Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-14-300-002 HPC Rear Rotating Airseal - Repair The Location Diameter By Metal Spray, Repair-002 (VRS6144)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Rear Rotating Airseal | QDY | Waspaloy - Heat Resisting-vac melt |

General

This TASK gives the procedure to Repair the Location Diameter on the HP Compressor Rear Rotating Airseal by Metal Spray.

This repair must only be done when the instruction to do so is given in inspection procedures (identified by the applicable part number) located in section 72-41-14.

Where reference is made to a SUBTASK within a TASK in the form "TASK, SUBTASK" the operator must read and apply the complete TASK. The SUBTASK is listed only when the TASK gives options for the processing of the component. The specified SUBTASK instructs what option must be used during a application of the TASK for the successful completion of the Repair Scheme VRS6144.

TASKS identified by SPM TASK are in the Standard Practices Manual (SPM).

Price and availability

Refer to International Aero Engines

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Fluorescent penetrant inspection equipment | 0AM53 | Fluorescent penetrant inspection equipment | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Flame spray equipment | LOCAL | Flame spray equipment | ||

| Vibro-peen equipment | LOCAL | Vibro-Peen Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-047 TAPE, HEAT REFLECTIVE | 52152 | CoMat 02-047 | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-140 ABRASIVE STONE SILICON CARBIDE | LOCAL | CoMat 05-140 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Task TASK 72-41-14-100-000 (CLEANING-000).

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-41-14-110-062 Chemically Clean

Refer to SPM TASK 70-33-59-300-503.

Chemically strip the coating from the HP Compressor Rear Rotating Airseal.

SUBTASK 72-41-14-110-065 Chemically Strip the Coating

Refer to SPM TASK 70-11-39-300-503.

Cold ferric chloride swab etch the abrasive blasted surfaces of the HP Compressor Rear Rotating Airseal.

NOTE

This SUBTASK is only required if abrasive blasting was required to remove residual coating from the repair area.

SUBTASK 72-41-14-110-066 Swab Etch the Abrasive Blasted Surface

Refer to SPM TASK 70-23-04-230-501.

Reject.

If cracking is detected:

Continue with the repair.

If no cracking is detected:

Do a fluorescent penetrant inspection.

SUBTASK 72-41-14-230-063 Fluorescent Penetrant Inspect

NOTE

This SUBTASK is only required if there was no coating applied previously or if damage is still evident on the base material after the coating was removed.NOTE

Single point machining can be used as an alternative to grinding when removing damage or the existing coating. Care must be taken not to reduce the dimensions of the component below those given in the relevant figures.Use a Grinding machine, locally manufactured grinding fixture, Standard workshop equipment and a Dial test indicators.

Install a locally manufactured grinding fixture onto the Grinding machine.

Use Standard workshop equipment and a Dial test indicators.

Install the HP Compressor Rear Rotating Airseal into the grinding fixture.

SUBTASK 72-41-14-324-051 Grind the Location Diameter

Refer to SPM TASK 70-11-39-300-503.

Cold ferric chloride swab etch the ground surfaces of the HP Compressor Rear Rotating Airseal.

NOTE

This subtask is only required if the coating or damage has been removed by machining.

SUBTASK 72-41-14-110-067 Swab Etch the Ground Surface

Refer to SPM TASK 70-23-04-230-501.

Reject.

If cracking is detected:

Continue with the repair.

If no cracking is detected:

Do a fluorescent penetrant inspection.

SUBTASK 72-41-14-230-056 Fluorescent Penetrant Inspect

Refer to SPM TASK 70-11-01-300-503.

Chemically clean the rear rotating seal.

SUBTASK 72-41-14-110-056 Chemically Clean

Reject.

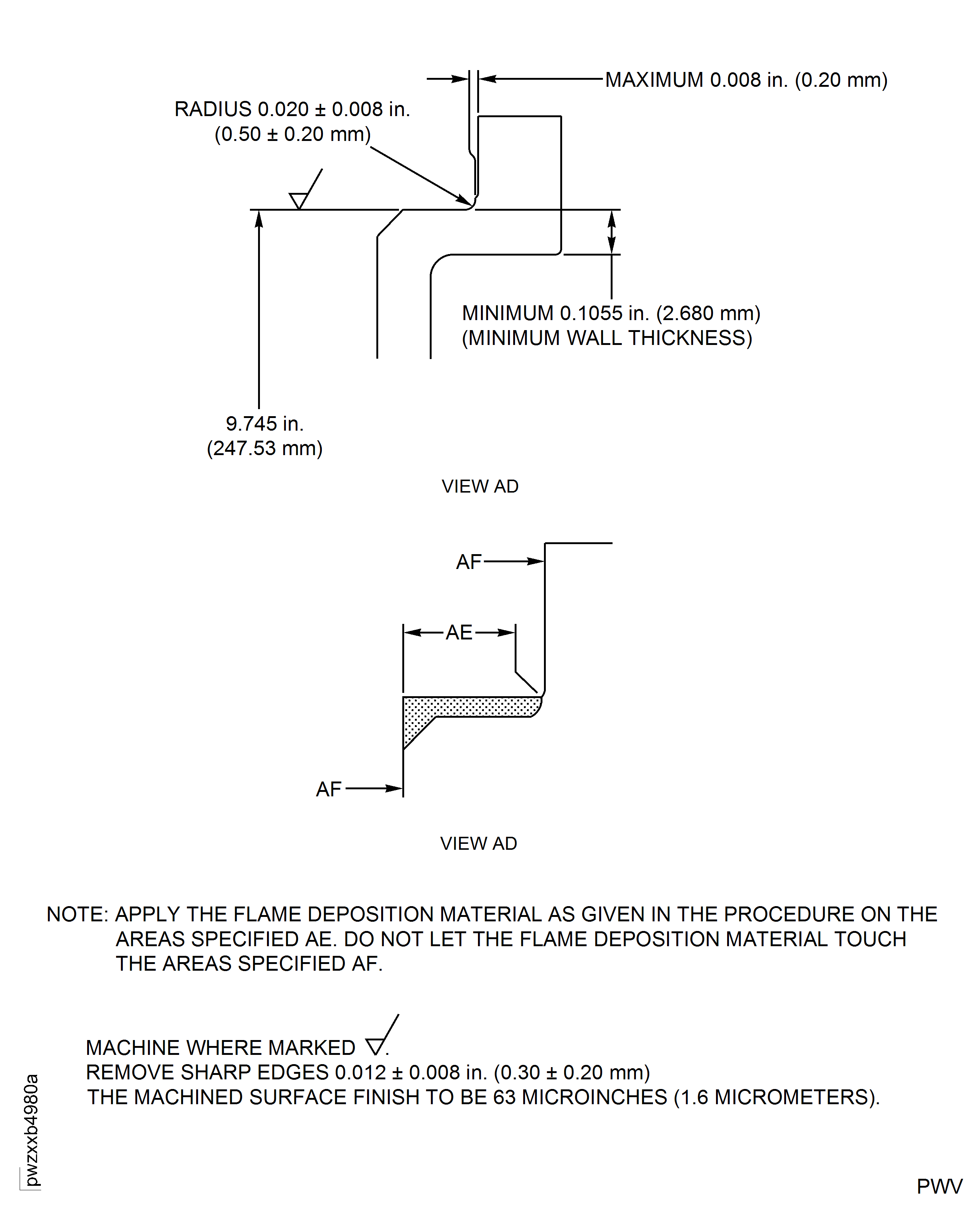

If the remaining wall thickness is less than the minimum wall thickness:

Continue with the repair.

If the remaining wall thickness is equal to or greater than the minimum wall thickness:

Dimensionally inspect the remaining wall thickness:

SUBTASK 72-41-14-220-098 Dimensionally Inspect the Remaining Wall Thickness, Assembly B Only

Refer to SPM TASK 70-12-02-120-501.

CAUTION

TO PREVENT CONTAMINATION, DO NOT TOUCH THE SURFACE WHICH IS CLEANED FOR REPAIR.Abrasive blast the surface for repair.

SUBTASK 72-41-14-120-051-A00 Abrasive Blast the Surface to be Coated

Refer to SPM TASK 70-34-01-340-501.

Apply metal spray to give a sufficient thickness to grind, up to a maximum thickness of 0.011 in. (0.28 mm).

Use metal spray equipment.

Apply metal spray.

SUBTASK 72-41-14-340-051 Metal Spray the Blasted Surface

Use Grinding machine, grinding fixture, Standard workshop equipment and a Dial test indicators.

Install a grinding fixture onto the Grinding machine.

Use Standard workshop equipment and a Dial test indicators.

Install the HP Compressor Rear Rotating Airseal into the grinding fixture.

Refer to SPM TASK 70-32-00-320-501.

Grind to the final dimension.

Grind the location diameter.

SUBTASK 72-41-14-324-052 Grind the Metal Sprayed Surface

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use Vibro-peen equipment.

Make a mark VRS6144 adjacent to the part number on the indicated surface.

SUBTASK 72-41-14-350-056 Identify the Repair

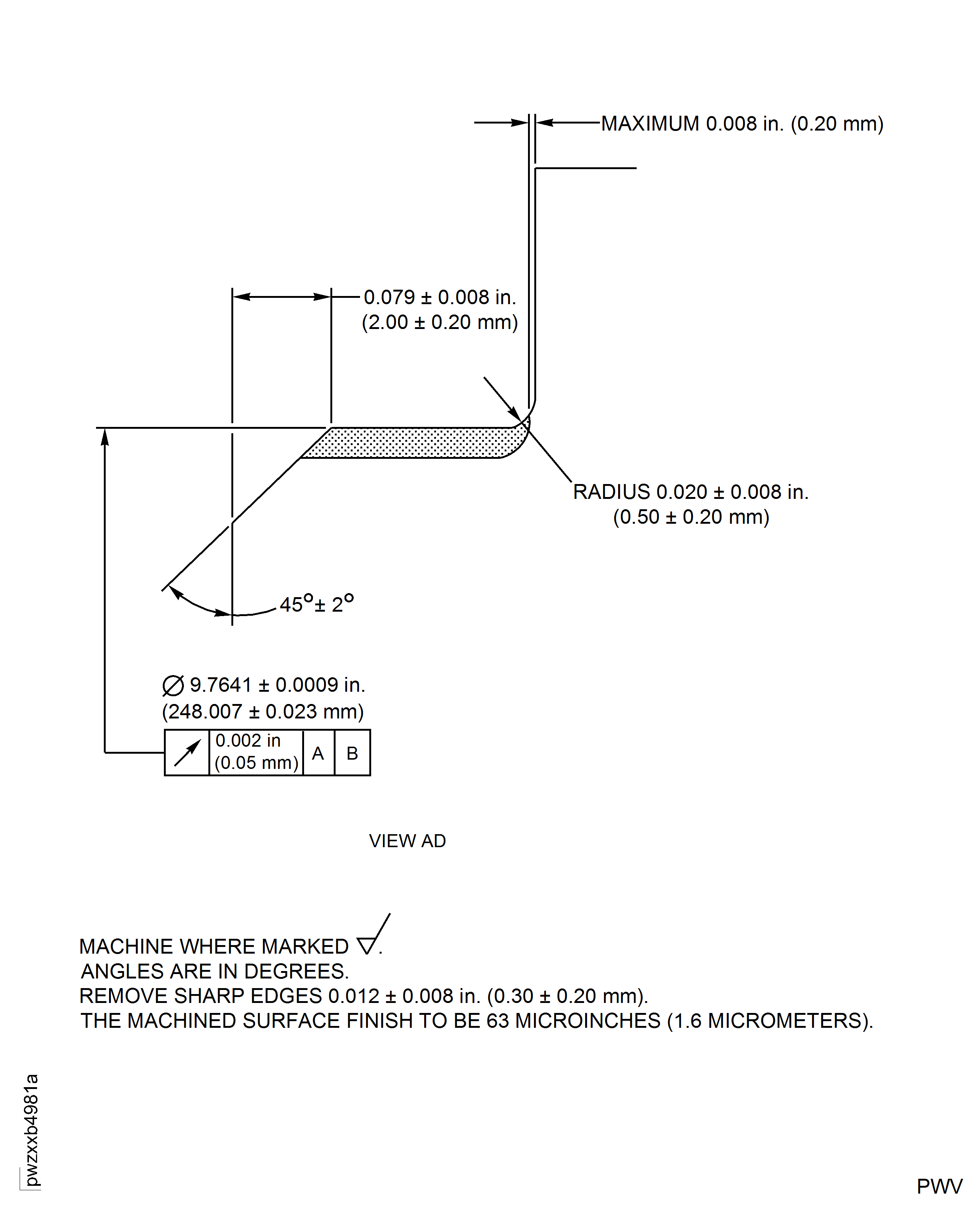

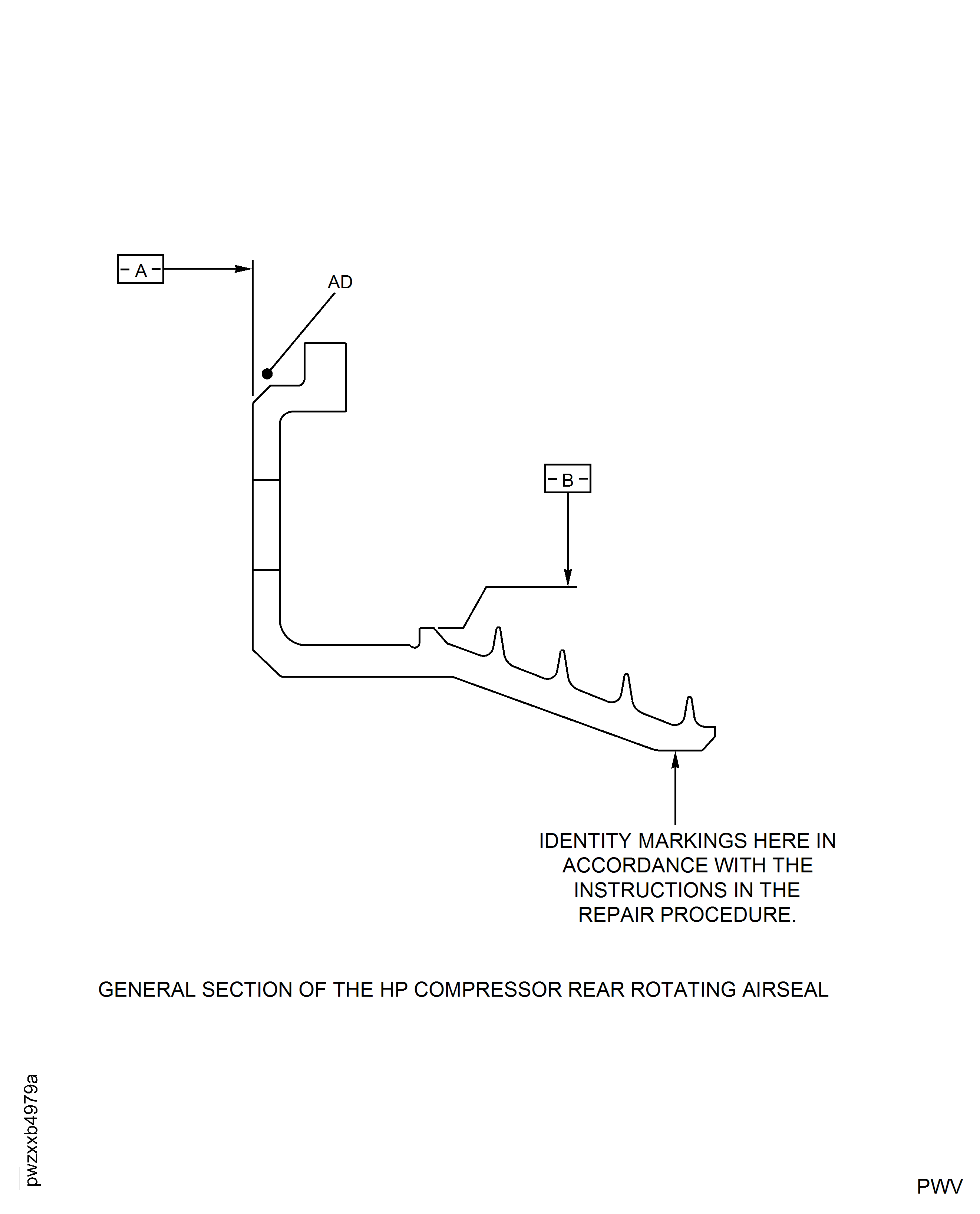

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly A

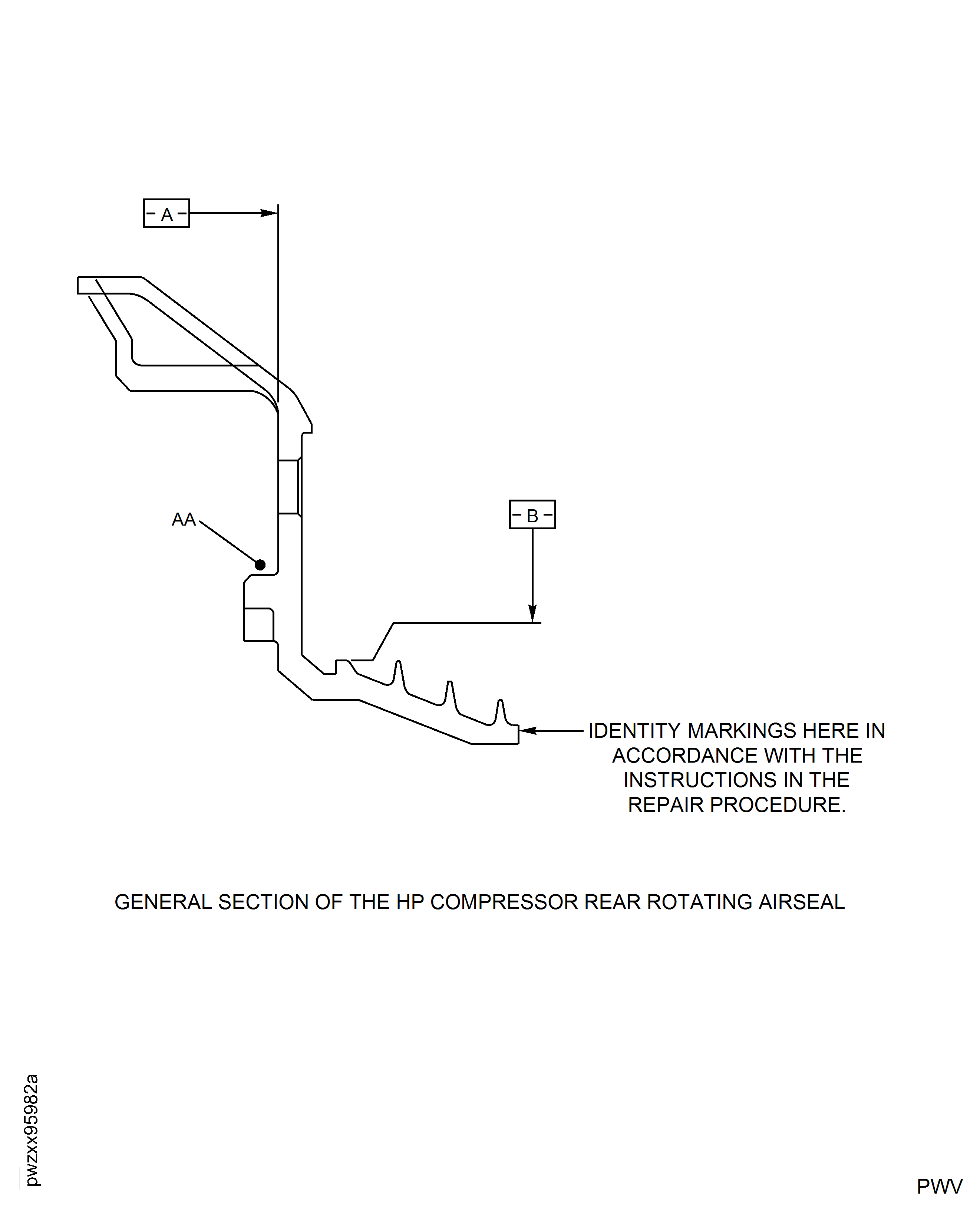

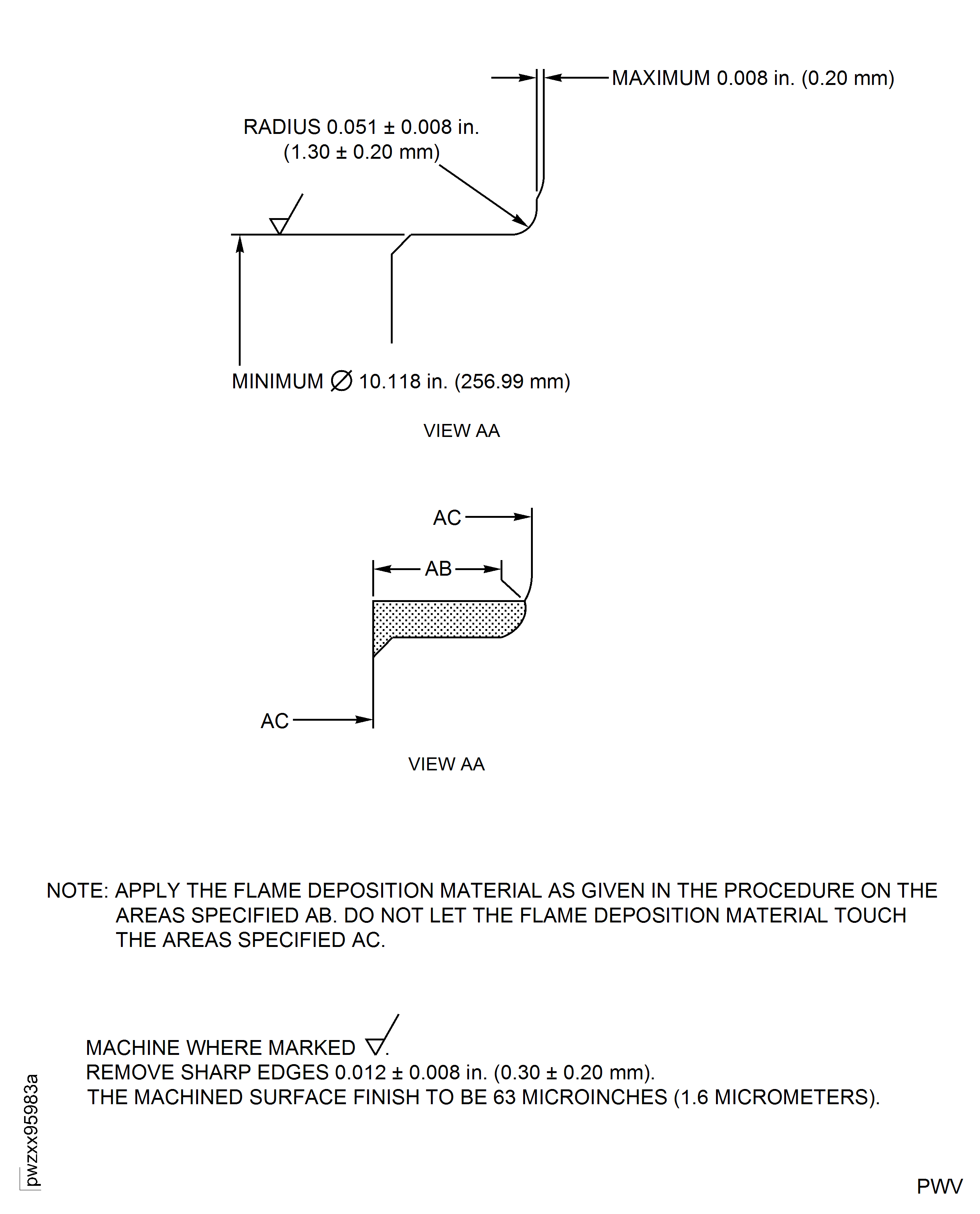

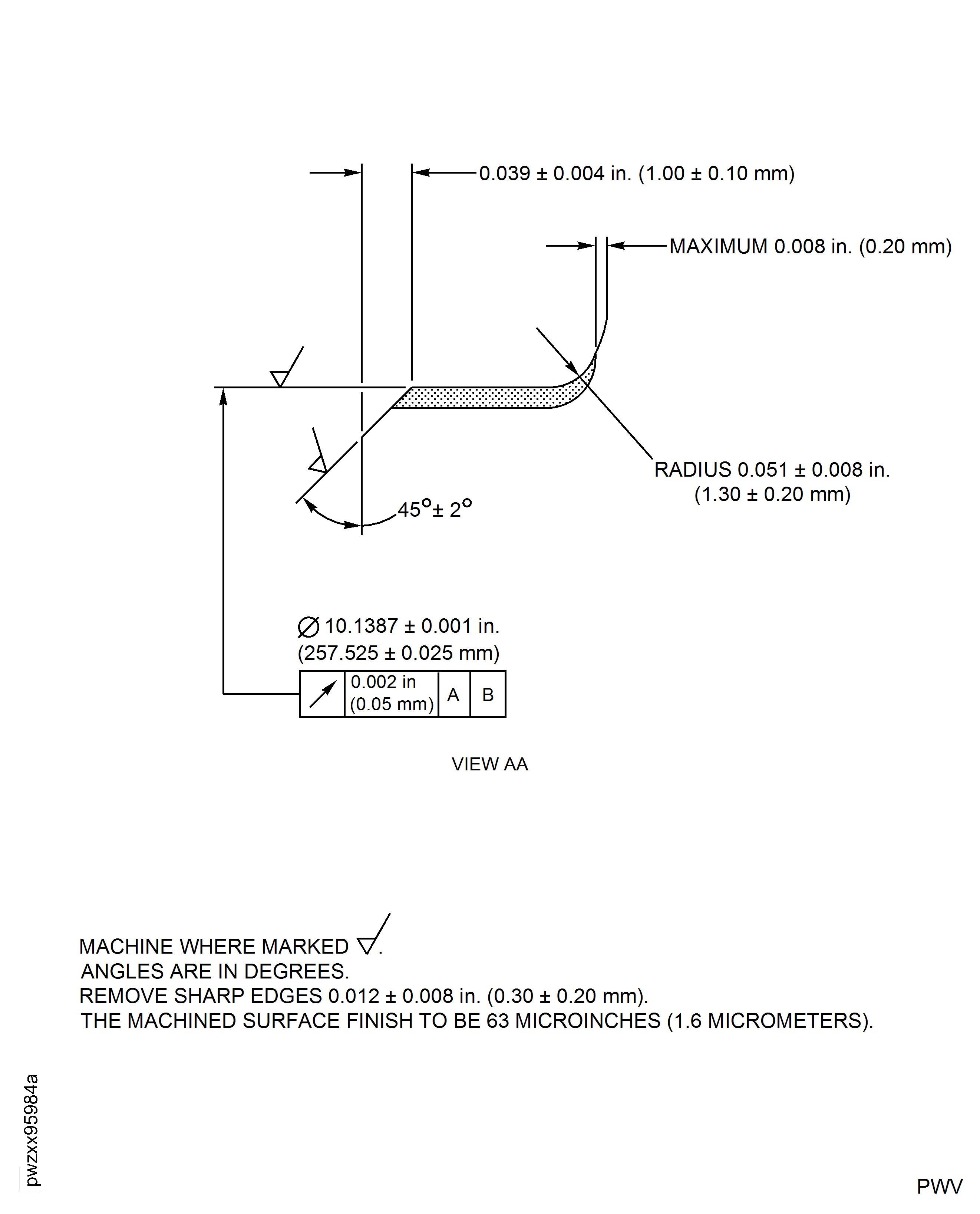

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B

Figure: HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B

HP Compressor Rear Rotating Airseal - Repair Details and Dimensions - Assembly B