Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-40-450-002 HP System Module Components - Install The Active Clearance Control (ACC) Actuator, Installation-012

General

The TASK gives the procedure to install the active clearance control (ACC) actuator.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

For standard torque data and procedure refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

For lockwire data and procedure refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITEM) Pub ref ITE-V2500-1IA for the illustrations of the special tools used in this procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

Do not remove the special plastic from electrical connections or tube connections which are not applicable in this procedure. This will give protection from unwanted material.

Apply CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL or CoMat 10-110 HIGH TEMPERATURE ANTI-SEIZE COMPOUND to all the threads and abutment faces of nuts and bolts unless other lubricants are referred to in this procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 | ||

| CoMat 02-149 DRY ICE | LOCAL | CoMat 02-149 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | LOCAL | CoMat 10-094 | ||

| CoMat 10-110 HIGH TEMPERATURE ANTI-SEIZE COMPOUND | K6835 | CoMat 10-110 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Packing | 1 | |||

| Packing | 1 | |||

| Packing | 1 | |||

| Packing | 1 | |||

| Packing | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

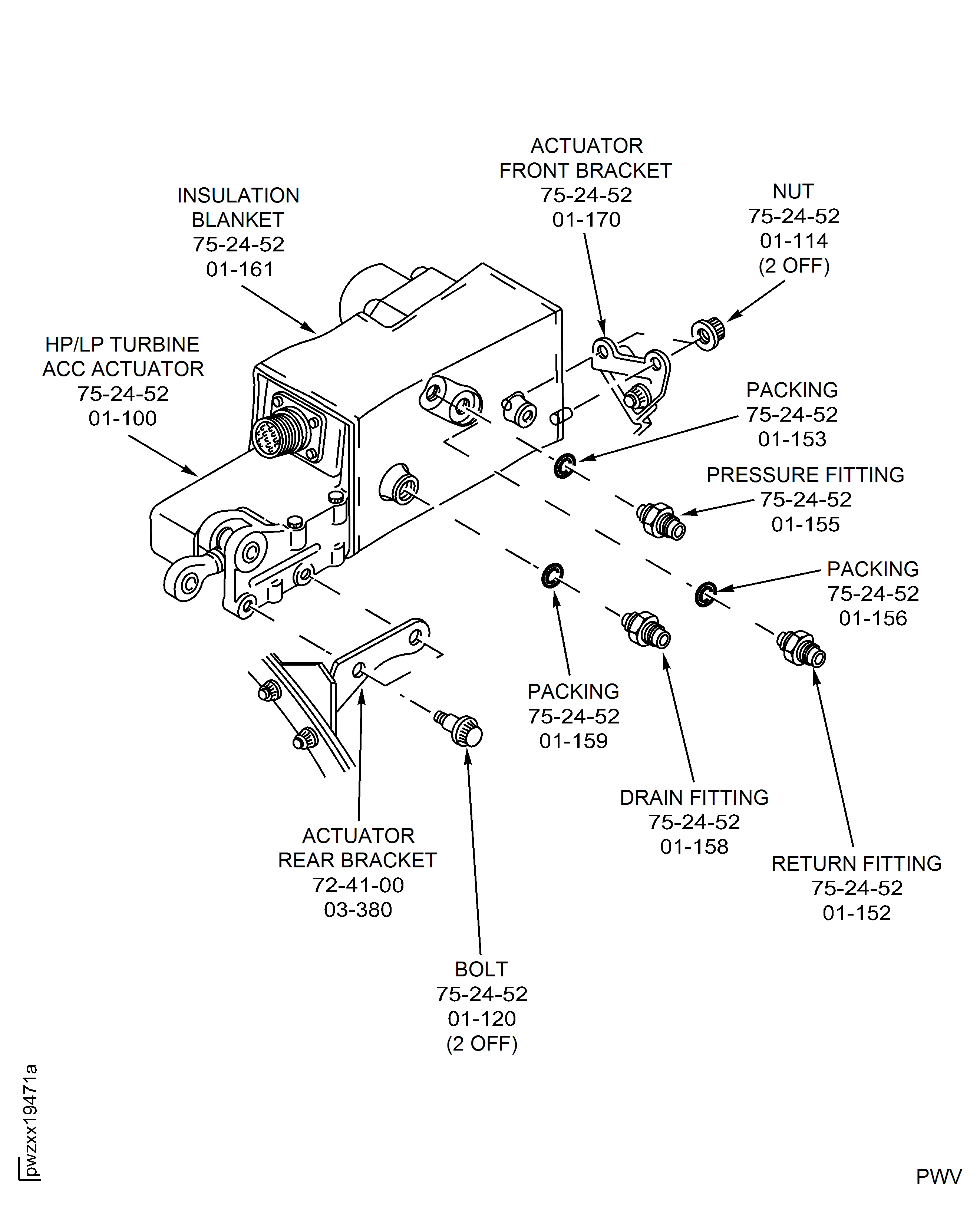

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-159) 1 off to the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158).

Install the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) into the actuator drain cavity.

Torque the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) to between 130 and 150 lbf.in (15 and 16.95 Nm).

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-158)1 off to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155).

Install the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) into the actuator pressure cavity.

Torque the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) to between 180 and 200 lbf.in (20.00 and 22.60 Nm).

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-153)1 off to the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152).

Install the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) into the actuator return cavity.

Torque the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) to between 210 and 230 lbf.in (23.73 and 28.00 Nm).

Safety the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) with CoMat 02-126 LOCKWIRE.

Safety the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) with CoMat 02-126 LOCKWIRE.

Connect the three fittings.

Install the insulation blanket Active Clearance Control (ACC) Actuator (75-24-52, 01-161) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Safety the insulation blanket Active Clearance Control (ACC) Actuator (75-24-52, 01-161) with CoMat 02-126 LOCKWIRE.

Install the insulation blanket to the ACC actuator.

Carefully install the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) on the actuator front bracket Active Clearance Control (ACC) Actuator (75-24-52, 01-170) and the actuator rear bracket HPC Assembly (72-41-00, 03-380) and install the two nuts Active Clearance Control (ACC) Actuator (75-24-52, 01-114) and the two bolts Active Clearance Control (ACC) Actuator (75-24-52, 01-120).

Torque the two bolts Active Clearance Control (ACC) Actuator (75-24-52, 01-120) and the two nuts Active Clearance Control (ACC) Actuator (75-24-52, 01-114) to between 85 and 105 lbf.in (10 and 12 Nm).

Install the ACC actuator.

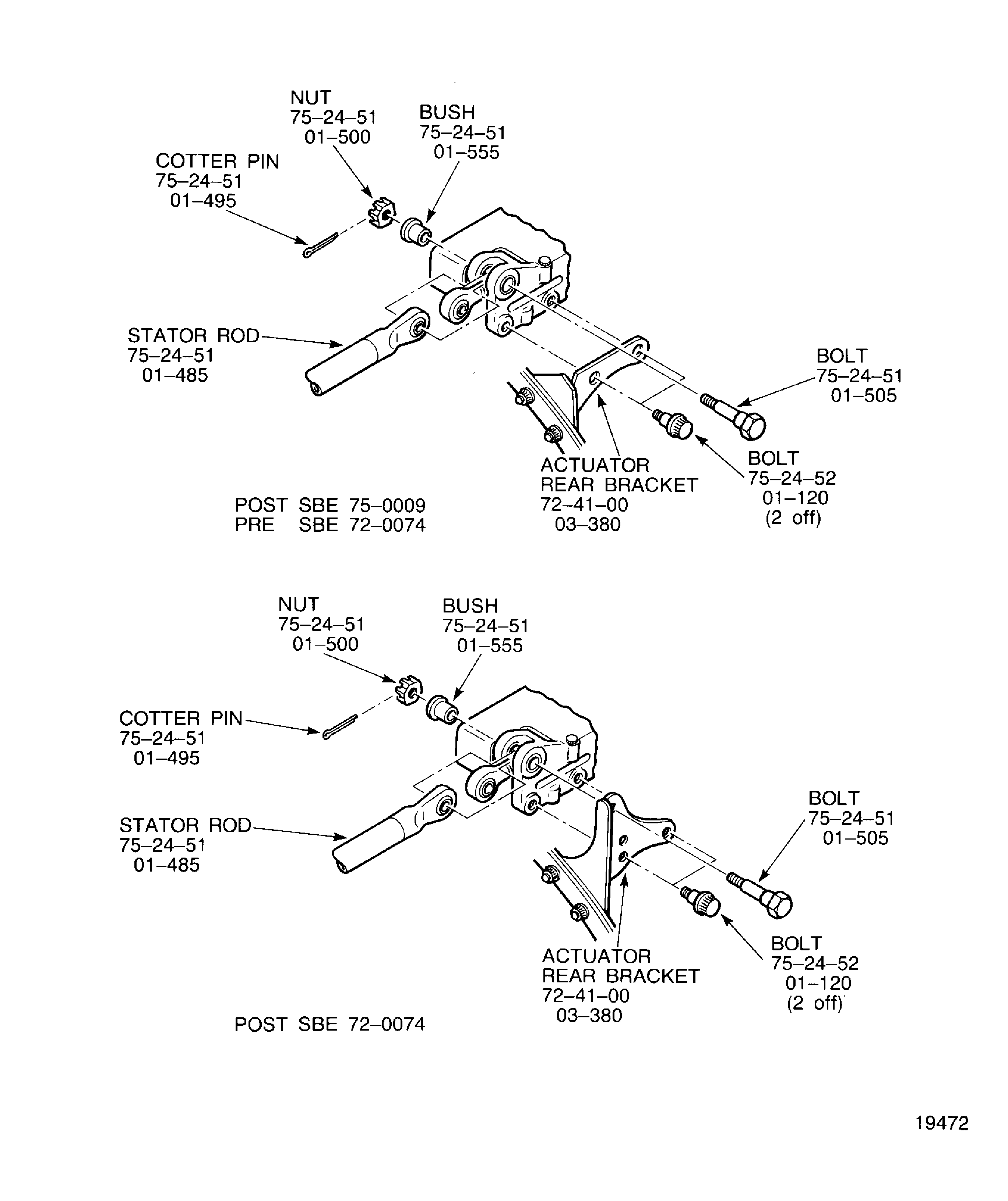

Use CoMat 02-149 DRY ICE to chill the two bushes Active Clearance Control (ACC) Valve (75-24-51, 01-555) for 15 minutes.

Put the stator rod Active Clearance Control (ACC) Valve (75-24-51, 01-485) between the holes of the ACC actuator.

Install the two bushes in to the holes of the ACC actuator.

Align the holes of the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) and stator rod Active Clearance Control (ACC) Valve (75-24-51, 01-485). Install the bolt Active Clearance Control (ACC) Valve (75-24-51, 01-505) and the nut Active Clearance Control (ACC) Valve (75-24-51, 01-500).

Torque the nut Active Clearance Control (ACC) Valve (75-24-51, 01-500) to between 32.5 and 42.5 * lbf.in (3.67 and 4.8 Nm).

Safety the nut with a new cotter pin Active Clearance Control (ACC) Valve (75-24-51, 01-495) 1 off.

Connect the stator rod.

Align the holes of the rod end of the ACC actuator and actuator rod Active Clearance Control (ACC) Valve (75-24-51, 01-400). Install the two bushes Active Clearance Control (ACC) Valve (75-24-51, 01-470), the bolt Active Clearance Control (ACC) Valve (75-24-51, 01-420) and the nut Active Clearance Control (ACC) Valve (75-24-51, 01-415).

Torque the nut Active Clearance Control (ACC) Valve (75-24-51, 01-415) to between 22.5 and 30 * lbf.in ((2.54 and 3.39 Nm).

Safety the nut with a new cotter pin Active Clearance Control (ACC) Valve (75-24-51, 01-410) 1 off.

Connect the actuator rod.

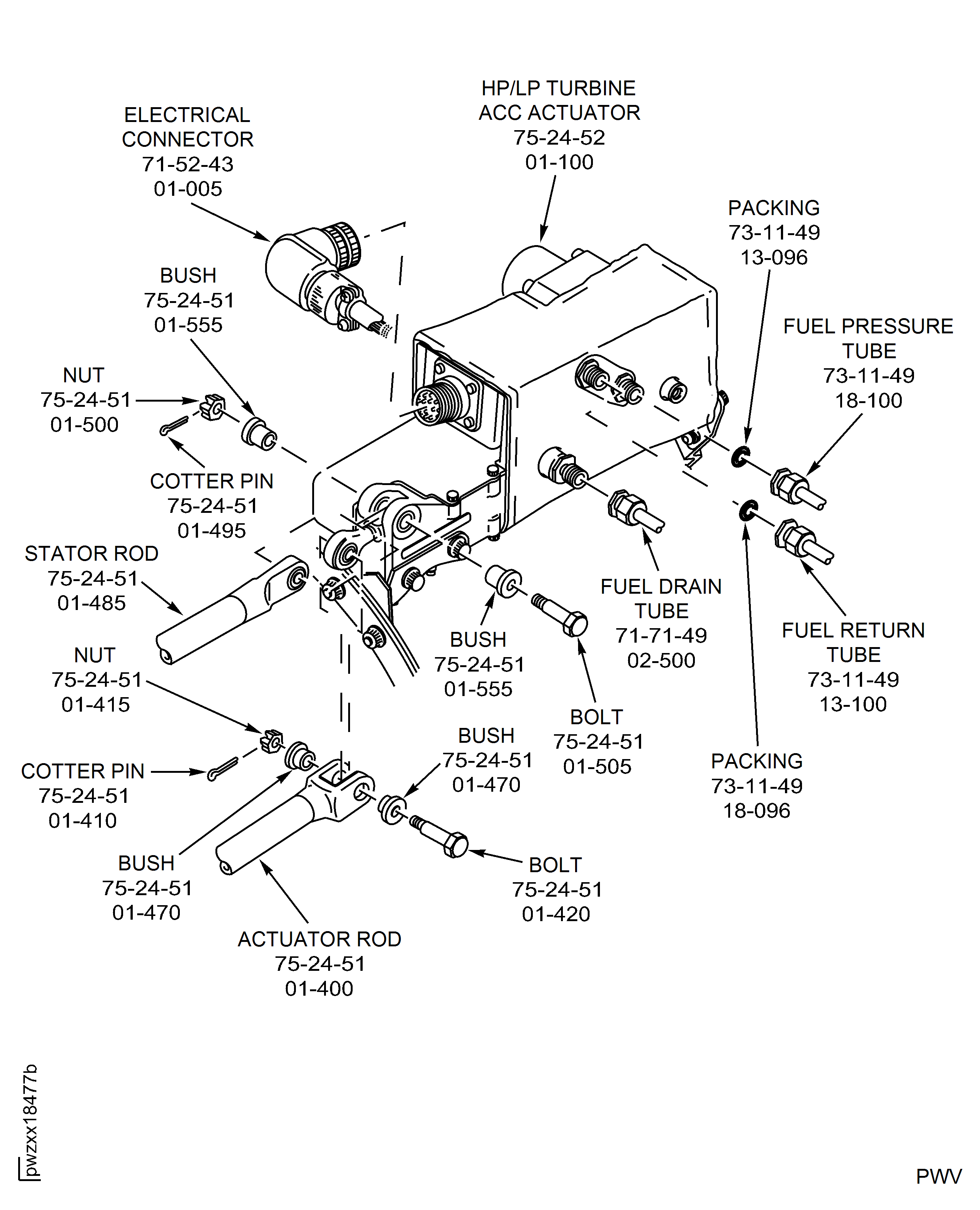

Install the new packing Control Fuel Tubes (73-11-49, 18-096)1 off to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155).

Connect the fuel pressure tube Control Fuel Tubes (73-11-49, 18-100) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel pressure tube.

Connect the fuel drain tube POWER PLANT-FUEL DRAIN TUBES-ENGINE (71-71-49, 02-500) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel drain tube.

Install the new packing Control Fuel Tubes (73-11-49, 13-096)1 off to the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-153).

Connect the fuel return tube Control Fuel Tubes (73-11-49, 13-100) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel return tube.

Connect the electrical connector EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 01-005) to the ACC actuator.

SUBTASK 72-00-40-450-052-A00 Install the Active Clearance Control (ACC) Actuator (Pre SBE 75-0009 and Pre SBE 72-0074)

Refer to Figure.

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-159)1 off to the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158).

Install the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) into the actuator drain cavity.

Torque the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) to between 130 and 150 lbf.in (15 and 16.95 Nm).

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-156)1 off to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155).

Install the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) into the actuator pressure cavity.

Torque the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) to between 180 and 200 lbf.in (20.00 and 22.60 Nm).

Install the new packing Active Clearance Control (ACC) Actuator (75-24-52, 01-153)1 off to the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152).

Install the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) into the actuator return cavity.

Torque the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) to between 210 and 230 lbf.in (23.73 and 26.00 Nm).

Safety the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-152) to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155) with CoMat 02-126 LOCKWIRE.

Safety the drain fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-158) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) with CoMat 02-126 LOCKWIRE.

Connect the three fittings.

Install the insulation blanket Active Clearance Control (ACC) Actuator (75-24-52, 01-161) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Safety the insulation blanket Active Clearance Control (ACC) Actuator (75-24-52, 01-161) with CoMat 02-126 LOCKWIRE.

Install the insulation blanket to the ACC actuator.

Carefully install the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) on the actuator front bracket Active Clearance Control (ACC) Actuator (75-24-52, 01-170) and the actuator rear bracket HPC Assembly (72-41-00, 03-380) and install the two nuts Active Clearance Control (ACC) Actuator (75-24-52, 01-114) and the two bolts Active Clearance Control (ACC) Actuator (75-24-52, 01-120).

Torque the two bolts Active Clearance Control (ACC) Actuator (75-24-52, 01-120) and the two nuts Active Clearance Control (ACC) Actuator (75-24-52, 01-114) to between 85 and 105 lbf.in (10 and 12 Nm).

Install the ACC actuator.

Use CoMat 02-149 DRY ICE to chill the bush Active Clearance Control (ACC) Valve (75-24-51, 01-555) for 15 minutes.

Put the stator rod Active Clearance Control (ACC) Valve (75-24-51, 01-485) between the holes of the ACC actuator.

Install the bush in to the hole of the ACC actuator.

Align the holes of the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100) and stator rod Active Clearance Control (ACC) Valve (75-24-51, 01-485). Install the bolt Active Clearance Control (ACC) Valve (75-24-51, 01-505) and the nut Active Clearance Control (ACC) Valve (75-24-51, 01-500).

Torque the nut Active Clearance Control (ACC) Valve (75-24-51, 01-500) to between 32.5 and 42.5 * lbf.in (3.67 and 4.8 Nm).

Safety the nut with a new cotter pin Active Clearance Control (ACC) Valve (75-24-51, 01-495) 1 off.

Connect the stator rod.

Align the holes of the rod end of the ACC actuator and the actuator rod Active Clearance Control (ACC) Valve (75-24-51, 01-400). Install the two bushes Active Clearance Control (ACC) Valve (75-24-51, 01-470), the bolt Active Clearance Control (ACC) Valve (75-24-51, 01-420) and the nut Active Clearance Control (ACC) Valve (75-24-51, 01-415).

Torque the nut Active Clearance Control (ACC) Valve (75-24-51, 01-415) to between 22.5 and 30 * lbf.in (2.54 and 3.39 Nm).

Safety the nut with a new cotter pin Active Clearance Control (ACC) Valve (75-24-51, 01-410) 1 off.

Connect the actuator rod.

Install the new packing Control Fuel Tubes (73-11-49, 18-096)1 off to the pressure fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-155).

Connect the fuel pressure tube Control Fuel Tubes (73-11-49, 18-100) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel pressure tube.

Connect the fuel drain tube POWER PLANT-FUEL DRAIN TUBES-ENGINE (71-71-49, 02-500) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel drain tube.

Install the new packing Control Fuel Tubes (73-11-49, 13-096)1 off to the return fitting Active Clearance Control (ACC) Actuator (75-24-52, 01-153).

Connect the fuel return tube Control Fuel Tubes (73-11-49, 13-100) to the ACC actuator Active Clearance Control (ACC) Actuator (75-24-52, 01-100).

Connect the fuel return tube.

Connect the electrical connector EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 01-005) to the ACC actuator.

SUBTASK 72-00-40-450-052-B00 Install the Active Clearance Control (ACC) Actuator (SBE 75-0009 and SBE 72-0074)

Refer to Figure.

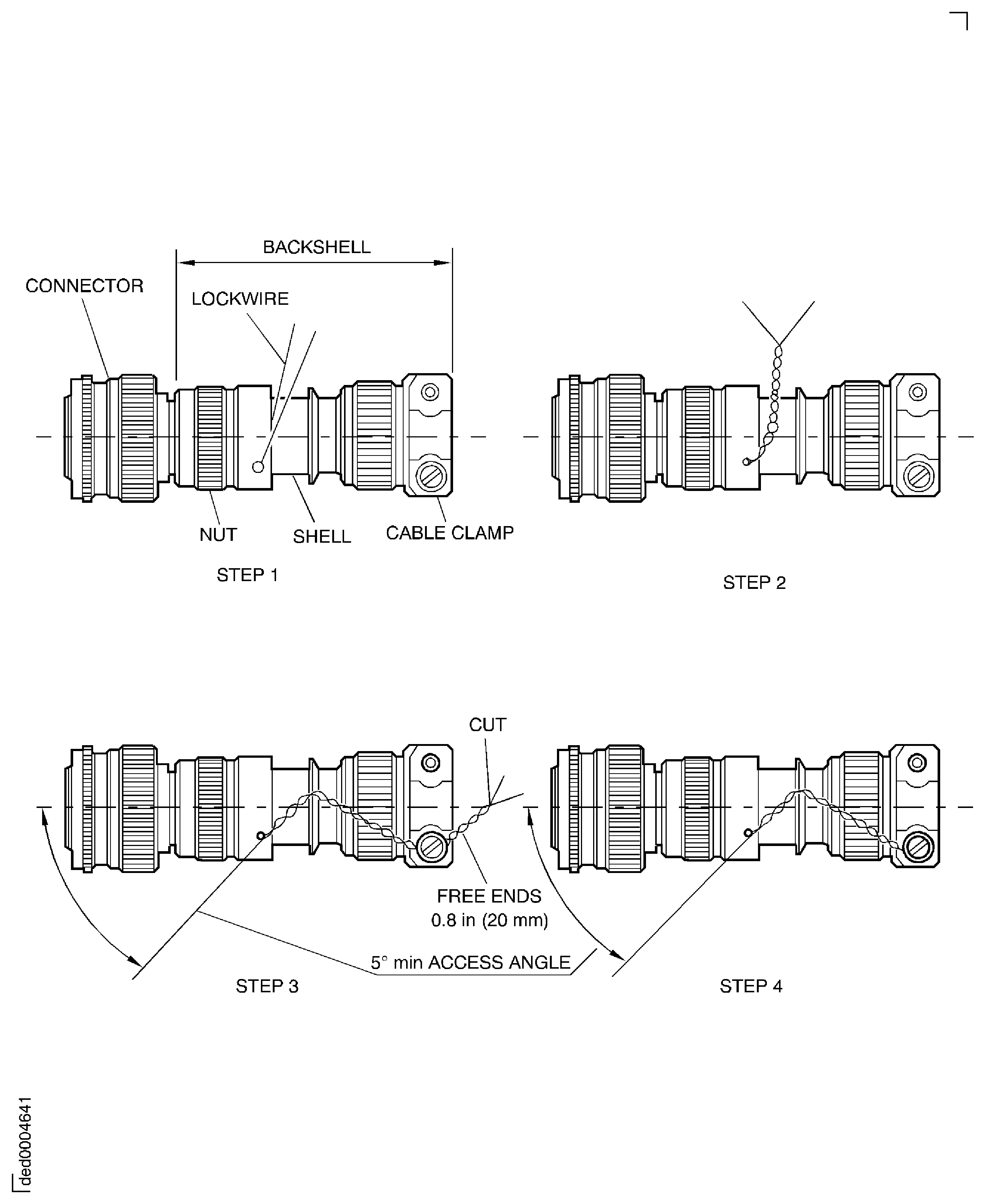

Pre SBE 70-0813 : Make sure that the backshell and cable clamp is safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SBE 70-0813 : Make sure the backshell and cable clamp is safetied with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

SUBTASK 72-00-40-210-068 Visually Inspect the EEC Harness Connector Electrical Backshell and Cable Clamp (SBE 70-0813)

Figure: Install The Active Clearance Control (ACC) Actuator

Install The Active Clearance Control (ACC) Actuator

Figure: Install The Active Clearance Control (ACC) Actuator

Install The Active Clearance Control (ACC) Actuator

Figure: Install the active clearance control (ACC) actuator

Install the active clearance control (ACC) actuator

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps