Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-23-300-007 Rotor Center Ring Seal Carrier Assembly - Replace The Flame Deposition Material, Repair-007 (VRS6111)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-720 | 6A2238 | Assembly A |

01-720 | 6A3890 | Assembly A |

01-720 | 6A3902 | Assembly A |

01-720 | 6A3916 | Assembly B |

General

This Repair must only be done when the instruction to do so is given in TASK 72-32-23-200-000 (INSPECTION-000).

This Repair is to replace the lining on the HP Compressor Seal Ring Carrier Assembly by Metal Spray.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability - none

Refer to International Aero Engines

Related repairs

HP Compressor Seal Ring Carrier Assembly - Repair or Replace the Surface Protection, refer to Repair VRS6119, TASK 72-32-23-300-012 (REPAIR-012).

NOTE

Equivalent equipment can be used.

More equipment and materials necessary to do this Repair are in TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Non-metallic scraper | LOCAL | Non-metallic scraper | ||

| Chemical strip equipment | LOCAL | Chemical strip equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Degreasing equipment | LOCAL | Degreasing equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Rockwell A (HRA) tester | LOCAL | Rockwell A (HRA) tester | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R18725 Turn/Grind Fixture | 0AM53 | IAE 3R18725 | 1 | |

| IAE 3R18729 Clamp plate | 0AM53 | IAE 3R18729 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-237 DELETED | 0AM53 | CoMat 03-237 | ||

| CoMat 03-229 METAL SPRAYING POWDER | LOCAL | CoMat 03-229 | ||

| CoMat 05-130 ABRASIVE DELETED | 0AM53 | CoMat 05-130 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Use IAE 3R18725 Turn/Grind Fixture 1 off with a Lathe.

Make sure the location surface runs true.

Use a Dial test indicators.

Install the turning fixture on the machine.

Use IAE 3R18729 Clamp plate 1 off.

Make sure the HP Compressor seal ring carrier assembly runs true.

Use a Dial test indicators.

Mount the HP Compressor seal ring carrier assembly on the fixture and clamp in place.

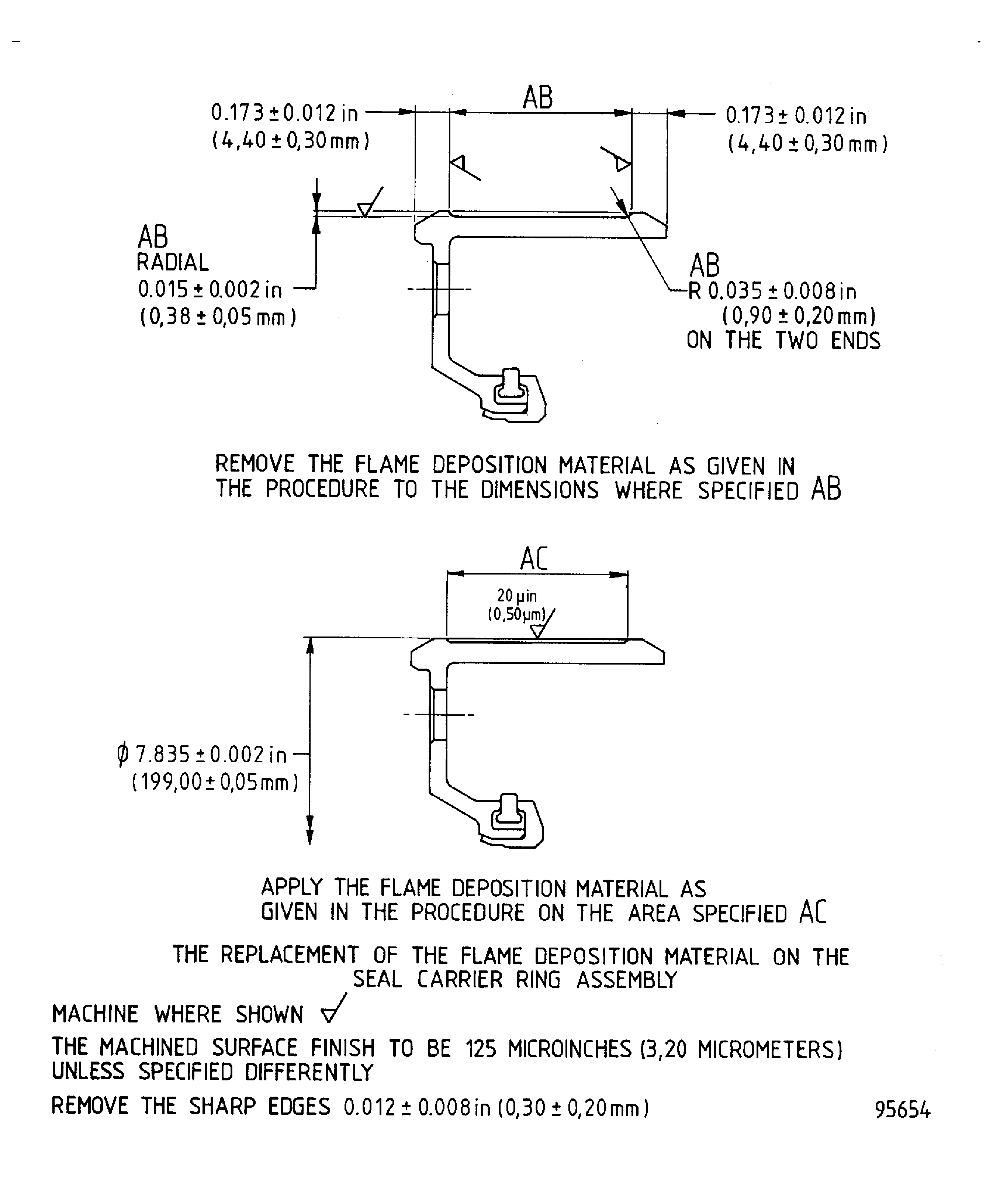

SUBTASK 72-32-23-325-051-A00 Remove the Lining, Assembly A

Refer to Figure.

Use IAE 3R18725 Turn/Grind Fixture 1 off with a Lathe.

Make sure the location surface runs true.

Use a Dial test indicators.

Install the turning fixture on the machine.

Use IAE 3R18729 Clamp plate 1 off.

Make sure the HP Compressor seal ring carrier assembly runs true.

Use a Dial test indicators.

Mount the HP Compressor seal ring carrier assembly on the fixture and clamp in place.

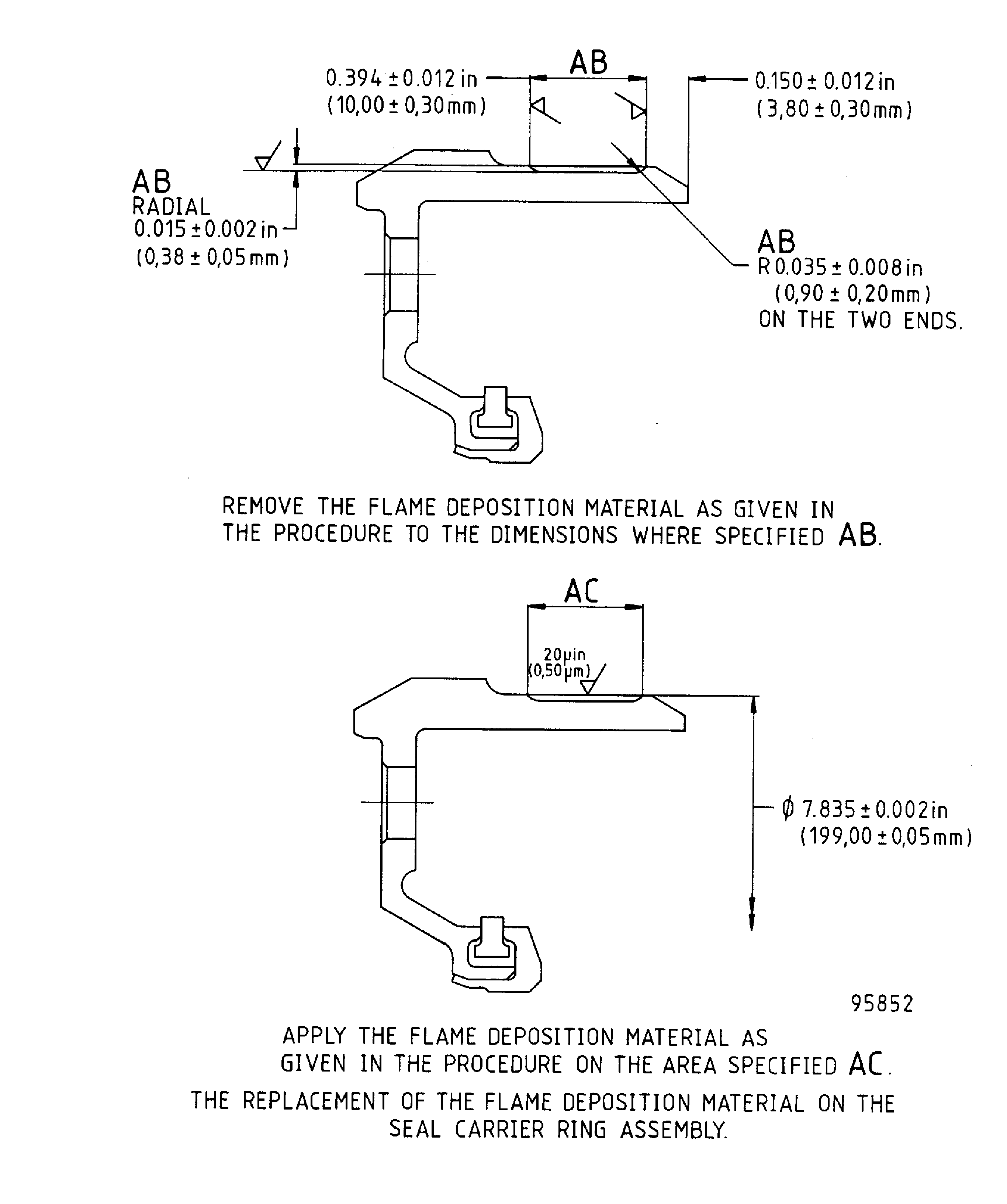

SUBTASK 72-32-23-325-051-B00 Remove the Lining, Assembly B

Refer to Figure

Use a Non-metallic scraper.

Remove the remaining bond coat by hand.

SUBTASK 72-32-23-350-056-A00 Remove the Bond Coat, Assembly A

NOTE

This SUBTASK is an alternative to Step.Refer to Figure.

Use a Non-metallic scraper.

Remove the remaining bond coat by hand.

SUBTASK 72-32-23-350-056-B00 Remove the Bond Coat, Assembly B

NOTE

This SUBTASK is an alternative to Step.Refer to Figure.

Refer to the SPM TASK 70-33-59-300-503.

Use chemical strip equipment.

Remove the remaining bond coat by chemical strip.

SUBTASK 72-32-23-330-051-A00 Remove the Bond Coat, Assembly A

NOTE

This SUBTASK is an alternative to Step.Refer to Figure.

Refer to the SPM TASK 70-33-59-300-503.

Use chemical strip equipment.

Remove the remaining bond coat by chemical strip.

SUBTASK 72-32-23-330-051-B00 Remove the Bond Coat, Assembly B

NOTE

This SUBTASK is an alternative to Step.Refer to Figure.

SUBTASK 72-32-23-220-074-A00 Examine, Assembly A

Refer to Figure.

SUBTASK 72-32-23-220-074-B00 Examine, Assembly B

Refer to the SPM TASK 70-23-04-230-501.

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-32-23-230-060 Do a Crack Test

Refer to the SPM TASK 70-11-01-300-503.

Use degreasing equipment.

Chemically clean the seal ring carrier assembly.

SUBTASK 72-32-23-110-056 Clean the HP Compressor Seal Ring Carrier Assembly

Refer to Figure.

Refer to the SPM TASK 70-12-02-120-501.

Use abrasive blast equipment.

Abrasive blast areas to be sprayed.

SUBTASK 72-32-23-120-051-A00 Abrasive Blast, Assembly A

Refer to Figure.

Refer to the SPM TASK 70-12-02-120-501.

Use abrasive blast equipment.

Abrasive blast areas to be sprayed.

SUBTASK 72-32-23-120-051-B00 Abrasive Blast, Assembly B

Refer to Figure

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002 and SUBTASK 70-34-01-340-025.

Apply the coat to a thickness of 0.003 to 0.005 in. (0.076 to 0.128 mm).

Use metal spray equipment.

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002, SUBTASK 70-34-01-340-004 and SUBTASK 70-34-01-340-031.

Apply the final coat to a thickness.

of 0.013 to 0.017 in. (0.33 to 0.43 mm), sufficient to allow for machining.

Use metal spray equipment.

Apply the final coat.

SUBTASK 72-32-23-340-051-A00 Apply the Sprayed Coat, assembly A

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501 , SUBTASK 70-34-01-340-002 and SUBTASK 70-34-01-340-025.

Apply the coat to a thickness of 0.003 to 0.005 in. (0.076 to 0.128 mm).

Use metal spray equipment.

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002, SUBTASK 70-34-01-340-004 and SUBTASK 70-34-01-340-031.

Apply the final coat to a thickness of 0.013 to 0.017 in. (0.33 to 0.43 mm), sufficient to allow for machining.

Use metal spray equipment.

Apply the final coat.

SUBTASK 72-32-23-340-051-B00 Apply the Sprayed Coat, Assembly B

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-004.

Average hardness value must be 85 to 95 R15N, outer limits 80 min, 100 max.

Use a hardness tester.

Do a hardness test.

SUBTASK 72-32-23-220-075-A00 Examine the Lining, Assembly A

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-004.

Average hardness value must be 85 to 95 R15N, outer limits 80 min, 100 max.

Use a hardness tester.

Do a hardness test.

SUBTASK 72-32-23-220-075-B00 Examine the Lining, Assembly B

Refer to Figure.

Use IAE 3R18725 Turn/Grind Fixture 1 off with a Lathe.

Make sure the location surface runs true.

Use a Dial test indicators.

Install the turning fixture on the machine.

Use IAE 3R18729 Clamp plate 1 off.

Make sure the HP Compressor seal ring carrier assembly runs true.

Use a Dial test indicators.

Mount the HP Compressor seal ring carrier assembly on the fixture and clamp in place.

SUBTASK 72-32-23-325-052-A00 Machine the Sprayed Diameter, Assembly A

Refer to Figure.

Use IAE 3R18725 Turn/Grind Fixture 1 off with a lathe.

Make sure the location surface runs true.

Use a Dial test indicators.

Install the turning fixture on the machine.

Use IAE 3R18729 Clamp plate 1 off.

Make sure the HP Compressor seal ring carrier assembly runs true.

Use a Dial test indicators.

Mount the HP Compressor seal ring carrier assembly on the fixture and clamp in place.

SUBTASK 72-32-23-325-052-B00 Machine the Sprayed Diameter, Assembly B

Refer to the SPM TASK 70-23-04-230-501.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-32-23-230-061 Do a Crack Test

Refer to Repair VRS6119, TASK 72-32-23-300-012 (REPAIR-012).

Apply the surface protection.

SUBTASK 72-32-23-380-053 Apply Surface Protection

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6111 adjacent to the assembly number.

SUBTASK 72-32-23-350-057 Identify the Repair

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly A and B

Repair details and dimensions - Assembly A and B