Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-017 HPC Stage 9 - 12 Drum Disk - Repair The Stage 9 Disk Front Outer Location Diameter By Metal Spray, Repair-017 (VRS6134)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-600 | 6A4131 | Assembly A |

01-600 | 6A7545 | Assembly A |

01-600 | 6A7574 | Assembly A |

01-600 | 6A4156 | Assembly B |

01-600 | 6A6546 | Assembly B |

01-600 | 6A7546 | Assembly B |

01-600 | 6A7547 | Assembly B |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor - Stage 9 to 12 Disks Shaft Assembly | QZD | Inconnel 718 |

General

The Repair must only be done when the instruction to do so is given in 72-41-12 Inspection (Inspection).

The practises and processes referred to in the procedures by the TASK/SUBTASK numbers, are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before the repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3R19387 Grinding fixture | 0AM53 | IAE 3R19387 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE 3R19387 Grinding fixture, 1 off or locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

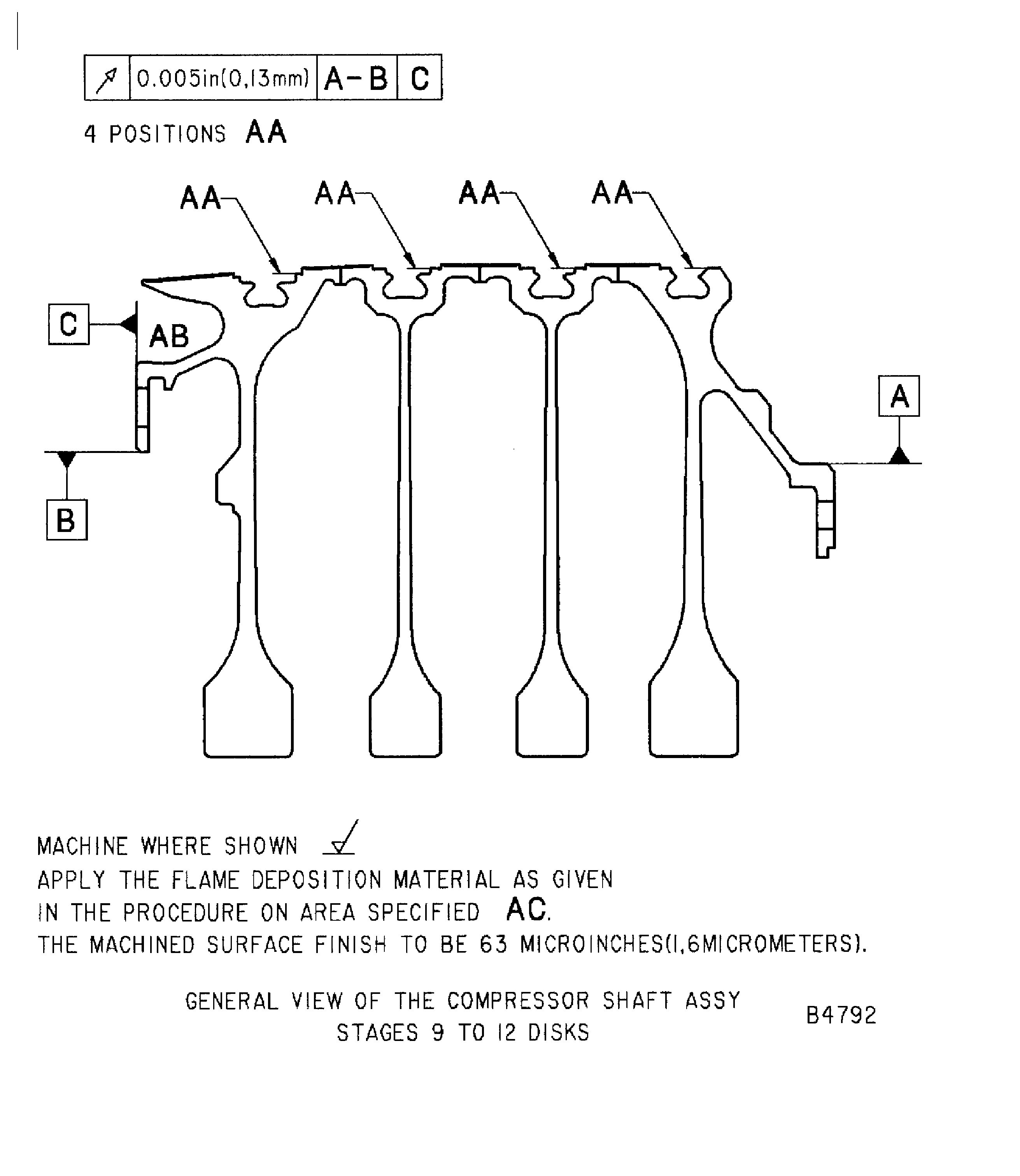

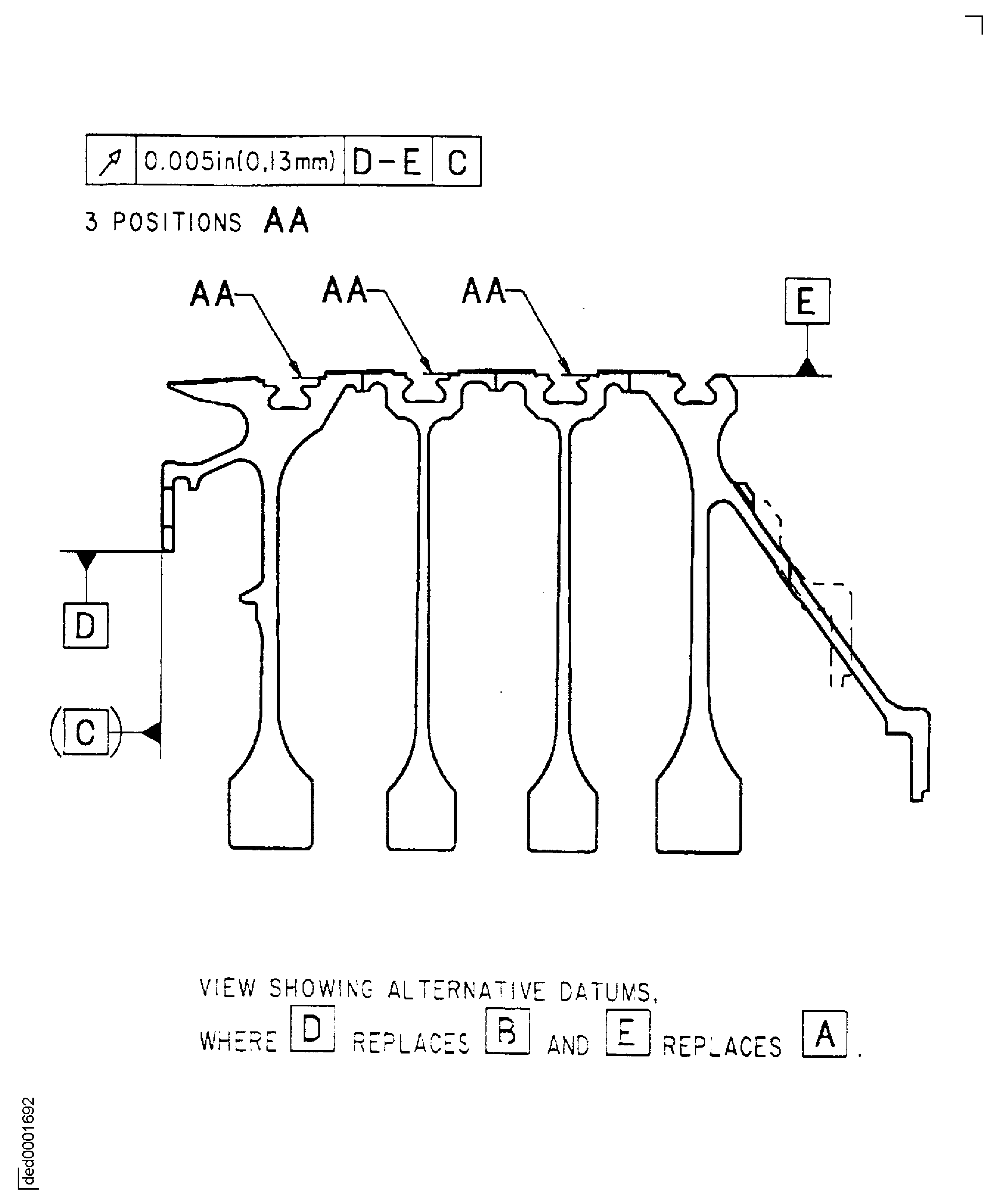

If Datum A is to be repaired, use the new Datum E. Refer to Figure.

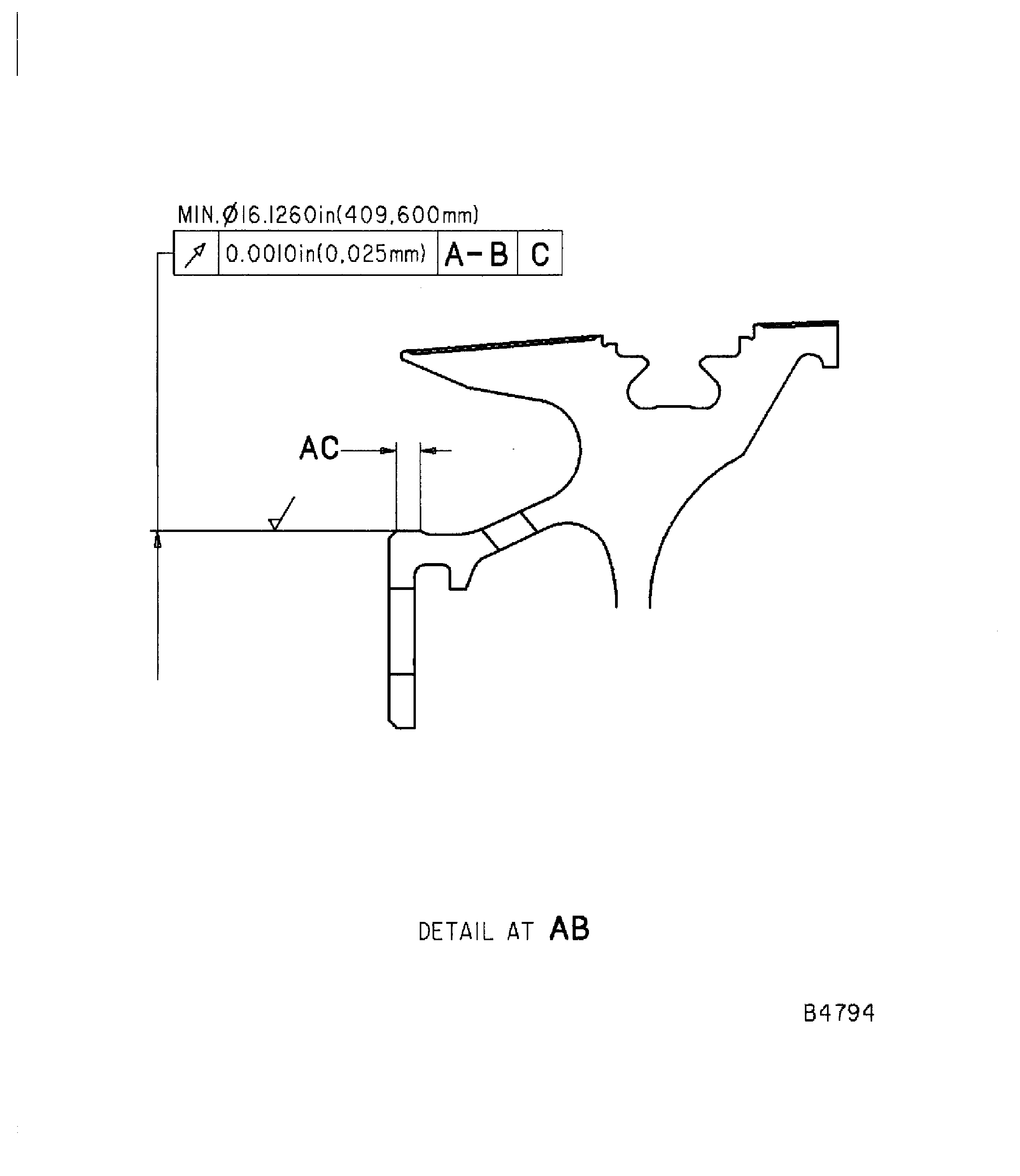

Grind/turn the front outer diameter AC to remove all damage, wear, and coat.

SUBTASK 72-41-12-324-063-A00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly A

Use IAE 3R19387 Grinding fixture, 1 off or locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

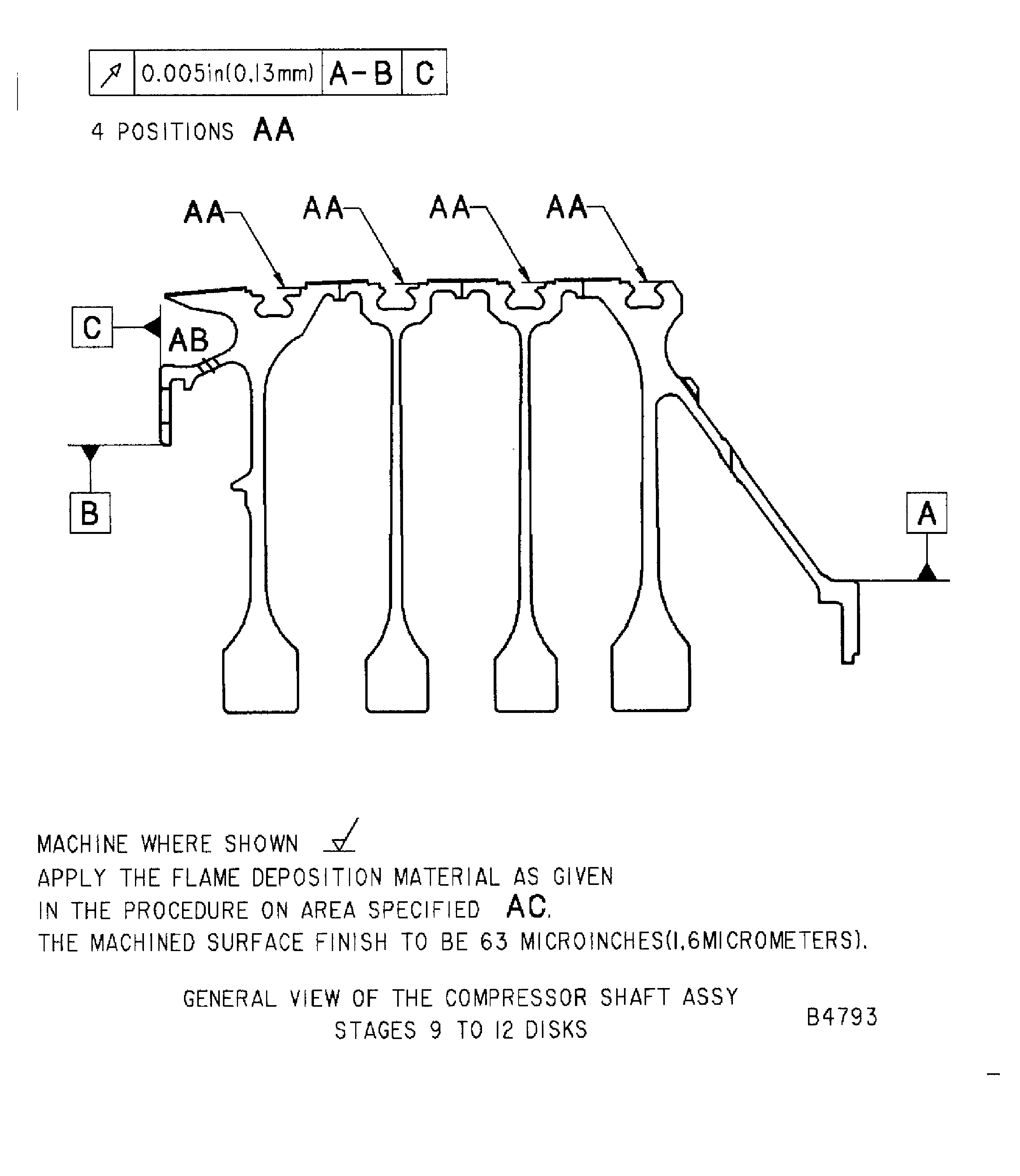

SUBTASK 72-41-12-324-063-B00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly B

Refer to Figure.

Refer to the SPM TASK 70-23-04-230-501.

Deleted.

Deleted.

Do a penetrant crack test on the front outer diameter AC.

SUBTASK 72-41-12-230-066 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503.

Deleted.

Chemically clean the assembly.

SUBTASK 72-41-12-110-064 Clean the HP Compressor - Stage 9 to 12 Disks Shaft Assembly

Deleted.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

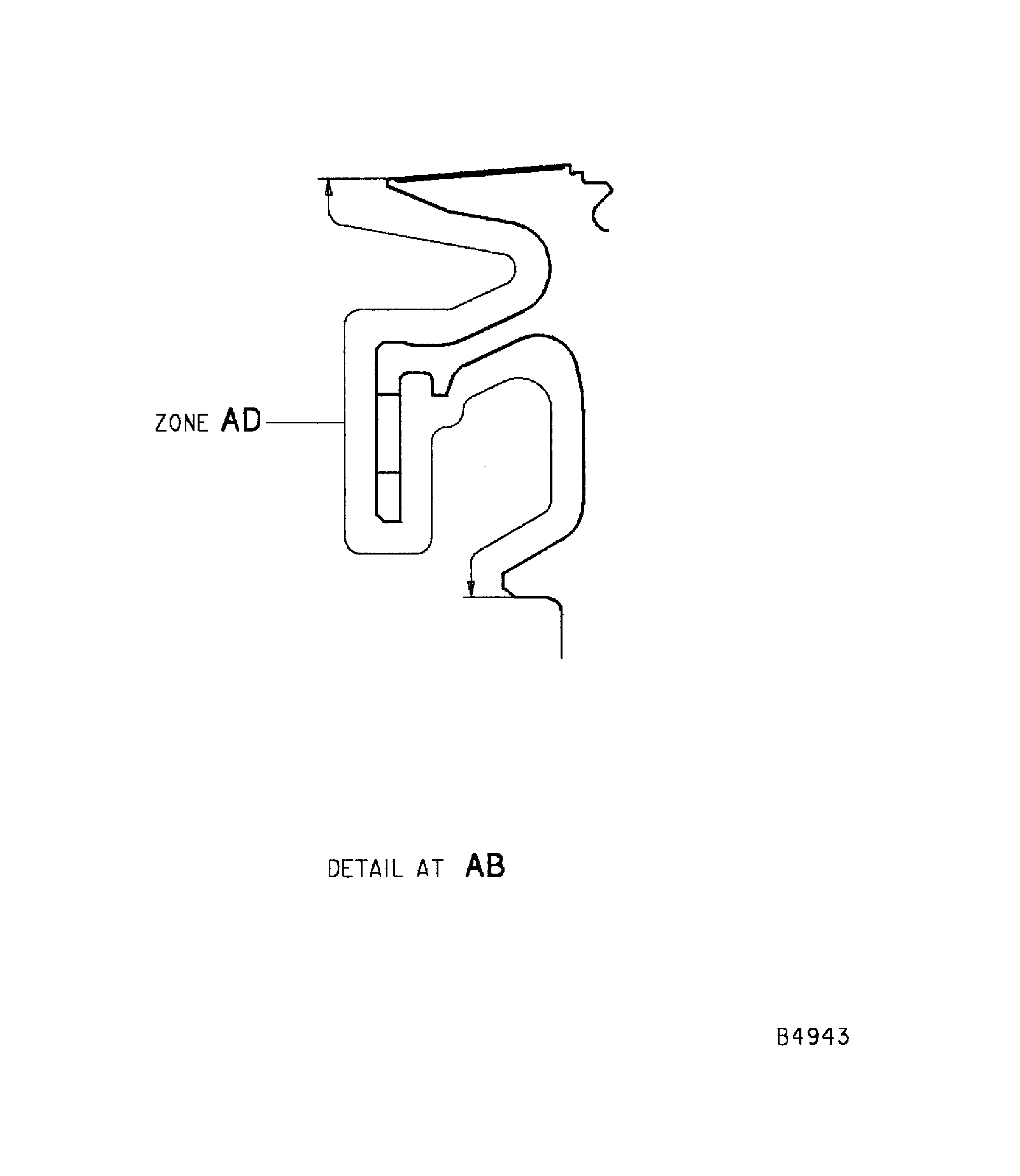

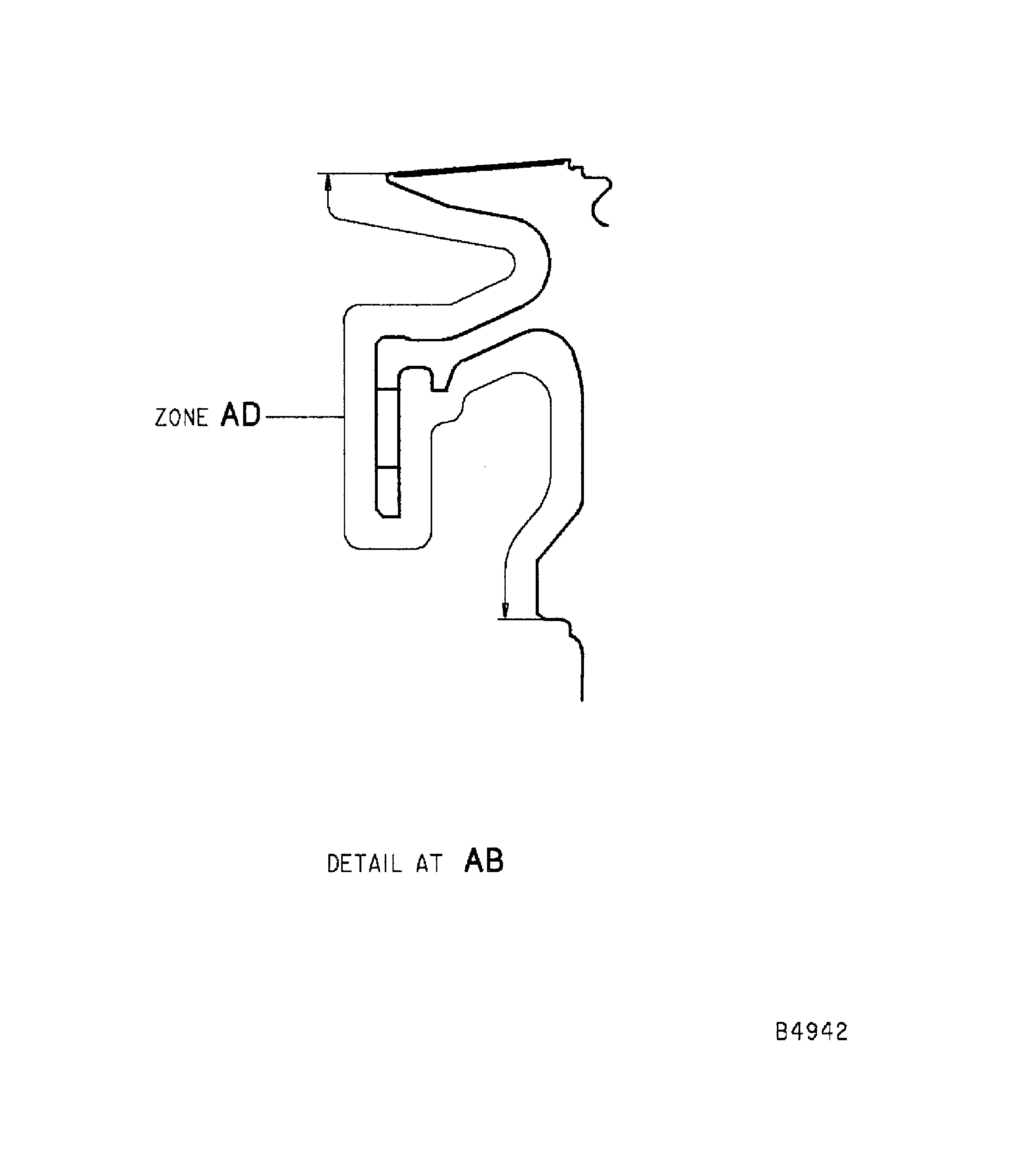

Minimum overspray is permitted in Zone AD.

Use automatic shot peening equipment.

Shot Peening Data

Machine type

Metal shot peen

Process type/mode

Dry/Auto

Shot type

Deleted

Deleted

Coverage

125 per cent minimum, 200 per cent maximum

Nozzle/work distance

120 mm

Number of nozzles

1

Almen intensity

0.006 to 0.009in. (0.15 to 0.23 mm) using

an 'A' type test strip

Shot peen the HP compressor stage 9 to 12 disks shaft assembly front outer location diameter.

SUBTASK 72-41-12-380-057-A00 Shot Peen the Area to be Repaired, Assembly A

Deleted.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Minimum overspray is permitted in Zone AD.

Use automatic shot peening equipment.

Shot Peening Data

Machine type

Metal shot peen

Process type/mode

Dry Auto

Shot type

Deleted

Deleted

Coverage

125 per cent minimum, 200 per cent maximum

Nozzle/work distance

120 mm

Number of nozzles

1

Almen intensity

0.006 to 0.009in. (0.15 to 0.23 mm) using

an 'A' type test strip

Shot-peen the HP compressor stage 9 to 12 disks shaft assembly front outer location diameter.

Deleted.

Deleted.

SUBTASK 72-41-12-380-057-B00 Shot-Peen the Area to be Repaired, Assembly B

Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the surface to be repaired, at diameter AC.

SUBTASK 72-41-12-120-055-A00 Abrasive Blast the Surface to be Repaired, Assembly A

CAUTION

TO PREVENT CONTAMINATION, DO NOT TOUCH THE SURFACE WHICH IS CLEANED FOR REPAIR.TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the surface to be repaired, at diameter AC.

SUBTASK 72-41-12-120-055-B00 Abrasive Blast the Surface to be Repaired, Assembly B

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the correct dimensions when you do finish operation.

Apply metal spray.

SUBTASK 72-41-12-340-055-A00 Metal Spray the Location Diameter AC, Assembly A

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021 or SUBTASK 70-34-01-340-025.

Apply sufficient metal spray to get the correct dimensions when you do finish operation.

Apply metal spray.

SUBTASK 72-41-12-340-055-B00 Metal Spray the Location Diameter AC, Assembly B

Use IAE 3R19387 Grinding fixture, 1 off or locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

If Datum A is to be repaired, use the new Datum E. Refer to Figure.

Break all the sharp edges to 0.010 in. - 0.020 in. (0.254 mm - 0.508 mm).

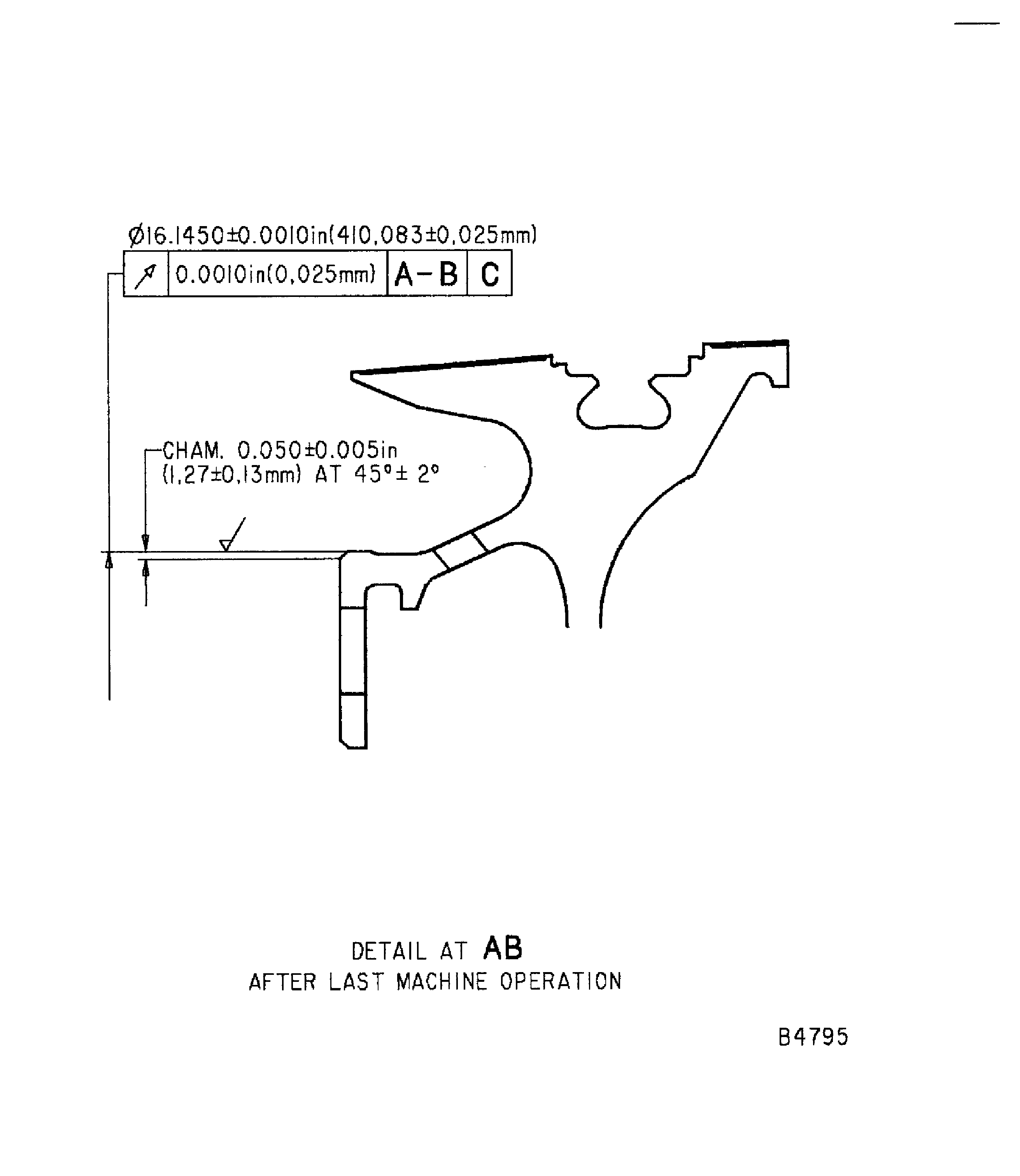

Grind/turn the front outer diameter AC.

Deleted.

SUBTASK 72-41-12-324-052-A00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly A

Use IAE 3R19387 Grinding fixture, 1 off or a locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

Deleted.

If Datum A is to be repaired, use the new Datum E. Refer to Figure.

Break all the sharp edges to 0.010 in. - 0.020 in. (0.254 mm - 0.508 mm).

Grind/turn the front outer diameter AC.

Deleted.

SUBTASK 72-41-12-324-052-B00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly B

Refer to the SPM TASK 70-11-03-300-503.

Deleted.

Chemically clean the assembly.

SUBTASK 72-41-12-110-065 Clean the HP Compressor - Stage 9 to 12 Disks Shaft Assembly

Refer to the SPM TASK 70-09-00-400-501.

Deleted.

Mark VRS6134 adjacent to the part number, use vibration peen method.

SUBTASK 72-41-12-350-073 Identify the Repair

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B