Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-015 HPC Stage 9 - 12 Drum Disk - Repair The Stage 8 to 11 Linings By Replacement, Repair-015 (VRS6008)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP compressor stage 9-12 disk shaft assembly | QZD | Inconel 718 nickel base alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-12 Inspection (INSPECTION). This repair replaces the stage 8 to 11 linings on the HP compressor stage 9 to 12 disks shaft assembly.

Pre SBE 72-0347

If the Stage 8 to 11 linings are to be replaced, on Pre SBE 72-0347 parts, you must do SBE 72-0347 in full and re-number accordingly in accordance with SBE 72-0347.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM. This is a Source Demonstration Repair that can only be done by approved vendors.

Price and availability

Refer to International Aero Engines.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | LOCAL | CoMat 02-198 | ||

| CoMat 03-037 METAL SPRAYING POWDER,Ni Al | 08662 | CoMat 03-037 | ||

| CoMat 03-043 METAL SPRAYING POWDER,Al OXIDE | LOCAL | CoMat 03-043 | ||

| CoMat 03-416 METAL SPRAYING POWDERNi, Al (95/5) | LOCAL | CoMat 03-416 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

The designation by IAE of an authorised repair vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work.However, IAE makes no warranties or representations concerning the qualification or quality standards of the repair vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor other than when IAE is listed as the repair vendor. Authorised repair vendors do not act as agents or representatives of IAE.

Authorised repair vendors for Repair VRS6008 are listed below:

GENERAL PLASMA INC.

12 THOMPSON ROAD,

EAST WINDSOR, CT 06088

ATTN. DIRECTOR, QUALITY ASSURANCE

MTU MAINTENANCE GMBH

FLUGHAFEN HANNOVER

MUNCHNER STRASSE 31

POSTFACH 1720

D3012 LANGENHAGEN

GERMANY

ATTN. MANAGER, QUALITY ASSURANCE

ROLLS-ROYCE PLC

AERO, REPAIR AND OVERHAUL

MAVOR AVENUE

NERSTON

EAST KILBRIDE

GLASGOW

G74 4PY

SCOTLAND

ATTN. BUSINESS MANAGER, COMPONENT REFURBISHMENT

MTU MAINTENANCE ZHUHAI CO. LTD

NO. 1 TIANKE ROAD

FREE TRADE ZONE

ZHUHAI, GUANGDONG

PC: 519030 P.R.CHINA

ATTN. MANAGER, PARTS REPAIR

CHRISTCHURCH ENGINE CENTRE-CHCEC

634 MEMORIAL AVENUE

CHRISTCHURCH INTERNATIONAL AIRPORT

CHRISTCHURCH

NEW ZEALAND

IHI Corporation

229 Tonogaya, Mizuho-Machi

Nishitama-gun

Tokyo 190-1297

JAPAN

Lufthansa Technik AG

HAM WR 420

PO Box 63 03 00

D-22313 Hamburg-Airport

Germany

Rolls-Royce Inchinnan

Inchinnan Drive

Inchinnan Business Park

Inchinnan, PA4 9AF

Scotland

The Source Demonstration requirements of this repair means that any facility not authorised to accomplish this repair, either utilise the Authorised Repair Vendors listed below or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility

IAE International Aero Engines AG

400 Main Street

M/S 121-10

East Hartford CT 06118

USA

Attn: Manager Technical Services

Repair Facilities

Refer to TASK 72-41-12-100-000 (CLEANING-000).

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-41-12-110-061 Clean the Assembly

CAUTION

REMOVE THE TOP COAT ONLY. THE BLAST OPERATION MUST STOP WHEN THE WHITE TOP COAT IS REMOVED. FAILURE TO STOP THE BLAST OPERATION AS SPECIFIED CAN RESULT IN SUBSEQUENT ENGINE FAILURE.NOTE

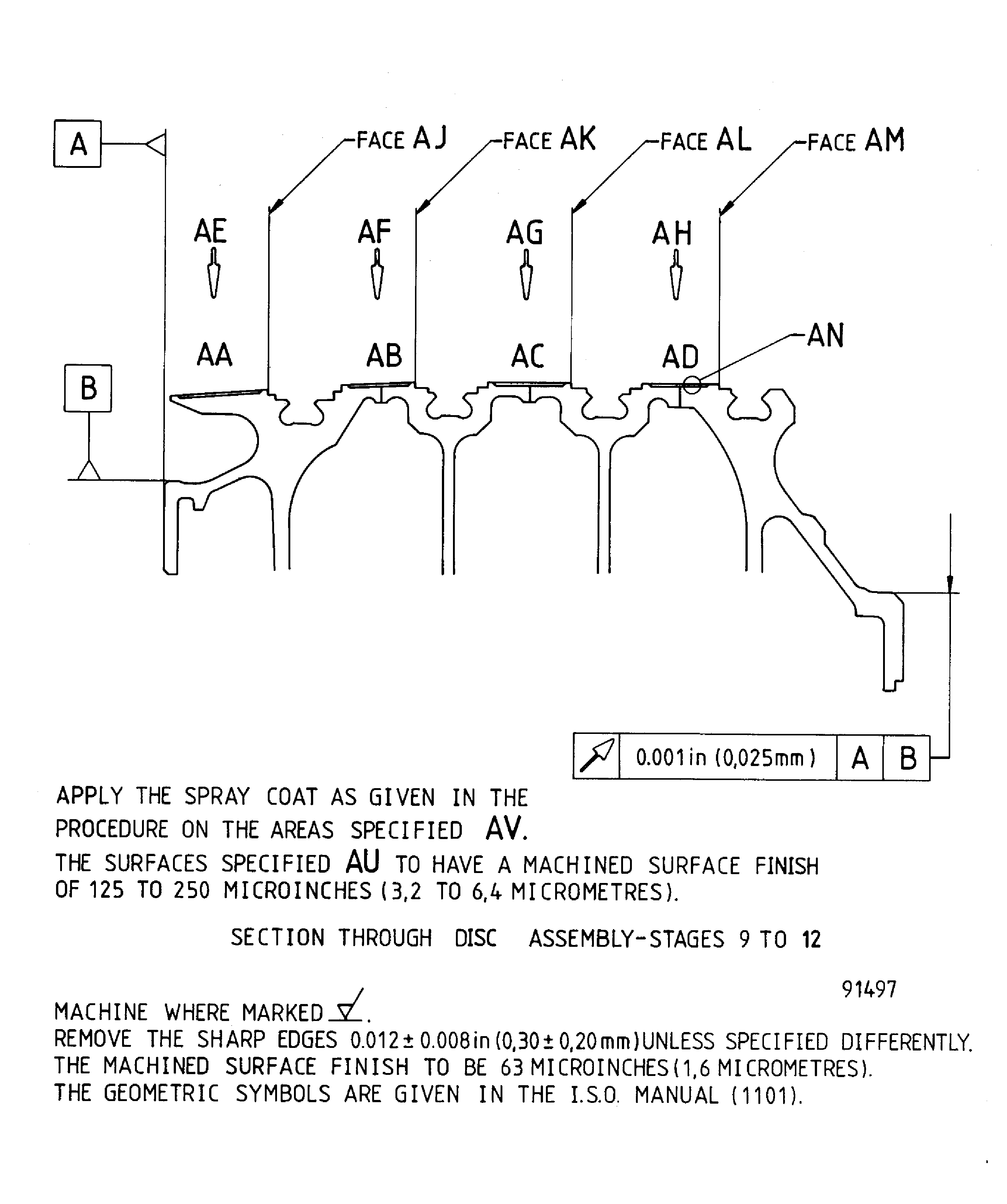

It is permitted to loosen the top coat lining in part, to allow the Nitric Acid by capillary action, to release both top and bond coats at each stage.Refer to Figure.

Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or equivalent masking listed in the SPM TASK 70-34-18-380-501 or refer to Step. Repair Facilities for approved vendor tools.

Seal all surfaces not to be blasted.

Refer to the SPM TASK 70-12-02-120-501.

Lightly dry blast to loosen the top coat lining at each stage.

SUBTASK 72-41-12-120-053-A00 Loosen the Top Coat Lining at Each Stage, Assembly A

CAUTION

REMOVE THE TOP COAT ONLY. THE BLAST OPERATION MUST STOP WHEN THE WHITE TOP COAT IS REMOVED. FAILURE TO STOP THE BLAST OPERATION AS SPECIFIED MAY RESULT IN SUBSEQUENT ENGINE FAILURE.NOTE

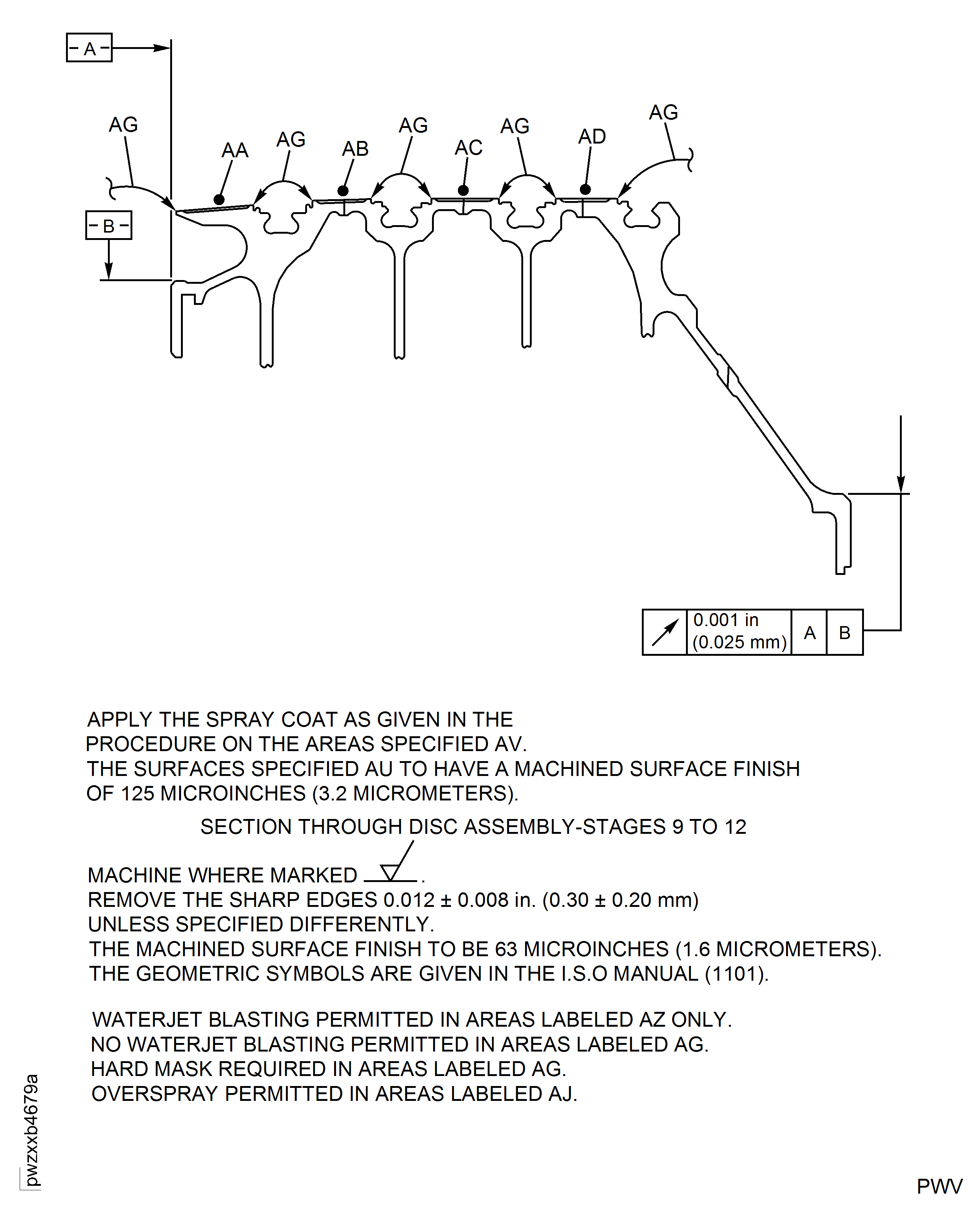

It is permitted to loosen the top coat lining in part, to allow the Nitric Acid by capillary action, to release both top and bond coats at each stage for chemical strip step. This step is optional when using water jet to remove linings.Refer to Figure.

Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or equivalent masking listed in the SPM TASK 70-34-18-380-501 or refer to Step. Repair facilities for approved vendor tools.

Seal all surfaces not to be blasted.

Refer to the SPM TASK 70-12-02-120-501.

Lightly dry blast to loosen top coat lining at each stage.

SUBTASK 72-41-12-120-053-B00 Loosen the Top Coat Lining at Each Stage, Assembly B

Refer to the SPM TASK 70-33-59-300-503.

Use CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE. Put the assembly into nitric acid solution and keep below surface until bubbles stop.

Remove the lining at each stage.

SUBTASK 72-41-12-330-052-A00 Chemically Remove the Linings at Each Stage, Assembly A

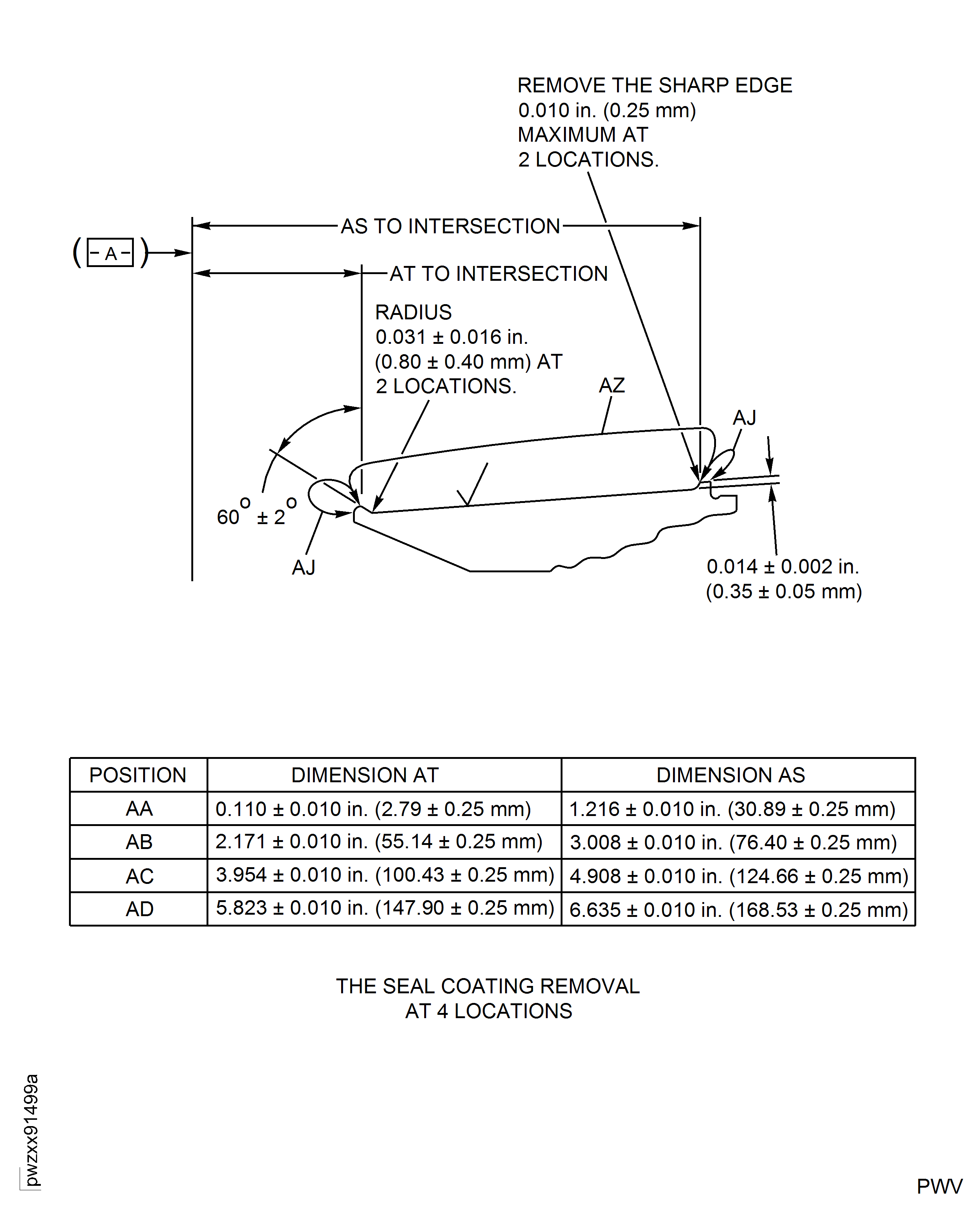

Waterjet blasting permitted in areas labeled AZ only.

Blasting outside of repair area is not allowed.

Hard mask required in areas labeled AG.

Refer to SPM TASK 70-15-01-160-501.

Make sure the liner is completely removed.

0.0005 in. (0.0127 mm) maximum erosion from waterjet allowed.

Overspray permitted in areas labeled AJ.

Remove the abradable lining.

Remove the lining at each stage by high pressure water blasting.

NOTE

This is a source demonstration processes which can only be done by approved vendors.NOTE

This method is applicable to PNs 6A7546 only.NOTE

This step is an alternative to Step.

SUBTASK 72-41-12-350-178-B00-001 Remove the Linings at Each Stage by Water Jet, Assembly B (PN 6A7546 only)

Refer to the SPM TASK 70-33-59-300-503.

Use CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE. Put the assembly into nitric acid solution and keep below surface until bubbles stop.

Remove the lining at each stage.

SUBTASK 72-41-12-330-052-B00-002 Chemically Remove the Linings at Each Stage, Assembly B

Refer to the SPM TASK 70-23-04-230-501.

No cracks allowed, reject part if found.

Do a penetrant crack test.

SUBTASK 72-41-12-230-061 Do a Crack Test

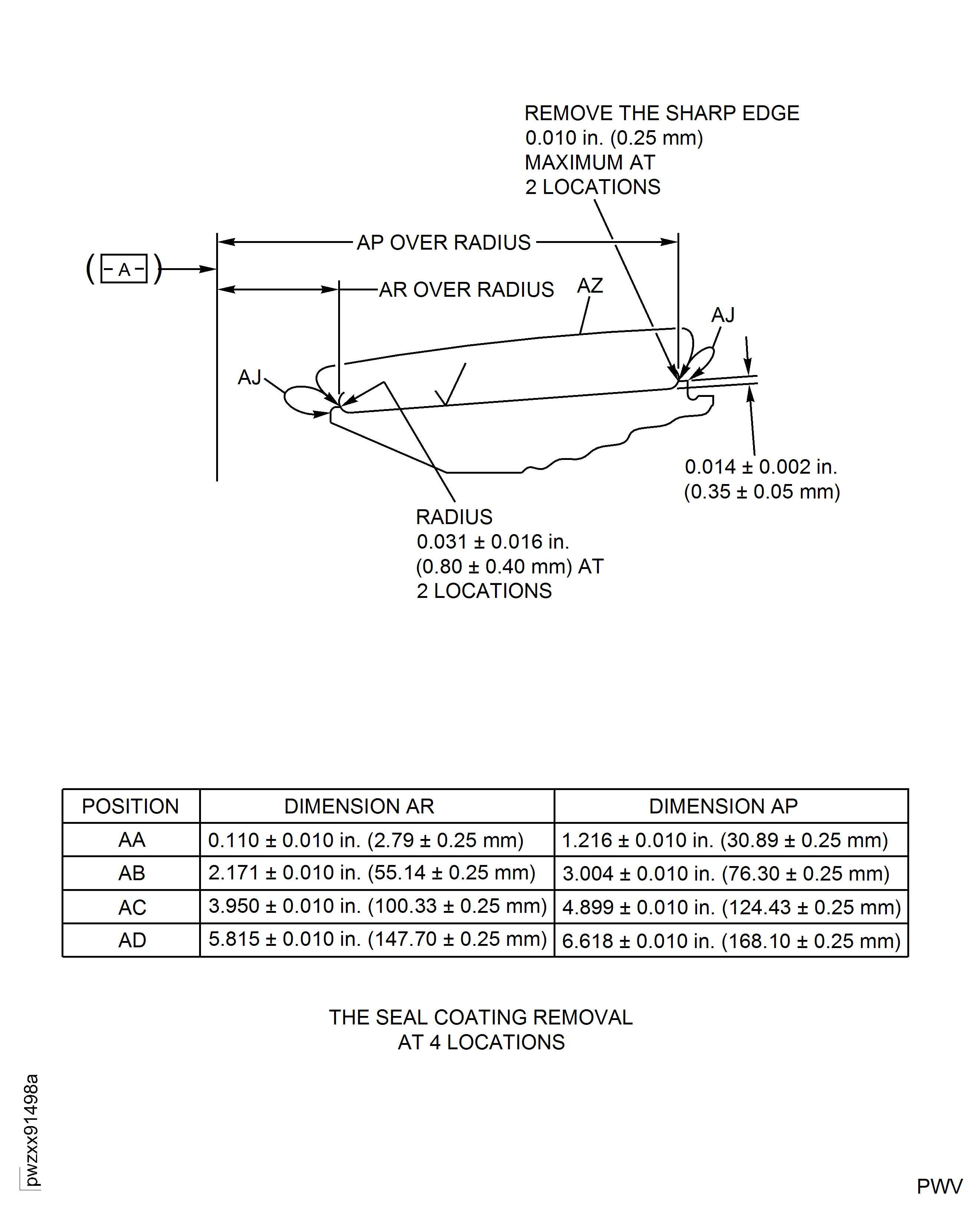

Refer to Figure.

NOTE

The adhesive tape (metal masking spray) permits the blasting and sprayed coating to be done in one operation.Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or equivalent tape listed in the SPM TASK 70-34-18-380-501.

Alternatively refer to step 4. Repair Facilities for approved vendor tools.

Seal applicable surfaces.

SUBTASK 72-41-12-350-064-A00 Seal all Surfaces not to be Repaired, Assembly A

Refer to Figure.

NOTE

The adhesive tape (metal masking spray) permits the blasting and sprayed coating to be done in one operation.Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or equivalent masking in the SPM TASK 70-34-18-380-501.

Alternatively refer to 4. Repair Facilities for approved vendor tools.

Seal applicable surfaces.

SUBTASK 72-41-12-350-064-B00 Seal all Surfaces not to be Repaired, Assembly B

Refer to the SPM TASK 70-12-02-120-501.

CAUTION

DO NOT TOUCH SURFACE(S) TO BE REPAIRED AFTER THEY ARE CLEANED.

CAUTION

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Lightly dry blast to prepare surfaces for the lining.

SUBTASK 72-41-12-120-054 Prepare Surfaces for Repair

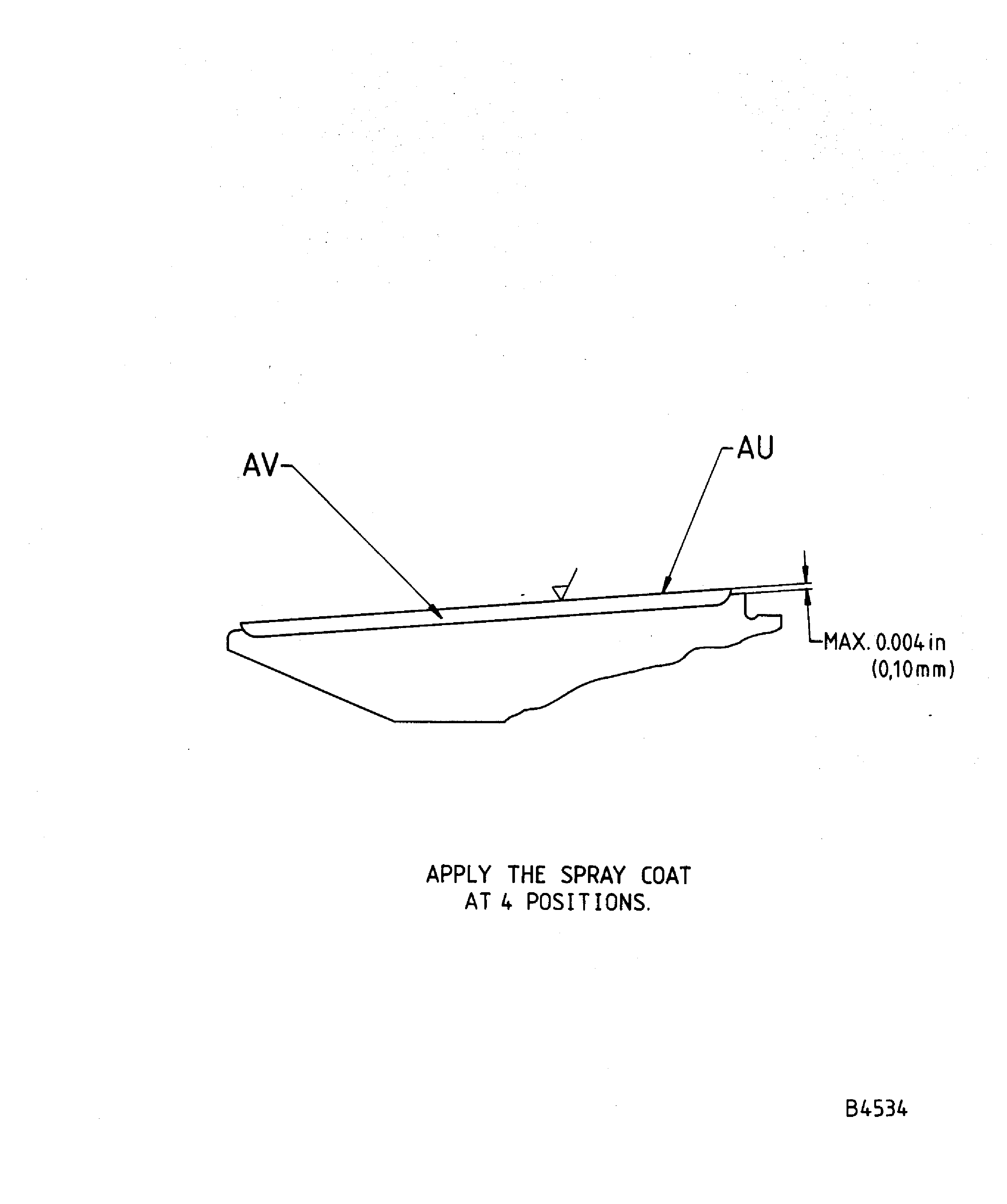

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-007 or SUBTASK 70-34-01-340-025.

Apply a thickness of 0.0080 to 0.0100 in. (0.203 to 0.254 mm).

NOTE

Pre SBE 72-0347.If the stage 8 to 11 linings are to be replaced, on Pre SBE 72-0347 parts, you must do SBE 72-0347 in full and re-number accordingly in accordance with SBE 72-0347.Apply the bond coat at each stage.

Refer to TASK SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-013.

Apply a layer of sufficient thickness to get the correct dimensions after assembly is machined.

Apply the top coat at each stage.

SUBTASK 72-41-12-340-054-A00 Apply the New Linings, Assembly A

Refer to the SPM TASK 70-34-01-340-501 SUBTASK 70-34-01-340-007 or SUBTASK 70-34-01-340-025.

Apply a thickness of 0.008 to 0.010 in. (0.203 to 0.254 mm).

NOTE

Pre SBE 72-0347.If the stage 8 to 11 linings are to be replaced, on Pre SBE 72-0347 parts, you must do SBE 72-0347 in full and re-number accordingly in accordance with SBE 72-0347.Apply the bond coat at each stage.

Refer to the SPM TASK 70-34-01-340-501 SUBTASK 70-34-01-340-013.

Apply a layer of sufficient thickness to get the correct dimensions after assembly is machined.

Apply the top coat at each stage.

SUBTASK 72-41-12-340-054-B00 Apply the new Linings, Assembly B

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine the new linings.

SUBTASK 72-41-12-220-088 Visually Examine

Refer to Step. Repair Facilities for approved vendor tools.

Set up the disk assembly to be machined.

SUBTASK 72-41-12-325-051-A00 Machine the Linings, Assembly A

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine repaired area.

SUBTASK 72-41-12-220-089-A00 Visually and Dimensionally Examine the Repair, Assembly A

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine repaired area.

SUBTASK 72-41-12-220-089-B00 Visually and Dimensionally Examine the Repair, Assembly B

Refer to TASK 72-41-00-100-000.

Chemically clean.

SUBTASK 72-41-12-110-062 Clean the Assembly

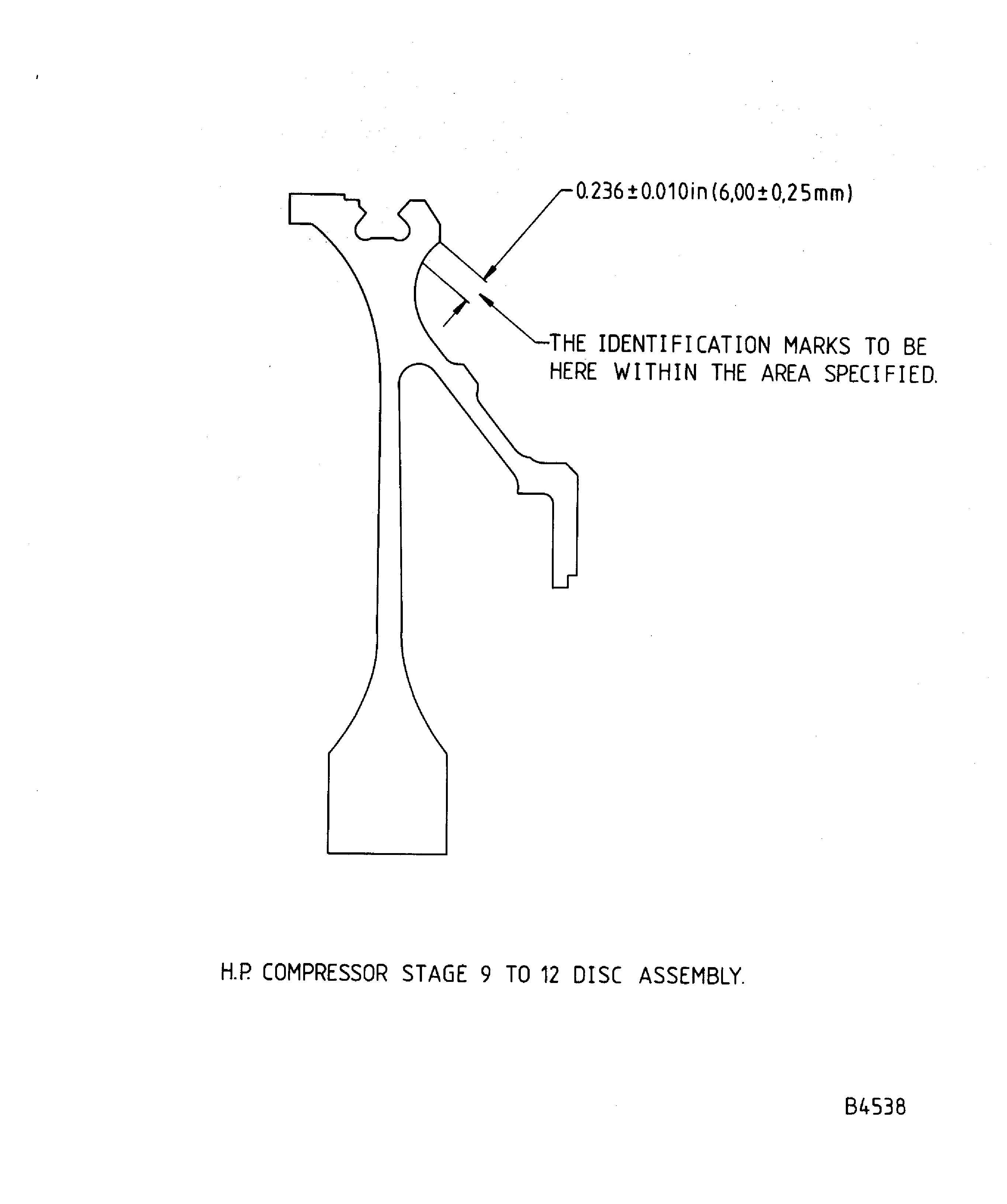

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

Pre SBE 72-0347.If the stage 8 to 11 linings are to be replaced, on Pre SBE 72-0347 parts, you must do SBE 72-0347 in full and re-number accordingly in accordance with SBE 72-0347.Vibro-engrave VRS6008 adjacent to the part number.

SUBTASK 72-41-12-350-066 Identify the Repair

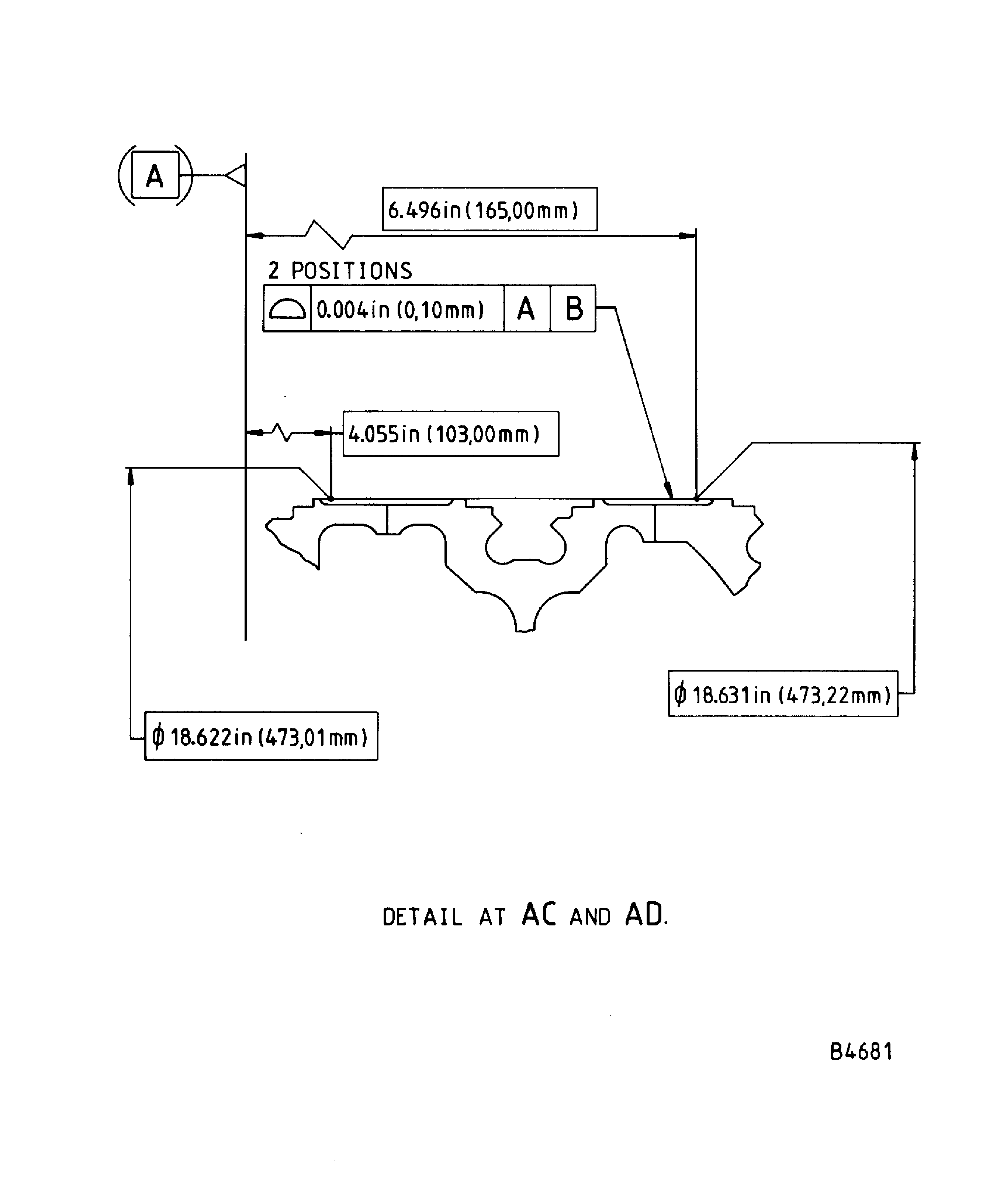

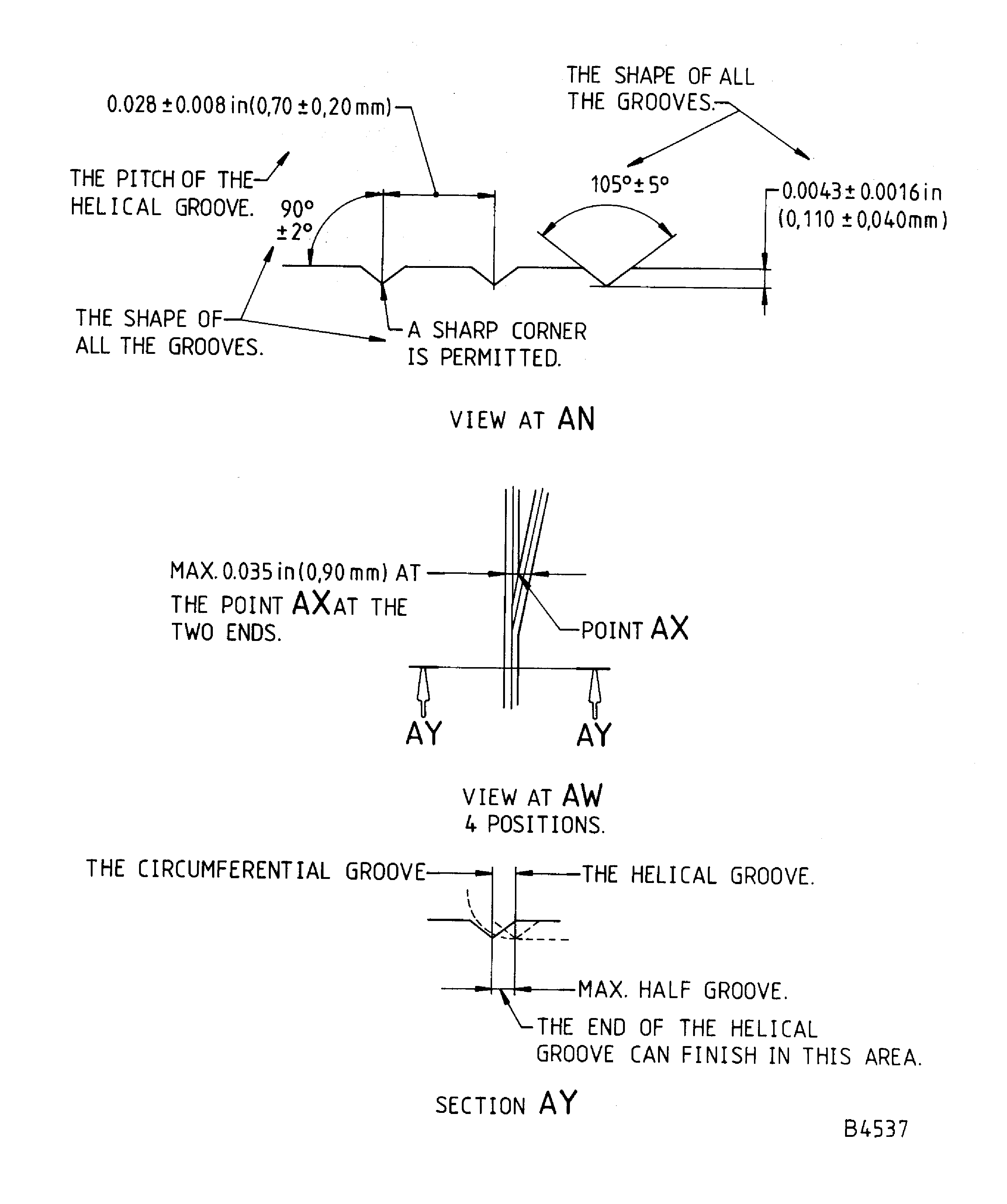

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions Assy B

Repair details and dimensions Assy B

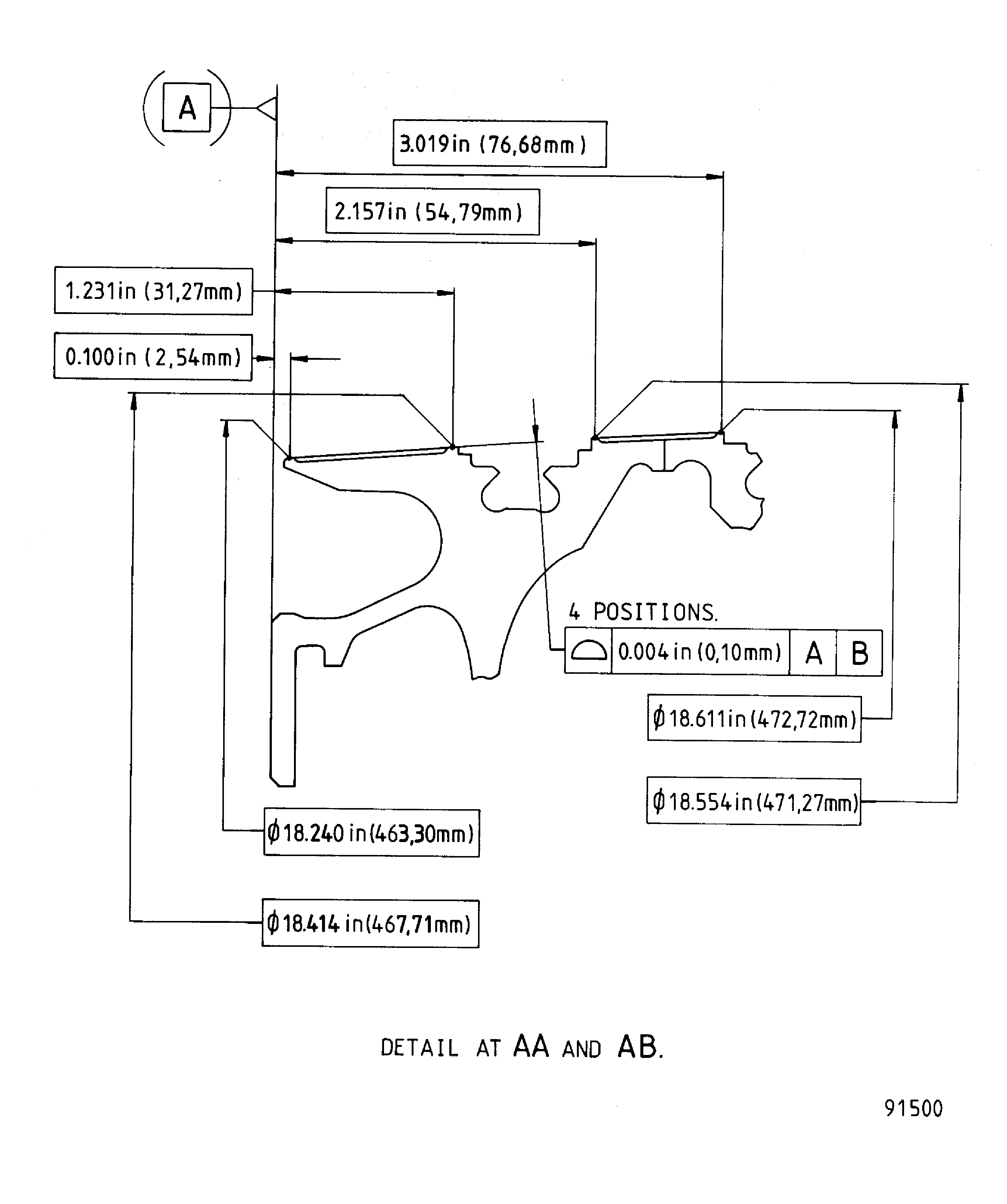

Figure: Repair details and dimensions - Assy A and Assy B

Repair details and dimensions - Assy A and Assy B

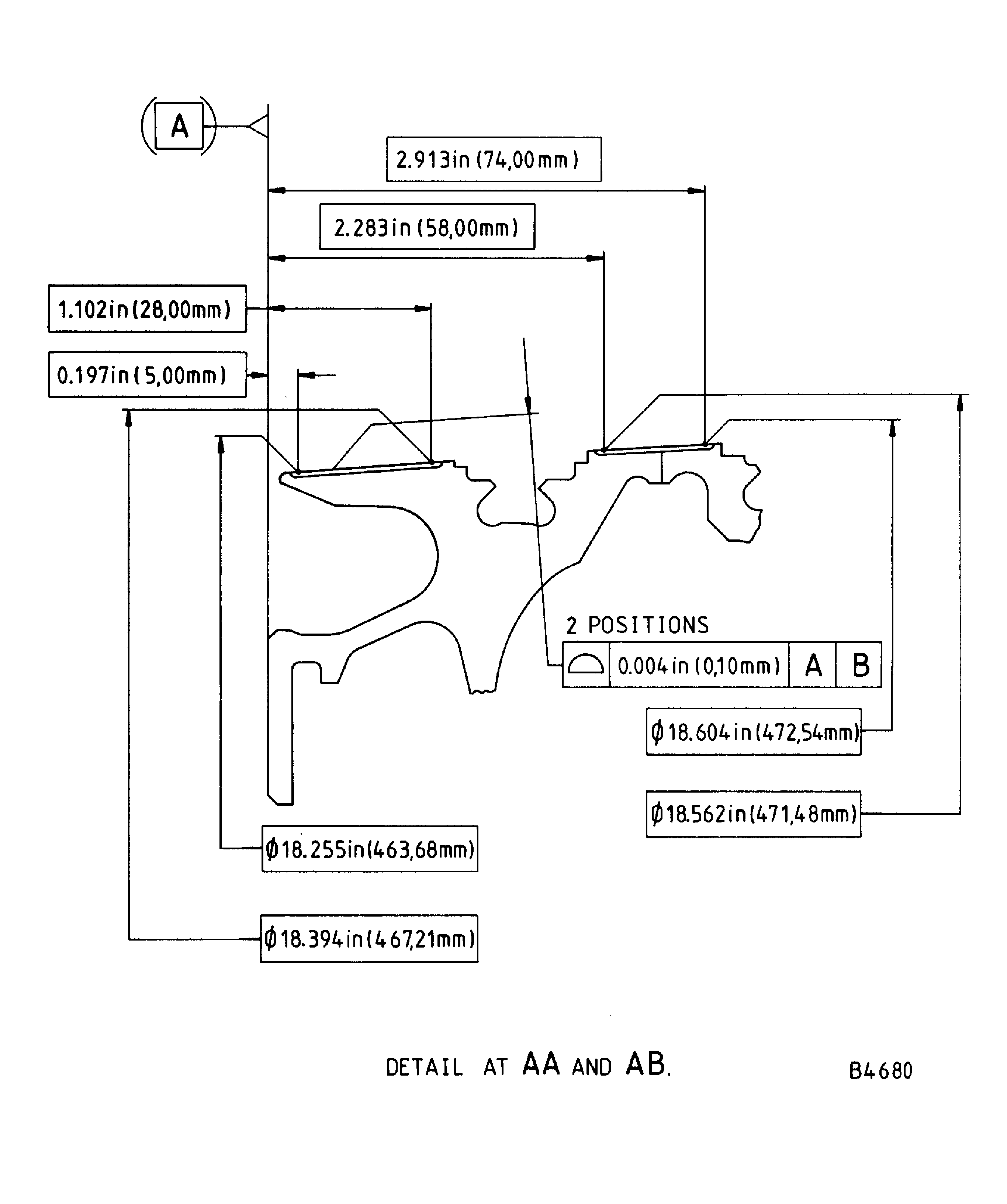

Figure: Repair details and dimensions - Assy A and Assy B

Repair details and dimensions - Assy A and Assy B

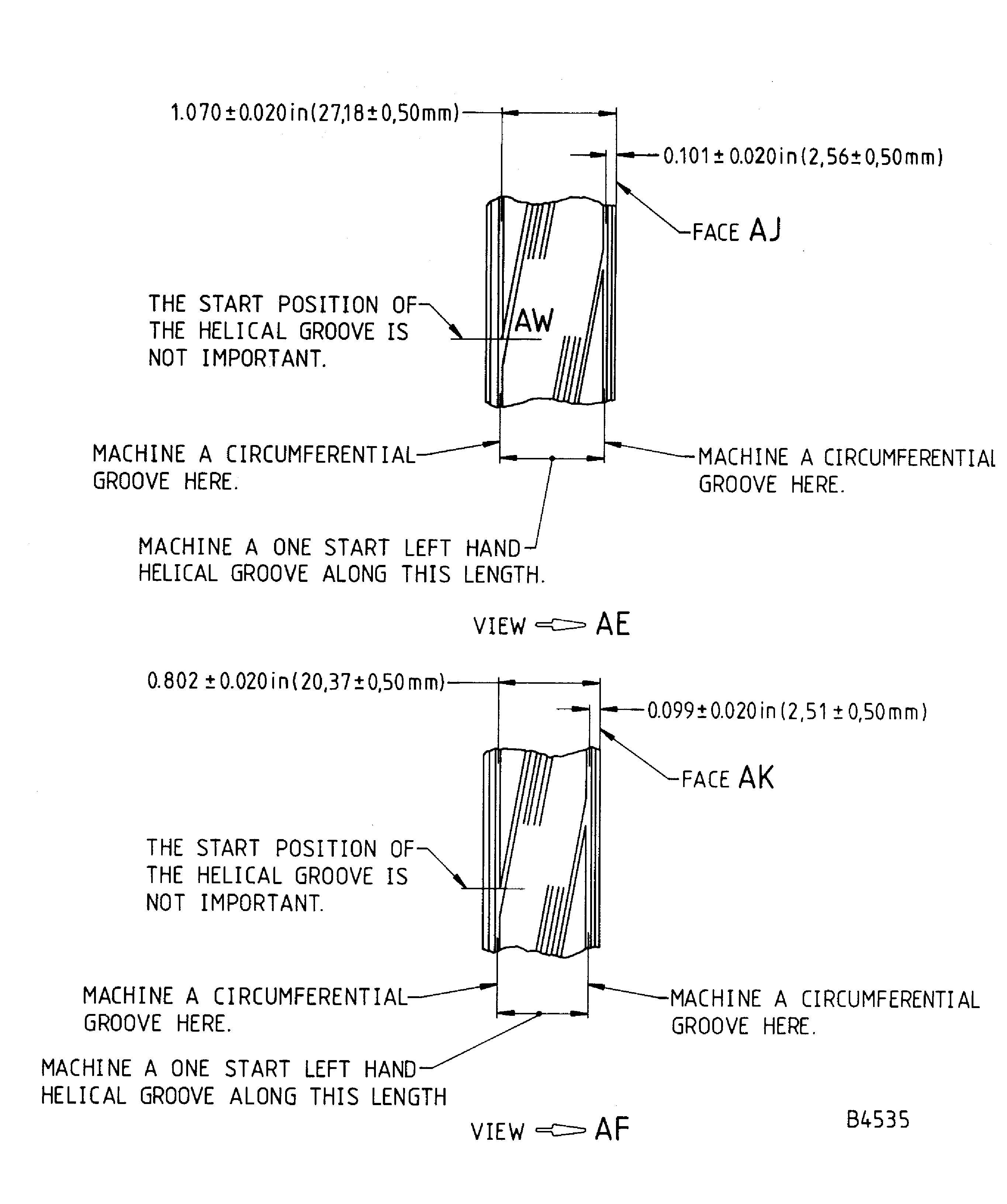

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

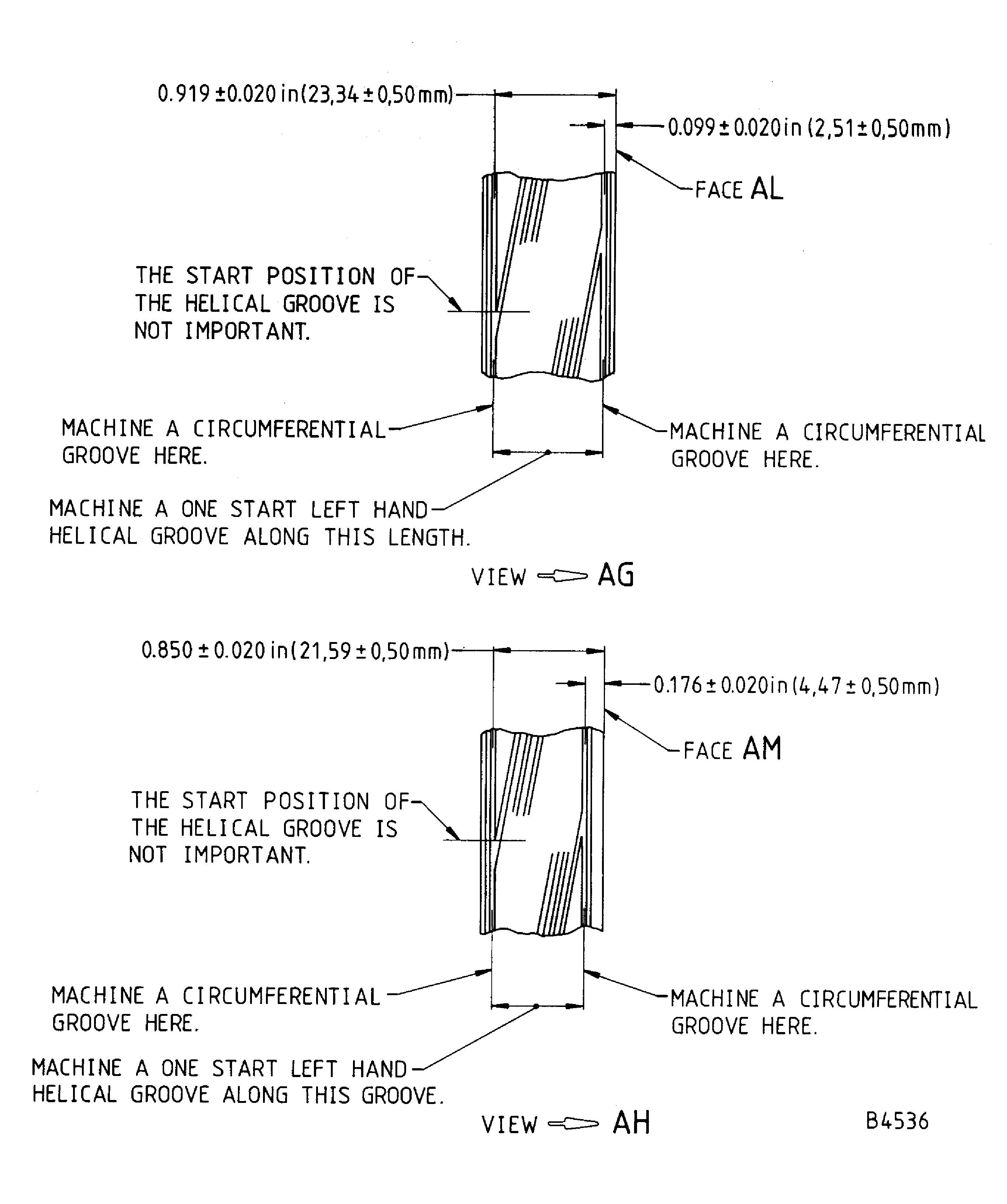

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

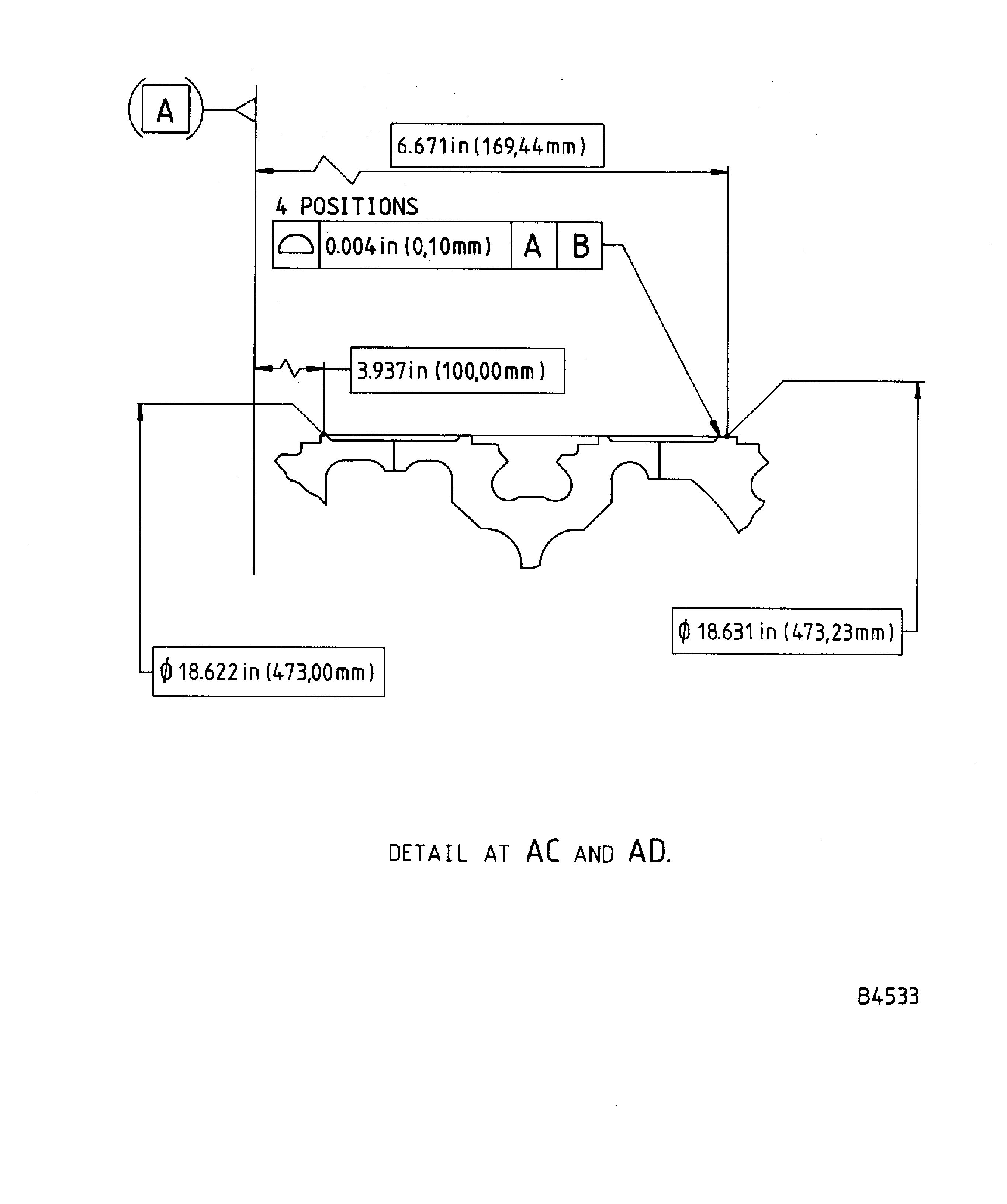

Figure: Repair details and dimensions - Assy A and Assy B

Repair details and dimensions - Assy A and Assy B

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A and Assy B

Repair details and dimensions - Assy A and Assy B