Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-50-440-001 LP Shaft And Bearing Assembly - Assemble The LP Shafts, No. 1 Bearing, And No. 2 Bearing Assembly, Assembly-001

General

This TASK gives the procedure to assemble the LP shaft, No. 1 and No. 2 Bearing Assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

For surface finish of balance lands refer to the SPM TASK 70-35-09-350-501.

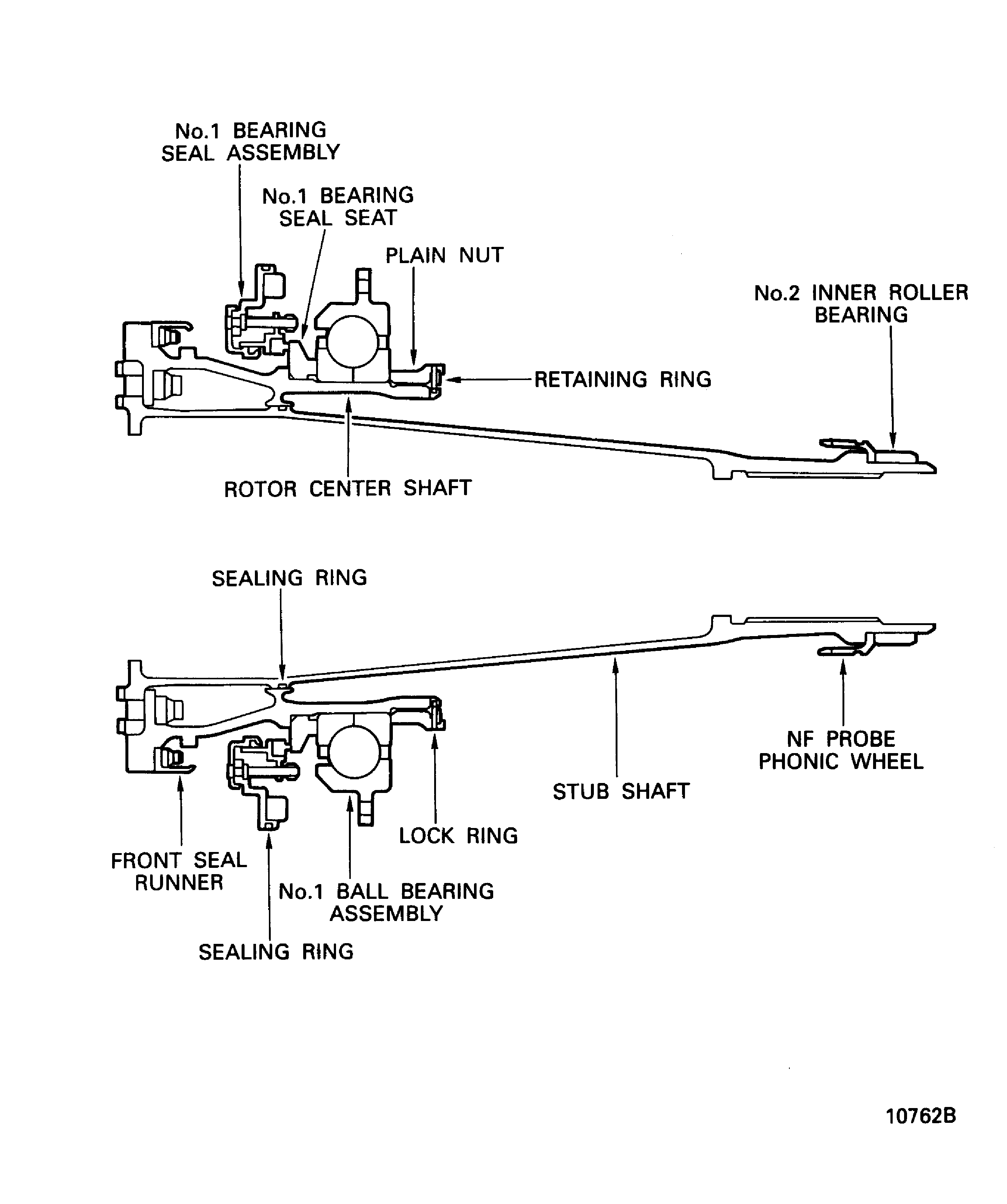

Pre SBE 72-0132 V2500-A1: Refer to Figure for a sectional view of the LP shaft, No. 1 and No. 2 Bearing Assembly.

Post SBE 72-0132 V2500-A1 and V2500-A5: Refer to Figure for a sectional view of the LP shaft, No. 1 and No. 2 Bearing Assembly.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Horizontal Balancing Machine | LOCAL | Schenck HL5U | ||

| Torque multiplier | LOCAL | SWEENEY 8200 | ||

| IAE 1J12106 Aligning pin set | 0AM53 | IAE 1J12106 | 1 | |

| IAE 1J12211 Storage stand | 0AM53 | IAE 1J12211 | 1 | |

| IAE 1J12335 Spanner wrench | 0AM53 | IAE 1J12335 | 1 | |

| IAE 1J12386 Restraint holder | 0AM53 | IAE 1J12386 | 1 | |

| IAE 1J12387 Work stand | 0AM53 | IAE 1J12387 | 1 | |

| IAE 1J12388 Hydraulic pusher | 0AM53 | IAE 1J12388 | 1 | |

| IAE 1J12392 Installation pusher | 0AM53 | IAE 1J12392 | 1 | |

| IAE 1J12394 Balance adapter | 0AM53 | IAE 1J12394 | 1 | |

| IAE 1J12395 Work stand | 0AM53 | IAE 1J12395 | 1 | |

| IAE 1J12397 Front sling | 0AM53 | IAE 1J12397 | 1 | |

| IAE 1J12398 PMI mandrel | 0AM53 | IAE 1J12398 | 1 | |

| IAE 1J12401 No.1 bearing holding plate | 0AM53 | IAE 1J12401 | 1 | |

| IAE 1J12473 Seal holder | 0AM53 | IAE 1J12473 | 1 | (A1 Pre SBE 72-0132) |

| IAE 1J12499 Aligning pin set | 0AM53 | IAE 1J12499 | 1 | (A1 Pre SBE 72-0132) |

| IAE 1J12500 Adapter | 0AM53 | IAE 1J12500 | 1 | (A1 Pre SBE 72-0132) |

| IAE 1J12501 Turnover sling | 0AM53 | IAE 1J12501 | 1 | |

| IAE 1J12506 No.1 bearing guide | 0AM53 | IAE 1J12506 | 1 | |

| IAE 1J12462 Seal holder | 0AM53 | IAE 1J12462 | 1 | (A1 SBE 72-0132 and A5) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Safety Requirements

NONEProcedure

Refer to Figure.

NOTE

The sub-module number follows the letters "SUB MODULE". The serial number is adjacent to the sub-module number.

SUBTASK 72-32-50-220-057 Identify the LP Shaft, No. 1 and No. 2 Bearing Assembly

Refer to Figure.

Reference dimensions at location 0107. If required, use the data written as a note in TASK 72-32-51-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0107

Stub Shaft Assembly ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350)

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100)

Stub Shaft Assembly Outside Diameter

9.8065

Intf

9.8076

0.0015

Rotor Center Shaft Bore Diameter

9.8032

0.0045

9.8049

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0107

Stub Shaft Assembly ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350)

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100)

Stub Shaft Assembly Outside Diameter

249.084

249.113

Intf

Rotor Center Shaft Bore Diameter

249.000

0.113

249.046

SUBTASK 72-32-50-220-054 Reference Fits and Clearances of the LP Stub Shaft and Rotor Centre at Location 0107

Refer to Figure.

Reference dimensions at location 0110. If required, use the data written as a note in TASK 72-32-51-200-000 (INSPECTION-000) and TASK 72-32-54-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0110

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100)

No. 1 Ball Bearing Inner Race ENGINE-NO.1 BEARING (72-32-54, 01-150)

Rotor Center Shaft Bearing Journal Outside Diameter

8.6664

Intf

8.6675

0.0050

No. 1 Ball Bearing Inner Race Bore Diameter

8.6610

0.0065

8.6614

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0110

Rotor Center Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100)

No. 1 Ball Bearing Inner Race ENGINE-NO.1 BEARING (72-32-54, 01-150)

Rotor Center Shaft Bearing Journal Outside Diameter

220.126

Intf

220.156

0.126

No. 1 Ball Bearing Inner Race Bore Diameter

219.988

0.167

220.000

SUBTASK 72-32-50-220-055 Reference Fits and Clearances of the Rotor Center Shaft and the No. 1 Ball Bearing Inner Race at Location 0110

Refer to Figure.

Reference dimensions at location 0113. If required, use the data written as a note in TASK 72-32-51-200-000 (INSPECTION-000) and TASK 72-32-52-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0113

Stub Shaft Assembly ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350)

No. 2 Roller Bearing Inner Race No. 2 Bearing (72-32-52, 01-160)

Stub Shaft Assembly Bearing Journal Outside Diameter

4.4491

Intf

4.4494

0.0002

No. 2 Roller Bearing Inner Race Bore Diameter

4.4485

0.0009

4.4488

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 0113

Stub Shaft Assembly ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350)

No. 2 Roller Bearing Inner Race No. 2 Bearing (72-32-52, 01-160)

Stub Shaft Assembly Bearing Journal Outside Diameter

113.005

Intf

113.015

0.005

No. 2 Roller Bearing Inner Race Bore Diameter

112.992

0.023

113.000

SUBTASK 72-32-50-220-056 Reference Fits and Clearances of the Stub Shaft Assembly and the No. 2 Roller Bearing Inner Race at Location 0113

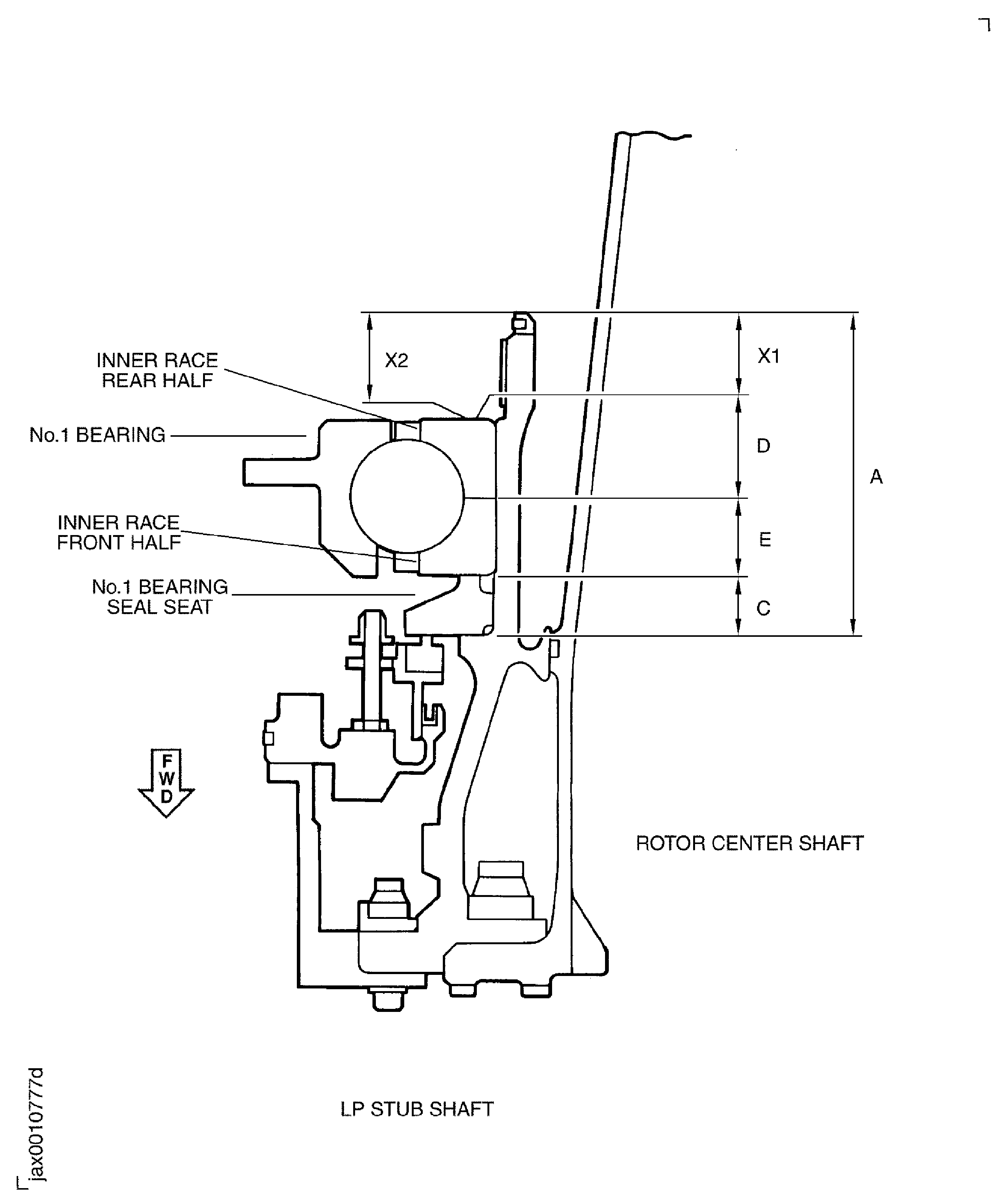

Refer to Figure.

Dimension A of the rotor center shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-100).

Dimension C of the No. 1 Bearing seat No. 1 Bearing Front Face Seal Assembly (72-32-53, 01-450).

Dimension E of the inner race front half of the No. 1 Bearing ENGINE-NO.1 BEARING (72-32-54, 01-150).

Dimension D of the inner race rear half of the No. 1 Bearing No. 1 Bearing Front Face Seal Assembly (72-32-53, 01-150).

Measure and record the following dimensions.

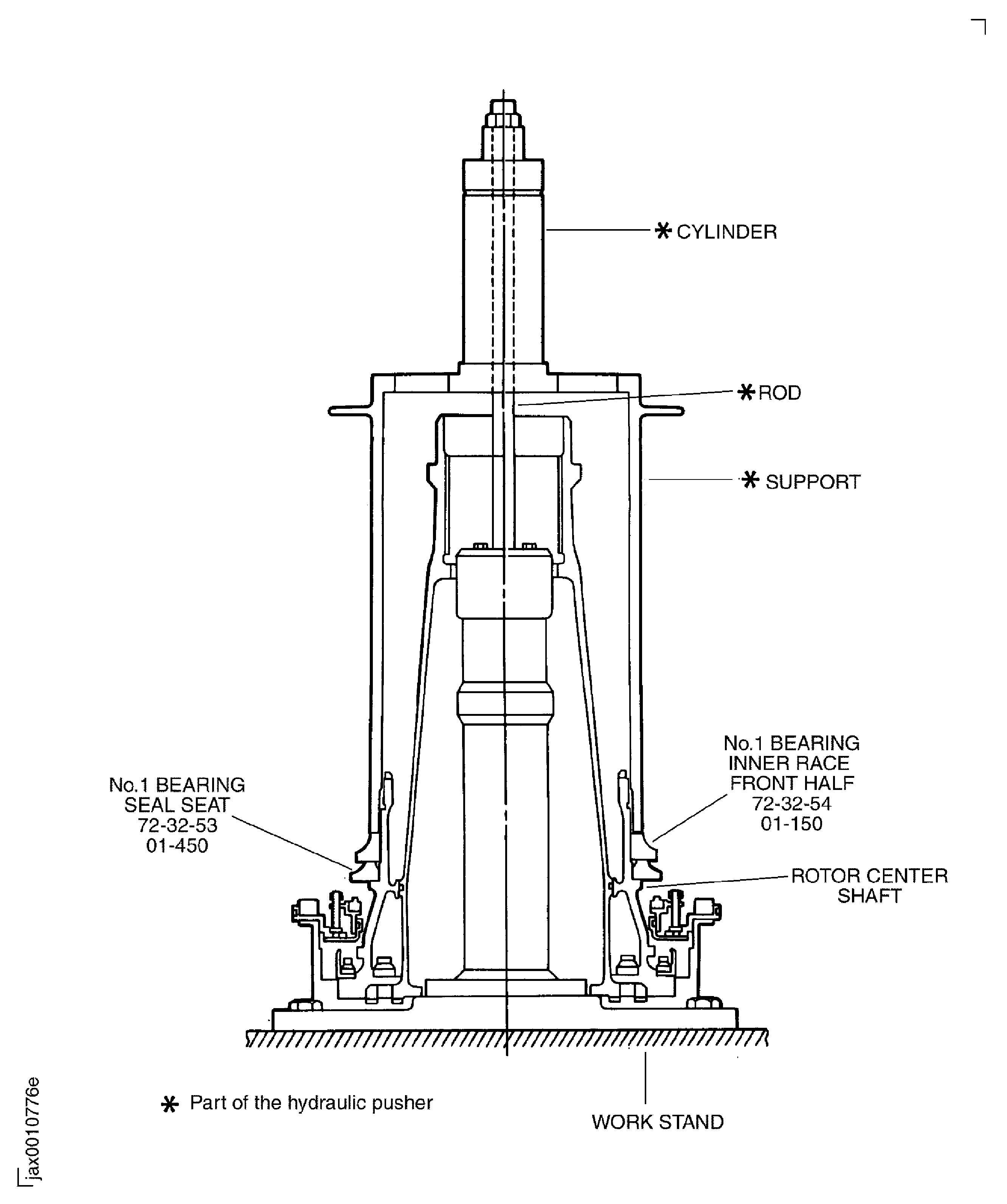

SUBTASK 72-32-50-440-077 Prepare the Rotor Center Shaft, No. 1 Bearing Seal Seat and No. 1 Bearing

Refer to Figure.

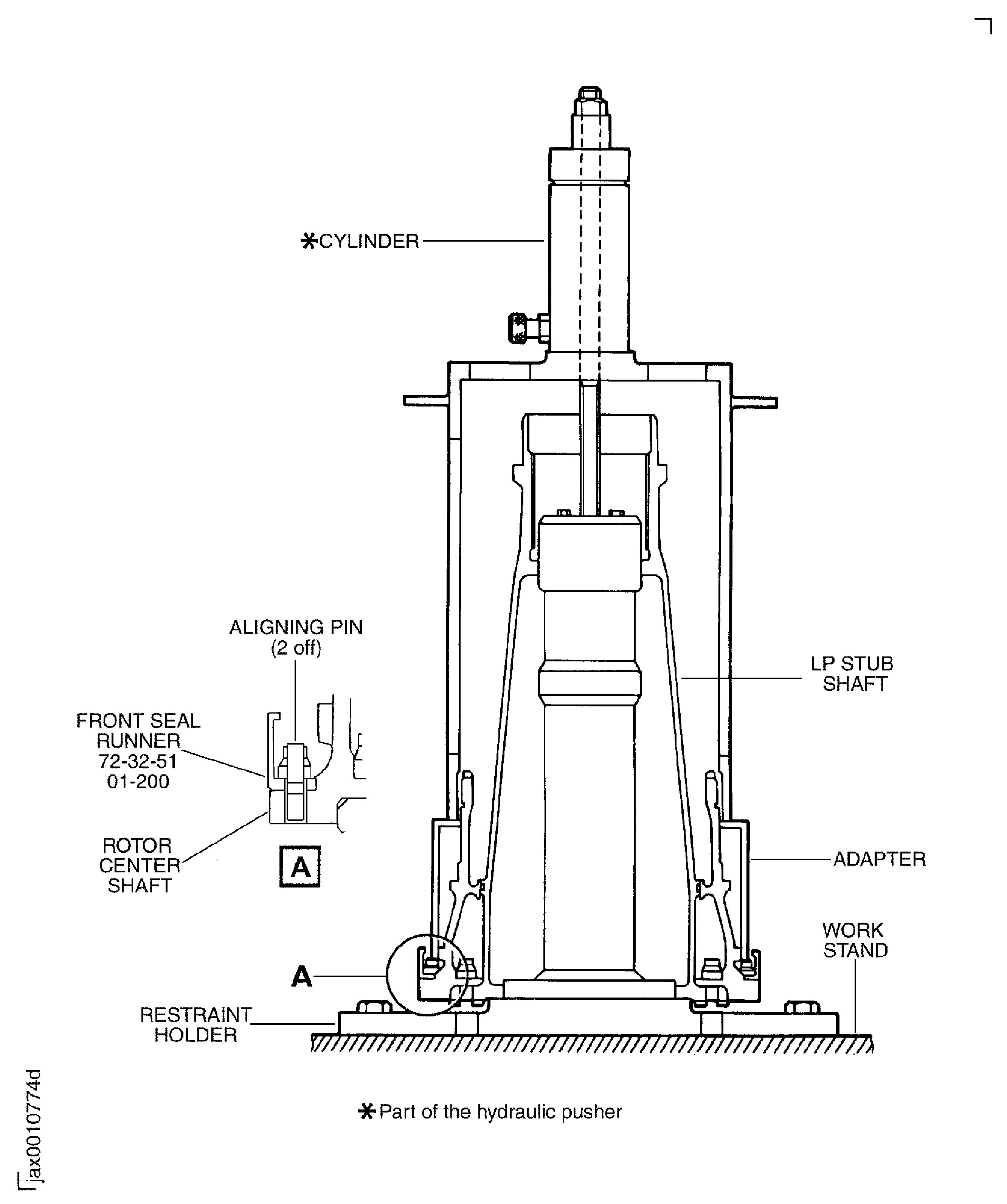

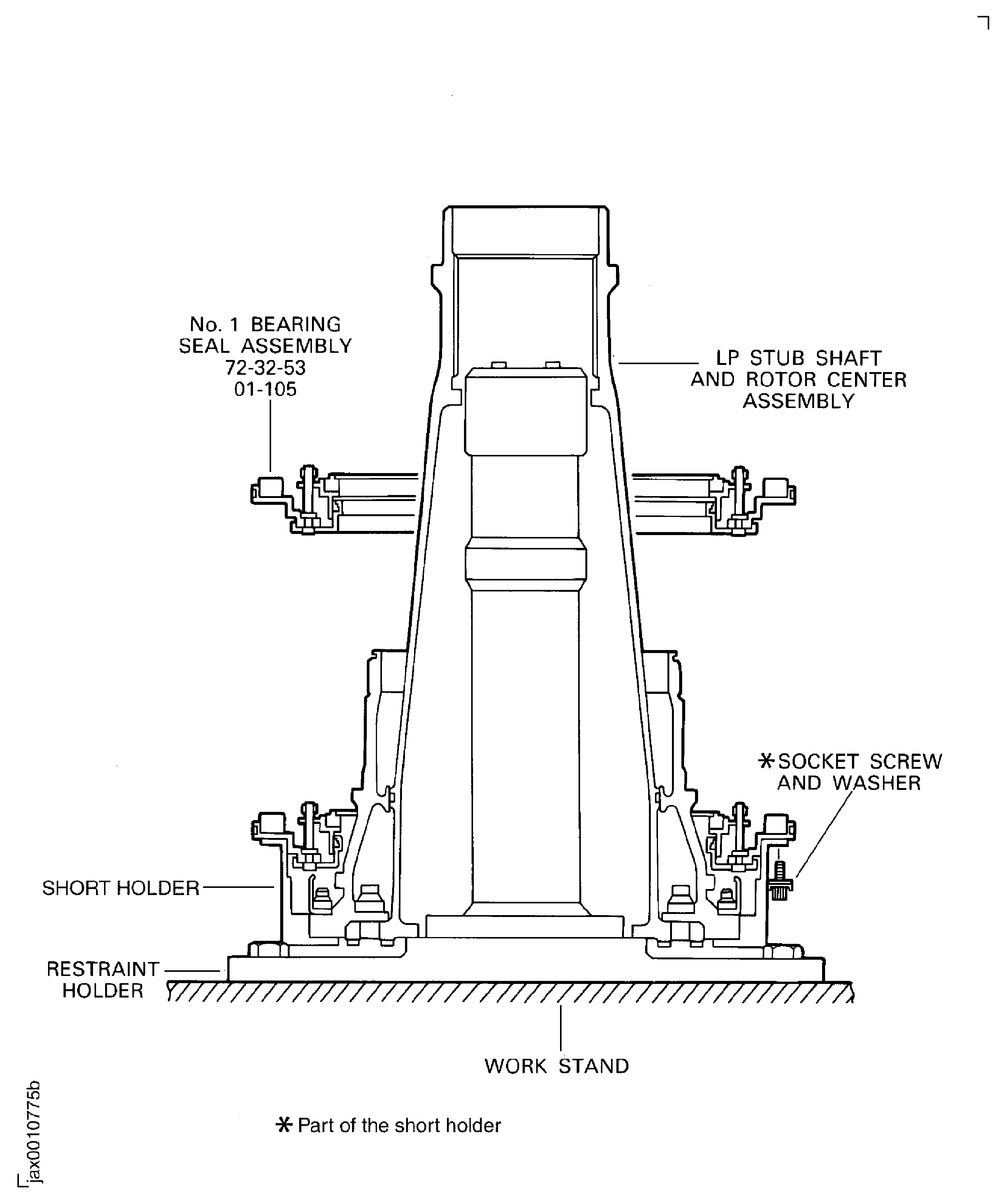

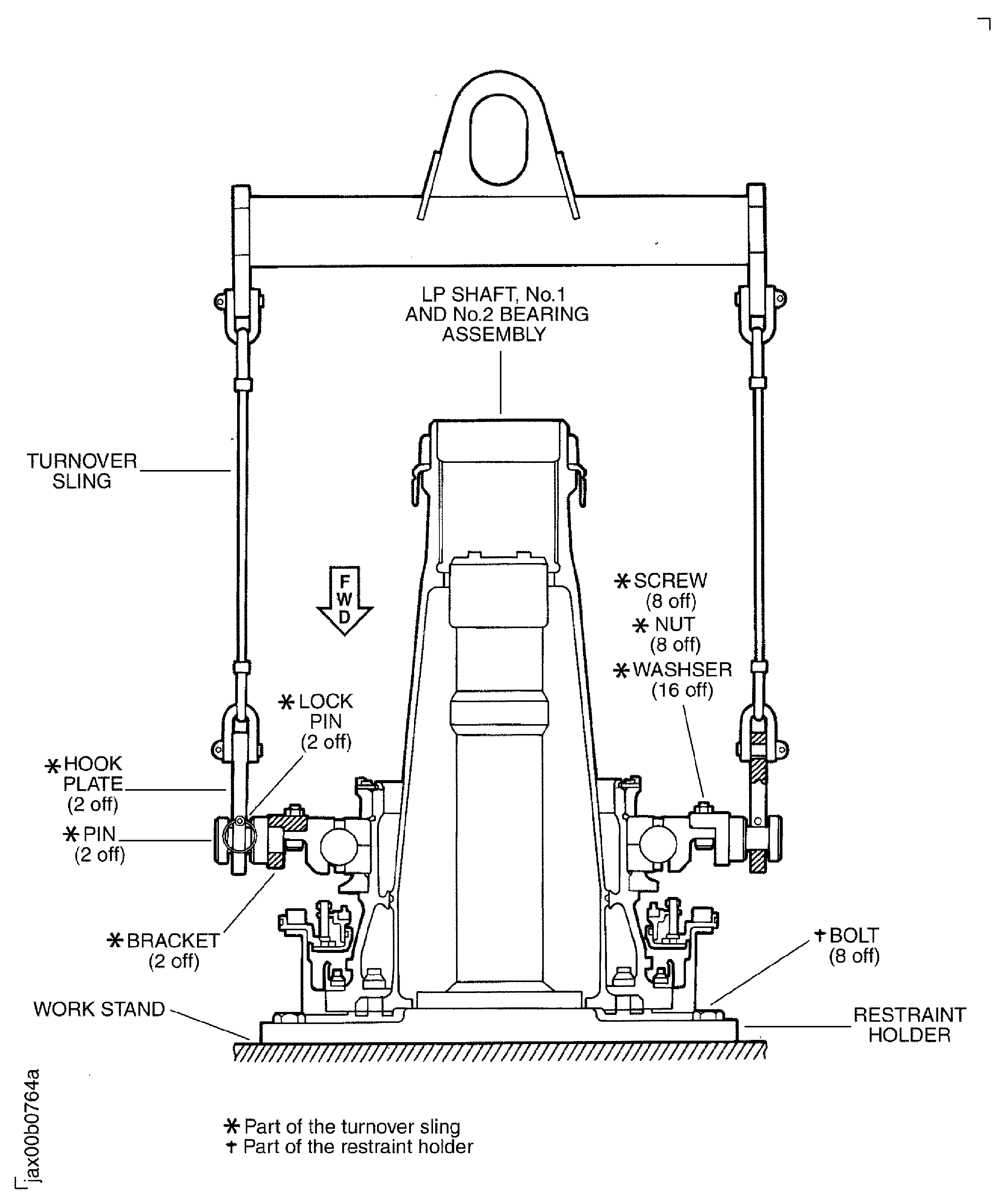

Install IAE 1J12386 Restraint holder 1 off on to IAE 1J12387 Work stand 1 off with the eight bolts (part of the restraint holder).

Install the Stub Shaft Assembly ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350) on to the restraint holder.

SUBTASK 72-32-50-440-051 Install the Stub Shaft Assembly to the Holder

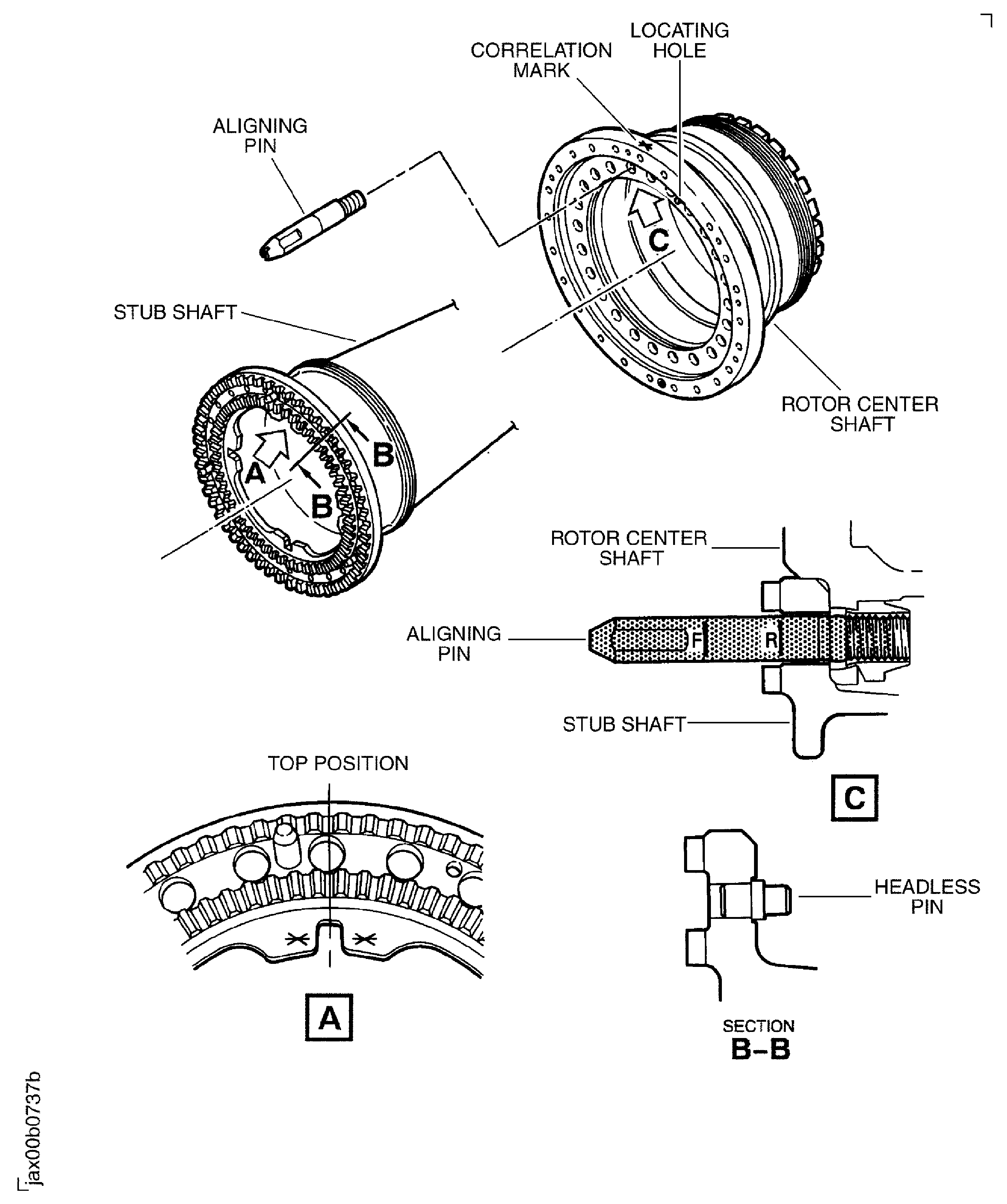

Lubricate the threads of the two aligning pins (part of IAE 1J12106 Aligning pin set 1 off) with CoMat 10-077 APPROVED ENGINE OILS.

SUBTASK 72-32-50-440-052 Prepare to Install the Rotor Center Shaft on to the Stub Shaft Assembly

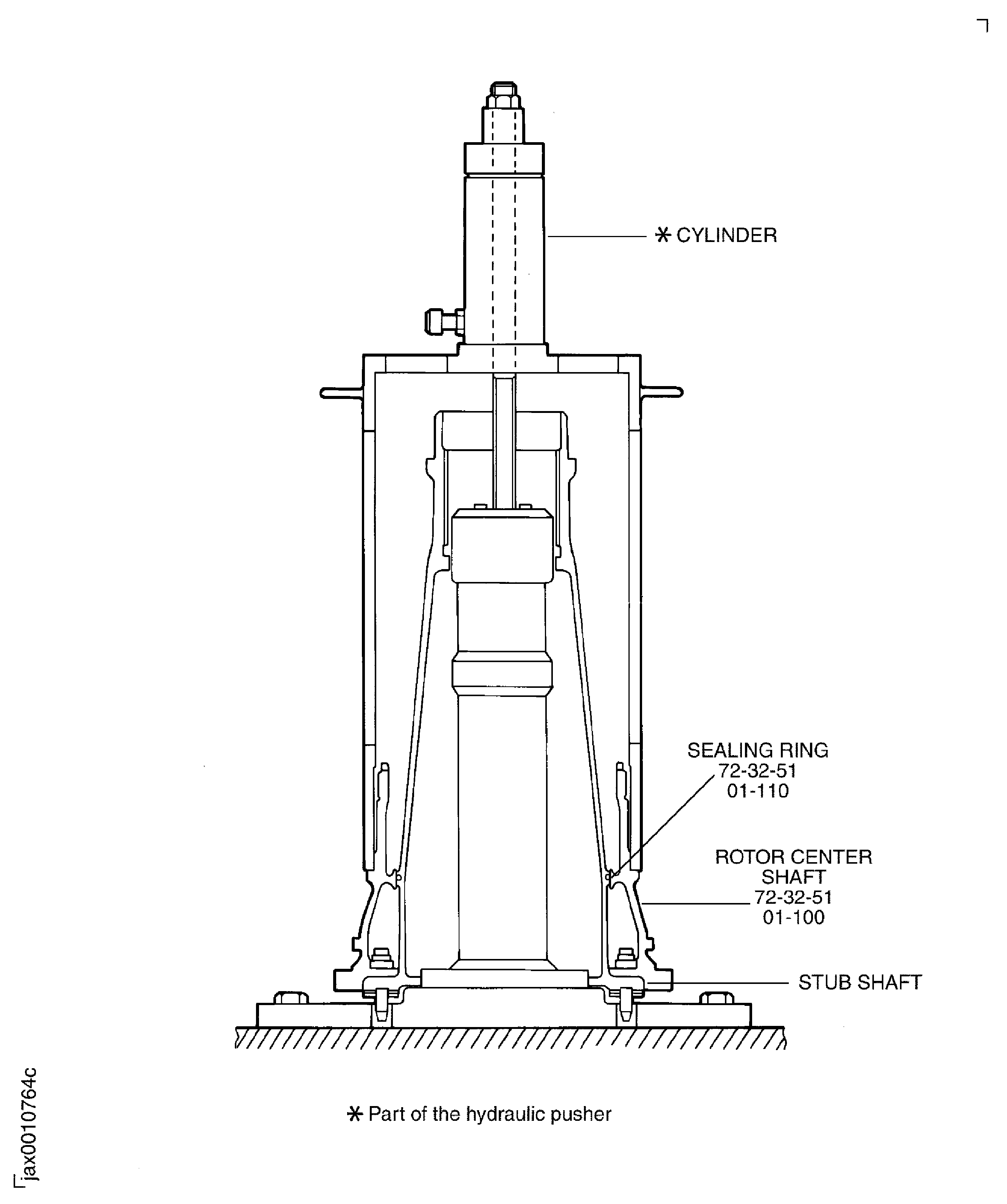

Lubricate the new ENGINE-LP STUB SHAFT AND ROTOR CENTRE ( 72-32-51, 01-110) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Install IAE 1J12388 Hydraulic pusher 1 off to the rotor center shaft.

SUBTASK 72-32-50-440-053 Install the Rotor Center Shaft (72-32-51, 01-100) on to the Stub Shaft Assembly

WARNING

BE CAREFUL BECAUSE THE ROTOR CENTER SHAFT IS HOT. USE APPROVED GLOVES WHEN YOU REMOVE IT FROM THE OVEN.Attach IAE 1J12394 Balance adapter 1 off to the Stub Shaft Assembly.

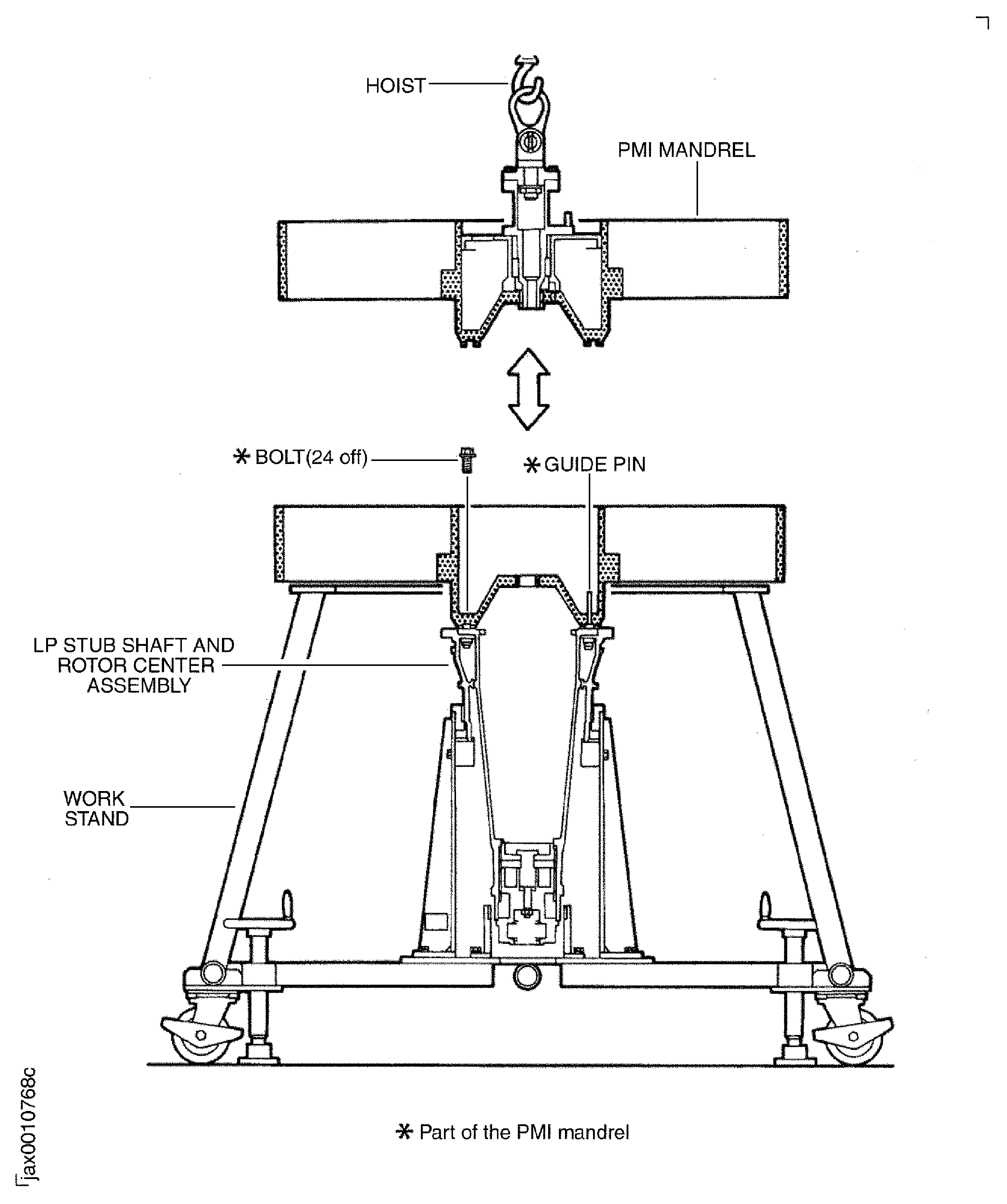

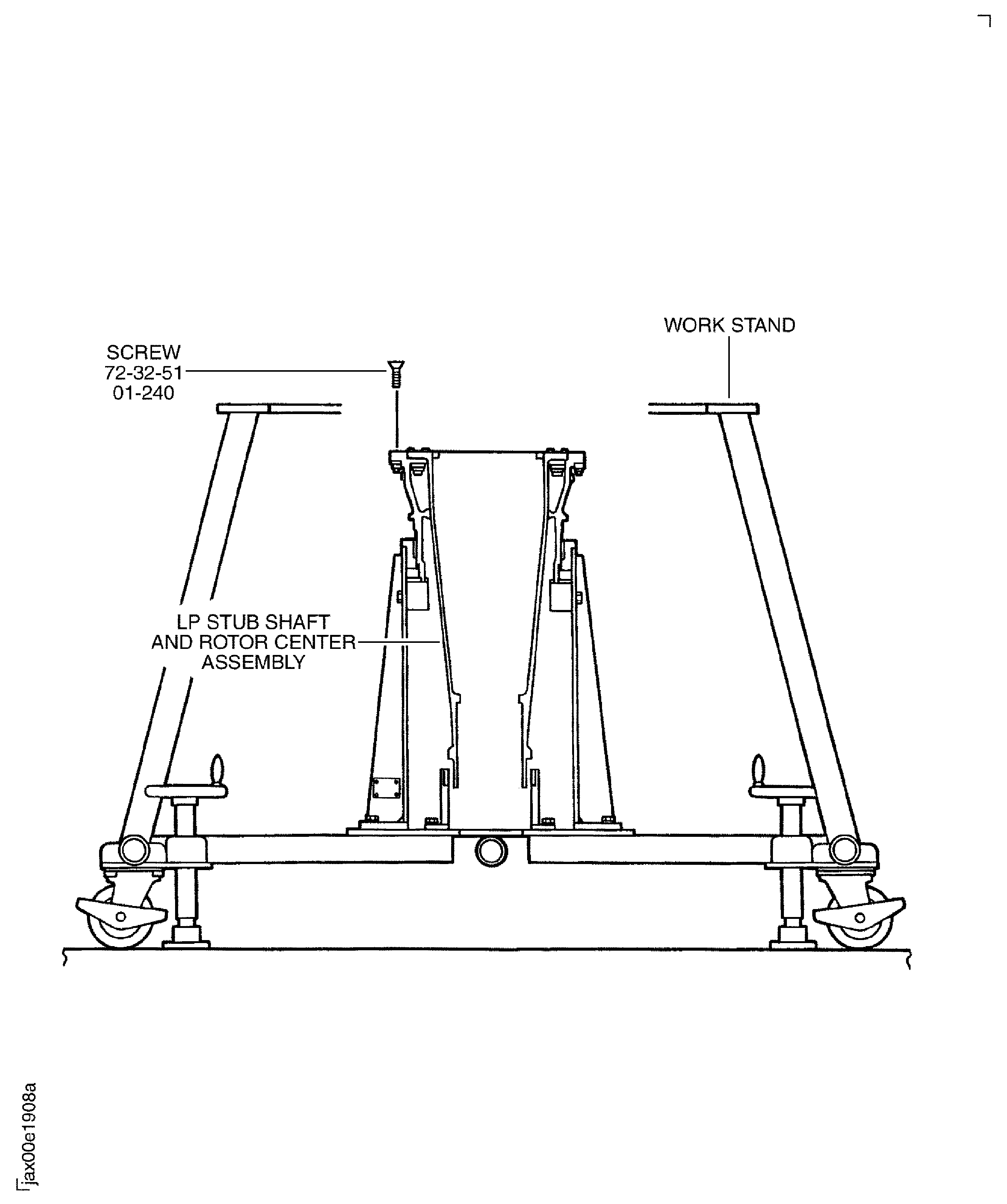

Turn the LP stub shaft and rotor center and put on IAE 1J12395 Work stand 1 off with the rear end down.

SUBTASK 72-32-50-440-055 Prepare the LP Stub Shaft and Rotor Center for Installation of PMI Mandrel

Install the three guide pins (part of IAE 1J12398 PMI mandrel 1 off) to the LP stub shaft and rotor center.

Install the guide pin (part of IAE 1J12397 Front sling) in the guide pin hole of the PMI mandrel. Put the guide in the PMI mandrel.

Put the adapter, the fork end and the eye (part of IAE 1J12397 Front sling) in the slot of the guide.

Install the lock pin (part of IAE 1J12397 Front sling) in the lock pin hole of the guide through the lock pin thread hole of the adapter.

Attach IAE 1J12397 Front sling 1 off in to IAE 1J12398 PMI mandrel 1 off.

Clean the curvic teeth of the PMI mandrel with CoMat 01-124 ISOPROPYL ALCOHOL.

Lubricate the threads of the 24 bolts with CoMat 10-077 APPROVED ENGINE OILS.

Torque the 24 bolts to 443 lbfin to 566 lbfin (50 Nm to 64 Nm) in the sequence given on Figure. Then torque the same bolts to 885 lbfin to 1133 lbfin (100 Nm to 128 Nm) in the sequence.

Install the PMI mandrel on the LP stub shaft and rotor center with the 24 bolts (part of the PMI mandrel).

SUBTASK 72-32-50-440-056 Attach the PMI Mandrel to the LP Stub Shaft and Rotor Center

Refer to Figure.

NOTE

The bolts that attach the end drive to the balancing machine must all have the same weight.

SUBTASK 72-32-50-440-078 Prepare the Balancing Machine for Use

Carefully lower the LP shaft and Mandrel Assembly on to the balancing machine. Make sure that the No. 2 Bearing location diameter (diameter ER) touches the No. 1 pedestal and the No. 1 Bearing location diameter EF) touches the No. 2 pedestal.

NOTE

Do not loosen the hoist until you have safetied the balancing machine upper roller of the No. 1 pedestal.

SUBTASK 72-32-50-440-057 Install the LP Stub Shaft, Rotor Center and PMI Mandrel Assembly (LP Shaft and Mandrel Assembly) on to the Balancing Machine

Refer to Figure.

SUBTASK 72-32-50-220-051 Measure the Runouts of the PMI Mandrel and the LP Stub Shaft and Rotor Center Assembly

Input the data measured in Step into the balancing machine.

Set the balancing machine.

SUBTASK 72-32-50-440-058 Measure the Unbalance of the LP Shaft and Mandrel Assembly

Put the LP shaft and Mandrel Assembly in to IAE 1J12395 Work stand 1 off.

Lubricate the threads of the two guide pins (part of the PMI mandrel) with CoMat 10-077 APPROVED ENGINE OILS.

Make a temporary mark on the PMI mandrel to show the location of the guide pin with CoMat 06-069 MARKER.

SUBTASK 72-32-50-440-059 Remove the PMI Mandrel

Refer to Figure.

Clean the curvic teeth of the PMI mandrel with CoMat 01-124 ISOPROPYL ALCOHOL.

Torque the 24 bolts to 443 lbfin to 566 lbfin (50 Nm to 64 Nm) in the sequence given on Figure. Then torque the same bolts to 885 lbfin to 1133 lbfin (100 Nm to 128 Nm) in the sequence.

SUBTASK 72-32-50-440-061 Turn the PMI Mandrel 180 Degrees

CAUTION

DO NOT ATTACH THE NYLON SLING AROUND THE BEARING MATING FACE. THE NYLON SLING CAN CAUSE DAMAGE TO THE BEARING MATING FACE.Carefully lower the LP shaft and Mandrel Assembly on to the balancing machine.

NOTE

Do not put the oil port of the rotor center shaft on the balancing machine rollers of the pedestal.

SUBTASK 72-32-50-440-062 Install the Balance Stub Shaft Assembly on to the Balance Machine

Refer to Figure.

SUBTASK 72-32-50-220-052 Measure the Runouts of the PMI Mandrel Again

Refer to Figure.

SUBTASK 72-32-50-440-063 Measure the Unbalance after You Turn the LP Shaft Assembly 180 Degrees to the PMI Mandrel

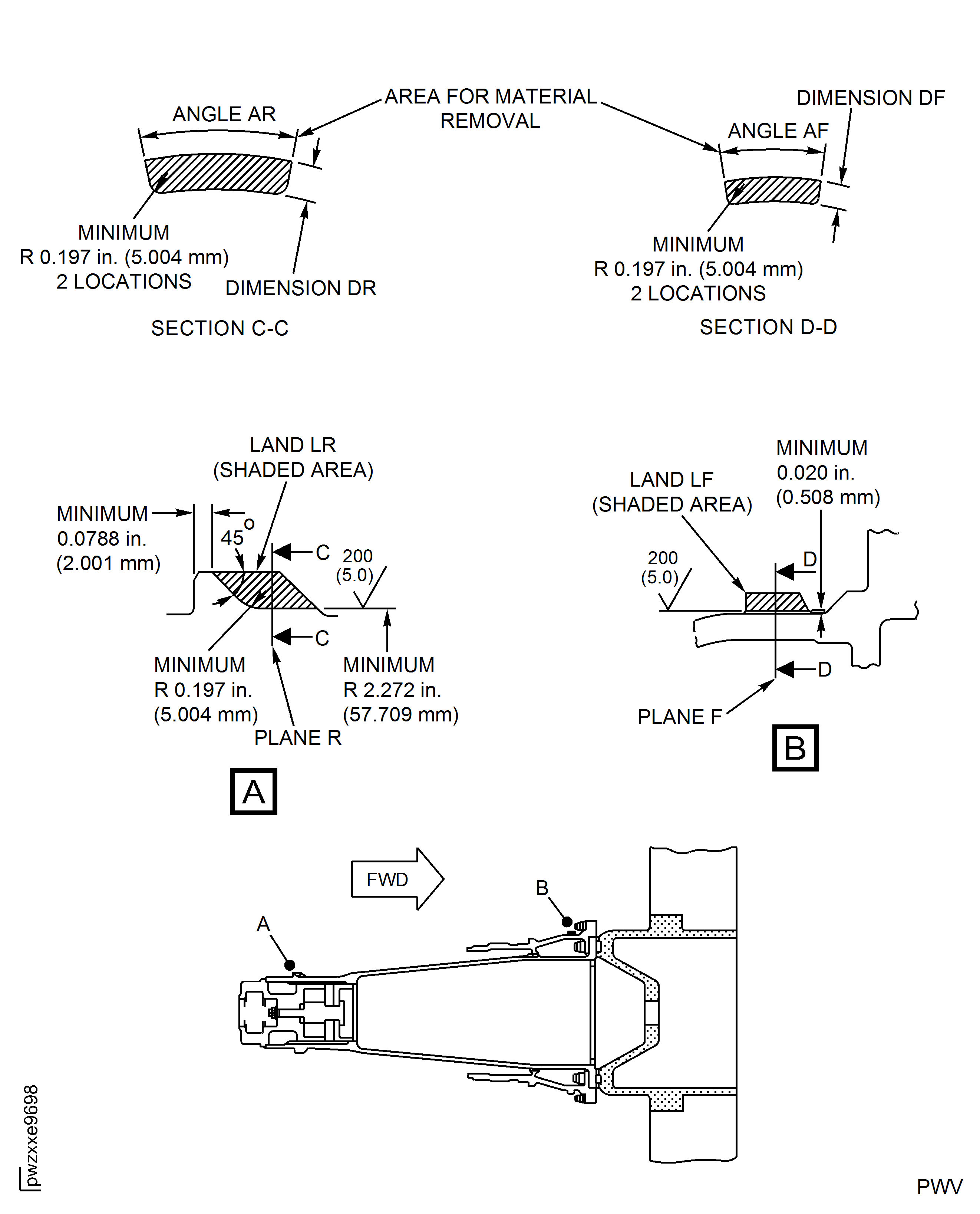

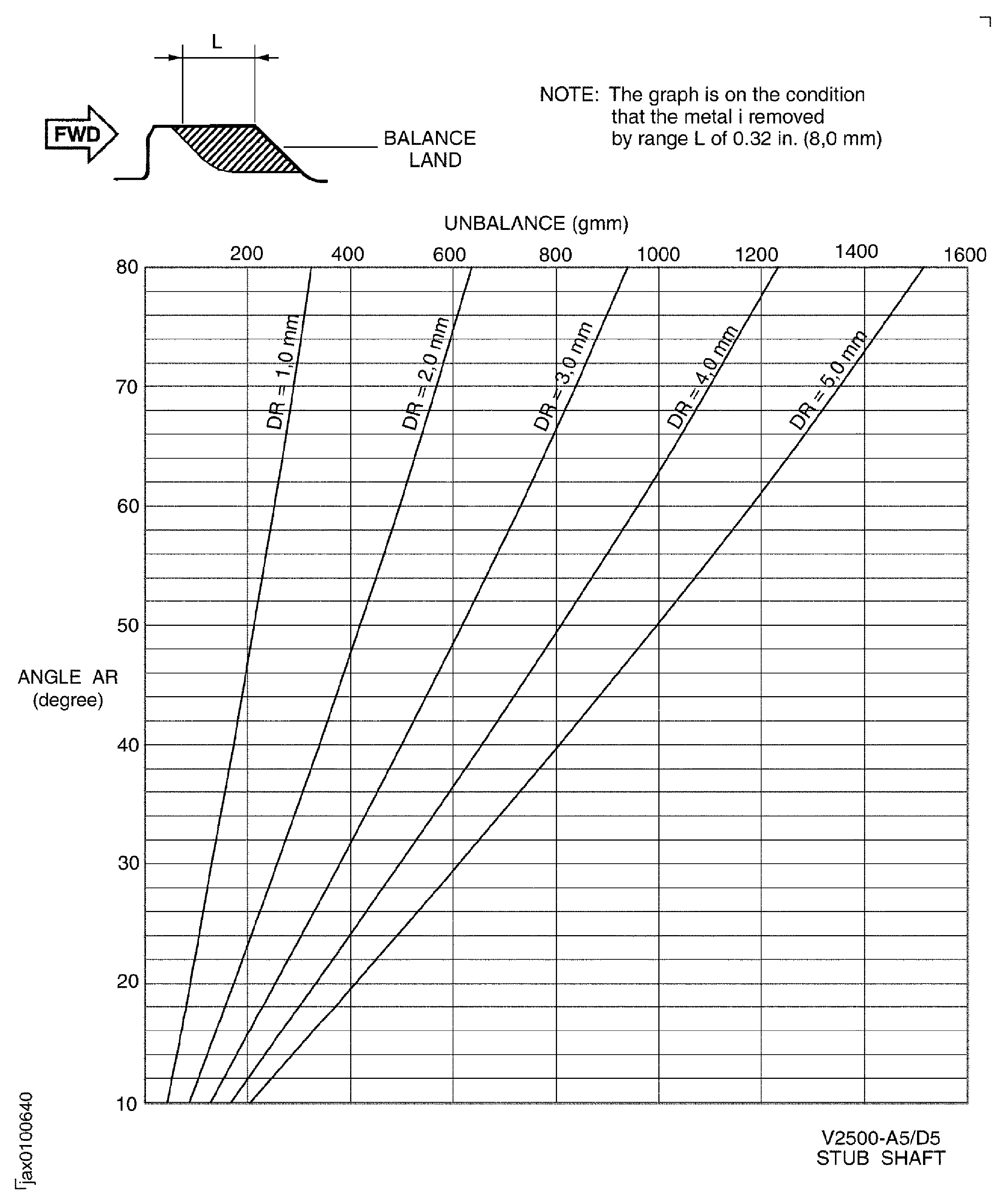

The surface finish of the planes F and R after blend must be 200 micro in. (5.08 micrometer). Refer to the SPM TASK 70-35-09-350-501 for the surface finish.

SUBTASK 72-32-50-440-065 Correct the Unbalances on the Planes F and R

Refer to Figure.

SUBTASK 72-32-50-440-066 Measure the Amounts of the Final Unbalance after the Correction of the Balance

Install the two aligning pins (part of IAE 1J12499 Aligning pin set 1 off) 180 degrees apart from each other in to the anchor nuts of the front seal runner.

WARNING

BE CAREFUL BECAUSE THE FRONT SEAL RUNNER IS HOT. USE APPROVED GLOVES WHEN YOU REMOVE IT FROM THE OVEN.Remove the front seal runner and the aligning pins assembly from the oven. Install the front seal runner and the aligning pins assembly to the rotor center shaft immediately after removal of the front seal runner and the aligning pins assembly from the oven.

NOTE

Installation of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240) in to the two threads is done in Step.Put IAE 1J12500 Adapter 1 off on to the front seal runner.

Install IAE 1J12388 Hydraulic pusher 1 off to the adapter.

Remove the Stub Shaft Assembly from the restraint holder. Install the Stub Shaft Assembly on to IAE 1J12395 Work stand 1 off with the rear end of the assembly down.

Safety the front seal runner and the aligning pins assembly with the two screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240). Torque the bolt to 40 lbfin (4.52 Nm).

Remove the aligning pins (part of IAE 1J12499 Aligning pin set) from the front seal runner and the aligning pins assembly.

Make sure that the heads of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240) are under the surface of the rotor center shaft flange.

SUBTASK 72-32-50-440-070-A00 V2500-A1: Install the Front Seal Runner (72-32-51, 01-200) on to the LP Stub Shaft and Rotor Center (Pre SBE 72-0132)

Refer to Figure.

Put the nut ring to the rotor center shaft.

NOTE

Installation of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240) in to the threads is done in Step.

Install the nut ring to the rotor center shaft.

Safety the nut ring with the two screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240). Torque the bolt to 40 lbfin (4.52 Nm).

Make sure that the heads of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240) are under the surface of the rotor center shaft flange.

SUBTASK 72-32-50-440-070-B00 V2500-A1: Install the Nut Ring (72-32-51, 01-200) on to the LP Stub Shaft and Rotor Center Assembly (SBE 72-0132)

Refer to Figure.

Put the nut ring to the rotor center shaft.

NOTE

Installation of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240) in to the threads is done in Step.

Install the nut ring to the rotor center shaft.

Safety the nut ring with the two screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-240). Torque the bolt to 40 lbfin (4.52 Nm).

Make sure that the heads of the screws ENGINE-LP STUB SHAFT AND ROTOR CENTRE(72-32-51, 01-240) are under the surface of the rotor center shaft flange.

SUBTASK 72-32-50-440-070-C00 V2500-A5: Install the Nut Ring (72-32-51, 01-200) on to the LP Stub Shaft and Rotor Center

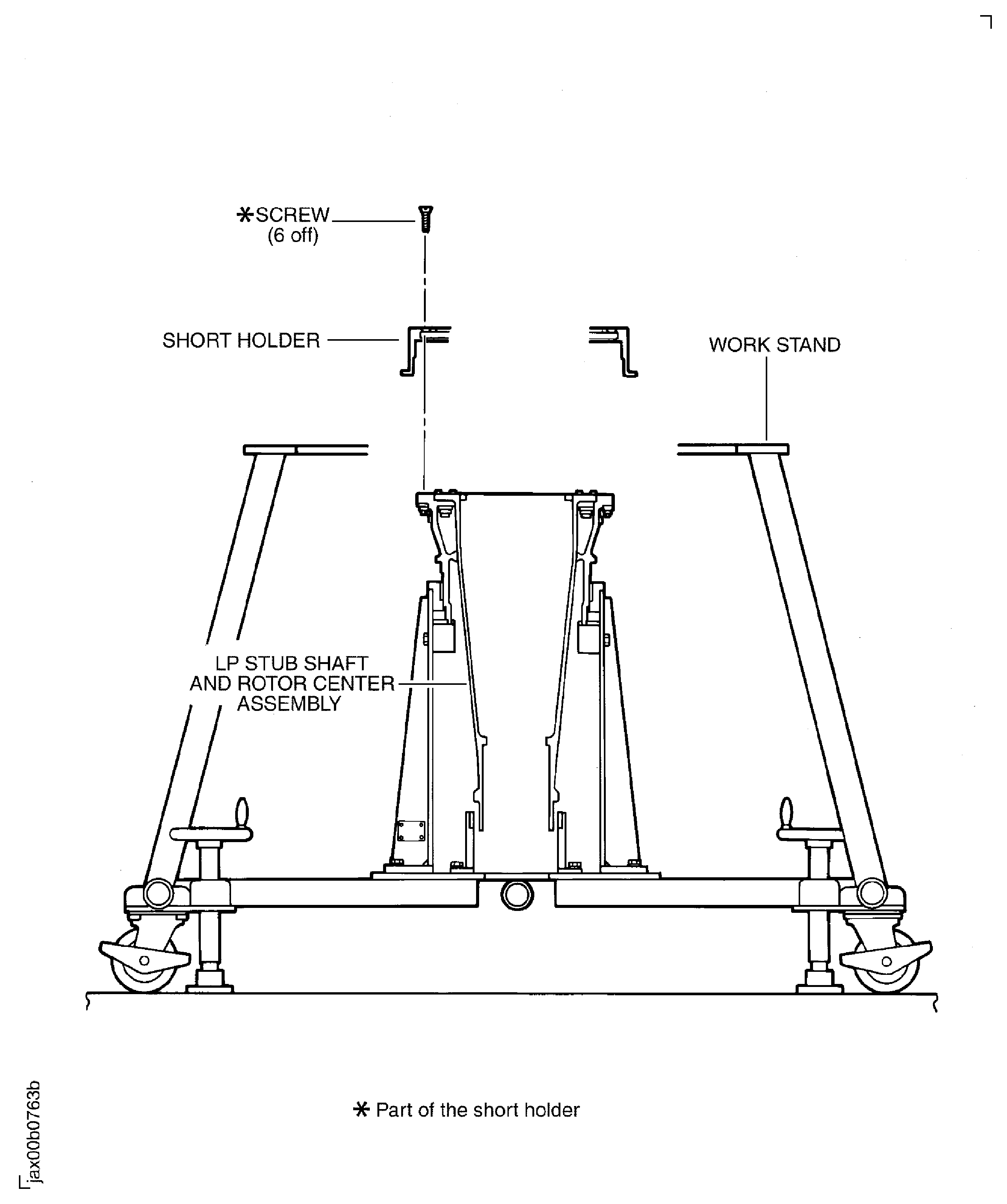

V2500-A1 Pre SBE 72-0132: Install IAE 1J12473 Seal holder 1 off to the rotor center shaft with the six screws.

V2500-A1 SBE 72-0132 and V2500-A5: Install IAE 1J12462 Seal holder 1 off to the rotor center shaft with the six screws.

NOTE

These pins are parts for preventing the rotation of the LP stub shaft and Rotor Center Assembly when you tighten the No. 1 Bearing plain nut in Step.Align the six holes of the holder (part of the restraint holder) with the heads of the six pins that were installed in the short holder in the Step.

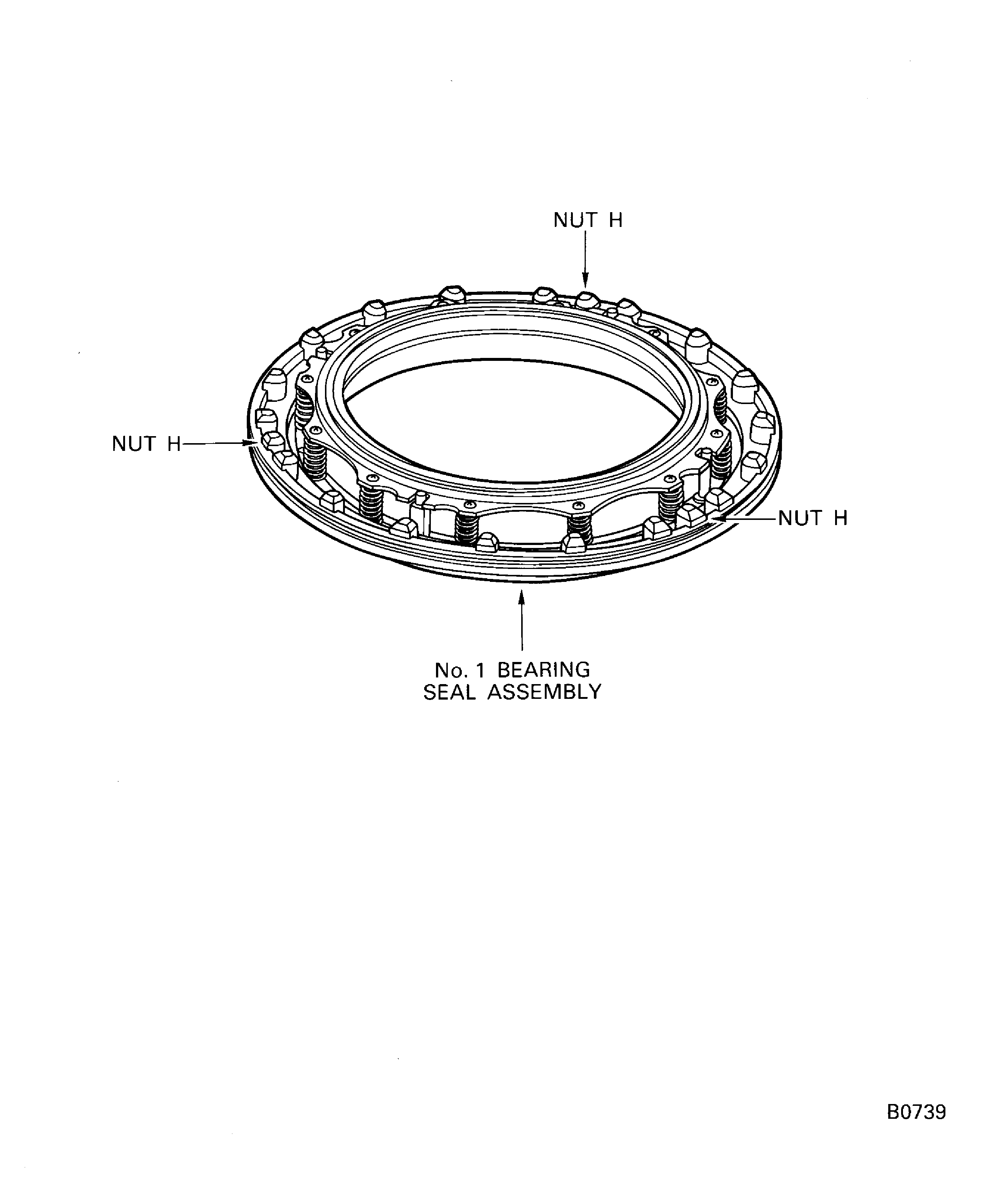

SUBTASK 72-32-50-440-071 Install the No. 1 Bearing Seal Assembly (72-32-53, 01-105) on to the Rotor Center Shaft

Install IAE 1J12388 Hydraulic pusher 1 off to the Stub Shaft Assembly.

Install IAE 1J12506 No.1 bearing guide 1 off on to the rotor center shaft.

Attach IAE 1J12401 No.1 bearing holding plate 1 off to the No. 1 Bearing outer race, cage and balls.

Lubricate the balls with CoMat 10-077 APPROVED ENGINE OILS.

Install the outer race, and the cage and balls of the No. 1 Bearing to the rotor center shaft.

CAUTION

YOU MUST MAKE SURE THAT THE NO. 1 BEARING BALL IN THE CORRECT POSITION BEFORE YOU INSTALL THE NO. 1 BEARING INNER RACE REAR HALF. INCORRECT POSITION CAN CAUSE DAMAGE TO THE BALLS WHEN YOU PUSH THE NO. 1 BEARING INNER RACE REAR HALF.Put the No. 1 Bearing inner race rear half in an oven. Increase the temperature in the oven to 302 deg F (150 deg C) and keep the same temperature for 20 minutes.

Install IAE 1J12388 Hydraulic pusher 1 off to the Stub Shaft Assembly.

SUBTASK 72-32-50-440-072 Install the No. 1 Bearing on to the Rotor Center Shaft

Refer to Figure.

SUBTASK 72-32-50-220-053 Examine the the LP Stub Shaft, the Rotor Center and No. 1 Bearing Assembly (LP Shaft and No. 1 Bearing Assembly)

Lubricate the thread of the plain nut with CoMat 10-077 APPROVED ENGINE OILS.

Lift the Torque multiplier up with a hoist.

Make sure that the plain nut is at the same angle as in Step or turned more clockwise within one degree.

Tighten the plain nut with IAE 1J12335 Spanner wrench 1 off.

Put the tab of the lock ring ENGINE-NO.1 BEARING (72-32-54, 01-110) in the grooves in the plain nut and the rotor center shaft.

Put the retaining ring ENGINE-NO.1 BEARING (72-32-54, 01-100) in the groove in the plain nut.

Install the lock ring.

SUBTASK 72-32-50-440-073 Install the Plain Nut (72-32-54, 01-120) on to the Rotor Center Shaft

Refer to Figure.

Align the pin at the top of the NF probe phonic wheel with the slot in the Stub Shaft Assembly. Install the NF probe phonic wheel on the Stub Shaft Assembly with IAE 1J12392 Installation pusher 1 off.

SUBTASK 72-32-50-440-074 Install the NF Probe Phonic Wheel (72-32-51, 01-250) and No. 2 Inner Roller Bearing (72-32-52, 01-160) on to the Stub Shaft Assembly

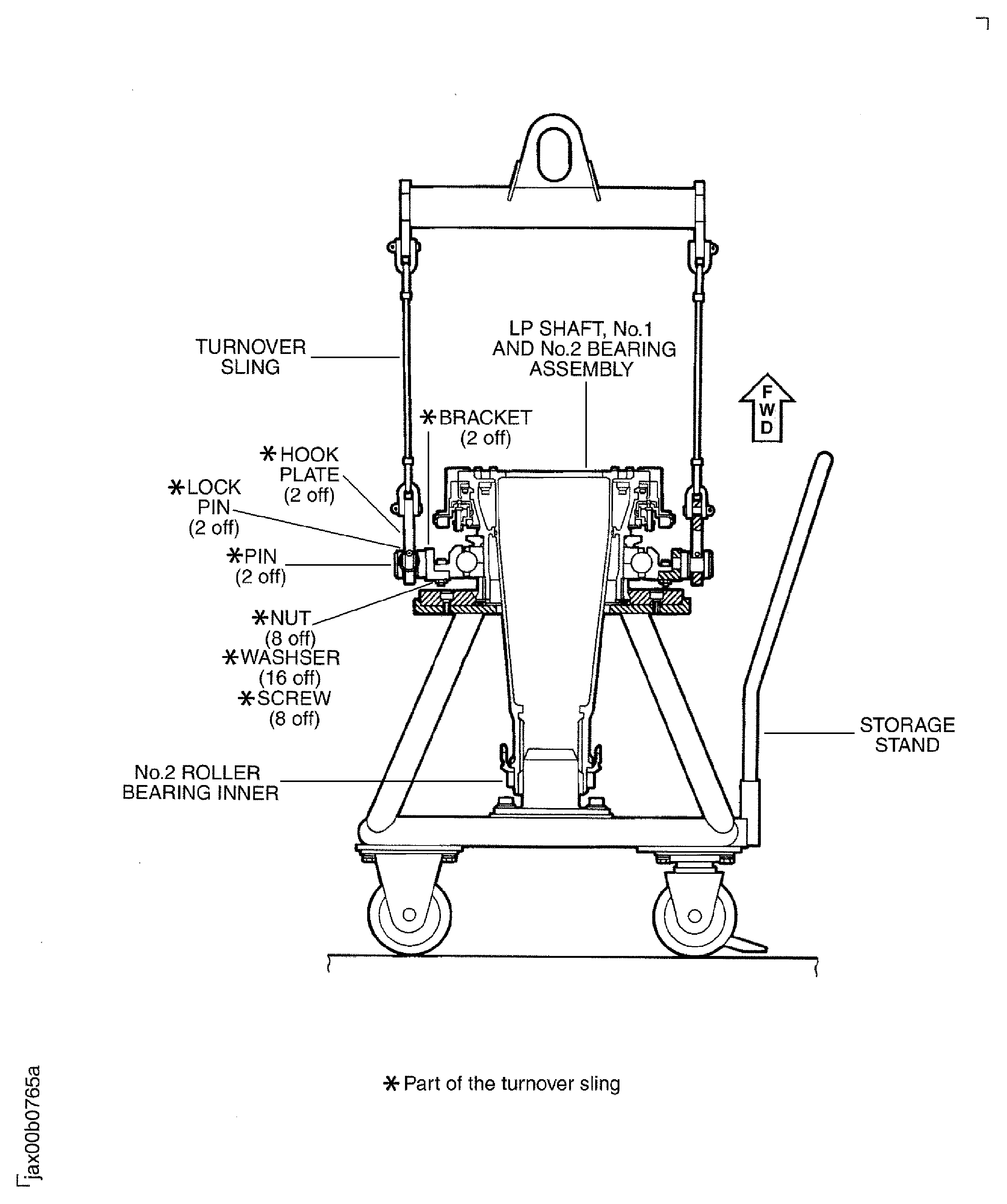

Install IAE 1J12501 Turnover sling 1 off to the assembly.

CAUTION

CAREFULLY LOWER THE ASSEMBLY SO THAT THE NO.2 ROLLER INNER BEARING DOES NOT TOUCH THE STORAGE STAND. THE STORAGE STAND CAN CAUSE DAMAGE TO THE BEARING.Slowly lower the assembly and install it in to IAE 1J12211 Storage stand 1 off.

SUBTASK 72-32-50-440-075 Move the LP Shaft, No. 1 and No. 2 Bearing Assembly from the Restraint Holder to the Storage Stand

Figure: Reference Fits and Clearances

Reference Fits and Clearances

Figure: V2500-A1 Pre SBE 72-0132: Sectional View of the LP Shaft, No. 1 and No. 2 Bearing Assembly

V2500-A1 Pre SBE 72-0132: Sectional View of the LP Shaft, No. 1 and No. 2 Bearing Assembly

Figure: V2500-A1, SBE 72-0132 and V2500-A5: Sectional View of the LP Shaft, No. 1 and No. 2 Bearing Assembly

V2500-A1, SBE 72-0132 and V2500-A5: Sectional View of the LP Shaft, No. 1 and No. 2 Bearing Assembly

Figure: Install the Stub Shaft Assembly to the Restraint Holder

Install the Stub Shaft Assembly to the Restraint Holder

Figure: V2500-A1 Pre SBE 72-0132: Install the Rotor Center Shaft on to the Stub Shaft Assembly

V2500-A1 Pre SBE 72-0132: Install the Rotor Center Shaft on to the Stub Shaft Assembly

Figure: V2500-A1 SBE 72-0132 and V2500-A5: Install the Rotor Center Shaft on to the Stub Shaft Assembly

V2500-A1 SBE 72-0132 and V2500-A5: Install the Rotor Center Shaft on to the Stub Shaft Assembly

Figure: Install the Rotor Center Shaft on to the Stub Shaft Assembly

Install the Rotor Center Shaft on to the Stub Shaft Assembly

Figure: Prepare the LP Stub Shaft and Rotor Center for Installation of PMI Mandrel

Sheet 1

Figure: Prepare the LP Stub Shaft and Rotor Center for Installation of PMI Mandrel

Sheet 2

Figure: Attach the PMI Mandrel to the LP Stub Shaft and Rotor Center

Sheet 3

Figure: Attach the PMI Mandrel to the LP Stub Shaft and Rotor Center

Sheet 4

Figure: Prepare the LP Stub Shaft and Rotor Center for Installation of PMI Mandrel

Prepare the LP Stub Shaft and Rotor Center for Installation of PMI Mandrel

Figure: The Torque Tightening Sequence for the PMI Mandrel Bolts

The Torque Tightening Sequence for the PMI Mandrel Bolts

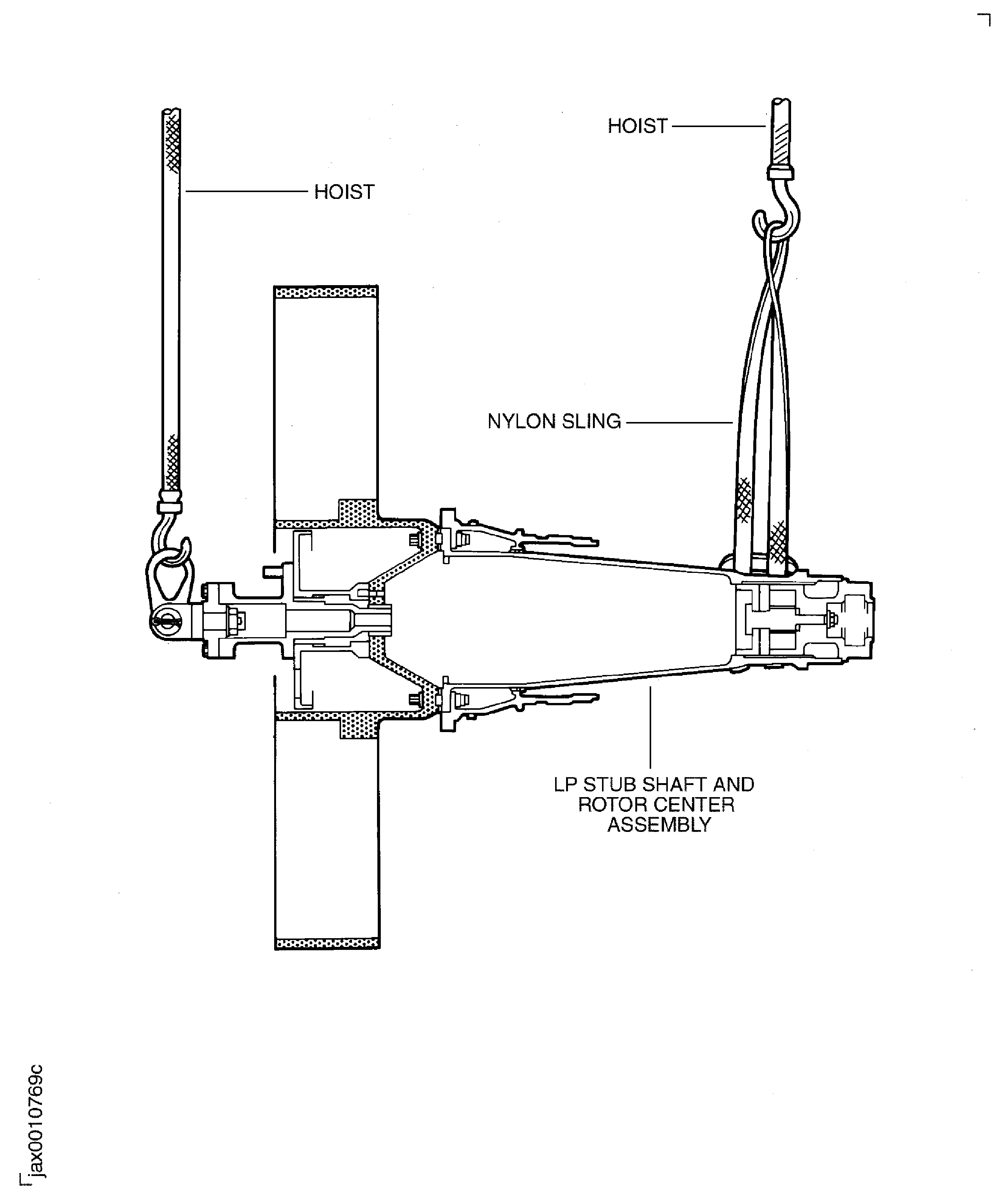

Figure: Lift the LP Shaft and Mandrel Assembly

Lift the LP Shaft and Mandrel Assembly

Figure: Put the LP Shaft and Mandrel Assembly on to the Balancing Machine

Put the LP Shaft and Mandrel Assembly on to the Balancing Machine

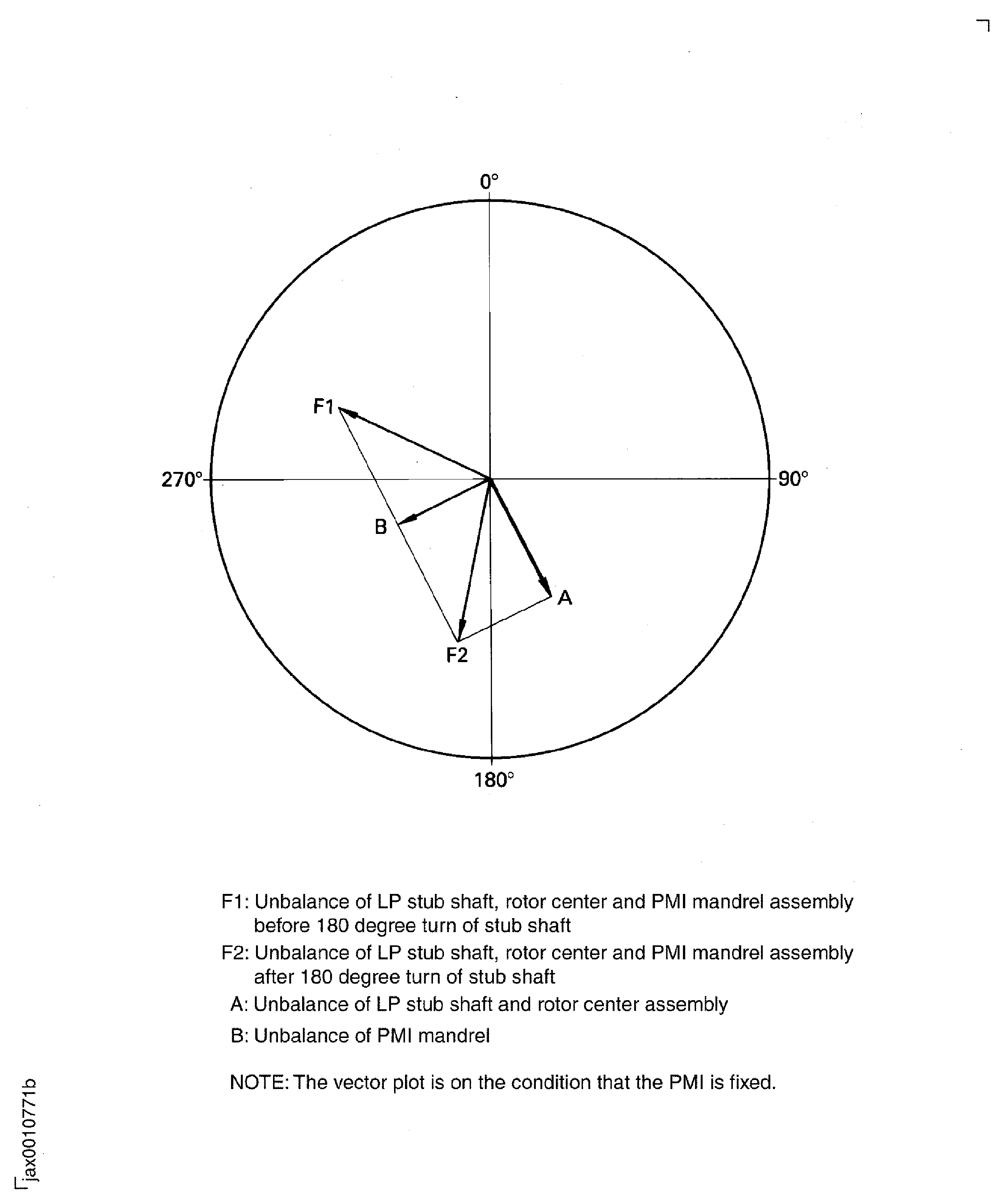

Figure: Vector Plot

Vector Plot

Figure: Correct the Unbalance of the LP Stub Shaft and Rotor Center

Correct the Unbalance of the LP Stub Shaft and Rotor Center

Figure: Graph for Finding Angle and Dimension of Metal to be Removed from the Rotor Center Shaft

Sheet 2

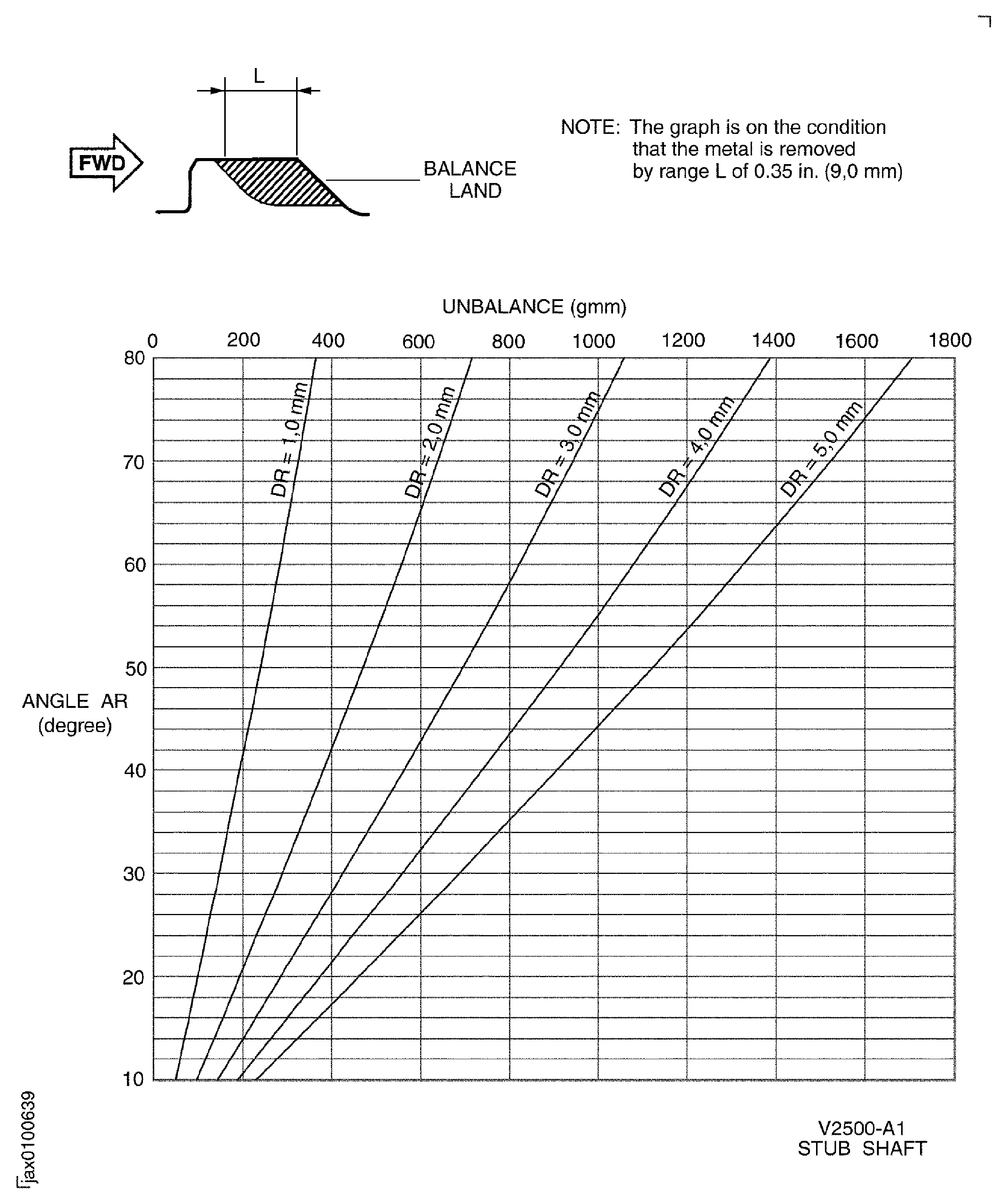

Figure: V2500-A1: Graph for Finding Angle and Dimension of Metal to be Removed from the Stub Shaft Assembly

Sheet 3

Figure: V2500-A5: Graph for Finding Angle and Dimension of Metal to be Removed from the Stub Shaft Assembly

Sheet 4

Figure: V2500-A1 Pre SBE 72-0132: Install the Front Seal Runner on to the LP Stub Shaft and Rotor Center

Sheet 1

Figure: V2500-A1 Pre SBE 72-0132: Install the Front Seal Runner on to the LP Stub Shaft and Rotor Center

Sheet 2

Figure: V2500-A1 SBE 72-0132 and V2500-A5: Install the Nut Ring on to the LP Stub Shaft and Rotor Center

V2500-A1 SBE 72-0132 and V2500-A5: Install the Nut Ring on to the LP Stub Shaft and Rotor Center

Figure: Install the Short Holder on to the Stub Shaft and Rotor Center

Sheet 1

Figure: Install the Six Pins in the Threaded Holes of the Short Holder

Sheet 2

Figure: Align the Six Holes of the Restraint Holder with the Six Pins

Sheet 3

Figure: V2500-A1 Pre SBE 72-0132: Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

V2500-A1 Pre SBE 72-0132: Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

Figure: V2500-A1 SBE 72-0132 and V2500-A5: Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

V2500-A1 SBE 72-0132 and V2500-A5: Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

Figure: Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

Install the No. 1 Bearing Seal Assembly on to the Rotor Center Shaft

Figure: Install the No. 1 Bearing and Seal Seat on to the Rotor Center Shaft

Sheet 1

Figure: Install the No. 1 Bearing and Seal Seat on to the Rotor Center Shaft

Sheet 2

Figure: Install the No. 1 Bearing and Seal Seat on to the Rotor Center Shaft

Sheet 3

Figure: Prepare the Rotor Center Shaft, No. 1 Bearing Seal Seat and No. 1 Bearing

Prepare the Rotor Center Shaft, No. 1 Bearing Seal Seat and No. 1 Bearing

Figure: Install the Plain Nut on to the Rotor Center Shaft

Install the Plain Nut on to the Rotor Center Shaft

Figure: Install the Plain Nut on to the Center Shaft

Install the Plain Nut on to the Center Shaft

Figure: Install the NF Probe Phonic Wheel and No. 2 Inner Roller Bearing on to the Stub Shaft Assembly

Install the NF Probe Phonic Wheel and No. 2 Inner Roller Bearing on to the Stub Shaft Assembly

Figure: Move the LP Shaft, No. 1 and No. 2 Bearing Assembly from the Restraint Holder to the Storage Stand

Move the LP Shaft, No. 1 and No. 2 Bearing Assembly from the Restraint Holder to the Storage Stand

Figure: Move the LP Shaft No. 1 and No. 2 Bearing Assembly from the Restraint Holder to the Storage Stand

Sheet 1

Figure: Remove the Six Pins from the Short Holder

Sheet 2

Figure: Identify the LP Shaft, No. 1 and No. 2 Bearing Assembly

Identify the LP Shaft, No. 1 and No. 2 Bearing Assembly