Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-047 LPC Stage 1.5 Stator - Replace The Abradable Seal, Repair-047 (VRS1765)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

LP compressor stage 1.5 vane assembly | Vane: Titanium alloy Inner ring: Aluminum alloy |

General

Price and availability - none

The area used for bonding must be segregated from normal workshop conditions, and must be kept clean. Refer to SPM TASK 70-36-07-360-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dry blast cabinet | LOCAL | Dry blast cabinet | ||

| Hardness tester (durometer) | LOCAL | Hardness tester (durometer) | ||

| Injector | LOCAL | Injector | (air pressure type) | |

| Plastic scraper | LOCAL | Plastic scraper | ||

| Vacuum cleaner | LOCAL | Vacuum cleaner | ||

| IAE 3J12775 Bond test fixture | 0AM53 | IAE 3J12775 | ||

| IAE 3J12785 Inspection stand | 0AM53 | IAE 3J12785 | ||

| IAE 3J12792 Inspection stand | 0AM53 | IAE 3J12792 | ||

| IAE 3J12807 Molding fixture | 0AM53 | IAE 3J12807 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-050 SILICON CARBIDE GRIT | 1E1X8 | CoMat 05-050 | ||

| CoMat 08-032 PRIMER | 71984 | CoMat 08-032 | ||

| CoMat 08-037 DELETED | LOCAL | CoMat 08-037 | ||

| CoMat 08-038 SILICONE RUBBER COMPOUND | 64101 | CoMat 08-038 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Apply adhesive tape for masking to the areas which do not require removing the remaining abradable seal.

Refer to SPM TASK 70-12-07-120-501.

Use dry plastic blast to remove the remaining abradable seal.

Remove adhesive tape for masking.

Remove the remaining abradable seal, if it is not fully removed by Step.

SUBTASK 72-32-83-360-098 Remove the Damaged Abradable Seal

Refer to Figure.

Refer to SPM TASK 70-36-06-360-501.

Use a CoMat 02-099 LINT-FREE CLOTH made moist.

Wipe the blasted surfaces.

SUBTASK 72-32-83-120-059 Clean the Surfaces which are to be Applied with Silicon Rubber Compound

Refer to SPM TASK 70-36-06-360-501.

Use CoMat 08-032 PRIMER.

NOTE

The primed surface must have a faint pink color. If there is no color, the primer layer is not continuous. If the color is bright, streaky bright or chalky, the primer is too thick.Keep the primer in a small container for single use only. The primer that remains must not be used.Immediately after the air dry, apply a very thin layer (thickness 0.0001 in. (0.003 mm) of primer to the molding surface with the use of a piece of cheese cloth.

Refer to SPM TASK 70-36-06-360-501, SUBTASK 70-36-06-360-001.

Cure the primed surface.

SUBTASK 72-32-83-360-099 Apply Primer to the Surfaces after Cleaning

Refer to SPM TASK 70-36-06-360-501.

NOTE

The silicone rubber compound has a shelf life of six months from the date of shipment.The compound, as received, must be kept at a temperature not higher than 90 deg F (32 deg C).Mix the silicone rubber compound with the use of a mixer with a drill press to between 70 deg F and 80 deg F (21 deg C and 27 deg C) for 20 minutes to 30 minutes.

SUBTASK 72-32-83-360-100 Mix the Silicone Rubber Compound

Use the IAE 3J12807 Molding fixture 1 off.

Clean the molding fixture.

SUBTASK 72-32-83-360-101 Mold the Silicone Rubber Compound

Refer to SPM TASK 70-36-06-360-501.

Cure the compound.

Refer to SPM TASK 70-36-06-360-501.

Cure the component.

SUBTASK 72-32-83-360-102 Cure the Silicone Rubber Compound

Refer to TASK 72-32-83-200-000 (INSPECTION/CHECK-000).

Refer to SPM TASK 70-36-06-360-501.

Visually examine the repaired area.

SUBTASK 72-32-83-220-172 Examine the Repaired Area

Refer to Figure.

Use IAE 3J12775 Bond test fixture 1 off, IAE 3J12785 Inspection stand 1 off and IAE 3J12792 Inspection stand 1 off.

No signs of bulging or air leakage are permitted.

NOTE

The bond test must be done after curing of the rubber compound on the following conditions:Inspection gas: Air or nitrogen gas.Gas pressure: 200 psig (1380 kPa).Inspection position: Change the pattern as necessary to examine the not fully repaired area.Probe angle: Approximately 45 degrees.Do a bond test to the repaired area.

SUBTASK 72-32-83-220-173 Do a Bond Test to the Repaired Area

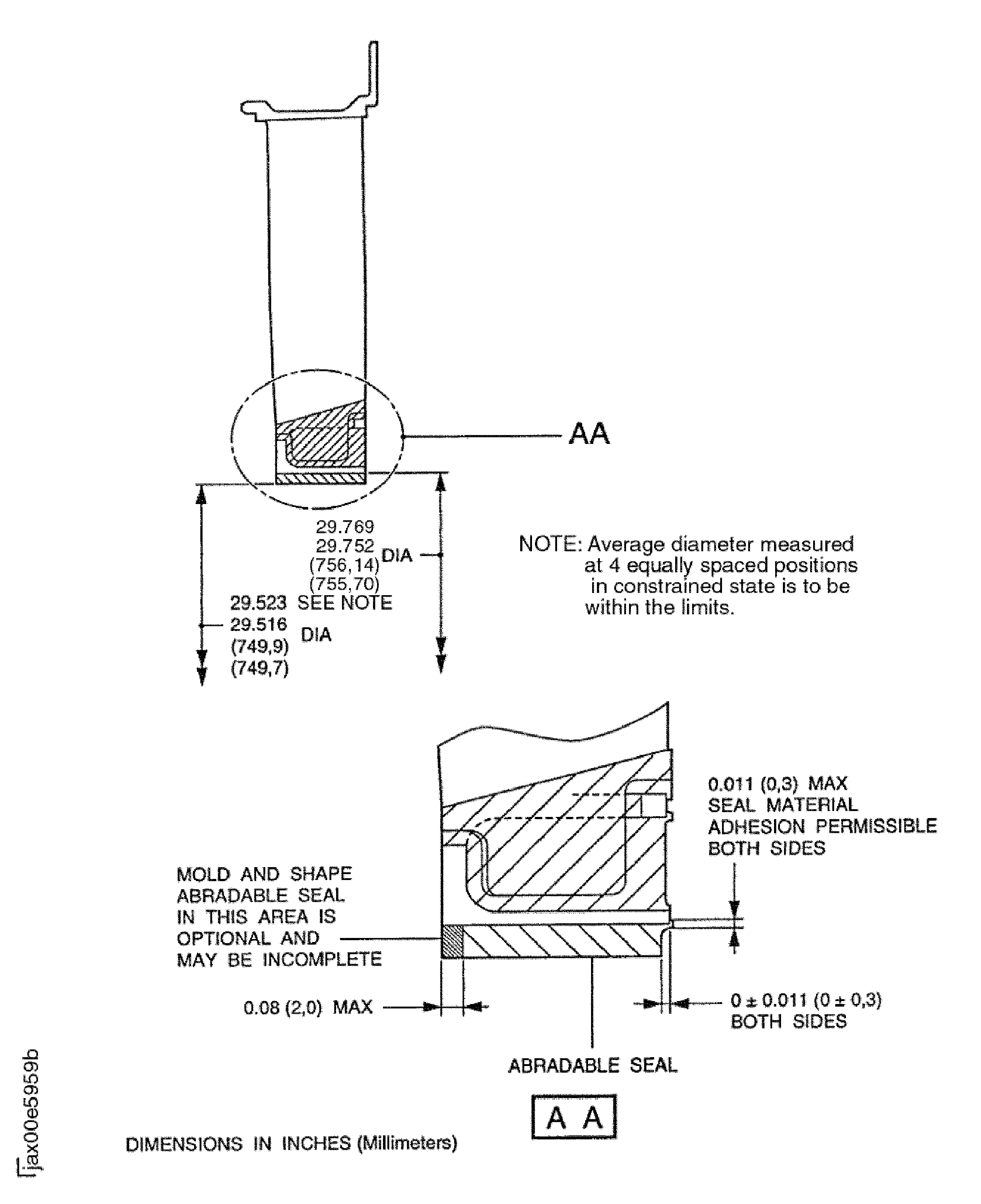

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions