Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-40-00-300-005 No. 4 Bearing/HPT Nut - Repair The Front Face By Machining, Repair-005 (VRS3010)

General

If you did the procedure in Rework 001, TASK 72-40-00-840-001 (REWORK-001) to get PN 2A2247, you do not have to remove the eight plugs (PN 2A2248) to do this repair.

This repair must only be done when the instruction to do so is given in V2500-D5-72-40-0000-00A-307A-C (INSPECTION/CHECK-000).

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - none

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figureand the SPM TASK 70-33-55-330-501.

Remove the silver plate and anti-galling compound from the retaining nut.

SUBTASK 72-40-00-330-053 Remove the Silver Plate and Anti-Galling Compound from the Bearing Retaining Nut

Refer to Figure.

You must fully remove all the surface damage.

Break the edge and check the minimum length, flatness, perpendicular and finish requirements given in the figure.

Machine the front face of the retaining nut to remove all of the surface damage.

SUBTASK 72-40-00-320-051 Machine the Front Face of the Bearing Retaining Nut

Refer to Figure.

Examine the retaining nut.

SUBTASK 72-40-00-220-117 Examine the Bearing Retaining Nut

Make a permanent mark by the SPM TASK 70-09-00-400-501.

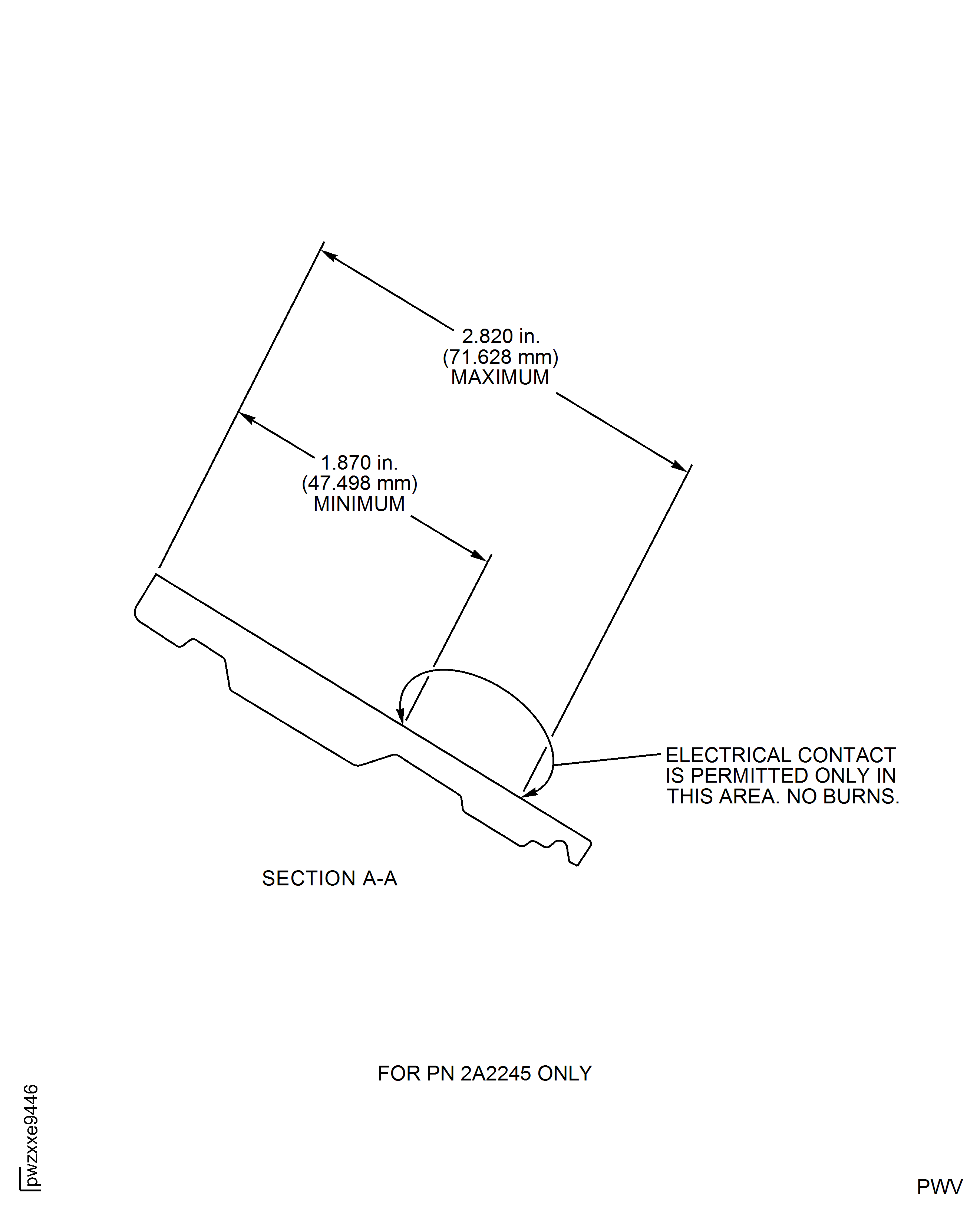

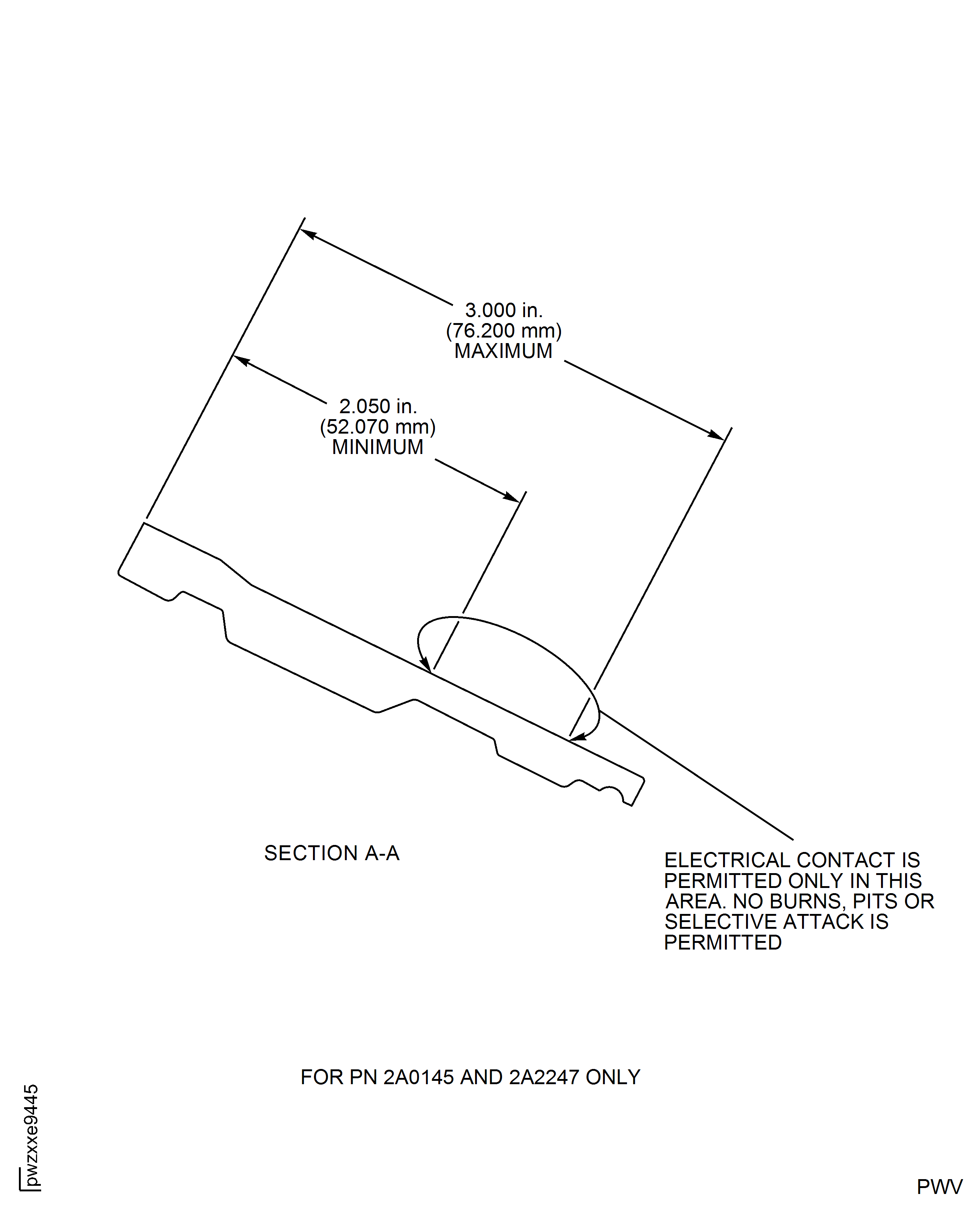

Refer to Figure for the location that only permits electrical contact.

Use the vibro-peen method to make a mark VRS3010 adjacent to the part number.

SUBTASK 72-40-00-350-061 Identify the Repair

Plate the bearing retaining nut with the silver plate and treat with anti-galling compound by the procedures given in Repair VRS3011 TASK 72-40-00-300-006.

SUBTASK 72-40-00-330-054 Plate the Bearing Retaining Nut

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions