Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

6A3508 6A3648 6A3934 6A3936 6A4189 6A4900 6A5467 6A55926A5594 6A5659 6A6473 6A7379 6A7380 6A7382 6A7383 6A7384 6A7385 6A74016A7705 6A8236 6A8316 6A8318 6A8350

Common Information

TASK 72-41-11-300-014 HPC Stage 3 - 8 Drum Disk - Repair The Stage 8 Location Diameter By Metal Spray, Repair-014 (VRS6154)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-200 | 6A3508 | |

01-200 | 6A3648 | |

01-200 | 6A3934 | |

01-200 | 6A3936 | |

01-200 | 6A4189 | |

01-200 | 6A4900 | |

01-200 | 6A5467 | |

01-200 | 6A5592 | |

01-200 | 6A5594 | |

01-200 | 6A5659 | |

01-200 | 6A6473 | |

01-200 | 6A7379 | |

01-200 | 6A7380 | |

01-200 | 6A7382 | |

01-200 | 6A7383 | |

01-200 | 6A7384 | |

01-200 | 6A7385 | |

01-200 | 6A7401 | |

01-200 | 6A7705 | |

01-200 | 6A8236 | |

01-200 | 6A8316 | |

01-200 | 6A8318 | |

01-200 | 6A8350 | |

01-200 | 6B1379 | |

01-200 | 6B1380 | |

01-200 | 6B1381 | |

01-200 | 6B1382 | |

01-200 | 6B1383 | |

01-200 | 6B1384 | |

01-200 | 6B1385 | |

01-200 | 6B1386 | |

01-200 | 6B1387 | |

01-200 | 6B1391 | |

01-200 | 6B1392 | |

01-200 | 6B1393 | |

01-200 | 6B1401 | |

01-200 | 6B1402 | |

01-200 | 6B1403 | |

01-200 | 6B1404 | |

01-200 | 6B1405 | |

01-200 | 6B1406 |

General Data

This Repair must only be done when the instruction to do so is given in TASK 72-41-11-200-000 (INSPECTION-000).

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the Standard Practices and Processes Manual (SPM).

NOTE

It is possible that some materials in the Consumable Materials chart cannot be used for some or all of the necessary applications. Before you use the materials, make sure the types, quantities and applications of the materials necessary are legally permitted in your location. All persons must obey all applicable federal, state, local and provincial laws and regulations when it is necessary to work with these materials.

To identify the consumable materials, refer to the Overhaul Processes and Consumables Index (PCI).

Other necessary consumable materials are referred to in the SPM TASKs.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical Cleaning Equipment | ||

| Dial indicator | LOCAL | Dial indicator | ||

| Lathe/Grinding machine | LOCAL | Lathe/Grinding machine | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Oven | LOCAL | Oven | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant Crack Test Equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| IAE 3R19389 Grinding fixture | 0AM53 | IAE 3R19389 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 76381 | CoMat 02-019 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | 00BB6 | CoMat 03-038 | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) | 37676 | CoMat 06-018 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE 3R19389 Grinding fixture grinding fixture 1 off a locally made fixture.

Use a lathe and standard workshop equipment.

Install the fixture in to the lathe.

SUBTASK 72-41-11-325-052 Turn the HP Compressor - Stages 3 to 8 Disk Shaft Assembly

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

DO NOT REMOVE MORE MATERIAL THAN IS NECESSARY.Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) or CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY).

Use penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the location diameter.

SUBTASK 72-41-11-230-077 Do a Crack Test

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast equipment.

Abrasive blast the surface to be repaired.

SUBTASK 72-41-11-120-056 Abrasive Blast the Surface to be Repaired

CAUTION

TO PREVENT CONTAMINATION, DO NOT TOUCH THE SURFACE WHICH IS CLEANED FOR REPAIR.

CAUTION

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SUBTASK 70-34-01-340-021.

Use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) or CoMat 03-248 METAL SPRAY POWDER with metal spray equipment.

Apply sufficient metal spray to get the correct dimensions when machined, refer to Step.

Apply metal spray.

SUBTASK 72-41-11-340-056 Metal Spray the Location Diameter

Use IAE 3R19389 Grinding fixture grinding fixture 1 off or a locally made fixture.

Use a lathe/grinding machine and standard workshop equipment.

Install the fixture in to the lathe/grinding machine.

Use a lathe/grinding machine and standard workshop equipment.

NOTE

If you use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) you can turn or grind the component.

If you use CoMat 03-248 METAL SPRAY POWDER you must grind the component.

Turn/grind the location diameter.

SUBTASK 72-41-11-320-054 Turn/Grind the HP Compressor - Stages 3 to 8 Disk Shaft Assembly

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

TITANIUM COMPONENT - YOU MUST ENSURE THAT DURING TURNING/GRINDING NO SPARKS ARE PRODUCED.Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

NOTE

If the parts are already identified with VRS6154 from a repair that was done before, more identification is not necessary.

Vibro-engrave VRS6154 adjacent to the part number.

SUBTASK 72-41-11-350-078 Identify the Repair

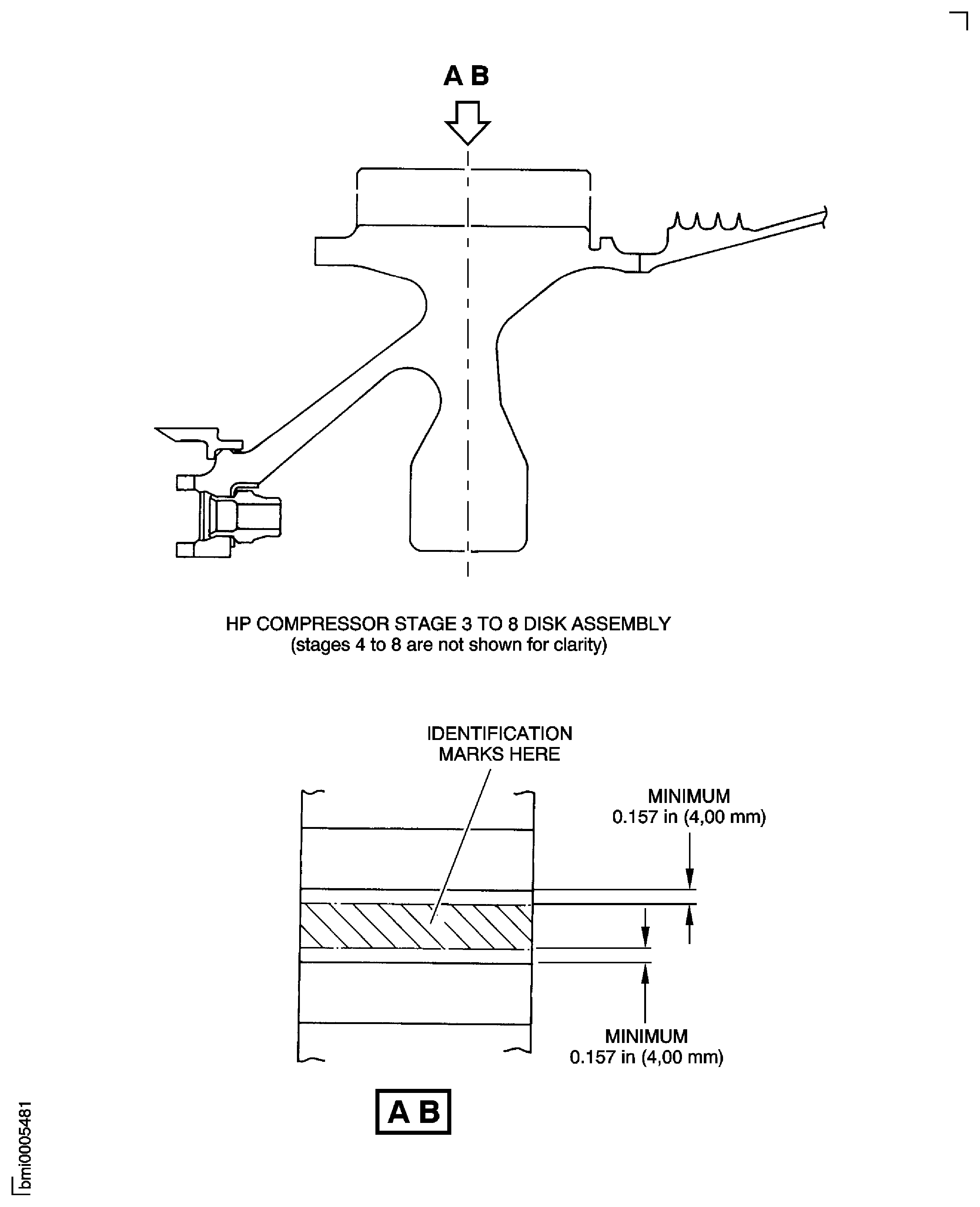

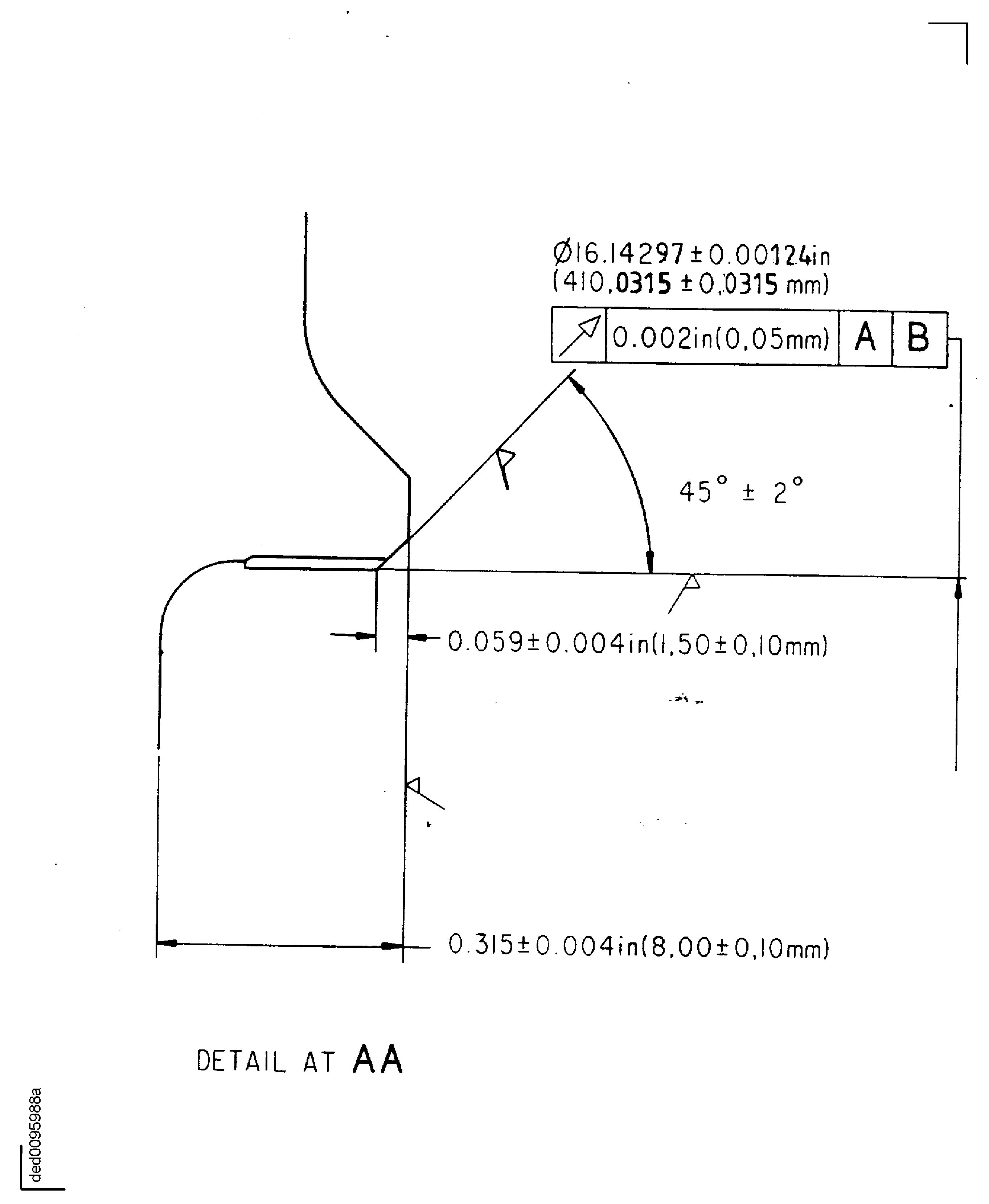

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

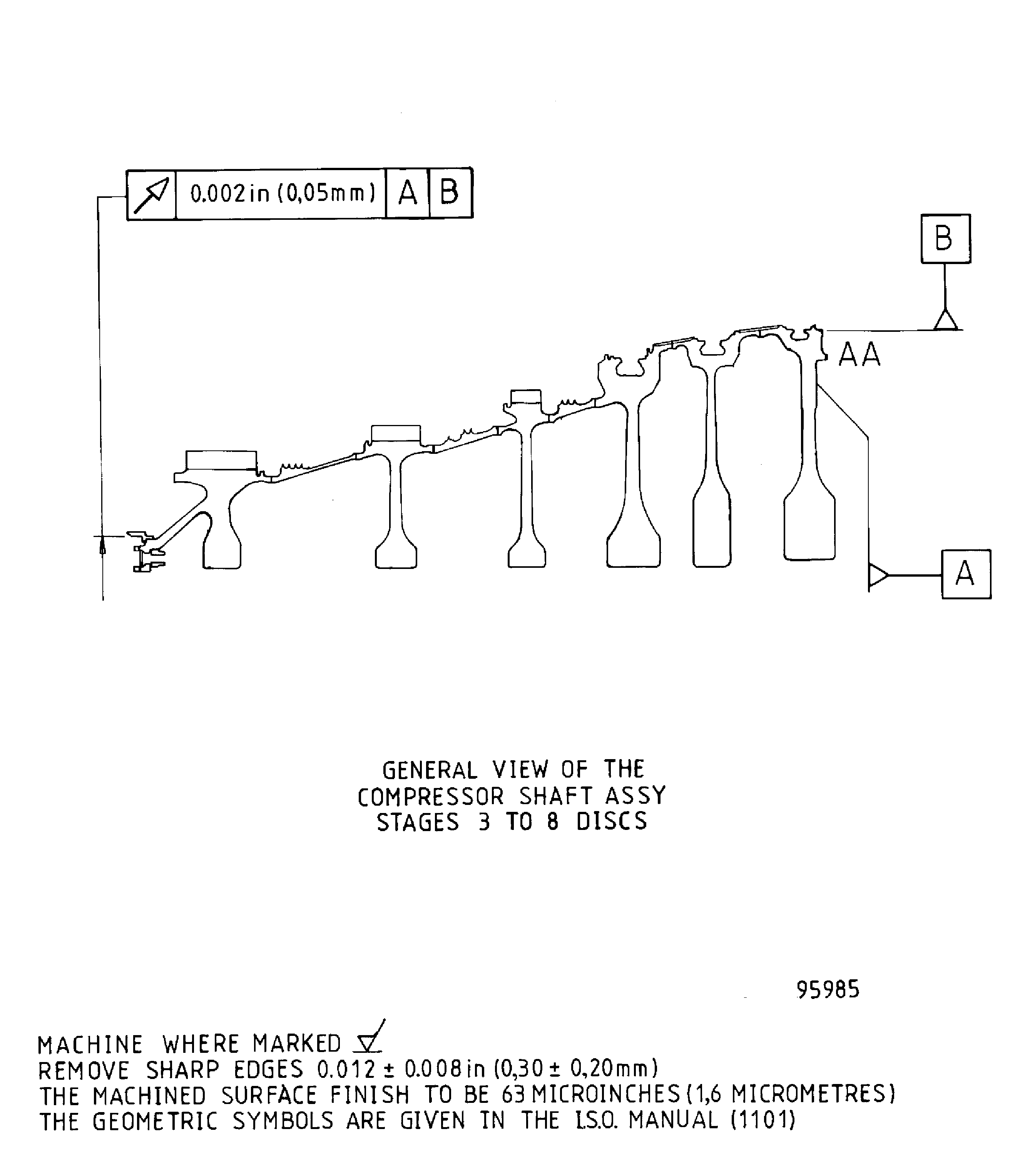

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

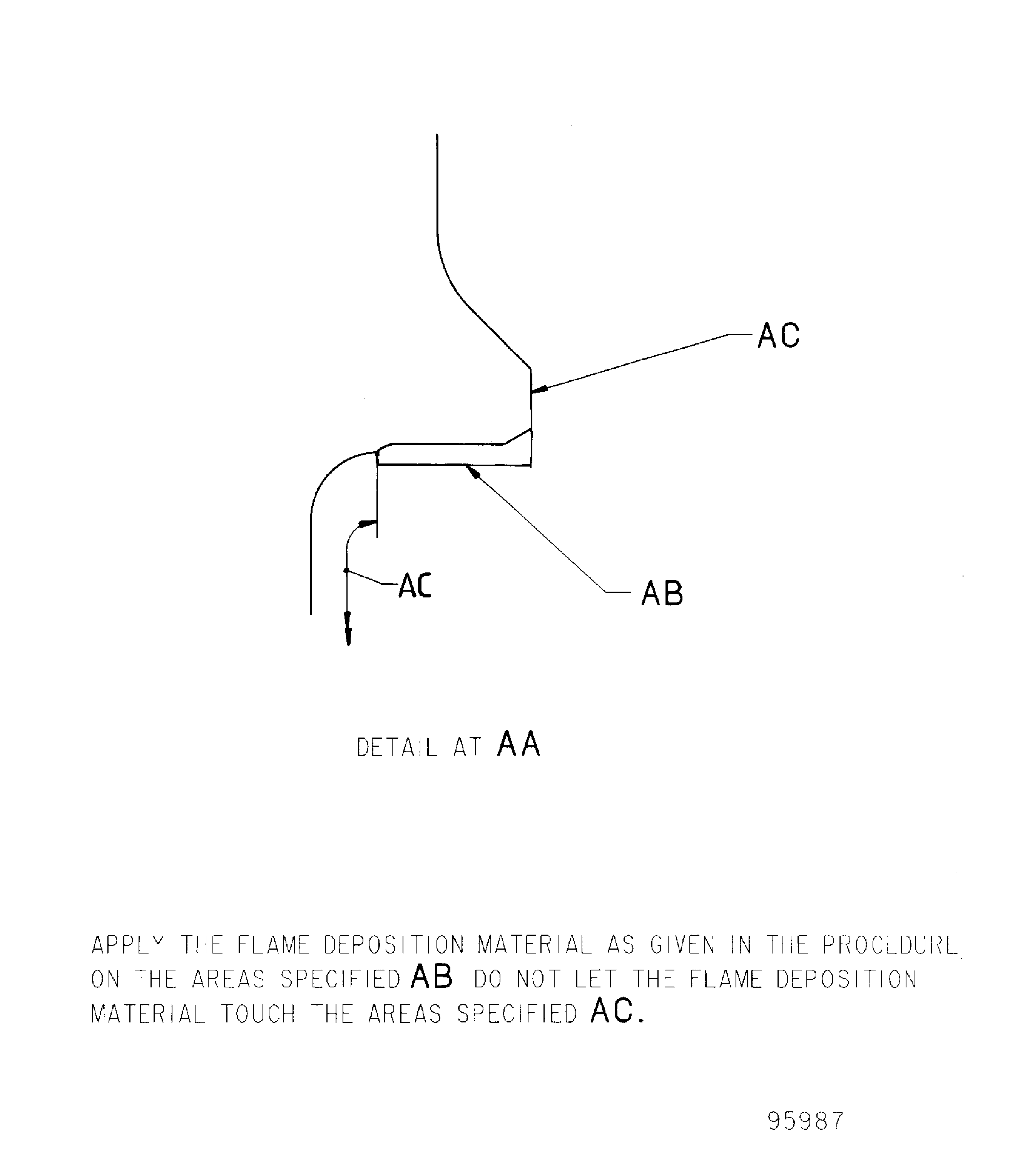

Figure: Repair Details and Dimensions

Repair Details and Dimensions