Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-11-230-002 Focus Inspection on HPC Stage 3 - 8 Drum Disk for Cracks

Effectivity

FIG/ITEM | PART NO. | SERVICE BULLETIN |

|---|---|---|

01-200 | 6A3508 | PRE SBE 72-0035 |

01-200 | 6A3648 | PRE SBE 72-0035 |

01-200 | 6A3934 | |

01-200 | 6A3936 | |

01-200 | 6A4189 | |

01-200 | 6A4900 | PRE SBE 72-0178 |

01-200 | 6A5467 | |

01-200 | 6A5592 | |

01-200 | 6A5594 | |

01-200 | 6A5659 | |

01-200 | 6A6473 | |

01-200 | 6A7379 | |

01-200 | 6A7380 | |

01-200 | 6A7382 | |

01-200 | 6A7383 | |

01-200 | 6A7384 | |

01-200 | 6A7385 | |

01-200 | 6A7401 | |

01-200 | 6A7705 | |

01-200 | 6A8236 | |

01-200 | 6A8316 | |

01-200 | 6A8318 | |

01-200 | 6A8350 | |

01-200 | 6B1379 | |

01-200 | 6B1380 | |

01-200 | 6B1381 | |

01-200 | 6B1382 | |

01-200 | 6B1383 | |

01-200 | 6B1384 | |

01-200 | 6B1385 | |

01-200 | 6B1386 | |

01-200 | 6B1387 | |

01-200 | 6B1391 | |

01-200 | 6B1392 | |

01-200 | 6B1393 | |

01-200 | 6B1401 | |

01-200 | 6B1402 | |

01-200 | 6B1403 | |

01-200 | 6B1404 | |

01-200 | 6B1405 | |

01-200 | 6B1406 |

General

The policy that is necessary for inspection is given in SPM TASK 70-20-01-200-501.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

References

Refer to the SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501,

Inspection of parts, SPM TASK 70-20-01-200-501.

Some data on these items is contained in this TASK. For more data on these items refer to the SPM:

Method of Testing for Crack Indications,

Chemical Processes.

Surface Protection.

NOTE

Preliminary Requirements

Pre-Conditions

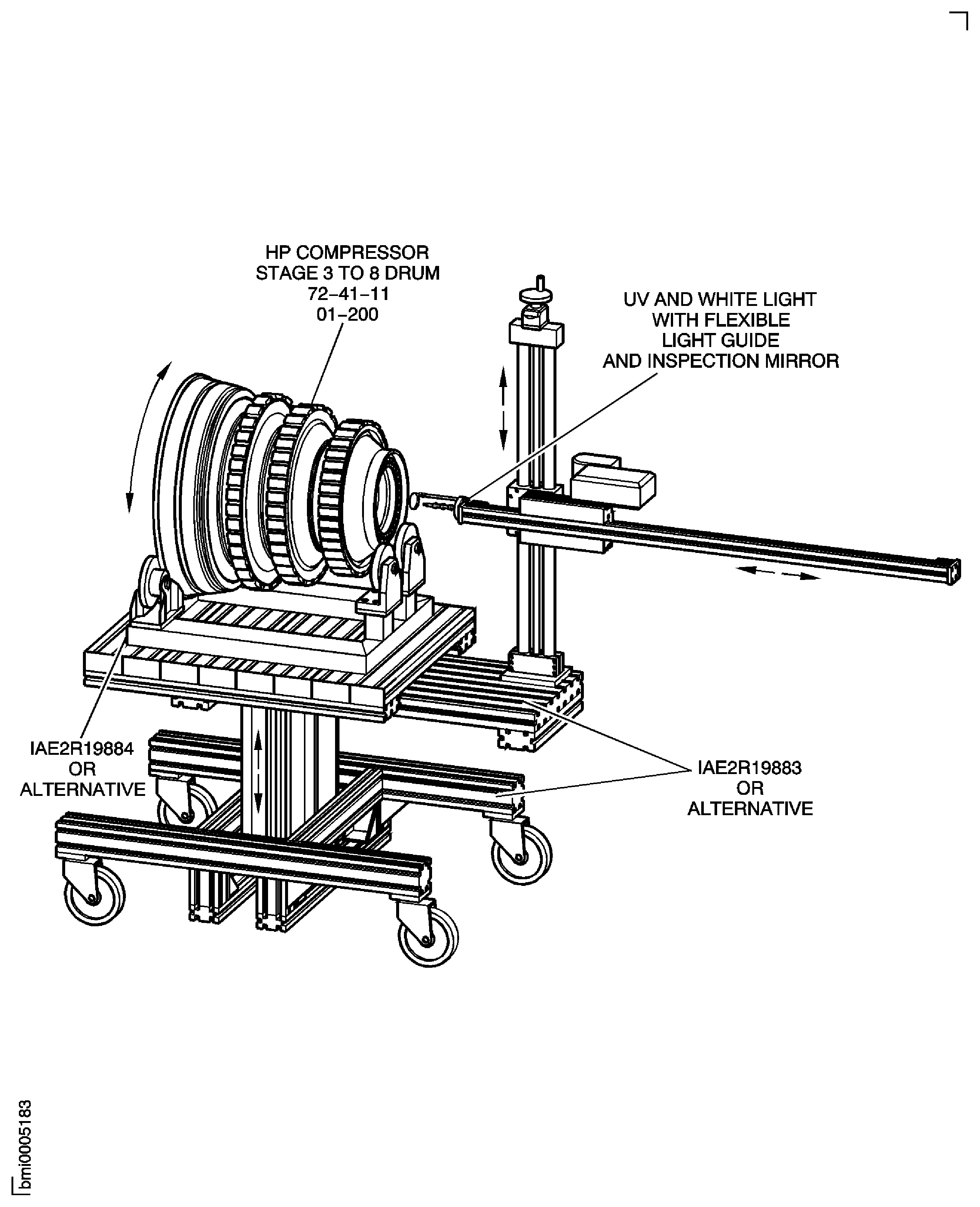

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Gloves | LOCAL | Gloves | Polythene or cotton | |

| IAE 2R19883 Rotary table inspection device | 0AM53 | IAE 2R19883 | ||

| IAE 2R19884 Adapter | 0AM53 | IAE 2R19884 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-030 NON AQUEOUS DEVELOPER | LOCAL | CoMat 06-030 |

Spares

NONESafety Requirements

CAUTION

Procedure

Do a focus crack inspection of HP Compressor Stages 3 to 8 drum. While you complete the fluorescent penetrant inspection in Step special attention must be given to the focus areas listed in the locations that follow:

If the part has operated with any standard of silver coated nut (up to and including SB 72-0596) installed in the stage 8 cavity, NMSB 72-0625 (Eddy Current Inspection (ECI)) can be accomplished as an additional option. Successful accomplishment of cleaning (TASK 72-41-11-100-001-A00 or TASK 72-41-11-110-001), fluorescent penetrant inspection (SPM TASK 70-23-04-230-501 or NMSB 72-0637) and an ECI will earn longer ultrasonic inspection grace periods. Refer to NMSB 72-0615 for details of grace periods.

Remove any applied masking tape.

SUBTASK 72-41-11-230-104 Do a General and Focus Inspection on Stages 3 to 8 HP Compressor Discs for Cracks

CAUTION

YOU MUST MAKE SURE ALL THE TAPE IS REMOVED AFTER THE INSPECTION.NOTE

Use fluorescent penetrant inspection SPM TASK 70-23-04-230-501 or NMSB 72-0637. Using NMSB 72-0637 will earn longer ultrasonic inspection grace periods. Refer to NMSB 72-0637 for detail of grace periods.NOTE

Use ultra high sensitivity fluorescent penetrant, for the inspection of all the components and for focus inspection of specified areas in this SUBTASK.

Figure: Stage 3 HP Compressor Disc - Inspection Locations

Stage 3 HP Compressor Disc - Inspection Locations

Figure: Stage 4 HP Compressor Disc - Inspection Locations

Stage 4 HP Compressor Disc - Inspection Locations

Figure: Stage 5 HP Compressor Disc - Inspection Locations

Stage 5 HP Compressor Disc - Inspection Locations

Figure: Stage 6 HP Compressor Disc - Inspection Locations

Stage 6 HP Compressor Disc - Inspection Locations

Figure: Stage 7 HP Compressor Disc - Inspection Locations

Stage 7 HP Compressor Disc - Inspection Locations

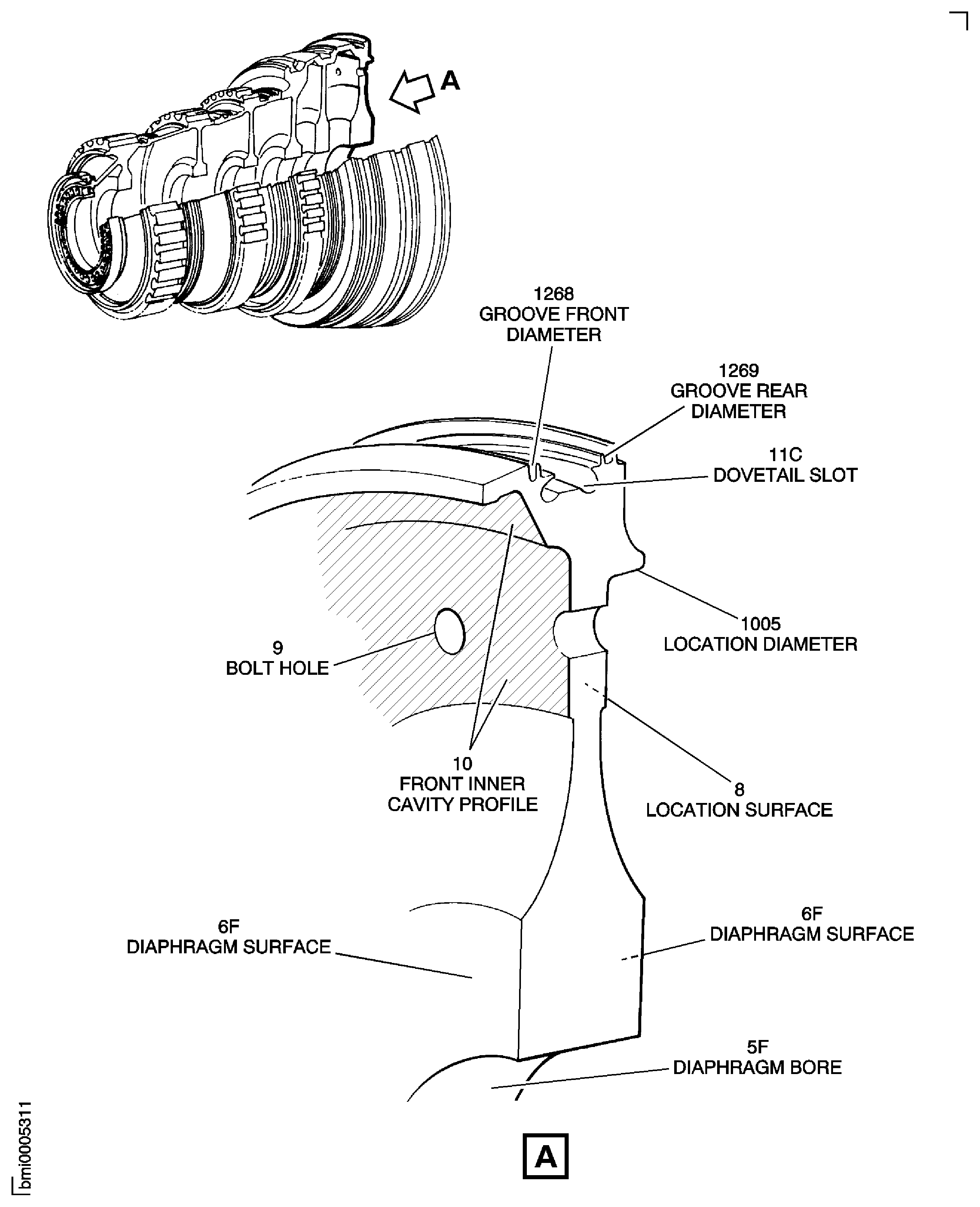

Figure: Stage 8 HP Compressor Disc - Inspection Locations

Stage 8 HP Compressor Disc - Inspection Locations

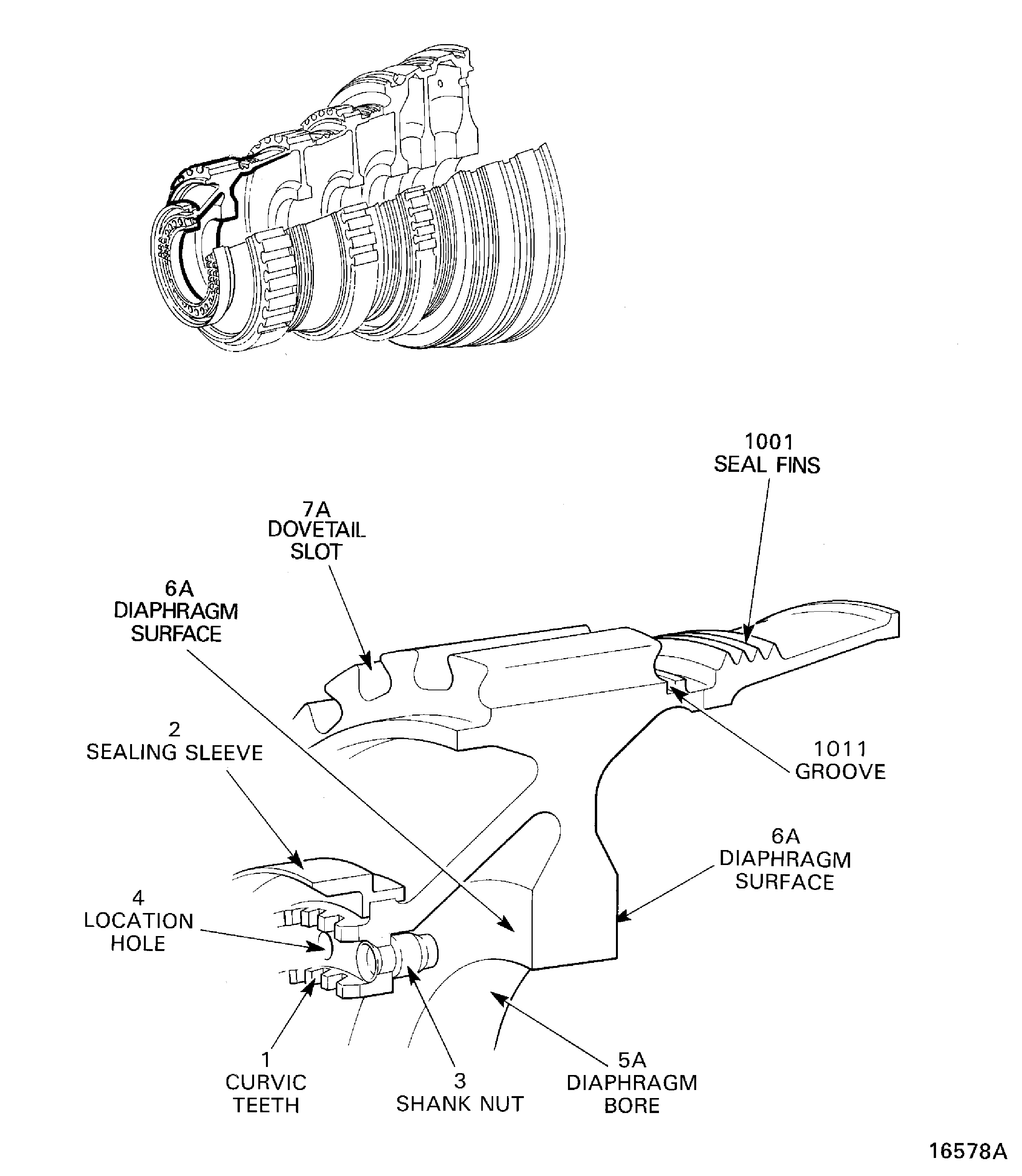

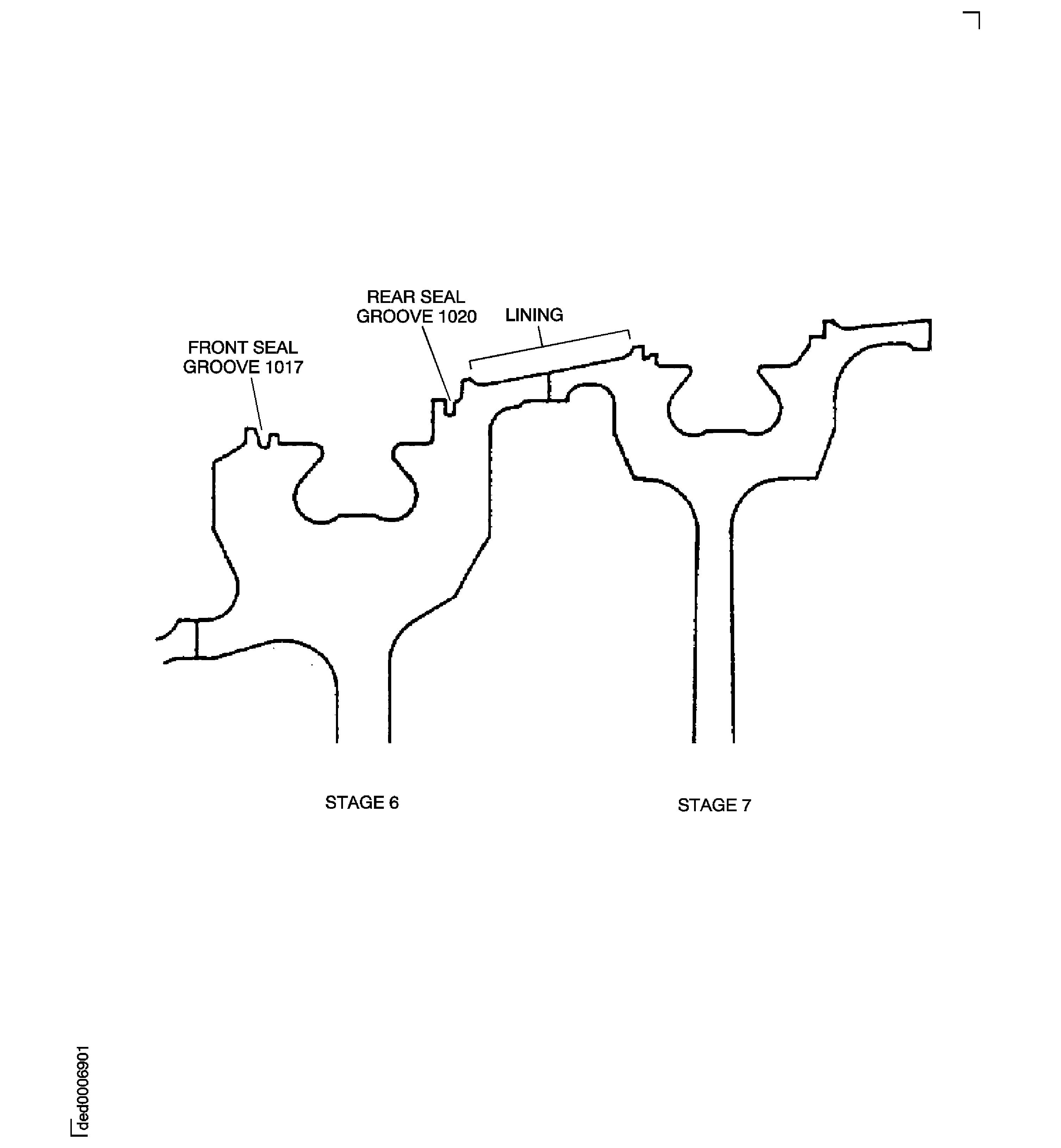

Figure: Focused Inspection - HP Compressor Stage 6 Seal Grooves

Focused Inspection - HP Compressor Stage 6 Seal Grooves

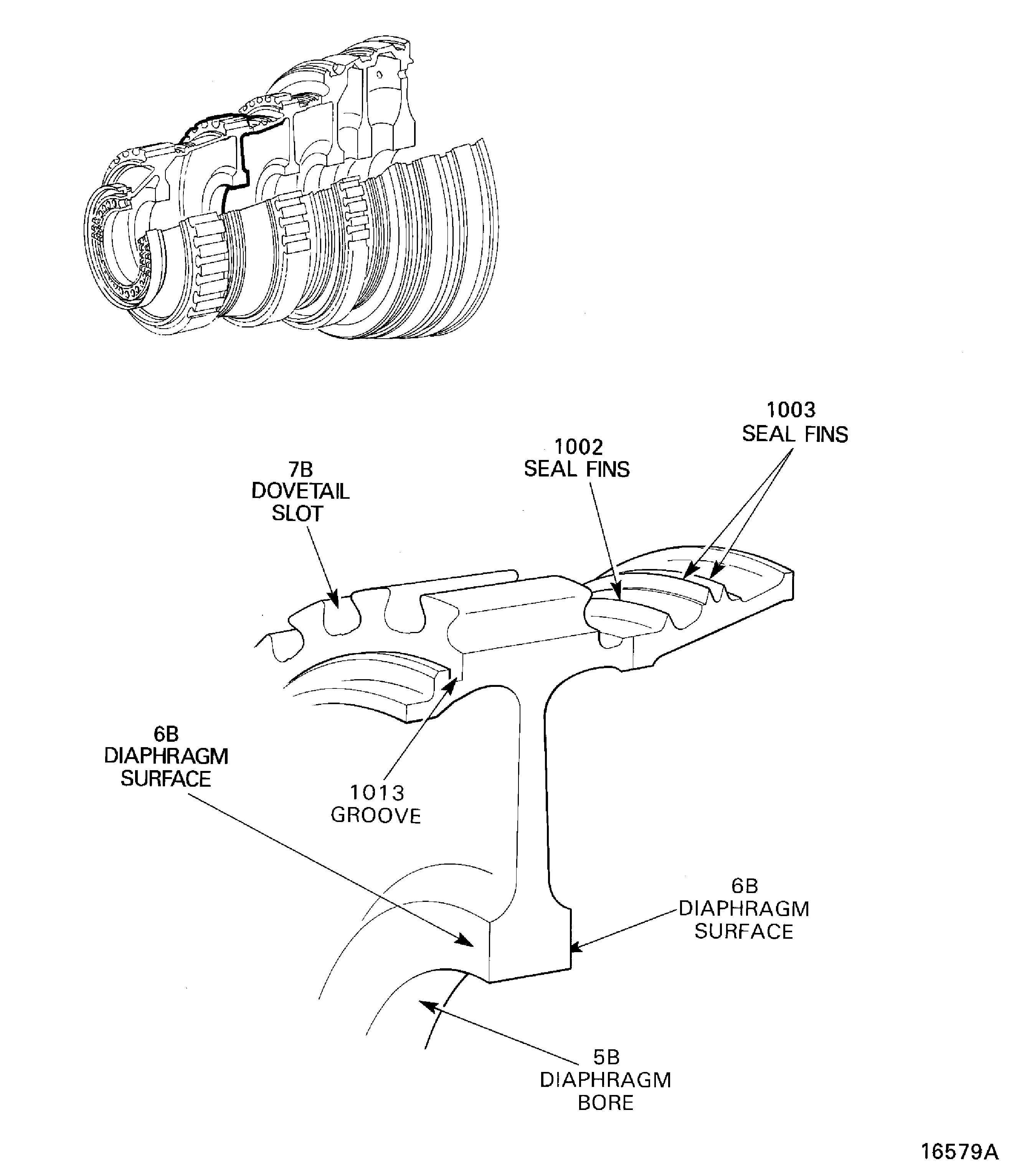

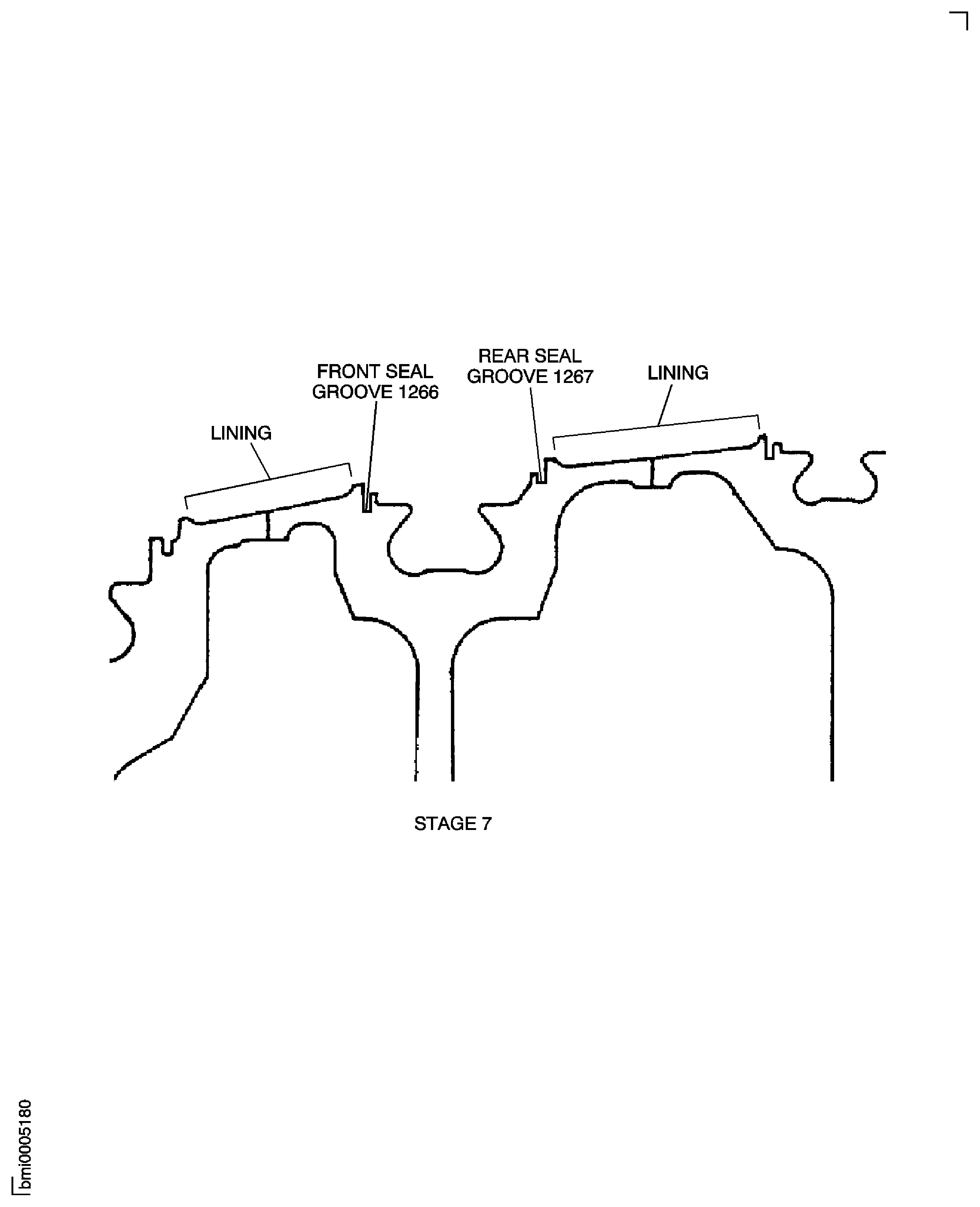

Figure: Focused Inspection - HP Compressor Stage 7 Seal Grooves

Focused Inspection - HP Compressor Stage 7 Seal Grooves

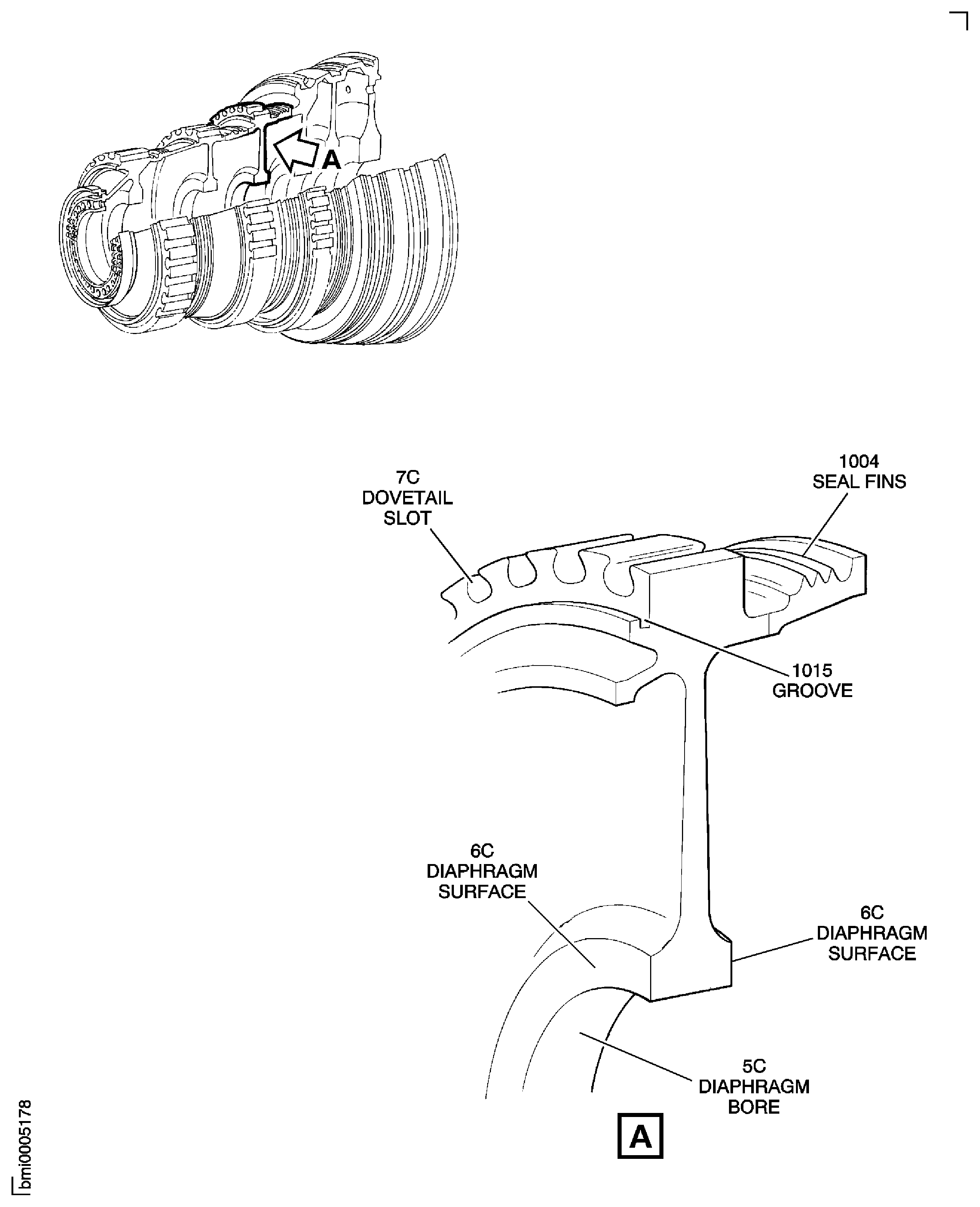

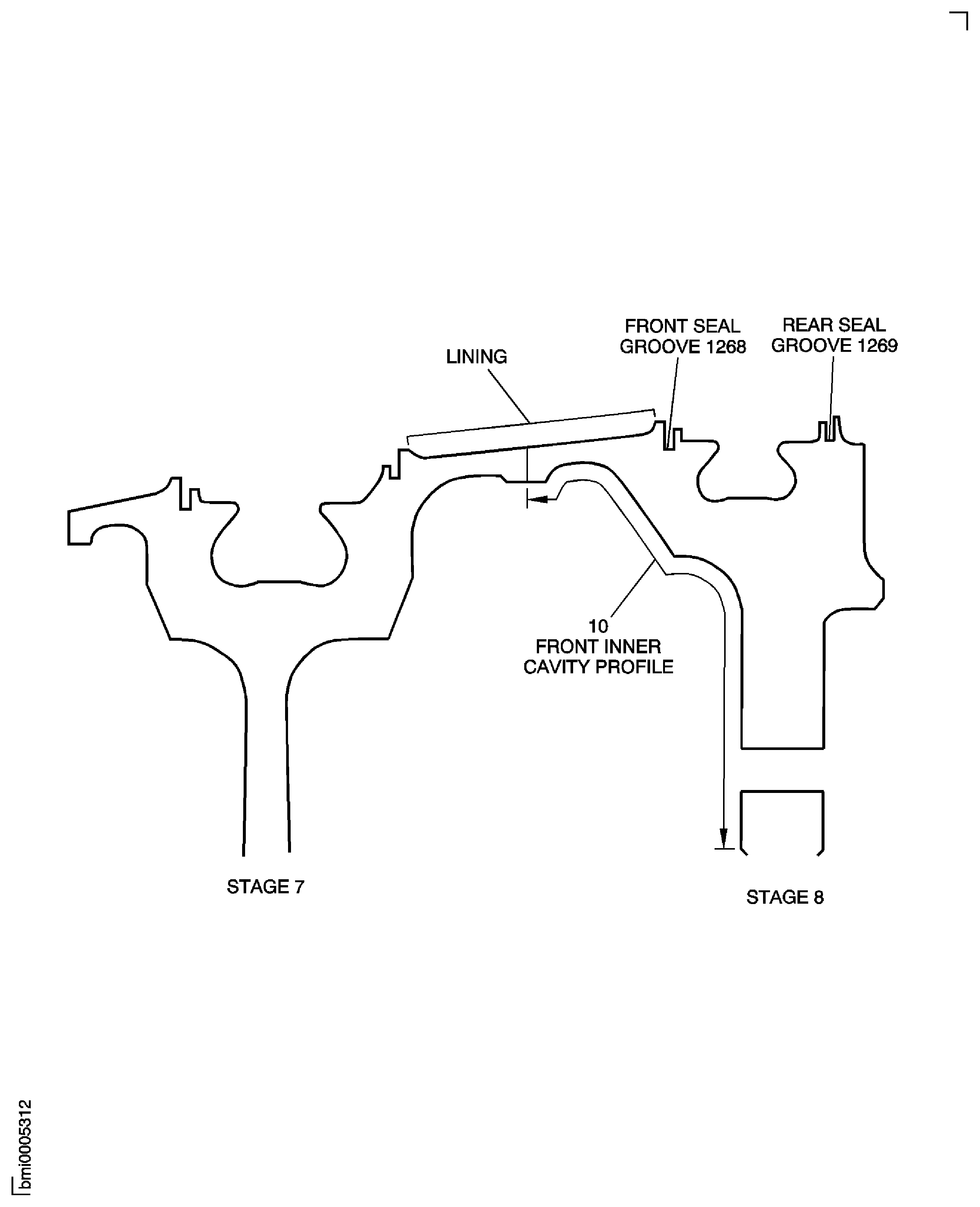

Figure: Focused Inspection - HP Compressor Stage 8 Seal Grooves and Inner Cavity

Focused Inspection - HP Compressor Stage 8 Seal Grooves and Inner Cavity

Figure: Focused Inspection - Stages 3-8 Discs Bores

Focused Inspection - Stages 3-8 Discs Bores

Figure: Stages 3, 4 and 5 Axial Dovetail Slot Inspection Zones

Stages 3, 4 and 5 Axial Dovetail Slot Inspection Zones

Figure: HP Compressor Stage 3 Axial Dovetail Slot Inspection Zones

HP Compressor Stage 3 Axial Dovetail Slot Inspection Zones

Figure: HP Compressor Stage 4 Axial Dovetail Slot Inspection Zones

HP Compressor Stage 4 Axial Dovetail Slot Inspection Zones

Figure: HP Compressor Stages 5 Axial Dovetail Slot Inspection Zones

HP Compressor Stages 5 Axial Dovetail Slot Inspection Zones

Figure: Stage 6, 7 and 8 HP Compressor Disc Circumferential Dovetail Slot Zones

Stage 6, 7 and 8 HP Compressor Disc Circumferential Dovetail Slot Zones

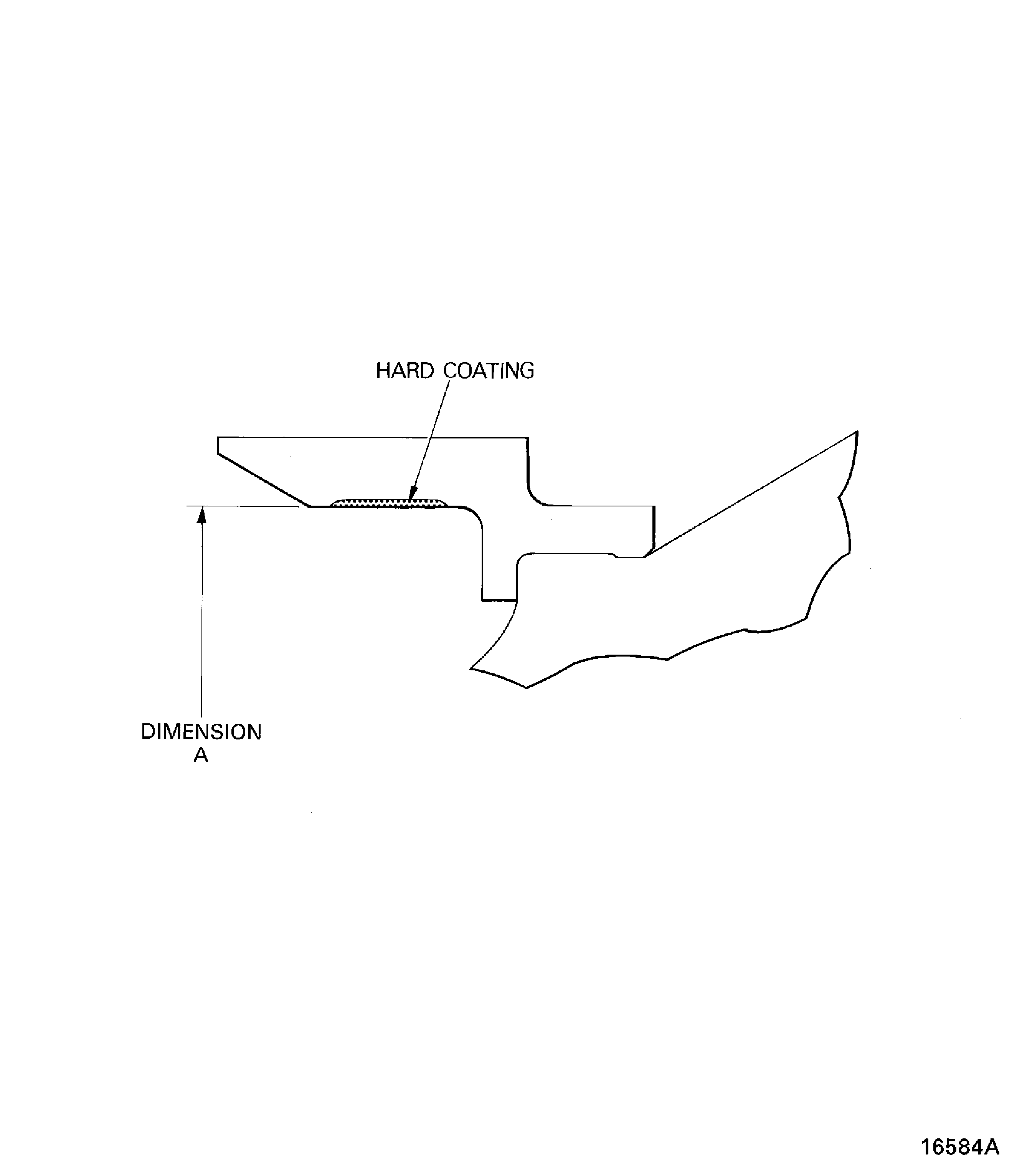

Figure: Examine the Sealing Groove

Examine the Sealing Groove

Figure: HP Compressor Stages 3 to 8 Drum Inspection Equipment for the Fluorescent Penetrant Inspection of Internal Surfaces

HP Compressor Stages 3 to 8 Drum Inspection Equipment for the Fluorescent Penetrant Inspection of Internal Surfaces