Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-87-300-005 Fan Case Rear Liner Panel - Repair Surface Erosion, Repair-005 (VRS1803)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

02-100 | 5A2149 | Assembly A |

02-100 | 5A0258 | Assembly A |

02-100 | 5A0842 | Assembly A |

02-100 | 5A1379 | Assembly A |

02-100 | 5A1743 | Assembly A |

02-100 | 5A0809 | Assembly B |

02-100 | 5A1622 | Assembly B |

02-100 | 5A1680 | Assembly B |

02-100 | 5A1737 | Assembly B |

02-100 | 5A1119 | Assembly C |

02-150 | 5A2149 | Assembly A |

02-150 | 5A0258 | Assembly A |

02-150 | 5A0842 | Assembly A |

02-150 | 5A1379 | Assembly A |

02-150 | 5A1743 | Assembly A |

02-150 | 5A0809 | Assembly B |

02-150 | 5A1622 | Assembly B |

02-150 | 5A1680 | Assembly B |

02-150 | 5A1737 | Assembly B |

02-150 | 5A1120 | Assembly C |

02-200 | 5A2150 | Assembly D |

02-200 | 5A0259 | Assembly D |

02-200 | 5A0843 | Assembly D |

02-200 | 5A1380 | Assembly D |

02-200 | 5A1744 | Assembly D |

02-200 | 5A0814 | Assembly E |

02-200 | 5A1623 | Assembly E |

02-200 | 5A1681 | Assembly E |

02-200 | 5A1738 | Assembly E |

02-200 | 5A1122 | Assembly F |

02-250 | 5A2151 | Assembly G |

02-250 | 5A0844 | Assembly G |

02-250 | 5A1381 | Assembly G |

02-250 | 5A0817 | Assembly H |

02-250 | 5A1625 | Assembly H |

02-290 | 5A0815 | Assembly J |

02-290 | 5A1626 | Assembly J |

02-300 | 5A2152 | Assembly K |

02-300 | 5A0260 | Assembly K |

02-300 | 5A0845 | Assembly K |

02-300 | 5A1382 | Assembly K |

02-300 | 5A1745 | Assembly K |

02-300 | 5A0818 | Assembly I |

02-300 | 5A1624 | Assembly I |

02-300 | 5A1682 | Assembly I |

02-300 | 5A1739 | Assembly I |

02-300 | 5A1125 | Assembly L |

02-350 | 5A2149 | Assembly A |

02-350 | 5A0258 | Assembly A |

02-350 | 5A0842 | Assembly A |

02-350 | 5A1379 | Assembly A |

02-350 | 5A1743 | Assembly A |

02-350 | 5A0809 | Assembly B |

02-350 | 5A1622 | Assembly B |

02-350 | 5A1680 | Assembly B |

02-350 | 5A1737 | Assembly B |

02-350 | 5A1121 | Assembly C |

02-400 | 5A2150 | Assembly D |

02-400 | 5A0259 | Assembly D |

02-400 | 5A0843 | Assembly D |

02-400 | 5A1380 | Assembly D |

02-400 | 5A1744 | Assembly D |

02-400 | 5A0814 | Assembly E |

02-400 | 5A1623 | Assembly E |

02-400 | 5A1681 | Assembly E |

02-400 | 5A1738 | Assembly E |

02-400 | 5A1123 | Assembly F |

02-450 | 5A2150 | Assembly D |

02-450 | 5A0259 | Assembly D |

02-450 | 5A0843 | Assembly D |

02-450 | 5A1380 | Assembly D |

02-450 | 5A1744 | Assembly D |

02-450 | 5A0814 | Assembly E |

02-450 | 5A1623 | Assembly E |

02-450 | 5A1681 | Assembly E |

02-450 | 5A1738 | Assembly E |

02-450 | 5A1124 | Assembly F |

02-500 | 5A2152 | Assembly K |

02-500 | 5A0260 | Assembly K |

02-500 | 5A0845 | Assembly K |

02-500 | 5A1382 | Assembly K |

02-500 | 5A1745 | Assembly K |

02-500 | 5A0818 | Assembly I |

02-500 | 5A1624 | Assembly I |

02-500 | 5A1682 | Assembly I |

02-500 | 5A1739 | Assembly I |

02-500 | 5A1126 | Assembly L |

02-550 | 5A2152 | Assembly K |

02-550 | 5A0260 | Assembly K |

02-550 | 5A0845 | Assembly K |

02-550 | 5A1382 | Assembly K |

02-550 | 5A1745 | Assembly K |

02-550 | 5A0818 | Assembly I |

02-550 | 5A1624 | Assembly I |

02-550 | 5A1682 | Assembly I |

02-550 | 5A1739 | Assembly I |

02-550 | 5A1143 | Assembly L |

General

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 07-080 TWO-PACK EPOXY PRIMER AND CATALYST | LOCAL | CoMat 07-080 | ||

| CoMat 07-081 EPOXY PRIMER CATALYST | 0AM53 | CoMat 07-081 | ||

| CoMat 07-082 THINNER | LOCAL | CoMat 07-082 | ||

| CoMat 07-153 POLYURETHANE PAINT GLOSSBLACK | LOCAL | CoMat 07-153 | ||

| CoMat 07-154 POLYURETHANE PAINT CATALYSTX-501 | LOCAL | CoMat 07-154 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 | ||

| CoMat 08-049 FIBREGLASS CLOTH | K6835 | CoMat 08-049 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Repaired area must be smoothly continuous with adjacent surface.

Refer to the SPM TASK 70-35-03-300-501.

NOTE

The repaired area can be used as it is. Epoxy resin and polyurethane paint may not be applied to the repaired area at location 5 in subsequent processes.Make smooth and/or hand polish to remove the damage.

SUBTASK 72-32-87-350-018 Repair the Damage at Location 5, Assembly H

Refer to the SPM TASK 70-11-26-300-503.

Clean the area that is to be repaired.

SUBTASK 72-32-87-350-008 Prepare Liner Panel for Repair

Use CoMat 08-015 RESIN and CoMat 08-016 HARDENER. Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-021.

WARNING

DURING THE OPERATION, WEAR PROTECTIVE GLOVES AND GOGGLES.

WARNING

DURING THE OPERATION, MAKE SURE THERE IS SUFFICIENT VENTILATION.NOTE

It is recommended to use one fiberglass cloth for approximately every 0.0059 in. (0.15 mm) in the depth.NOTE

When there are locally deep erosion areas on the repaired area, fill the areas with the mixture of epoxy resin and fiberglass cloth which is cut into fine strips.Make up the epoxy resin from the two parts.

SUBTASK 72-32-87-380-011 Apply Epoxy Resin to the Damaged Area

Use CoMat 07-080 TWO-PACK EPOXY PRIMER AND CATALYST and CoMat 07-081 EPOXY PRIMER CATALYST in equal parts.

NOTE

If necessary, the CoMat 07-082 THINNER can be added up to 10 percent by volume.NOTE

The mixture must be allowed to stand for 30 minutes before it is used.NOTE

The pot life of the mixture is eight hours. If you do not use the mixture within eight hours, discard it.Mix the primer base and the catalyst.

SUBTASK 72-32-87-380-013 Make up the Epoxy Primer

Use CoMat 07-153 POLYURETHANE PAINT GLOSSBLACK and CoMat 07-154 POLYURETHANE PAINT CATALYSTX-501 in equal parts.

NOTE

If necessary, the CoMat 07-082 THINNER can be added, up to 10 percent of the volume.NOTE

The mixture must be allowed to stand for 30 minutes before it is used.NOTE

The pot life of the mixture is eight hours. If you do not use the mixture within eight hours, discard it.Mix the primer base and the catalyst.

SUBTASK 72-32-87-380-014 Make up the Polyurethane Paint

Visually examine the repaired area. Nicks, dents, scratches, delamination or other damages are not permitted. Refer to TASK 72-32-87-200-000 (INSPECTION-000).

Visually examine the panel.

SUBTASK 72-32-87-220-073 Examine the Panel Liner

Use the ink method. Refer to the SPM TASK 70-09-00-400-501.

Make a mark VRS1803 with permanent ink adjacent to the part number.

SUBTASK 72-32-87-350-010 Mark Repair Number on Panel Liner

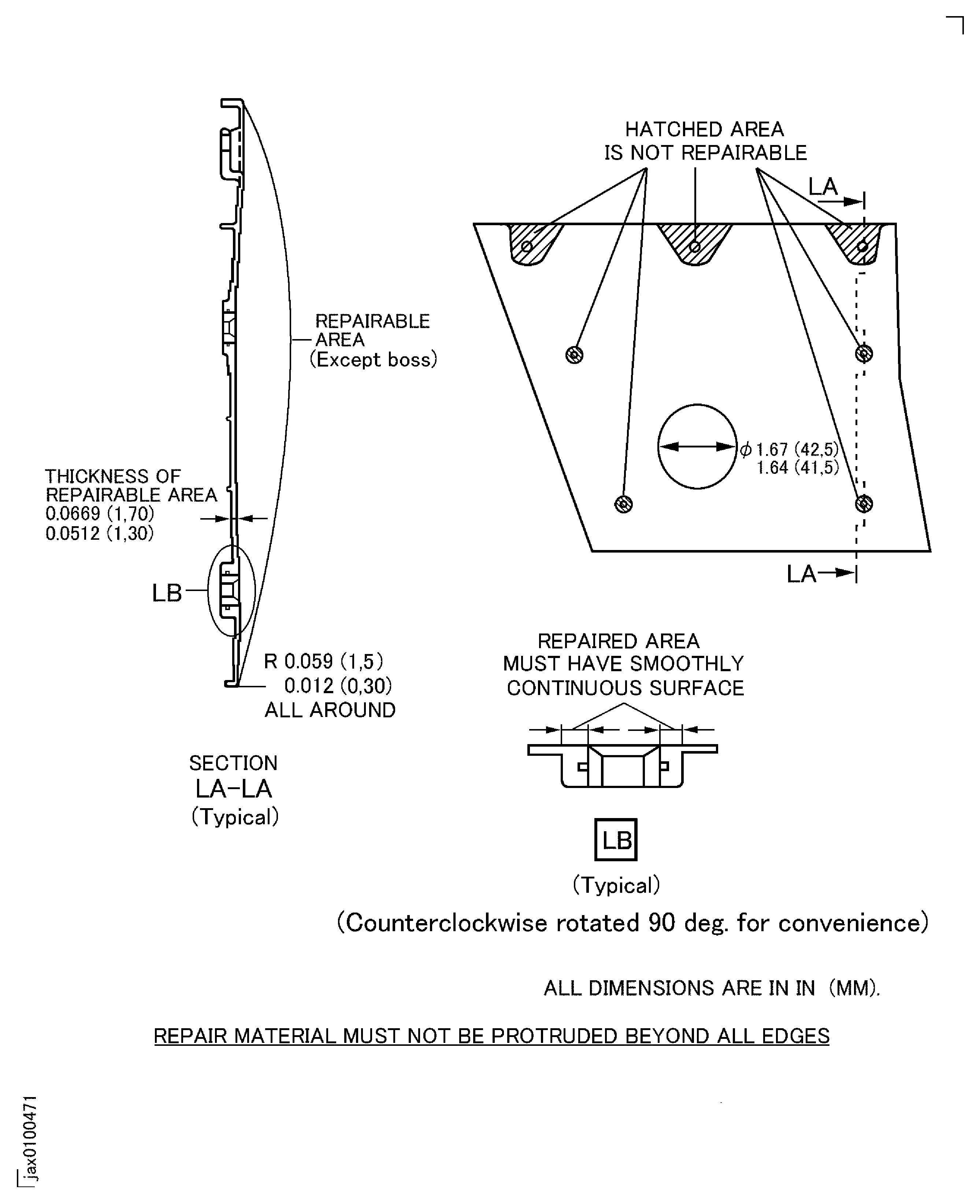

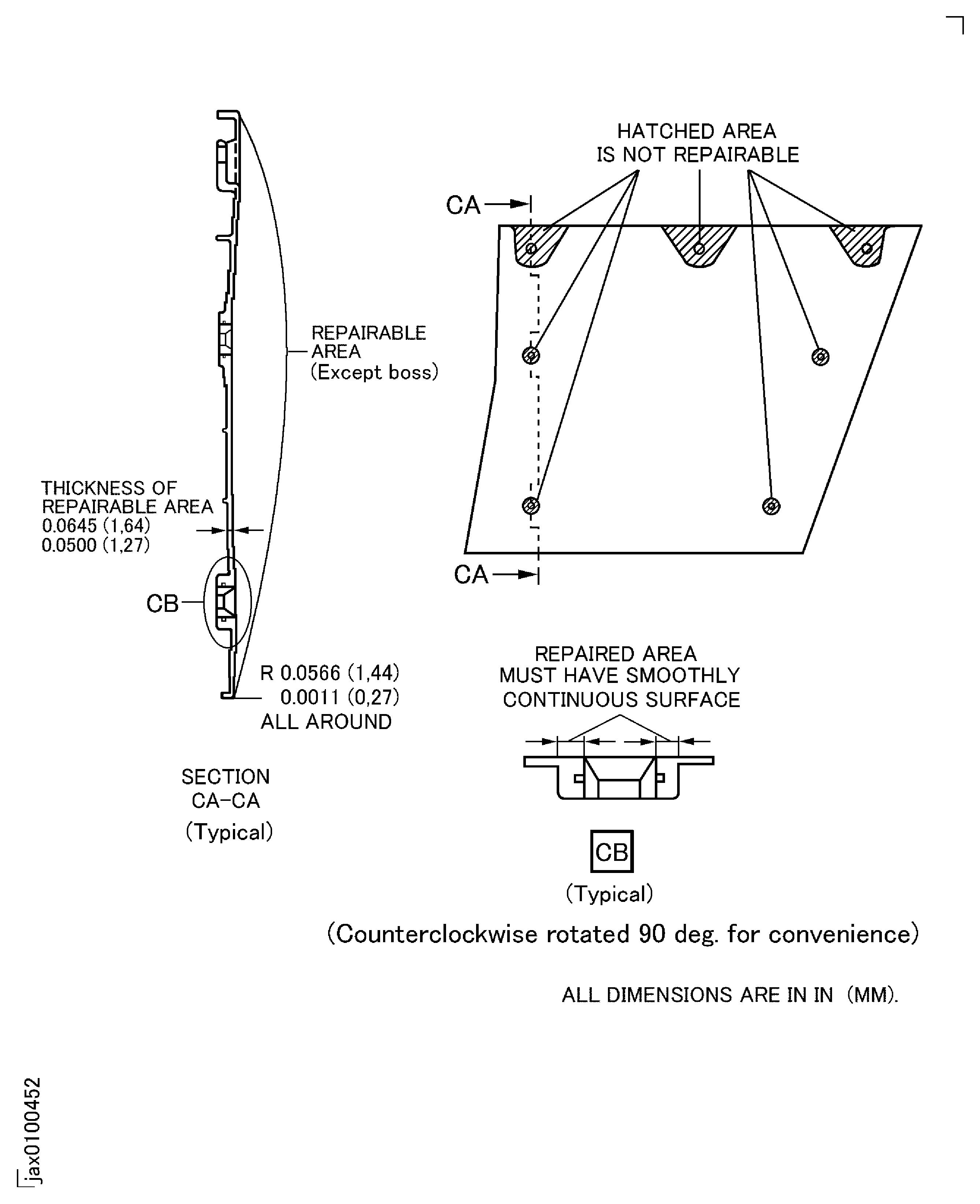

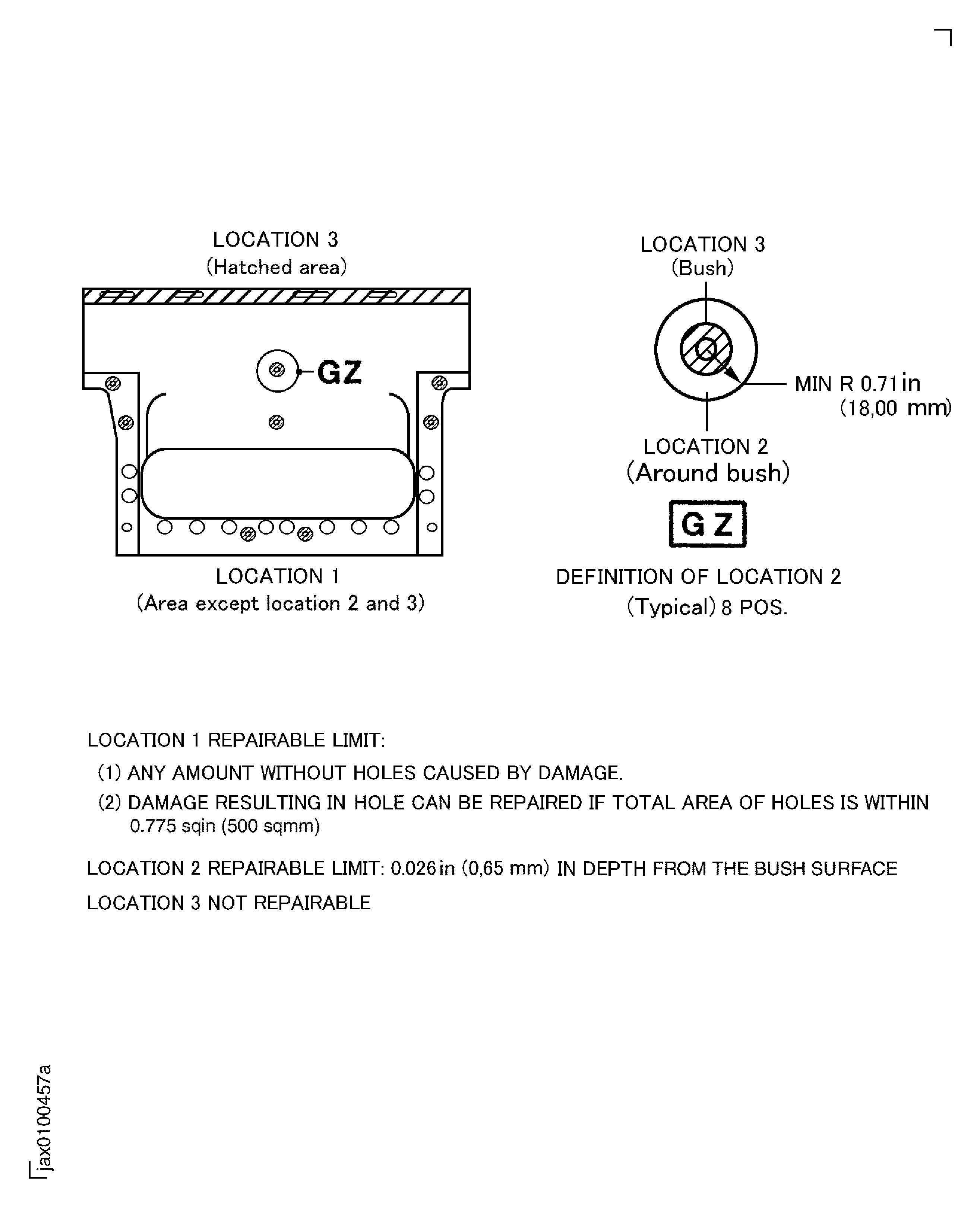

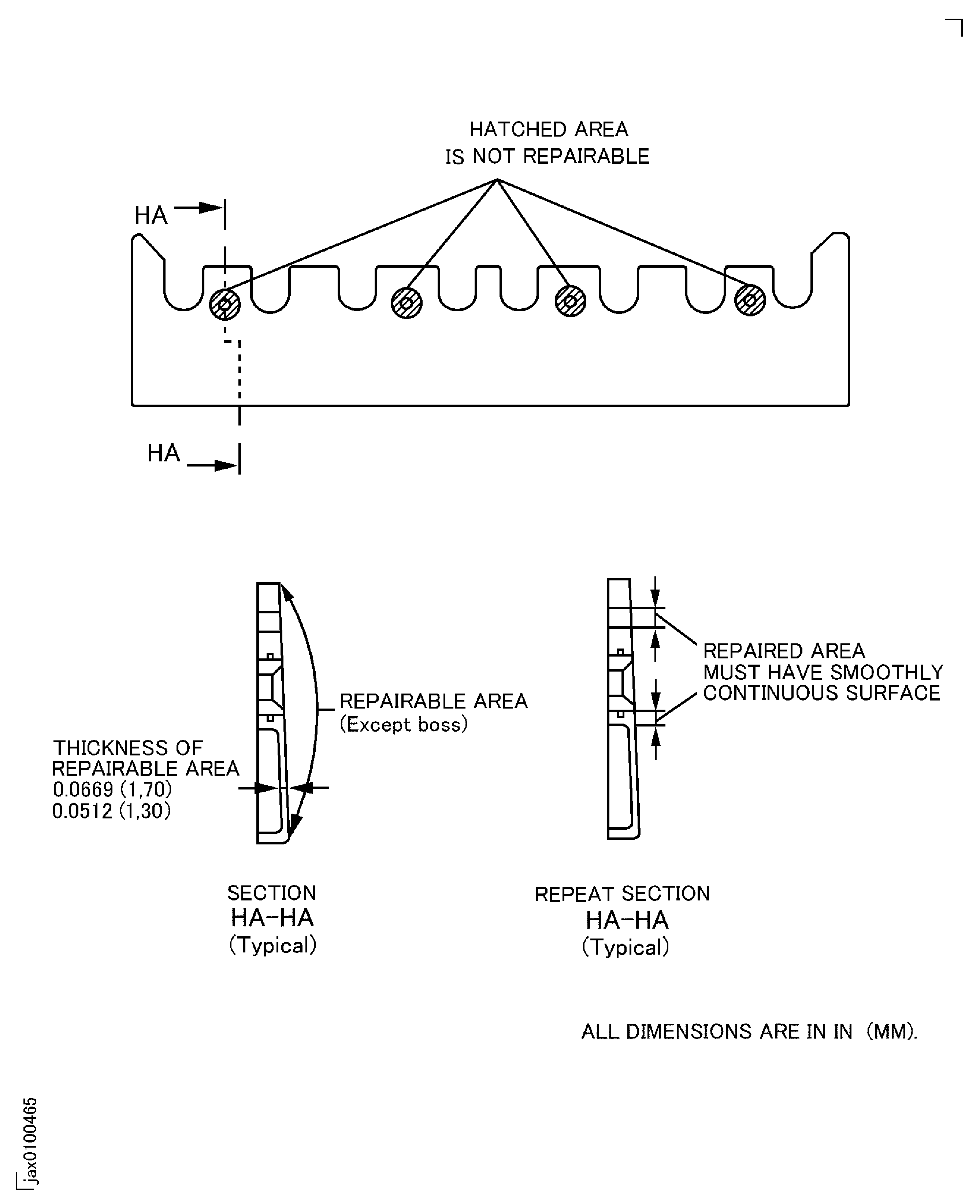

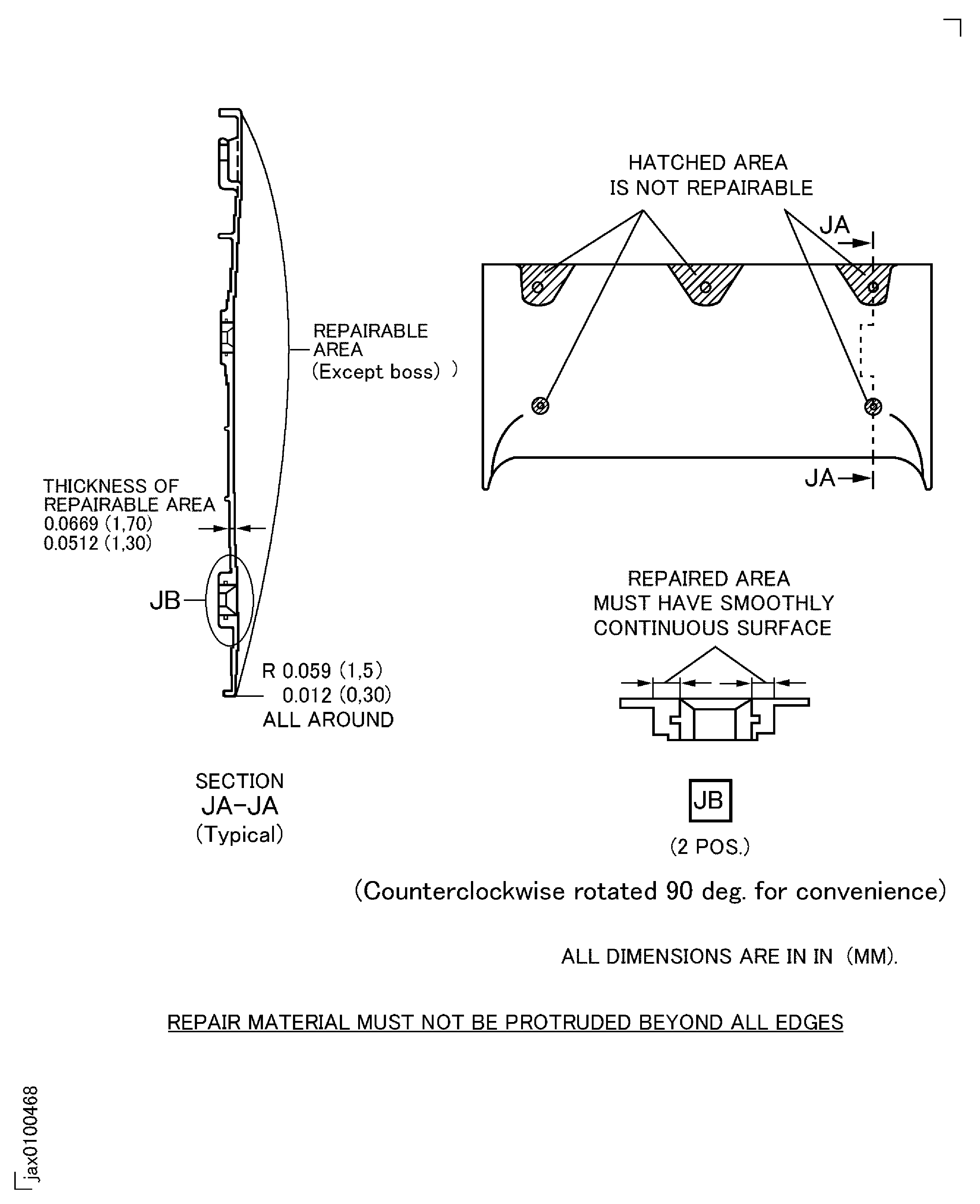

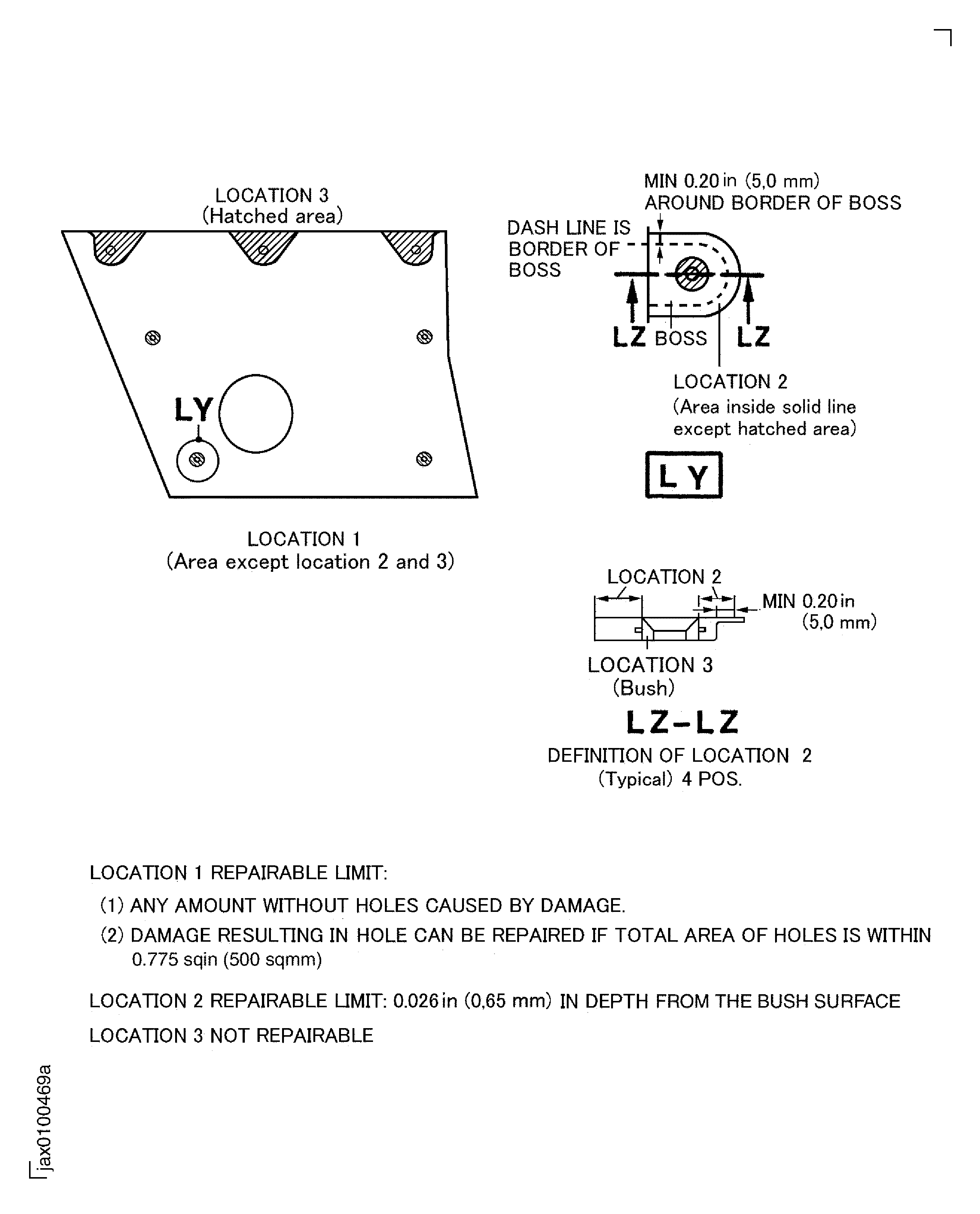

Figure: Repairable limit for Assembly A, D and K

Repairable limit for Assembly A, D and K

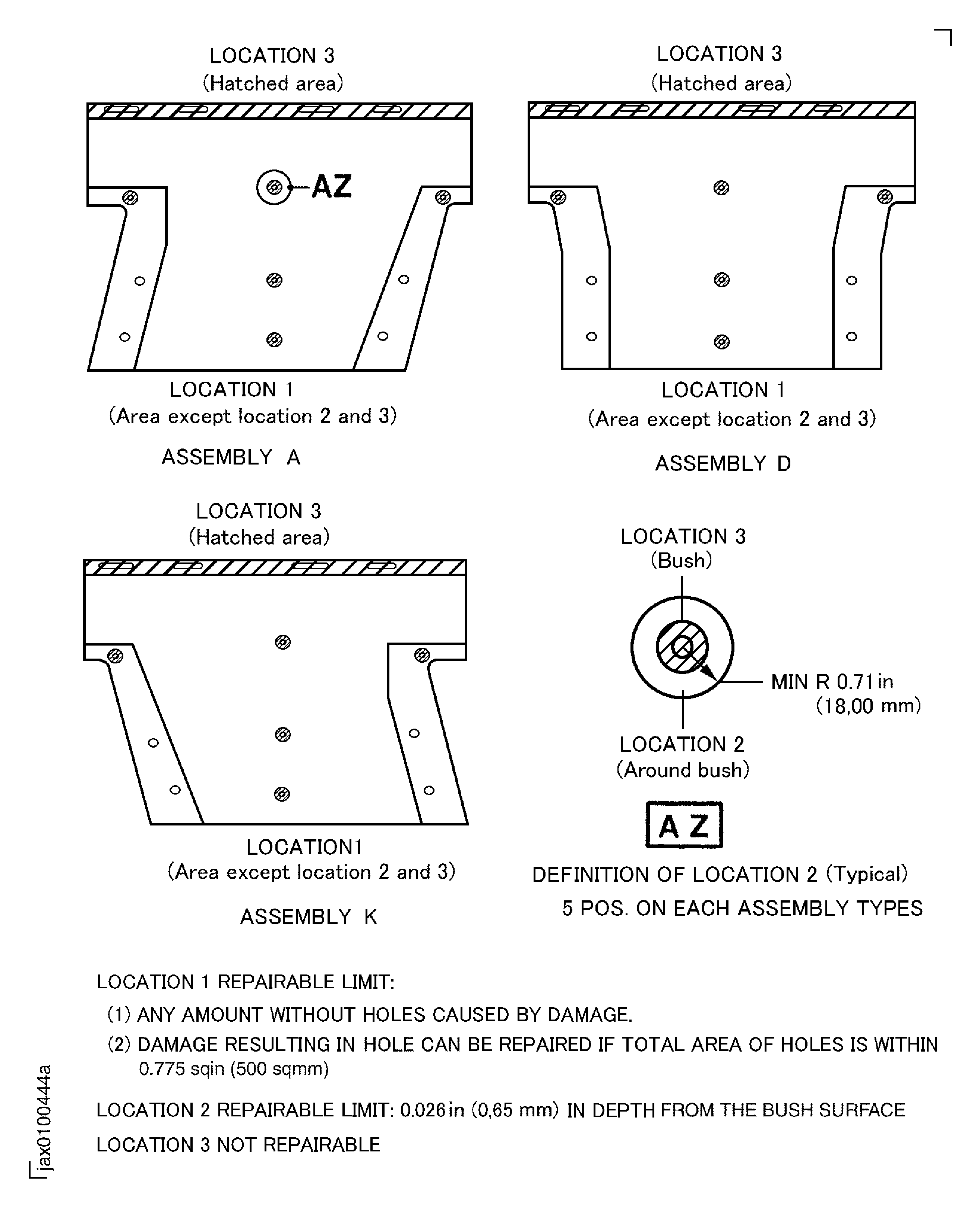

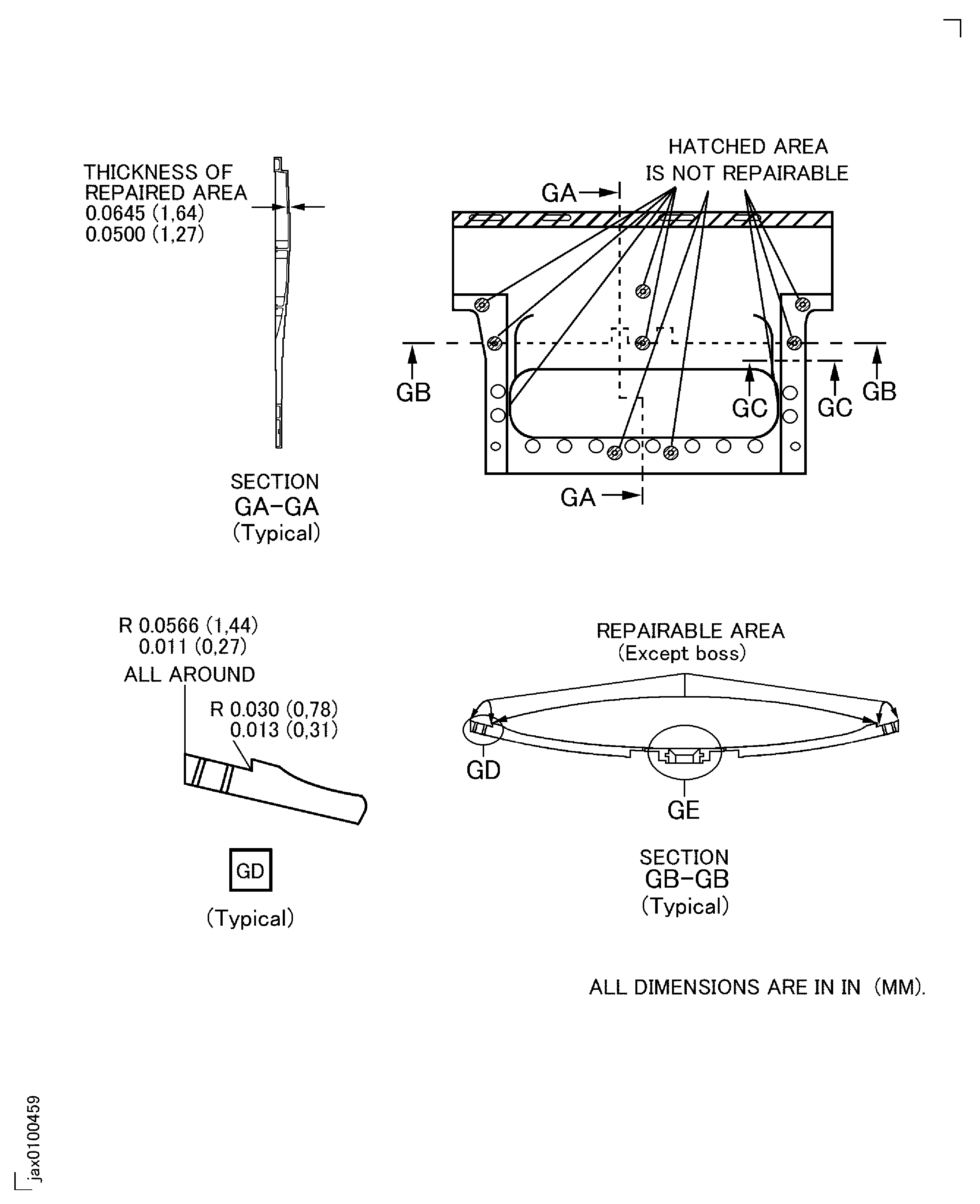

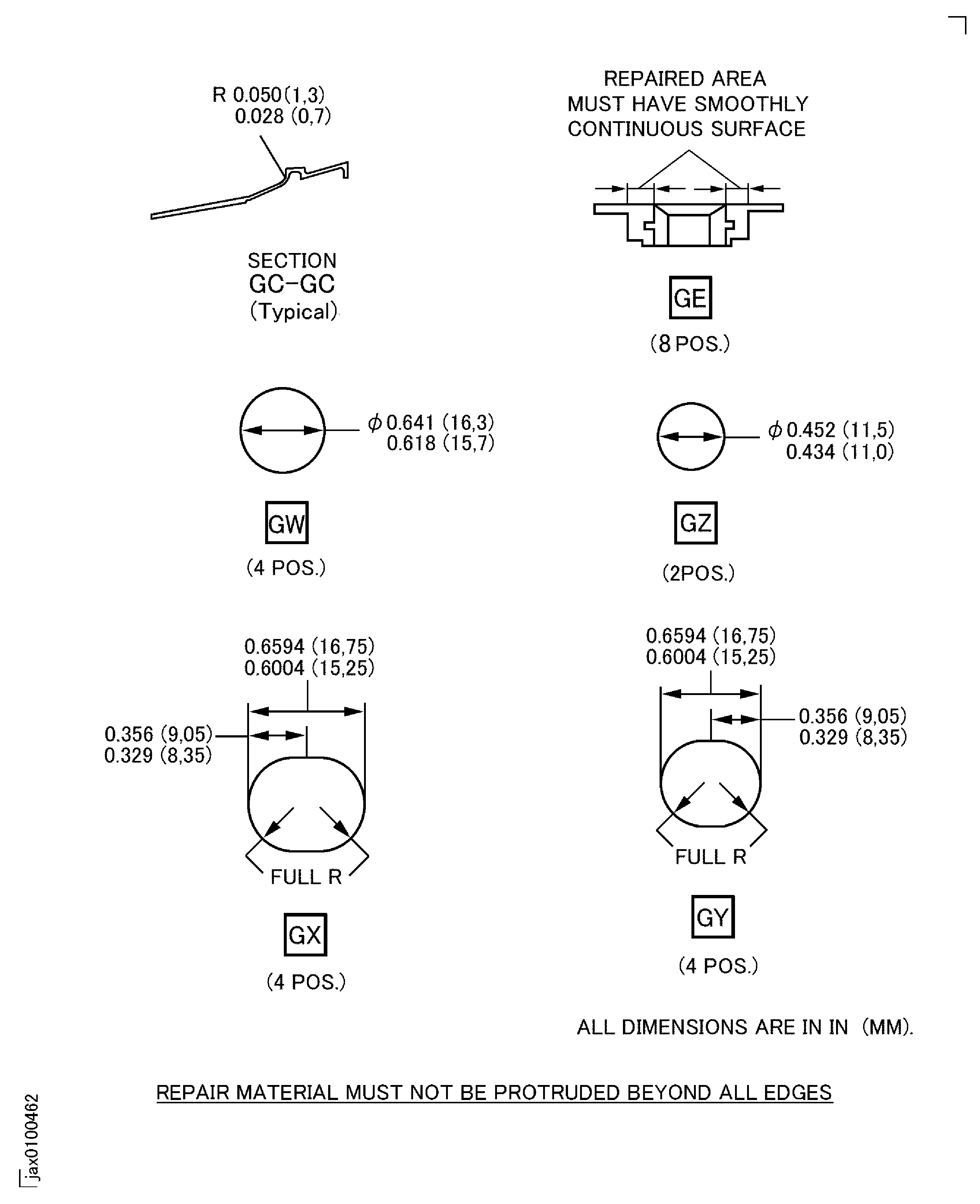

Figure: In process dimension before painting polyurethane paint for Assembly A, D and K

In process dimension before painting polyurethane paint for Assembly A, D and K

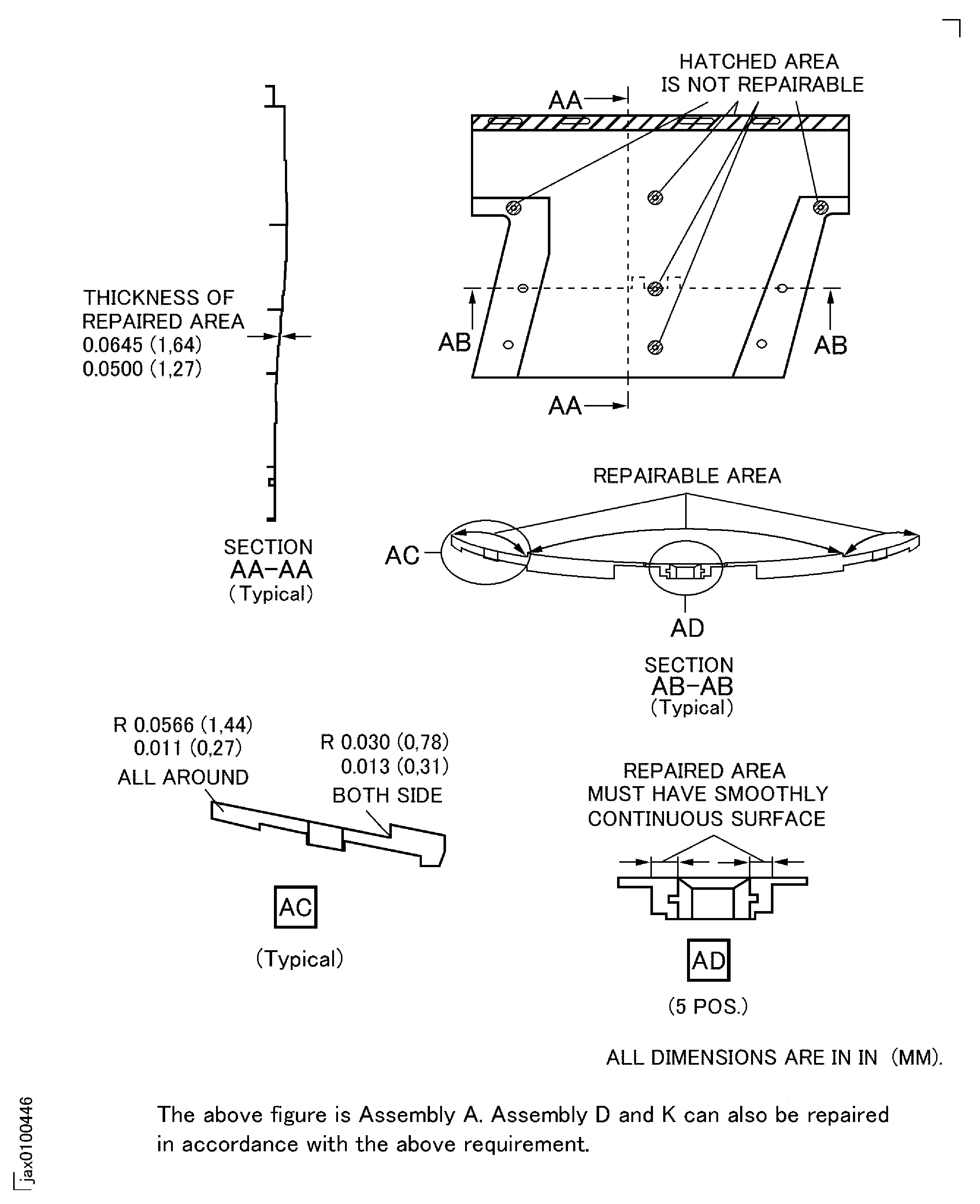

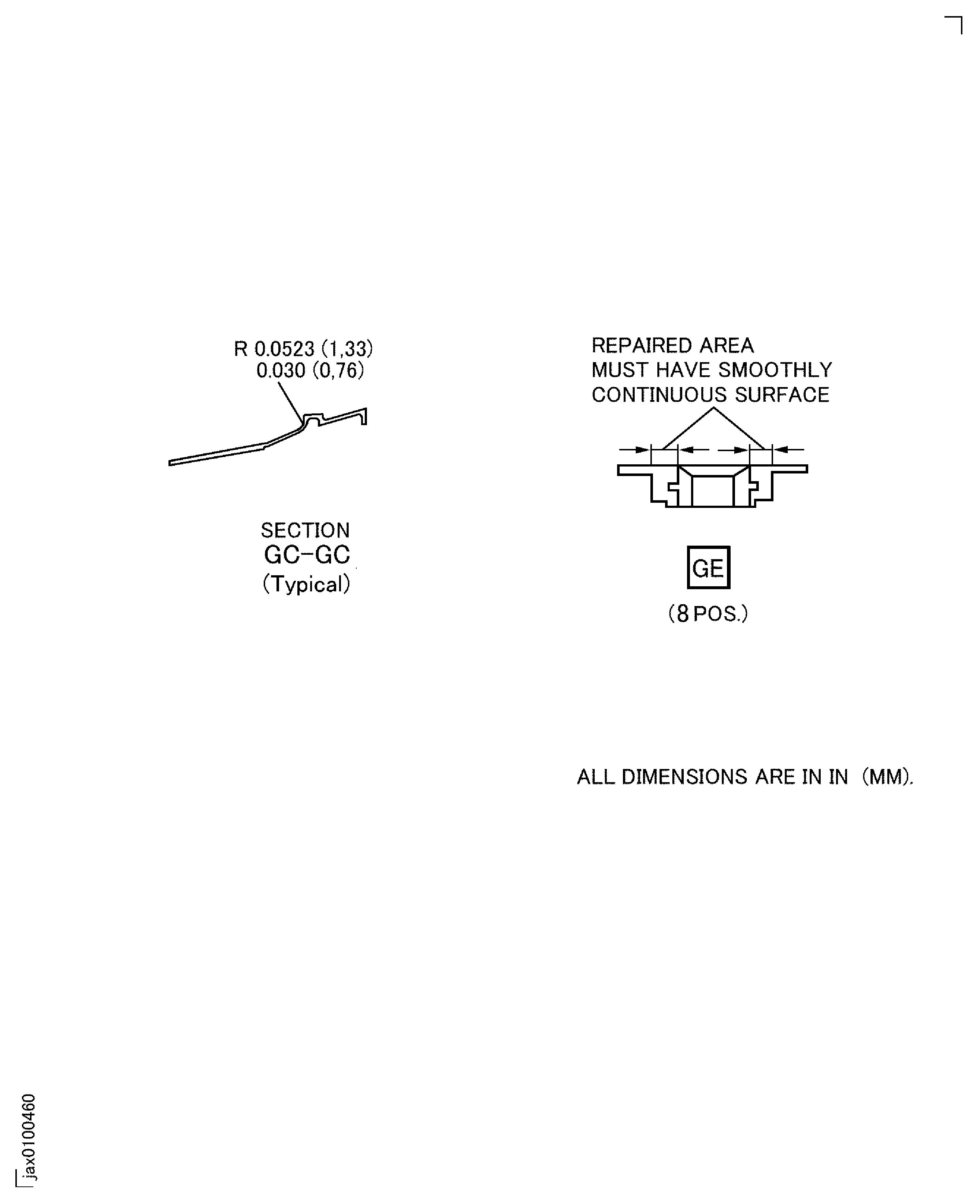

Figure: Detail dimension of repair for Assembly A, D and K

Detail dimension of repair for Assembly A, D and K

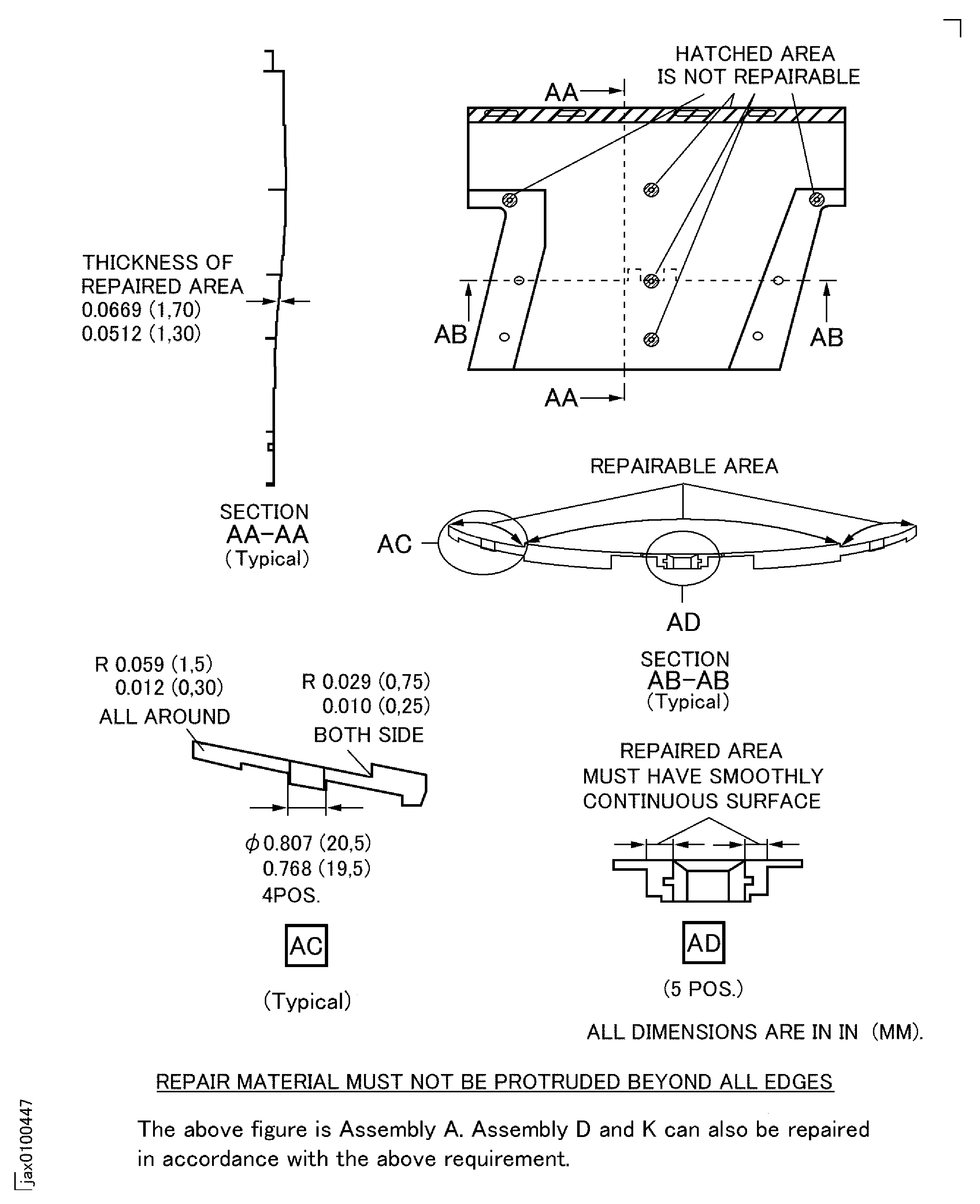

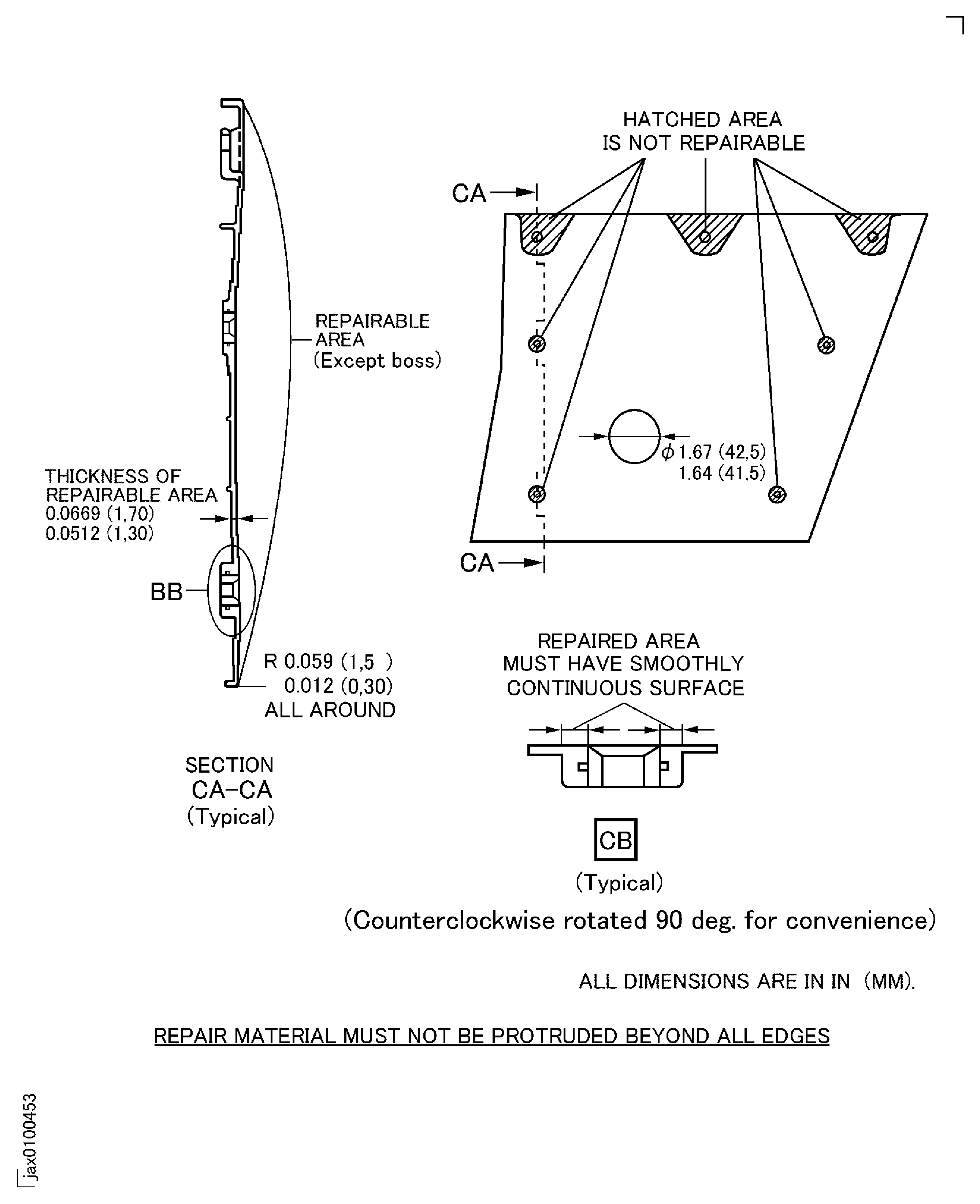

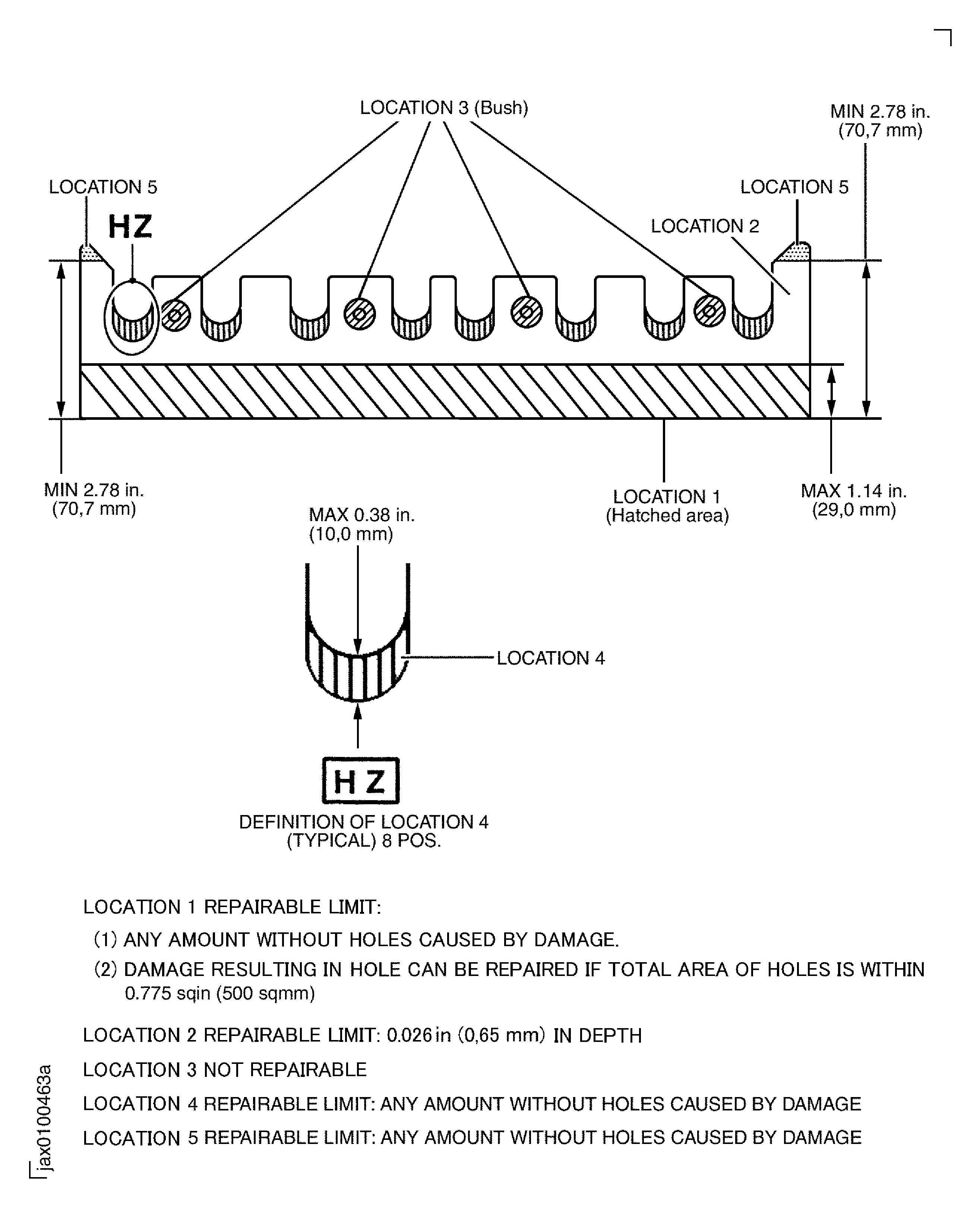

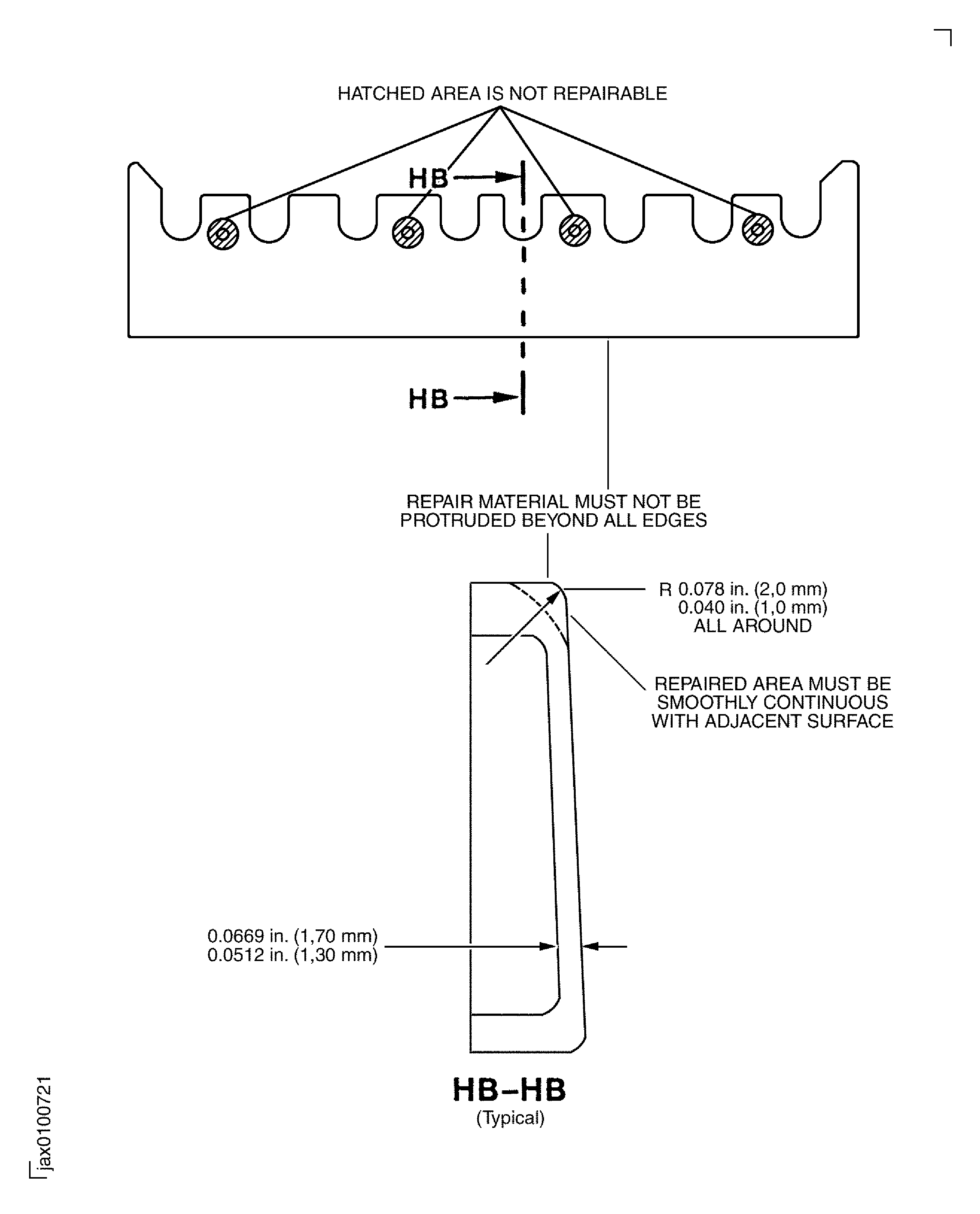

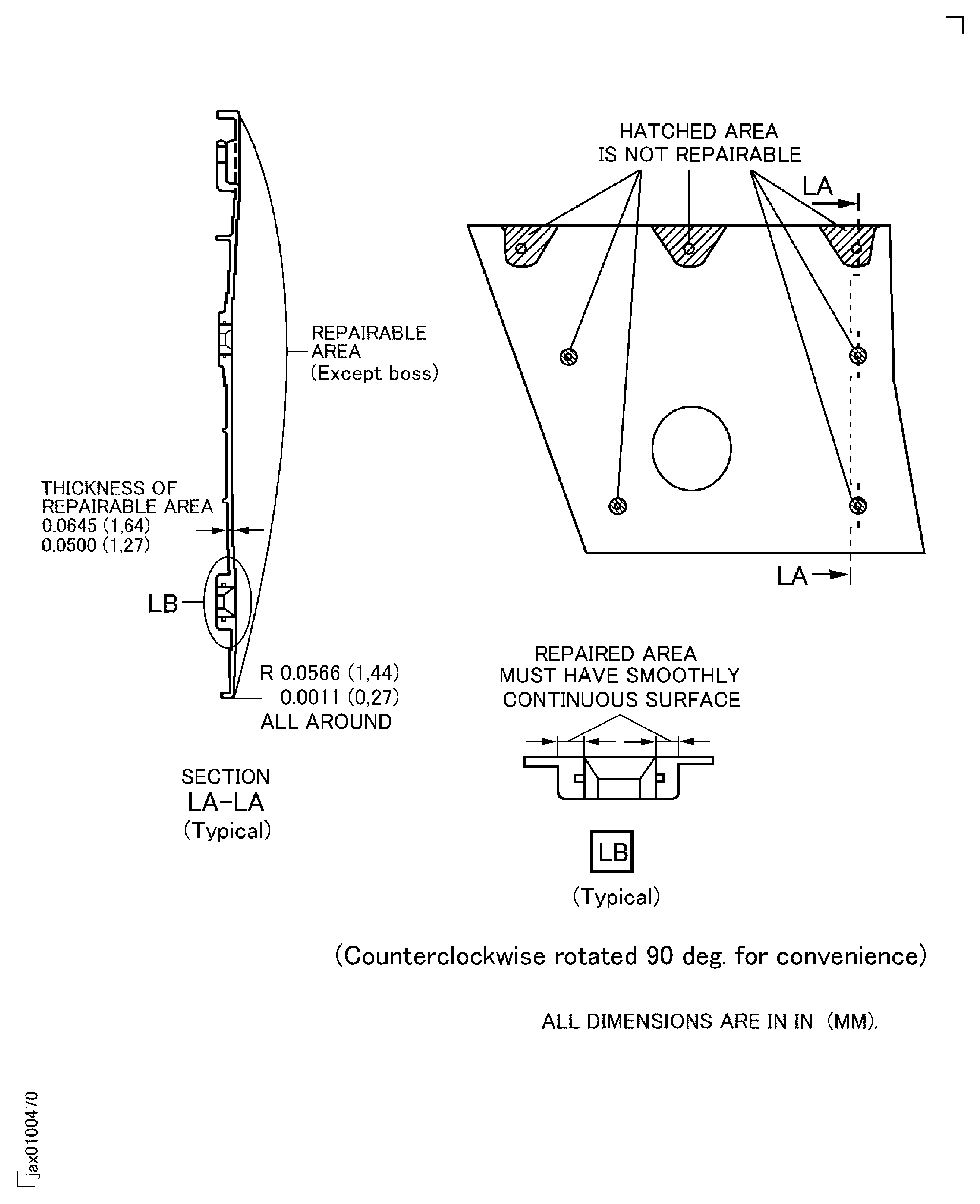

Figure: Repairable limit for Assembly B, E and I

Repairable limit for Assembly B, E and I

Figure: In process dimension before painting polyurethane paint for Assembly B, E and I

In process dimension before painting polyurethane paint for Assembly B, E and I

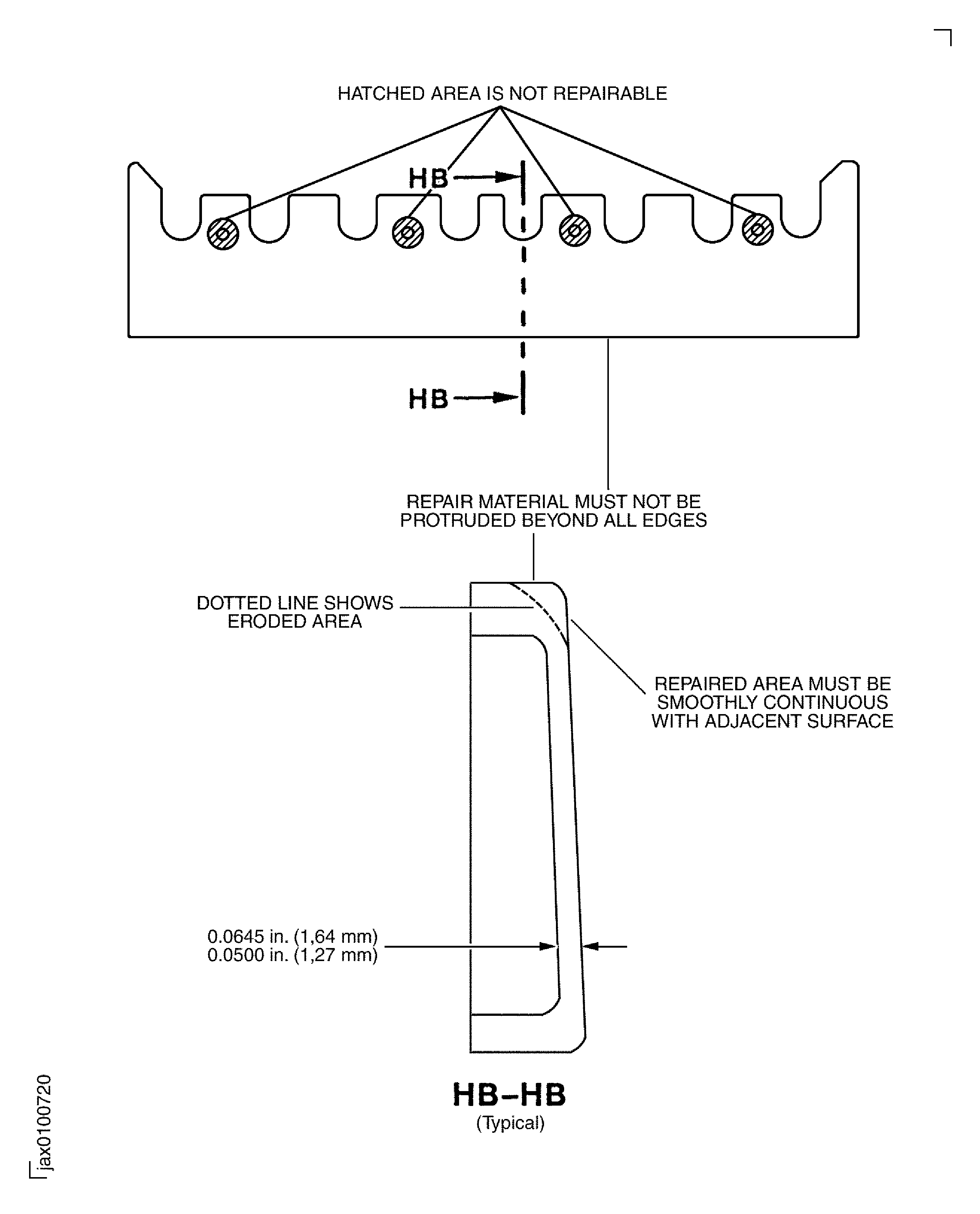

Figure: Detail dimension of repair for Assembly B, E and I

Detail dimension of repair for Assembly B, E and I

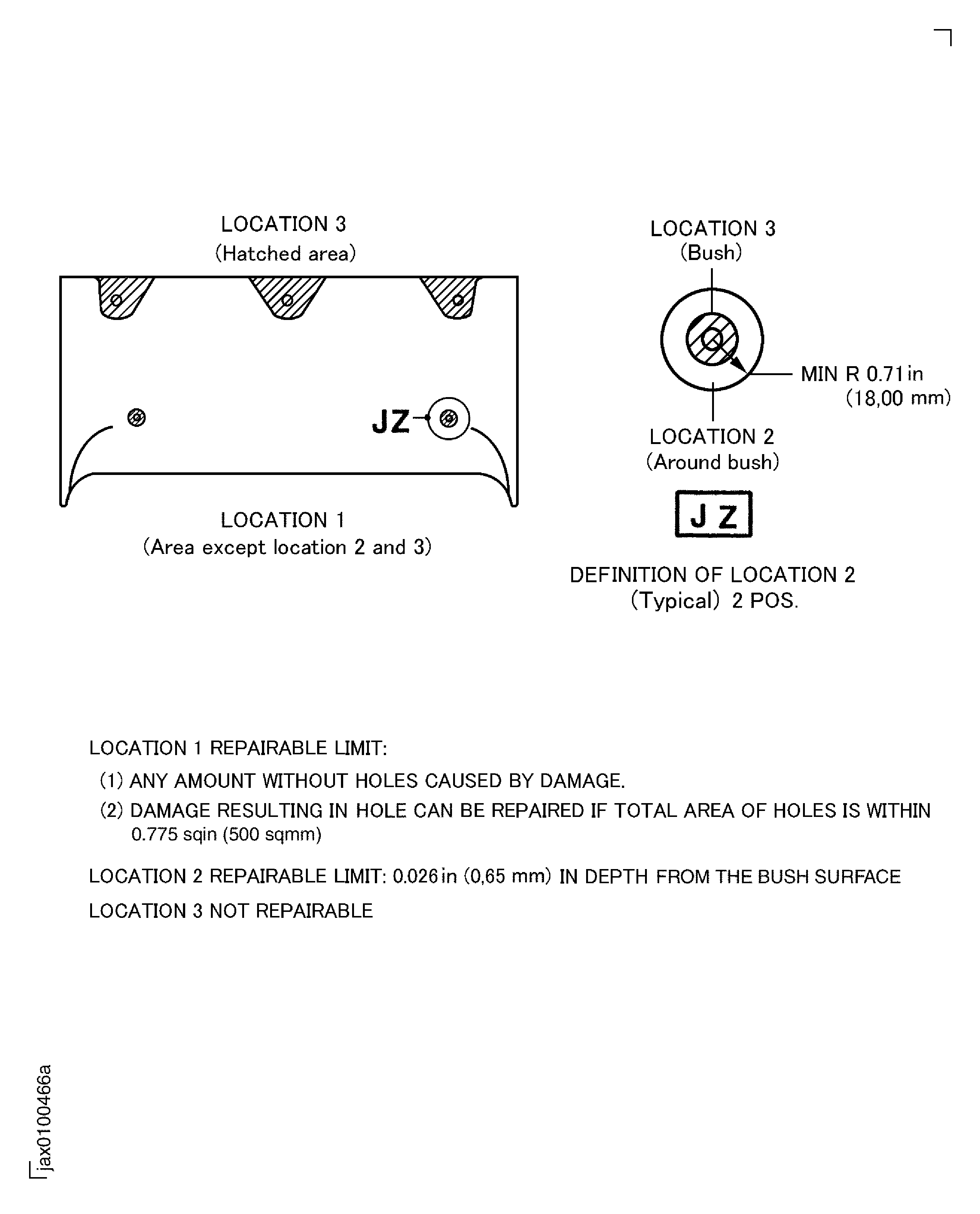

Figure: Repairable limit for Assembly C

Repairable limit for Assembly C

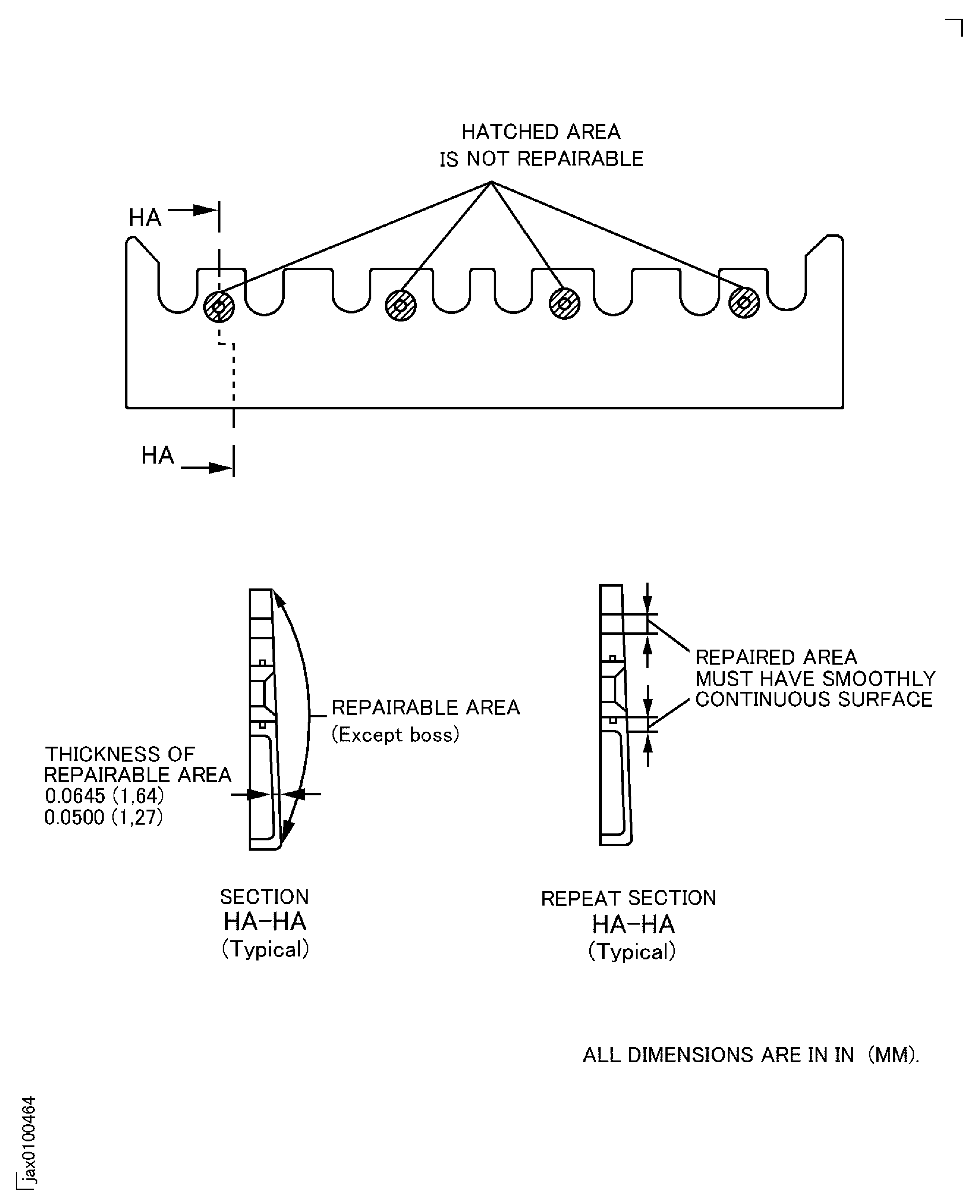

Figure: In process dimension before painting polyurethane paint for Assembly C

In process dimension before painting polyurethane paint for Assembly C

Figure: Detail dimension of repair for Assembly C

Detail dimension of repair for Assembly C

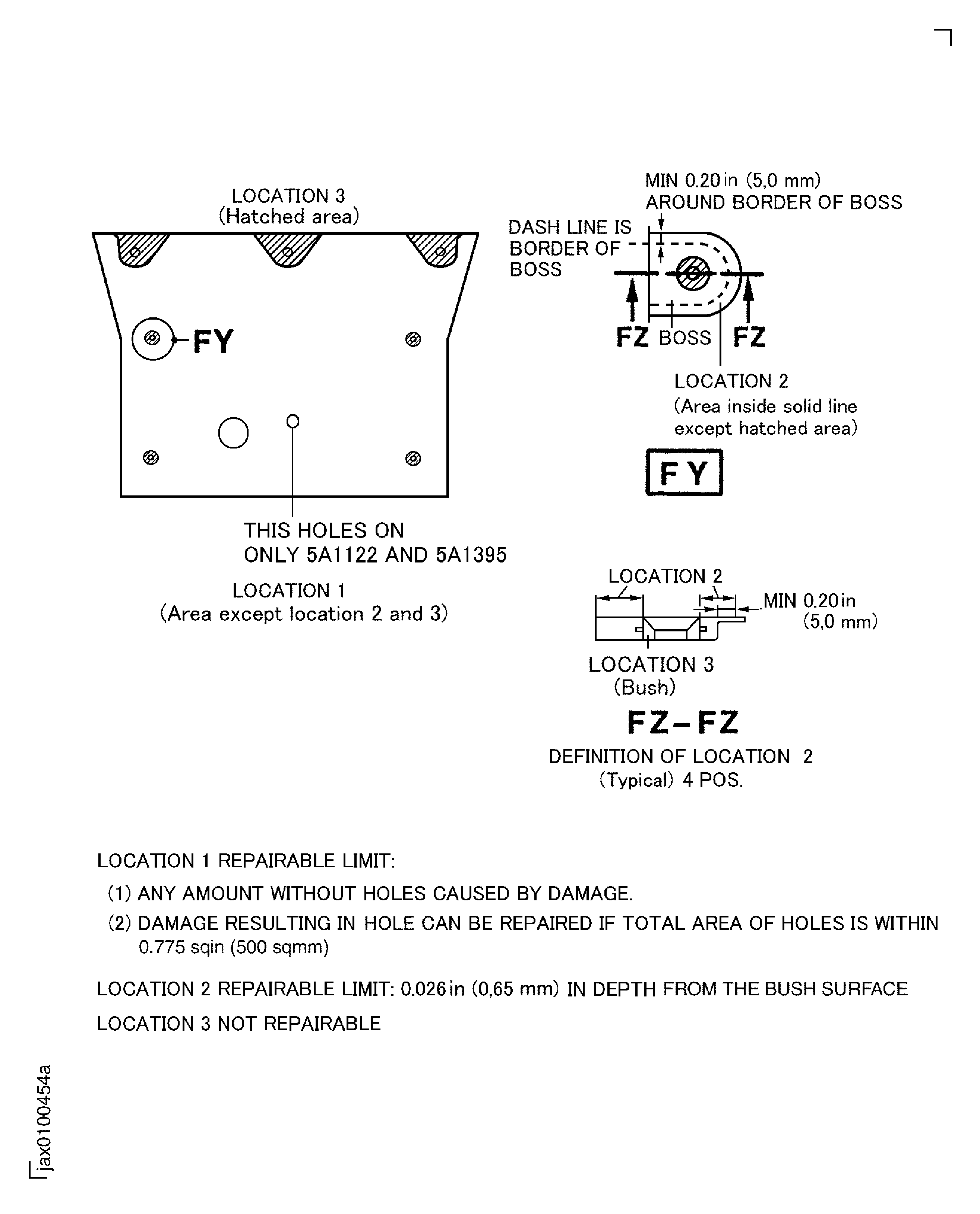

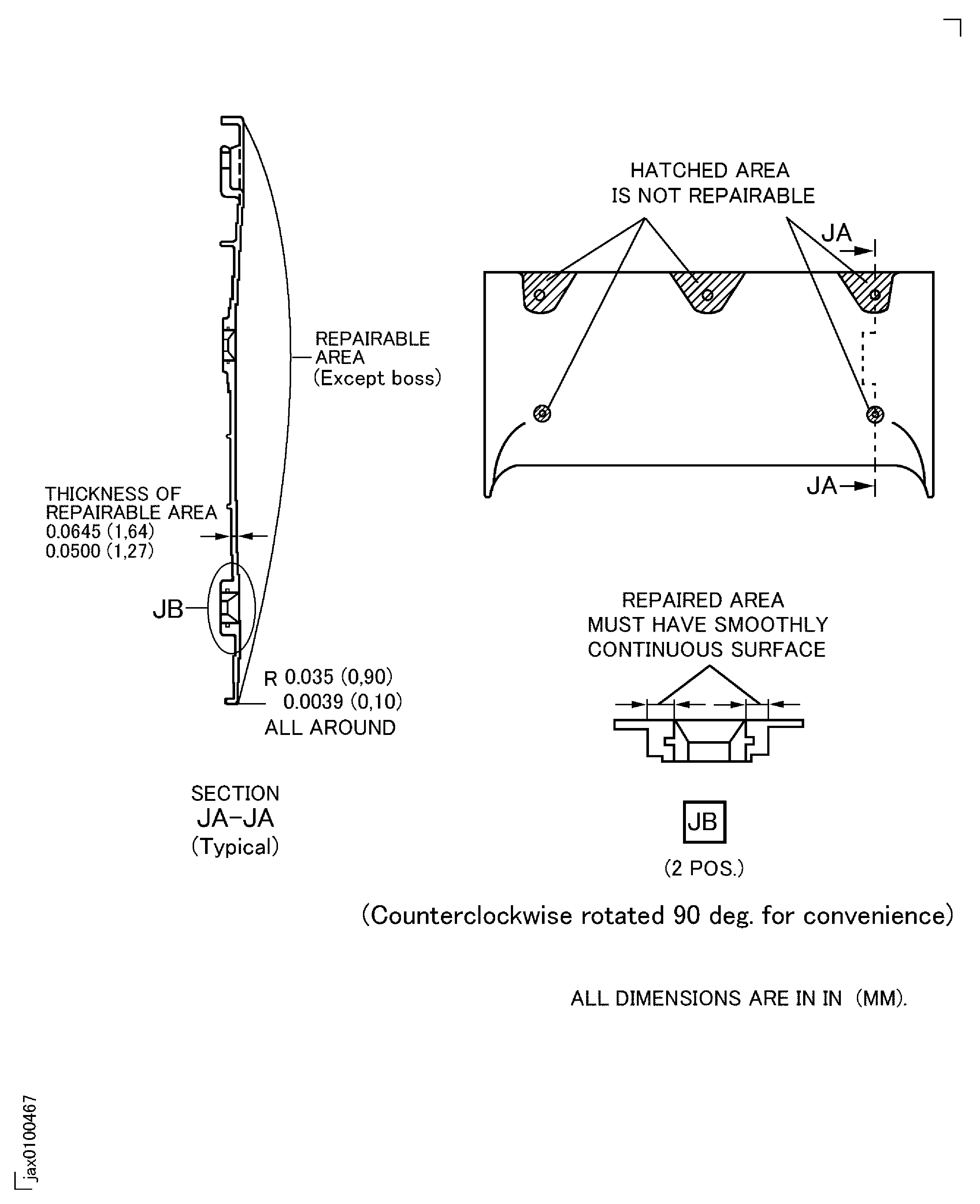

Figure: Repairable limit for Assembly F

Repairable limit for Assembly F

Figure: In process dimension before painting polyurethane paint for Assembly F

In process dimension before painting polyurethane paint for Assembly F

Figure: Detail dimension of repair for Assembly F

Detail dimension of repair for Assembly F

Figure: Repairable limit for Assembly G

Repairable limit for Assembly G

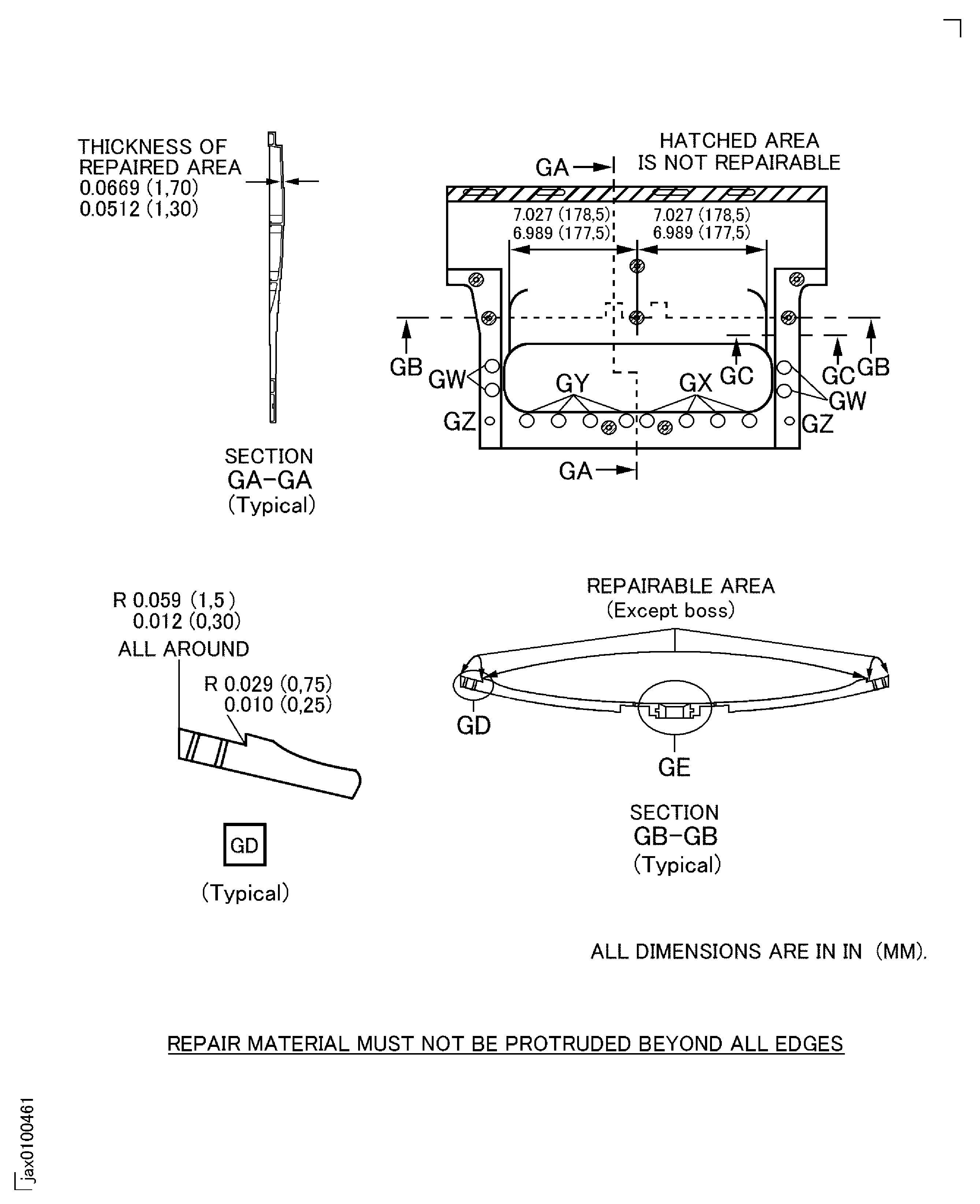

Figure: In process dimension before painting polyurethane paint for Assembly G

Sheet 1

Figure: In process dimension before painting Polyurethane paint for Assembly G

Sheet 2

Figure: Detail dimension of repair for Assembly G

Sheet 1

Figure: Detail dimension of repair for Assembly G

Sheet 2

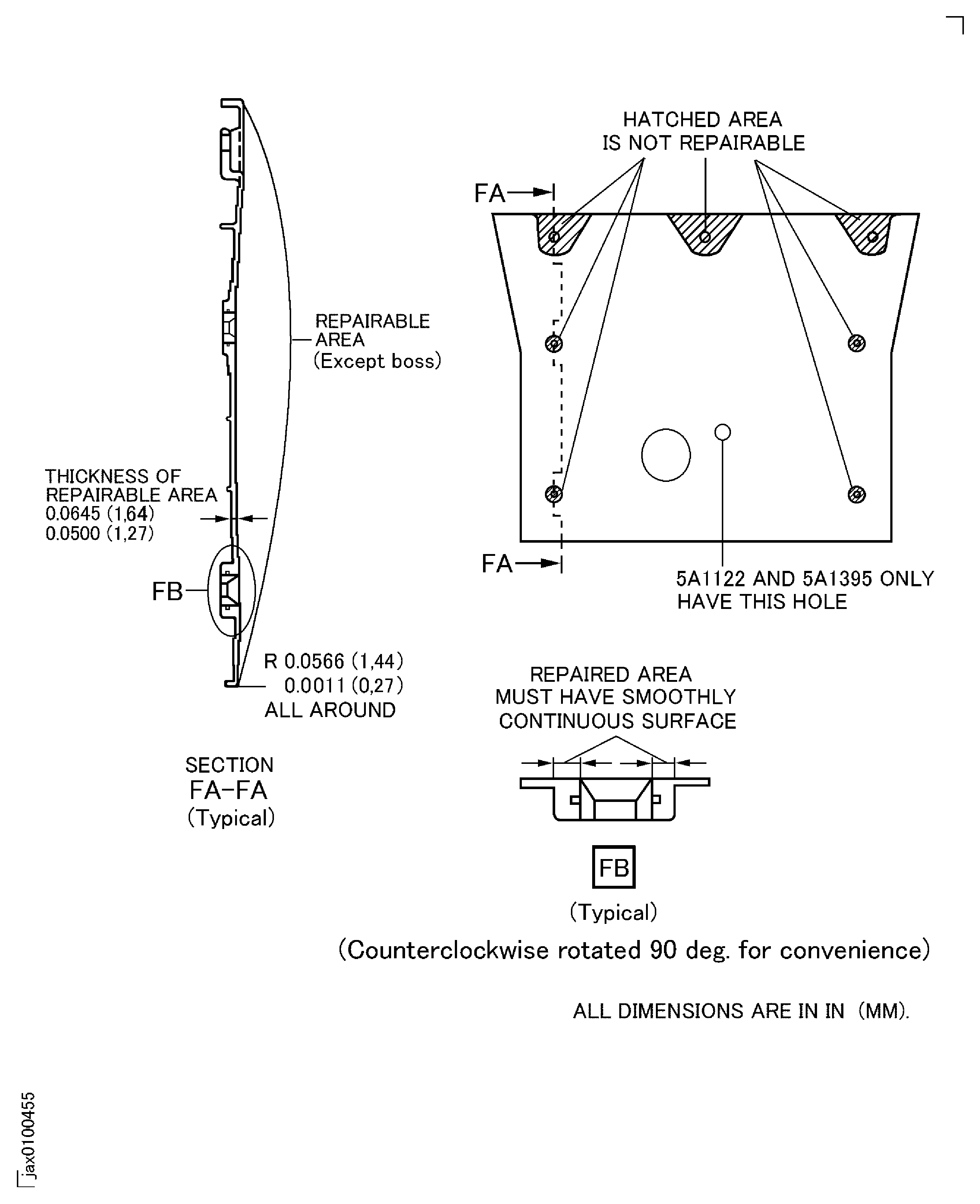

Figure: Repairable limit for Assembly H

Repairable limit for Assembly H

Figure: In process dimension before painting polyurethane paint for Assembly H

Sheet 1

Figure: In process dimension before painting polyurethane paint for Assembly H

Sheet 2

Figure: Detail dimension of repair for Assembly H

Sheet 1

Figure: Detail dimension of repair for Assembly H

Sheet 2

Figure: Repairable limit for Assembly J

Repairable limit for Assembly J

Figure: In process dimension before painting polyurethane paint for Assembly J

In process dimension before painting polyurethane paint for Assembly J

Figure: Detail dimension of repair for Assembly J

Detail dimension of repair for Assembly J

Figure: Repairable limit for Assembly L

Repairable limit for Assembly L

Figure: In process dimension before painting polyurethane paint for Assembly L

In process dimension before painting polyurethane paint for Assembly L

Figure: Detail dimension of repair for Assembly L

Detail dimension of repair for Assembly L