Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-82-200-003-B00 LPC Stage 1.5 Blade - Examine, Inspection-003

General

This TASK gives the procedure for the inspection of the LP compressor stage 1.5 blades.

The policy that is necessary for inspection is given in the SPM TASK 70-20-00-200-501.

All parts must be cleaned before any part is examined. Refer to the SPM TASK 70-11-14-300-503.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in Step. Do the test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All the parts must be examined to make sure that all repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to the SPM for data on these items.

Definitions of Damage, SPM TASK 70-02-02-350-501

Inspection of Parts, SPM TASK 70-20-00-200-501

Some data on these items are contained in this TASK. For more data on these items refer to the SPM.

Method of Testing for Crack Indications

Chemical Processes

Surface Protection

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

NOTE

For the method to clean the part, refer to the SPM TASK 70-11-14-300-503.Clean the parts. Refer to TASK 72-32-82-100-000 (CLEANING-000).

SUBTASK 72-32-82-230-057 Examine the LP Compressor Stage 1.5 Blades (01-400) for Cracks

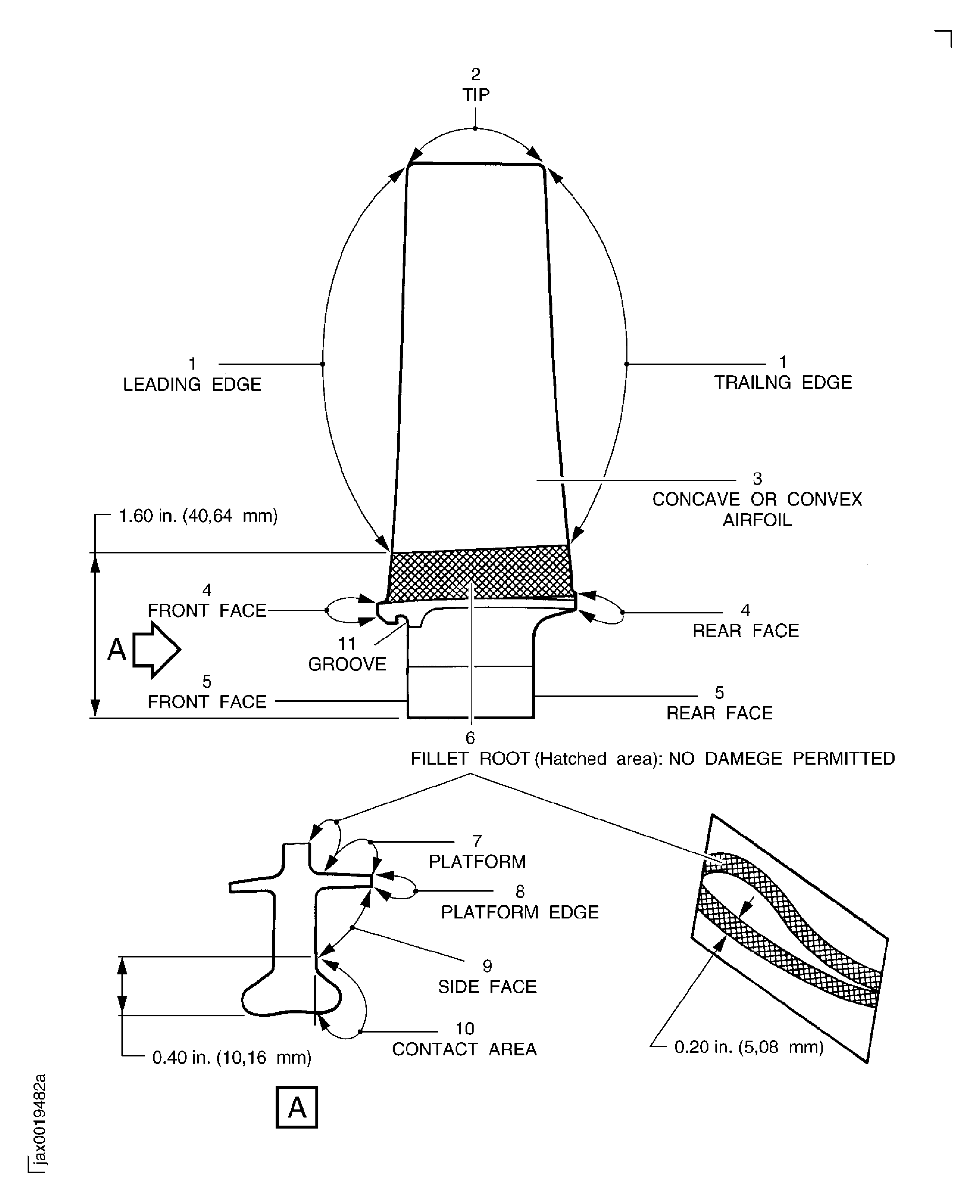

Refer to Figure.

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Nicked and dented

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Erosion

Examine the leading and trailing edges at location 1.

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Nicked and dented

Examine the concave and convex airfoil surfaces at location 3.

SUBTASK 72-32-82-220-074 Examine the LP Compressor Stage 1.5 Blade (01-400) Airfoils

Refer to Figure.

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Nicked and dented

Examine the platform at location 7.

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Nicked and dented

Examine the front and rear faces at location 4.

More than in Step

Galled.

Examine the platform edge at location 8.

SUBTASK 72-32-82-220-075 Examine the LP Compressor Stage 1.5 Blades (01-400) Platform

Repair, VRS1385 TASK 72-32-82-300-001 (REPAIR-001)

Any nicks and dents

Examine the front and rear faces at location 5 and side face at location 9.

Repair, VRS1377 TASK 72-32-82-300-017 (REPAIR-017)

Less then 0.002 in. (0.05 mm) in depth

Fretted.

Examine the dovetail side face contact area at location 10.

SUBTASK 72-32-82-220-076 Examine the LP Compressor Stage 1.5 Blades (01-400) Dovetail

Refer to Figure.

SUBTASK 72-32-82-220-077 Examine the LP Compressor Stage 1.5 Blades (01-400) Groove

Refer to Figure.

Repair, VRS1384 TASK 72-32-82-300-008 (REPAIR-008)

Deteriorated or unbonded

Examine the sealing strip.

SUBTASK 72-32-82-220-078 Examine the LP Compressor Stage 1.5 Blades (01-400) Sealing Strip

Refer to Figure.

SUBTASK 72-32-82-220-115 Examine the LP Compressor Stage 1.5 Blades (01-400) Fillet Root

Repair, VRS1387 TASK 72-32-82-300-002 (REPAIR-002)

Apply dry film coating

SUBTASK 72-32-82-380-074 Apply the Dry Film Coating

Figure: Locations on the LP compressor stage 1.5 blades

Locations on the LP compressor stage 1.5 blades

Figure: Location of the LP compressor stage 1.5 blades sealing strip

Location of the LP compressor stage 1.5 blades sealing strip

Figure: Dovetail contact area of the LP Compressor 1.5 Blades

Dovetail contact area of the LP Compressor 1.5 Blades