Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-013 LPC Fan Blade - Replace The Chocking Pads, Repair-013 (VRS1028)

General

The practices and processes referred to in the procedure by the TASK number are in SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-024 BARIUM CHROMATE BaCrO4 | 70657 | CoMat 01-024 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-060 ACETONE (CH3)2CO | LOCAL | CoMat 01-060 | ||

| CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER | LOCAL | CoMat 01-201 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 05-004 ABRASIVE MEDIUM, ALUMINUM OXIDE, 140/400 GRADE | IE241 | CoMat 05-004 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | K6835 | CoMat 05-017 | ||

| CoMat 06-021 SURFACE INSPECTION FLUID | LOCAL | CoMat 06-021 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Front chocking pad assembly | 6A2787 | 1 | ||

| Rear chocking pad assembly | 6A3495 | 1 |

Safety Requirements

NONEProcedure

Refer to TASK 72-31-11-100-000 (CLEANING-000) for the applicable cleaning TASK. Use non metallic scraper.

Remove adhesive residue.

SUBTASK 72-31-11-110-058 Remove Adhesive Residue from the Bottom of the Blade Root

Refer to TASK 72-31-11-200-000 (INSPECTION/CHECK-000) for the applicable Inspection/Check TASK.

Use fluorescent penetrant inspection equipment.

CAUTION

FOLLOWING THE CRACK TEST PROCEDURE ENSURE THAT FLUORESCENT PENETRANT IS THOROUGHLY REMOVED FROM THE FAN BLADE ROOT COATING.Fluorescent penetrant examine the blade root.

SUBTASK 72-31-11-230-057 Examine the Fan Blade Assembly for Cracks

Refer to: Figure

Refer to SPM TASK 70-11-26-300-503.

Swab degrease the bonding areas.

Use an air pressure of 20 psi (140 Kpa) for the minimum time necessary to clean the parts.

Refer to SPM TASK 70-12-02-120-501.

Use abrasive blast equipment.

Overspray is not permitted.

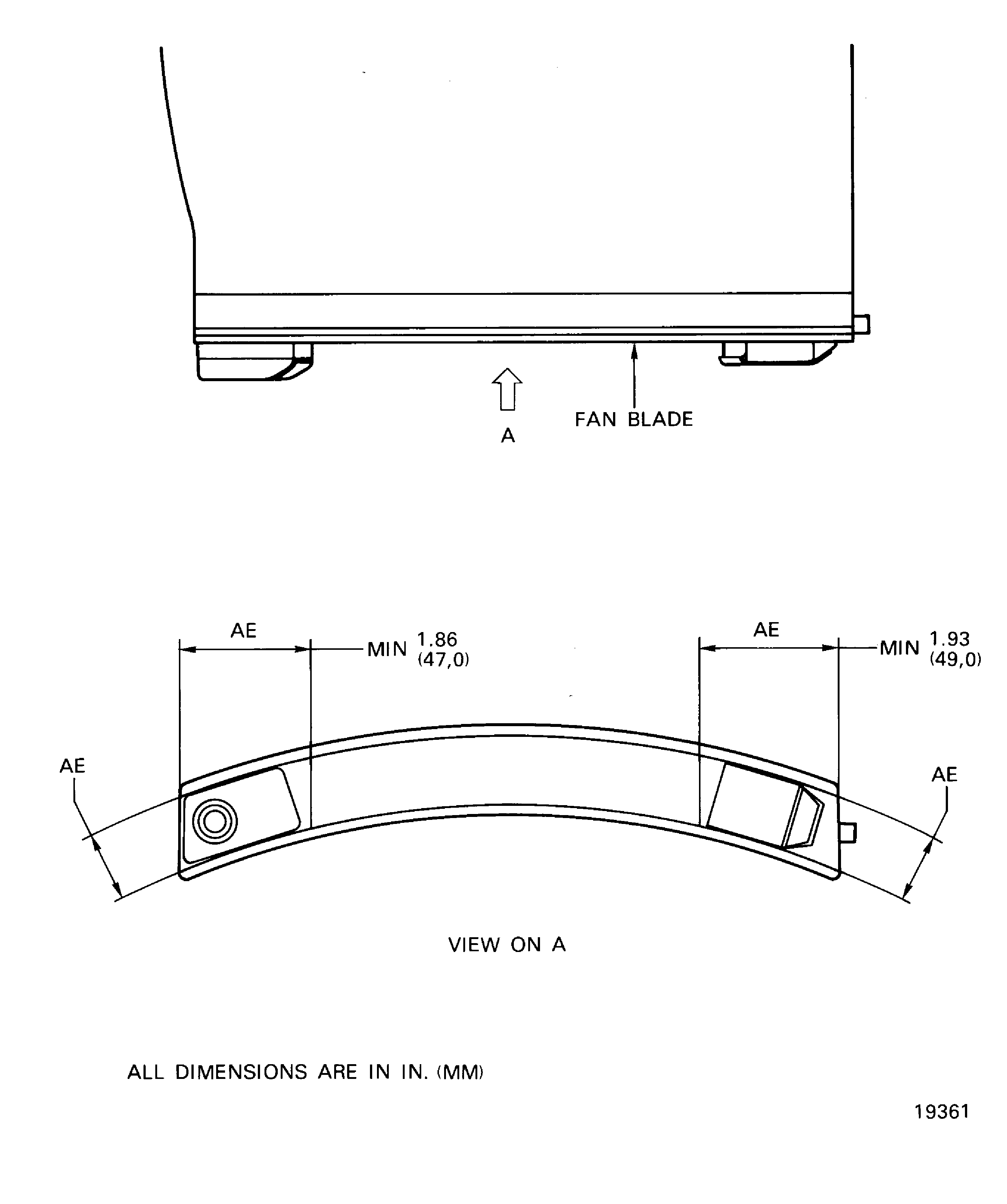

Dry abrasive blast surface areas enclosed by dimensions AE (bottom of the blade root).

Use a clean soft hair brush with clean CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER.

Refer to SPM TASK 70-36-02-360-501.

Do a water break test to make sure that the bonding surfaces are clean.

SUBTASK 72-31-11-110-059 Prepare the LPC Rotor Blade for Bonding, Assembly A

Refer to Figure.

Refer to SPM TASK 70-11-26-300-503.

Swab degrease the bonding areas.

Refer to SPM TASK 70-36-02-360-501.

Do a water break test to make sure that the bonding surfaces are clean.

Refer to SPM TASK 70-36-02-360-501.

Remove the break test fluid by swabbing.

SUBTASK 72-31-11-110-092 Prepare the LPC Rotor Blade for Bonding, Assembly B

Refer to SPM TASK 70-36-02-360-501.

Hand clean the bonding surface of the chocking pads.

SUBTASK 72-31-11-360-051 Prepare the Chocking Pad for Bonding

Refer to SPM TASK 70-36-02-360-501.

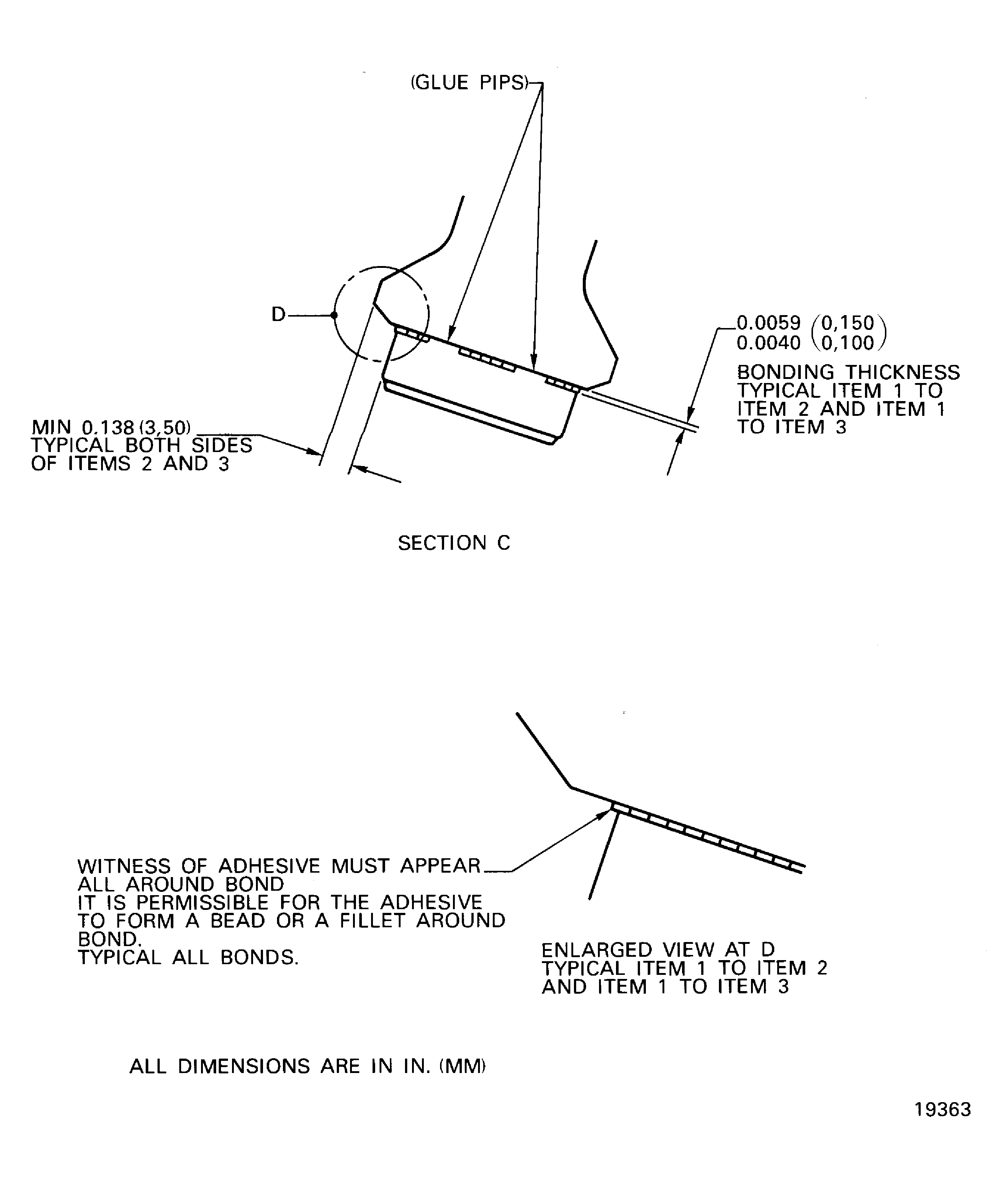

Apply a thin layer of primer to each of the prepared mating surfaces of the blade and the chocking pads. Dry in air for 30 minutes.

Use a corrugated scraper.

Refer to SPM TASK 70-36-02-360-501.

Apply the cold curing silicone compound, to each of the mating surfaces of the fan blade and the chocking pads.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) to hold the chocking pad in position.

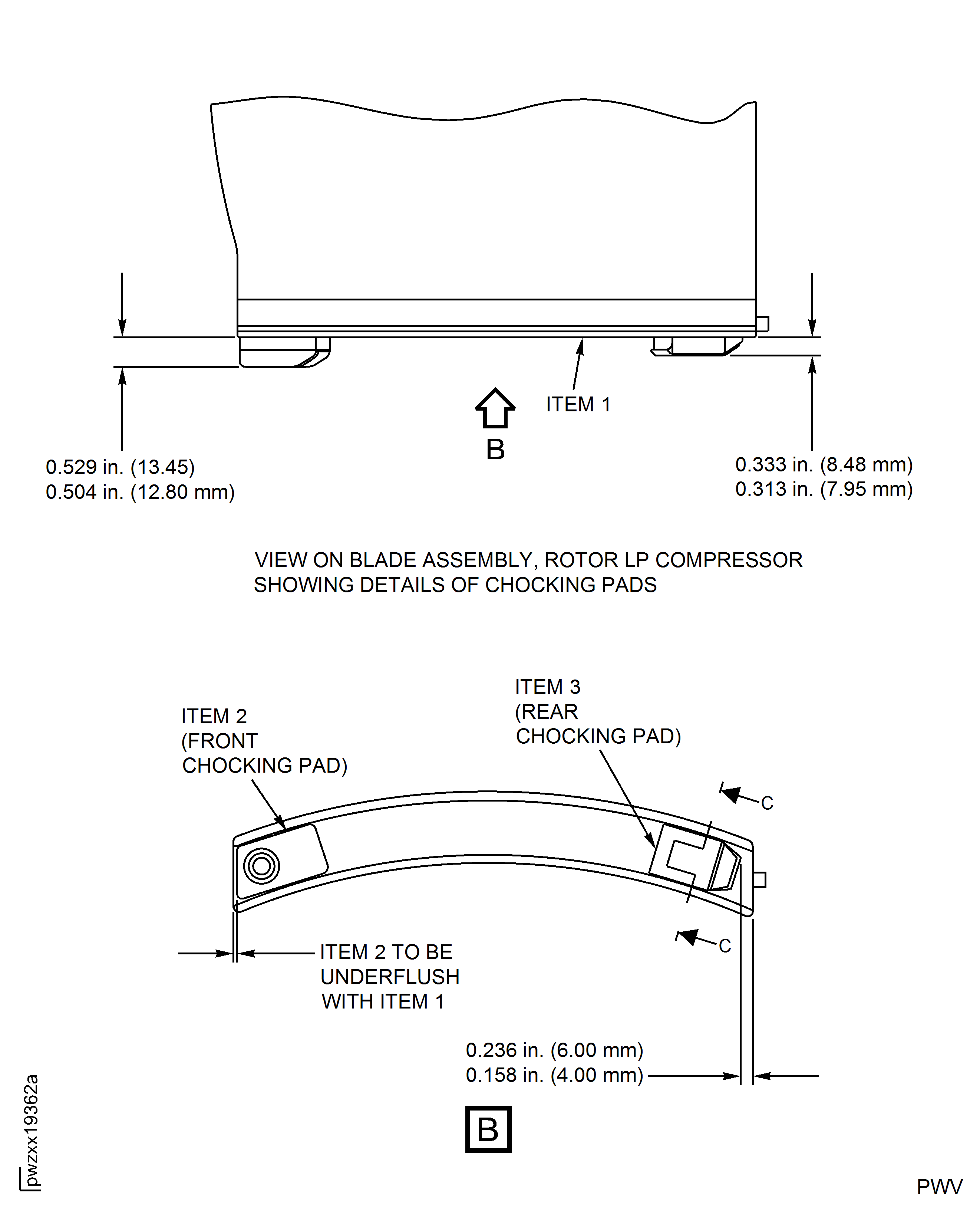

Assemble the front and rear chocking pads to the fan blade immediately.

SUBTASK 72-31-11-360-052 Apply and Cure the Cold Curing Silicone Rubber Compounds

CAUTION

YOU MUST NOT EAT ANYTHING OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.

Figure: Replace the Front and Rear Chocking Pads

Replace the Front and Rear Chocking Pads

Figure: Replace the Front and Rear Chocking Pads

Replace the Front and Rear Chocking Pads

Figure: Replace the Front and Rear Chocking Pads

Replace the Front and Rear Chocking Pads