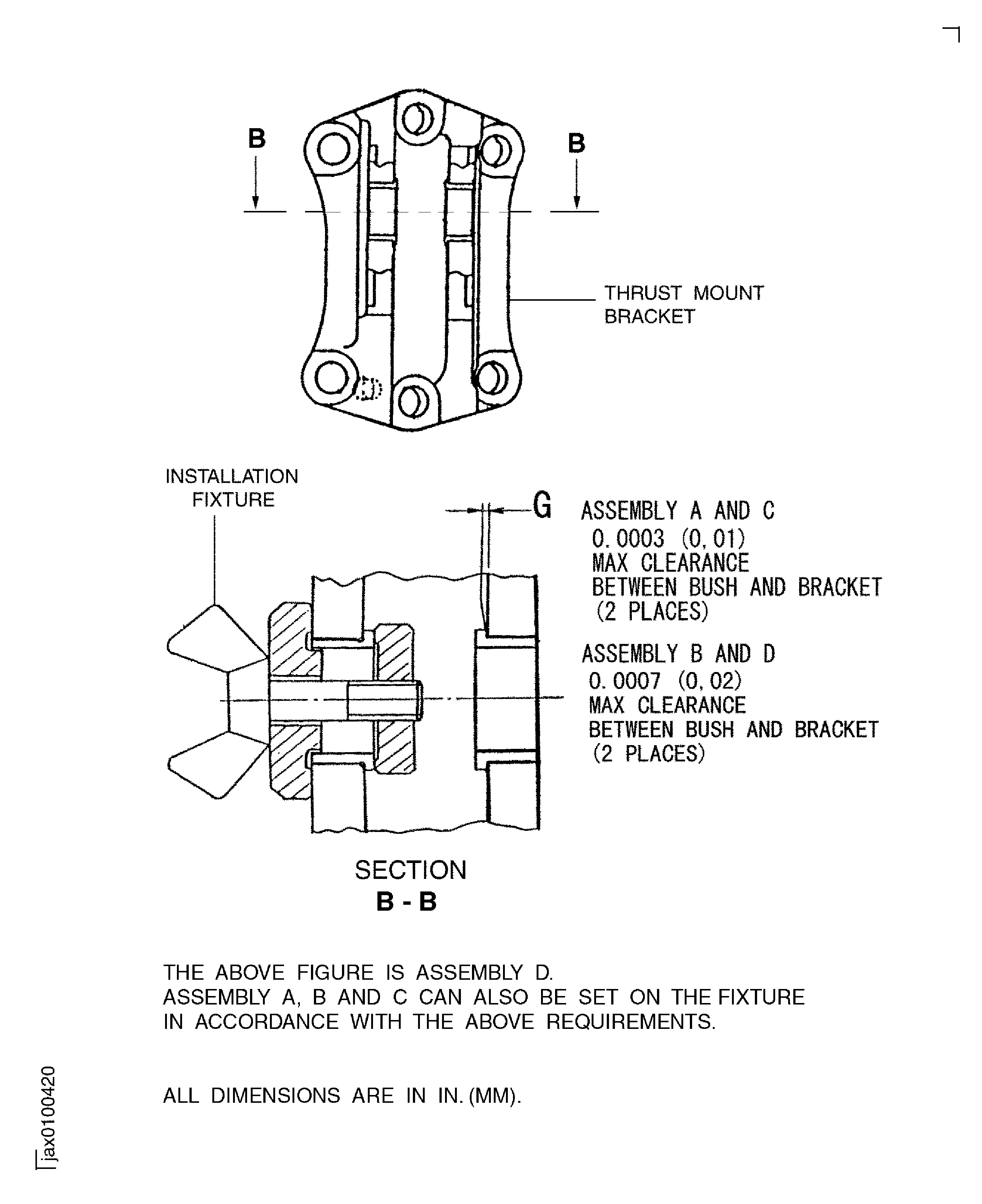

Figure: Position of setting up installation fixture and dimension of clearance between thrust mount bracket and bush

Position of setting up installation fixture and dimension of clearance between thrust mount bracket and bush

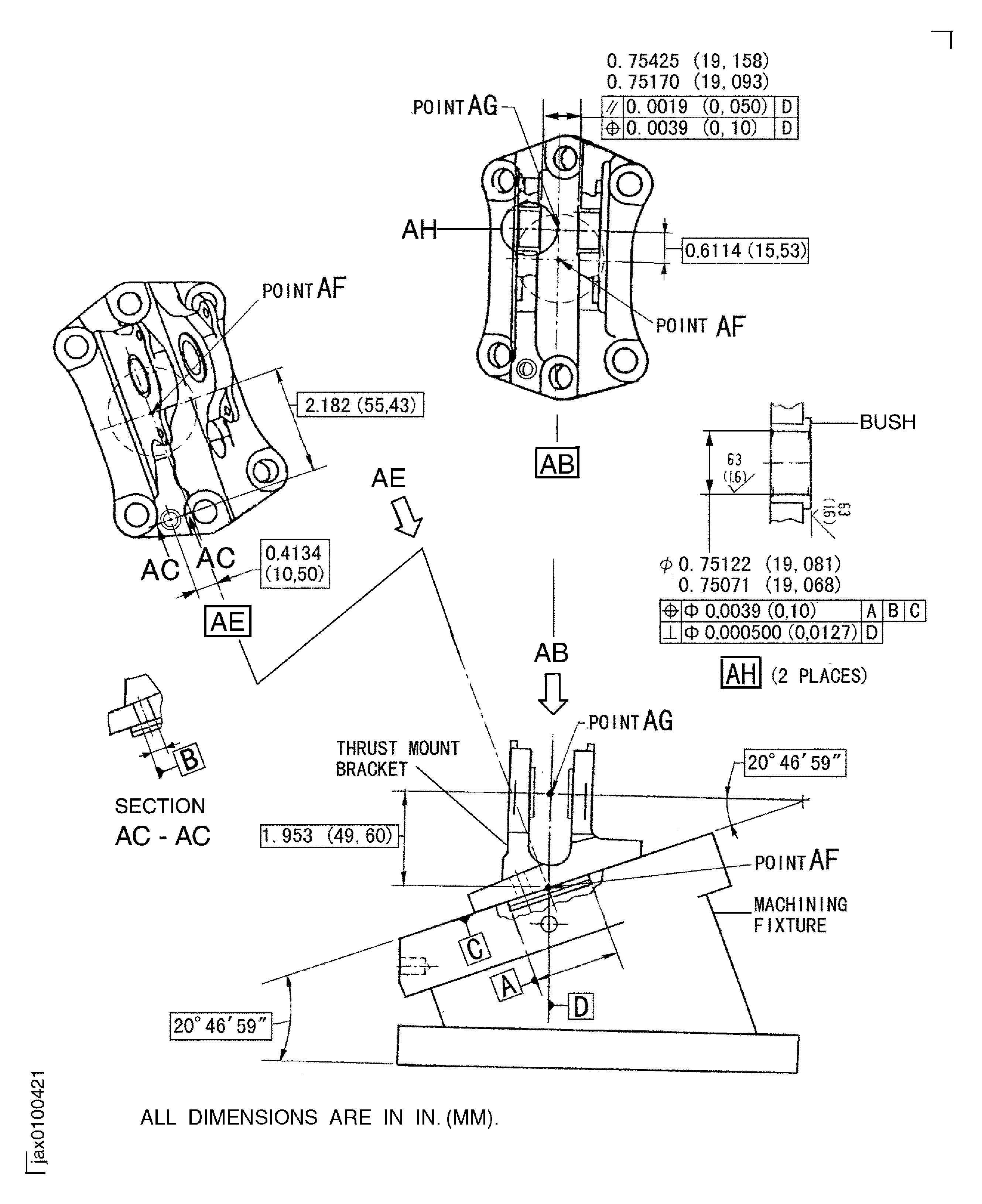

Figure: Details and dimensions for repair - Assembly A

Details and dimensions for repair - Assembly A

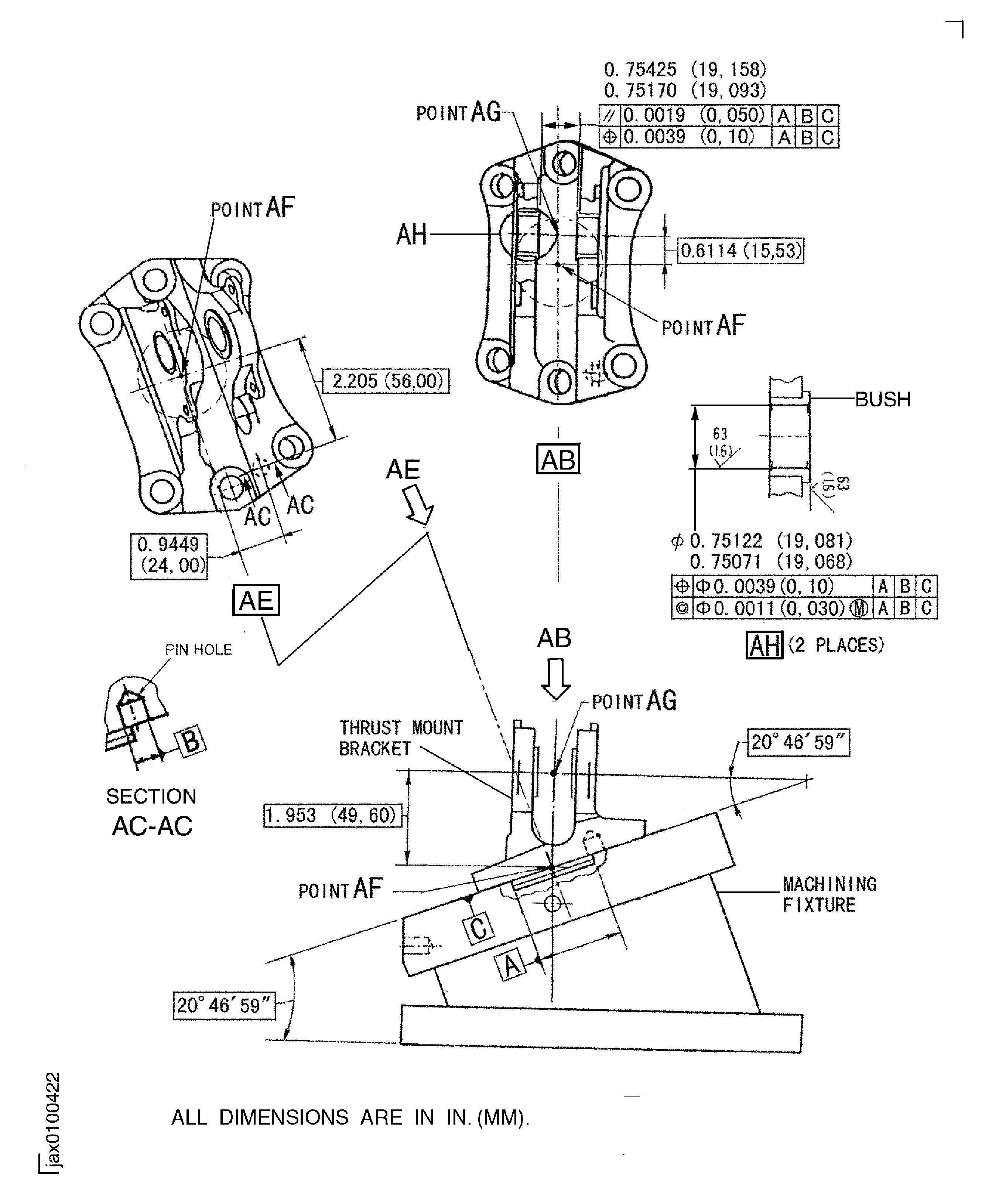

Figure: Details and dimensions for repair - Assembly B

Details and dimensions for repair - Assembly B

Figure: Details and dimensions for repair - Assembly C

Details and dimensions for repair - Assembly C

Figure: Details and dimensions for repair - Assembly D

Details and dimensions for repair - Assembly D