Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-009 HPC Stage 9 - 12 Drum Disk - Repair The Rear Diameter, Repair-009 (VRS3441)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-600 | 2A2100-01 |

01-600 | 2A2200-01 |

01-600 | 2A2600-01 |

01-600 | 2A3200-01 |

01-600 | 2A3300-01 |

01-600 | 2A3400-01 |

01-600 | 2A3500-01 |

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - not applicable

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Plasma spray equipment | LOCAL | Plasma spray equipment | ||

| Grit blast equipment | LOCAL | Grit blast equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Shot peening equipment | LOCAL | Shot peening equipment | ||

| NC lathe | LOCAL | NC lathe | ||

| Standard inspection equipment | LOCAL | Standard inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-097 LINT-FREE GLOVES | LOCAL | CoMat 02-097 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure requirements.

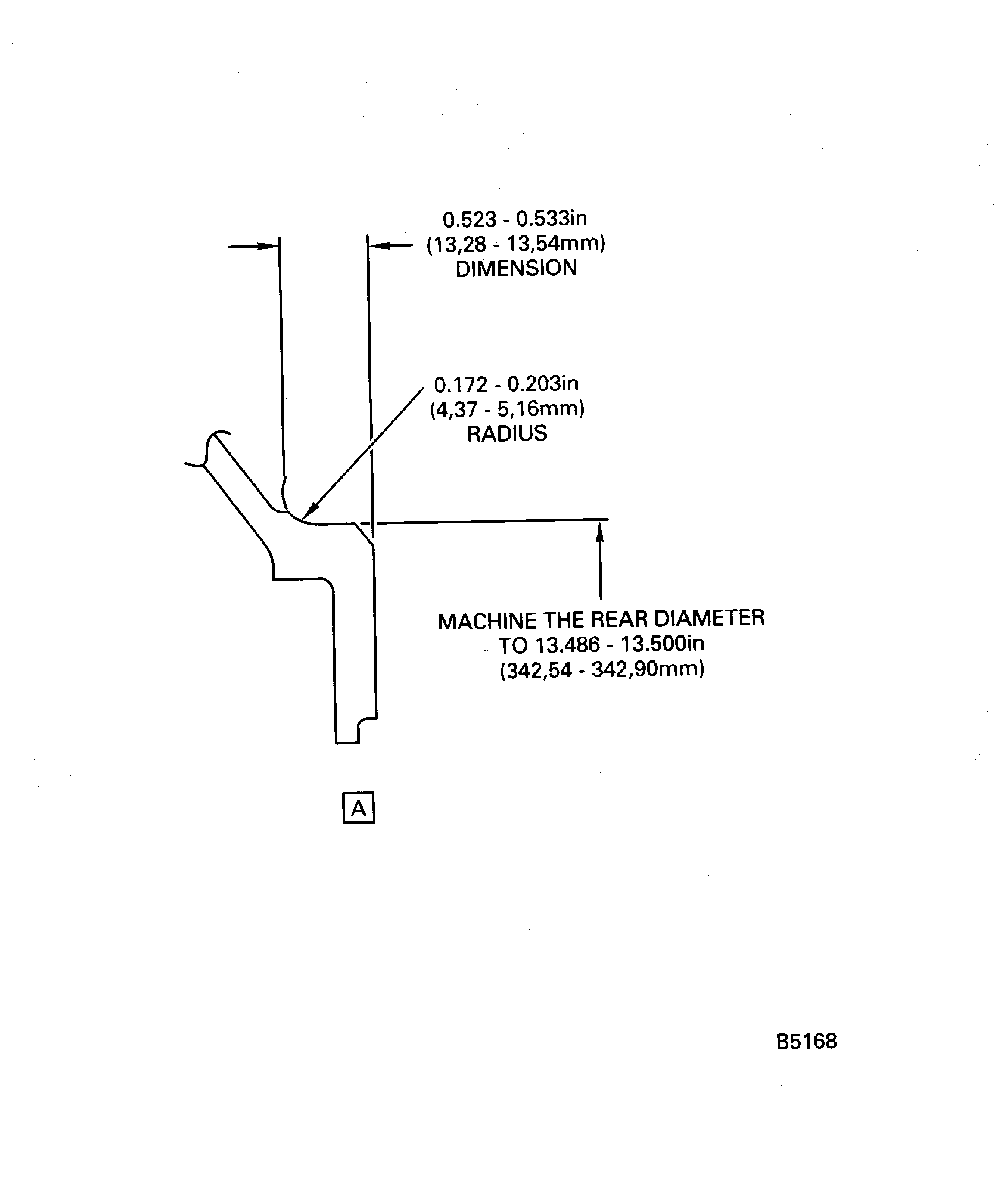

Set up and machine the rear diameter.

SUBTASK 72-41-12-320-054 Machine the Rear Diameter

Refer to Figure.

Do the procedure given in the SPM TASK 70-23-04-230-501.

No cracks are permitted.

Fluorescent penetrant inspect the repair for cracks.

SUBTASK 72-41-12-230-059 Fluorescent Penetrant the Repaired Area

Refer to Figure.

Do the procedure given in the SPM TASK 70-38-13-380-501.

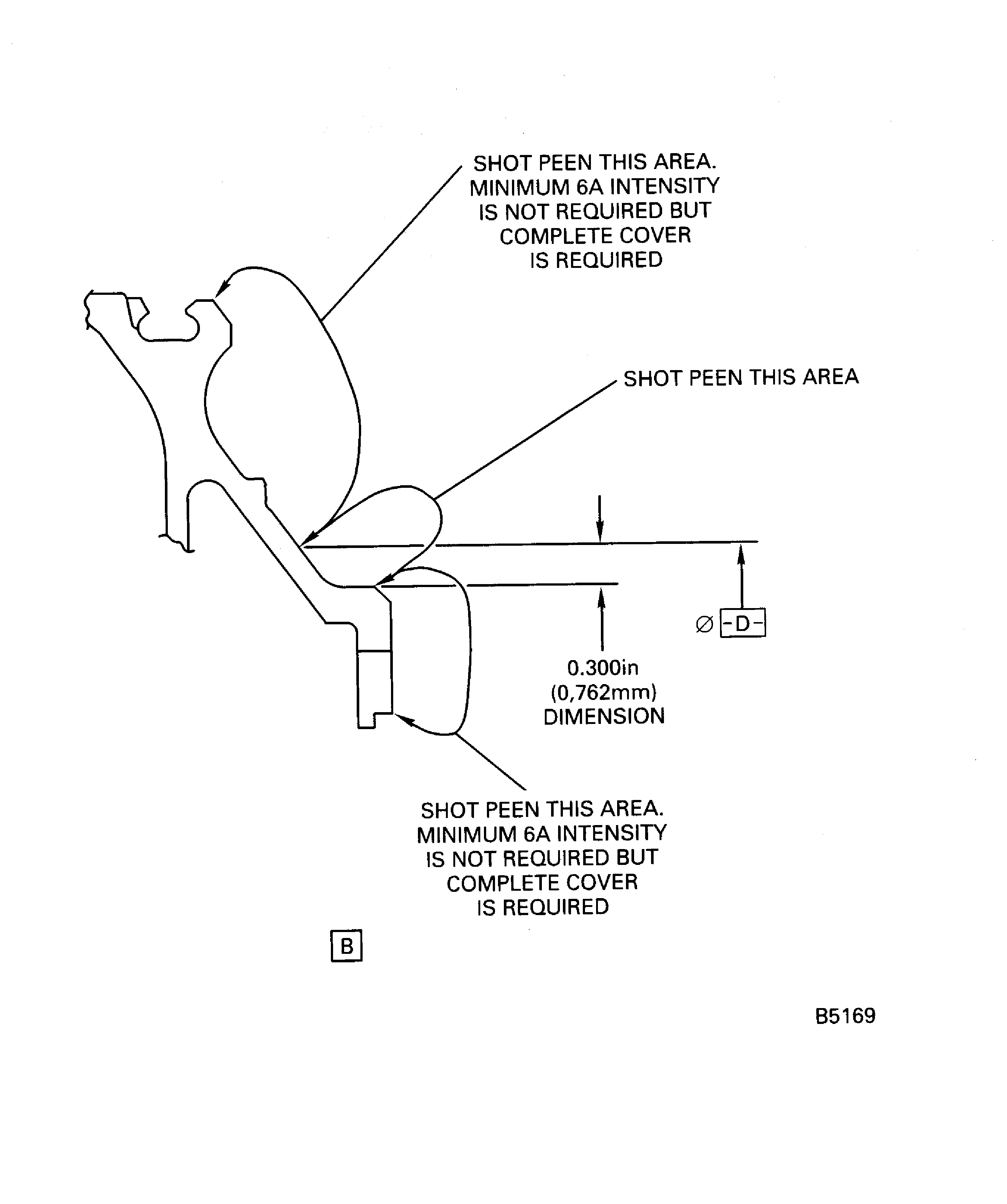

Shot peen the repaired surface at an intensity of 6A or equivalent.

SUBTASK 72-41-12-380-054 Shot Peen the Repaired Area

Refer to the SPM TASK 70-34-18-380-501.

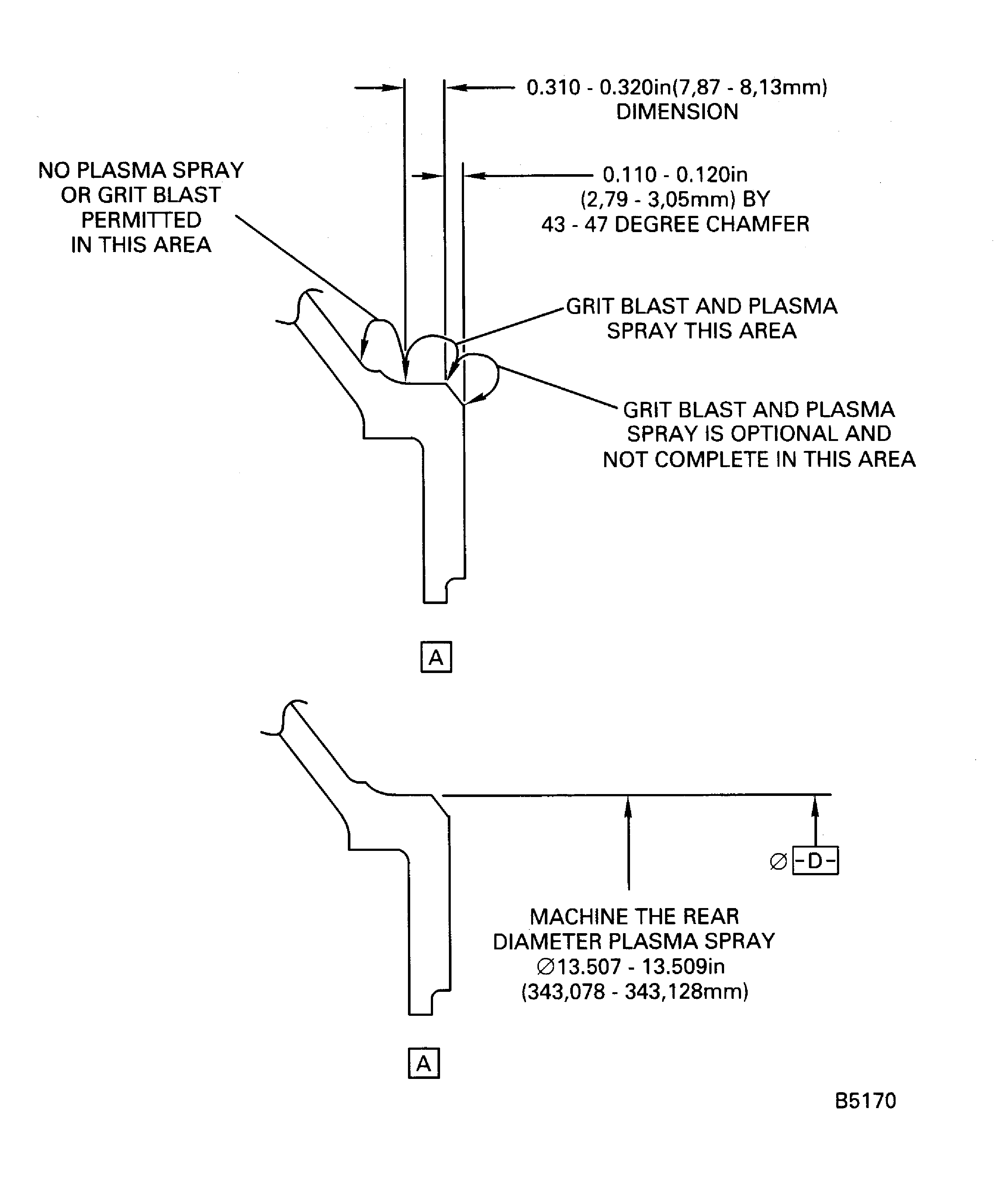

Prepare the surface for coating.

SUBTASK 72-41-12-380-064 Prepare the Surface of the Rear Diameter

Refer to Figure.

The maximum thickness of plasma spray to be applied is 0.015 in. (0.38 mm).

Do the procedure given in the SPM TASK 70-34-03-340-501 and use CoMat 03-096 PLASMA SPRAY POWDER.

No overspray permitted in the fillet area.

Plasma spray the rear diameter.

SUBTASK 72-41-12-340-053 Plasma Spray the Rear Diameter

Refer to Figure requirements.

The minimum plasma spray coating thickness is 0.003 in. (0.076 mm).

The runout must be 0.001 in. (0.025 mm) FIR in relation to Diameters B and D.

Set up and machine the rear diameter.

SUBTASK 72-41-12-320-055 Machine the Rear Diameter

Refer to Figure.

Visually examine the coated area for chips, cracks, lifted material, coating that is not attached to the base metal and surfaces that show heat cracks. None are acceptable.

SUBTASK 72-41-12-220-075 Examine the Repair

Refer to Figure.

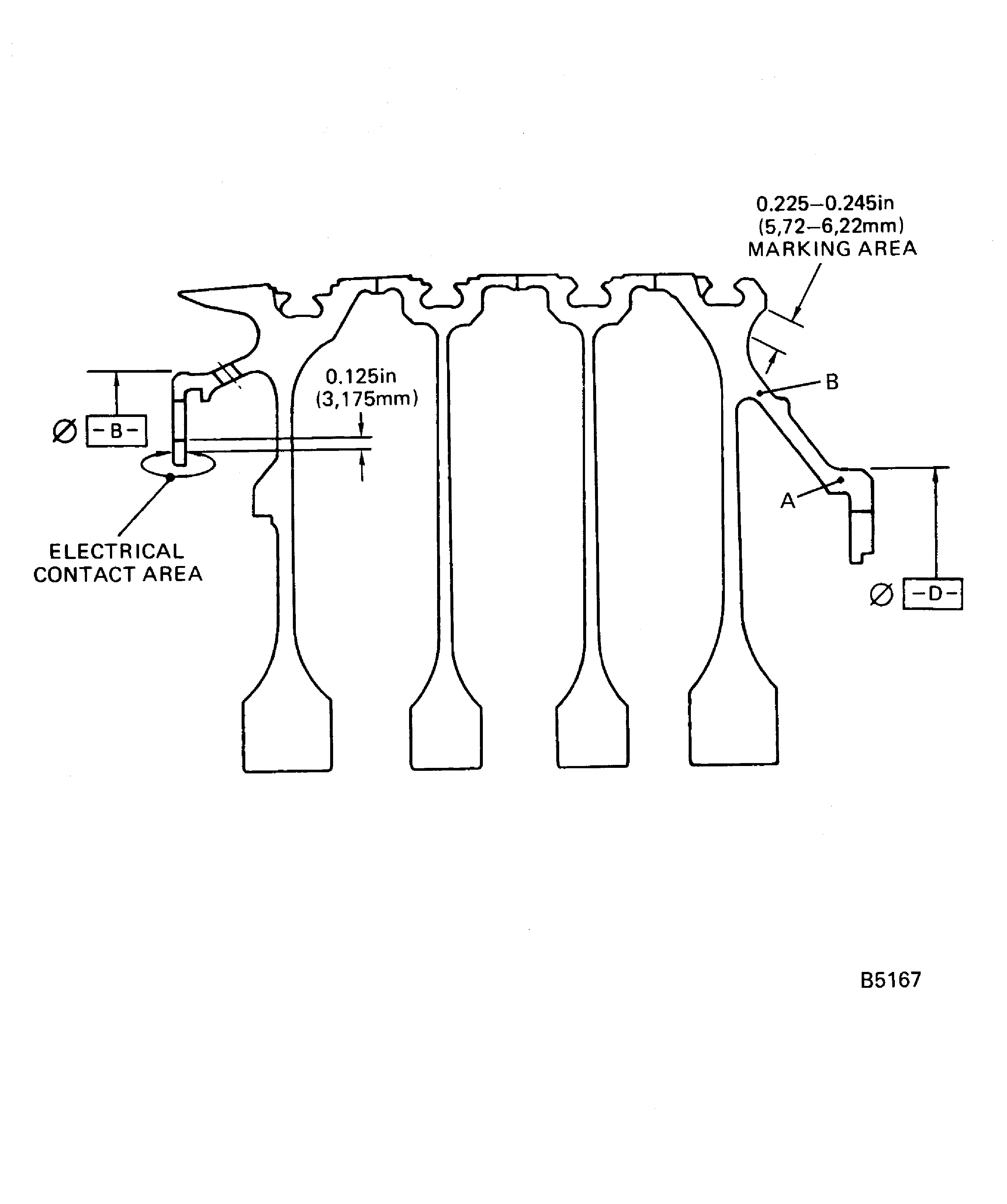

Make a permanent mark by the procedures given in the SPM TASK 70-09-00-400-501.

Use the deep etch method.

See the Figure for the electrical contact area.

No burning, pitting or selective attack permitted from the electrical contact.

Make a mark VRS3441 adjacent to part number.

SUBTASK 72-41-12-350-059 Identify the Repair

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4