Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-40-00-300-012Active Clearance Control (ACC) Valve Bracket - Replace The Slotted Entry Bearing, Repair-012 (VRS6666)

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Case Assembly | TEG | Titanium Aluminium Vanadium Alloy |

General

This repair must only be done when the instruction to do so is given in 72-40-00, Inspection/Check.

This repair gives the instruction to replace the slotted entry bearings on the ACC mounting brackets.

Price and availability - refer to IAE

Related repairs - none.

Note

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical Cleaning Equipment | ||

| Penetrant Crack Test Equipment | LOCAL | |||

| Press | LOCAL | |||

| Standard workshop equipment | LOCAL | |||

| Vibro-engraving equipment | LOCAL | |||

| Vertical Milling Machine | LOCAL | |||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| IAE 3R19072 Trepanning cutter | 0AM53 | IAE 3R19072 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bearing Assembly | VTB12350E | 1 | ||

| Bearing Assembly | VTB12350E | 1 | ||

| Bearing Assembly | P25000 | 1 | ||

| Bearing Assembly | P25000 | 1 | ||

| Bearing, Spherical | 0AM53 | VTB12351 | 1 | |

| Bearing, Spherical | 0AM53 | VTB12351 | 1 | |

| Bearing, Spherical | 0AM53 | P25001 | 1 | |

| Bearing, Spherical | 0AM53 | P25001 | 1 |

Safety Requirements

NONEProcedure

Refer to SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Clean the assembly.

SUBTASK 72-40-00-110-075 Chemically Clean the Bracket Assemblies

Refer to SPM TASK 70-23-05-230-501. Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) and penetrant crack test equipment.

Any Cracks - Reject.

Do a local penetrant crack test of the bearing.

SUBTASK 72-40-00-230-068 Do a Crack Test

If necessary use IAE 3R19072 Trepanning cutter, trepanning cutter, 1 off or suitable equivalent, with a vertical milling machine.

Machine the lip of the bearing that is to be replaced.

SUBTASK 72-40-00-350-074-001 Remove the Bearing - Method 1 - Assemblies A or Assemblies B

CAUTION

MAKE SURE THE BRACKET ASSEMBLY IS HELD CORRECTLY AND TAKE CARE WHEN YOU PRESS OUT THE BEARING NOT TO DAMAGE THE BEARING LOCATION HOLE.SUBTASK 72-40-00-350-074-002 Remove the Bearing - Method 1 - Assemblies A or Assemblies B

CAUTION

MAKE SURE THE BRACKET ASSEMBLY IS HELD CORRECTLY AND TAKE CARE WHEN YOU PRESS OUT THE BEARING NOT TO DAMAGE THE BEARING LOCATION HOLE.NOTE

This is an alternative to Step.Refer to SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the area bracket assembly.

SUBTASK 72-40-00-110-076 Chemically Clean

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Any cracks - Reject.

Do a local penetrant crack test of the bearing adjacent area(s).

SUBTASK 72-40-00-230-069 Crack Test

SUBTASK 72-40-00-350-076 Install a New Bearing - Assemblies A or Assemblies B

NOTE

Before you install a new bearing assembly, you must remove the ball bearing and keep it safe.Refer to SPM TASK 70-42-06-400-501, SUBTASK 70-42-06-400-004. Use a staking tool, 1 off, available from the bearing vendor.

Stake the new bearing in to the bracket assemblies.

SUBTASK 72-40-00-350-077 Ring Stake the New Bearing - Assemblies A or Assemblies B

Refer to SPM TASK 70-23-05-230-501. Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) and penetrant crack test equipment.

Any Cracks - Reject.

Do a local penetrant crack test of the bearing.

SUBTASK 72-40-00-230-070 Do a Crack Test

Refer to SPM TASK 70-42-06-400-501, SUBTASK 70-42-06-400-004.

Make sure the new bearing is located correctly.

Visually examine the bracket assemblies.

SUBTASK 72-40-00-220-170 Do a Visual and Dimensional Inspection - Assemblies A or Assemblies B

SUBTASK 72-40-00-350-078 Do a Bearing Pull Out Check

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Make a mark VRS6666 adjacent to the part number.

SUBTASK 72-40-00-350-081 Identify the Repair

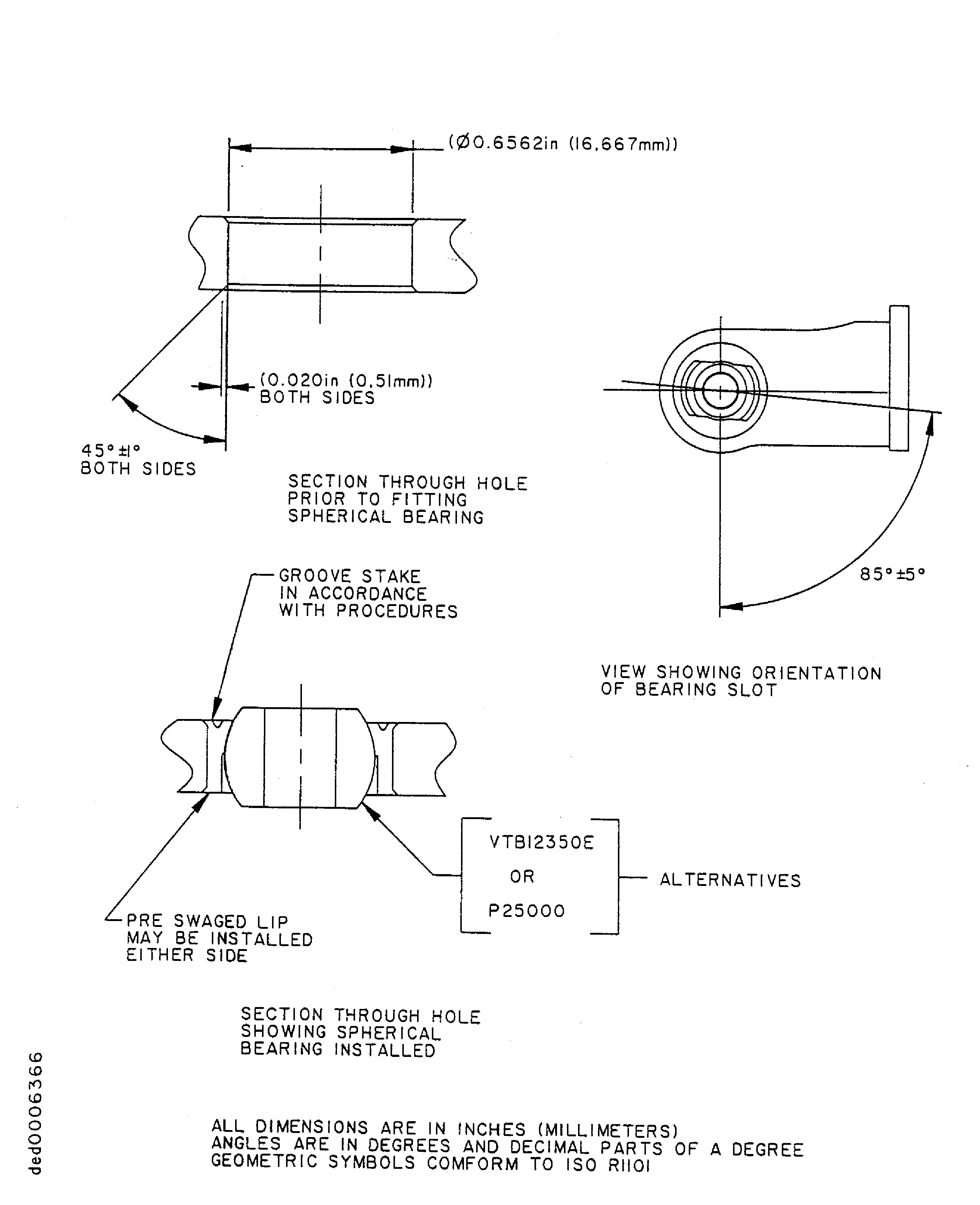

Figure: Install the Spherical Bearing - Assemblies A

Install the Spherical Bearing - Assemblies A

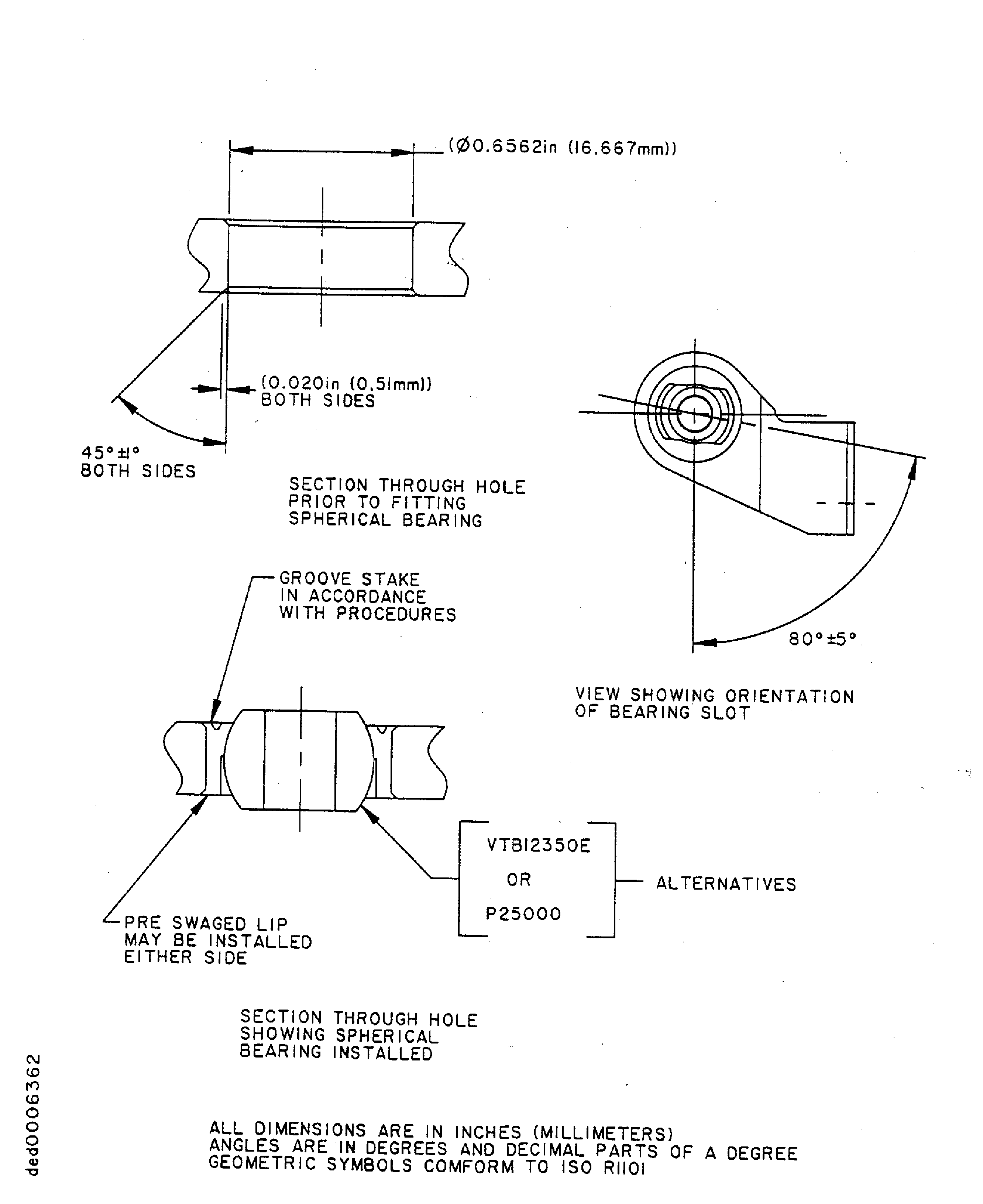

Figure: Install the Spherical Bearing - Assemblies B

Install the Spherical Bearing - Assemblies B