Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-046 HP Compressor Rotor Blades, (Stages 3 To 5) - Restore The Dry Film Lubricant, Repair-046 (VRS6486)

Effectivity

FIG/ITEM | PART NO. | SERVICE BULLETIN | ASSEMBLY |

|---|---|---|---|

01-200 | 6A3938 | 72-0035 | A |

01-200 | 6A4188 | - | A |

01-200 | 6A5942 | 72-0201/70-0726 | A |

01-200 | 6A7503 | 70-0714 | A |

01-200 | 6A8353 | 72-0487 | A |

01-200 | 6A8398 | 72-0481 | A |

01-200 | 6A8688 | 72-0561 | A |

01-500 | 6A3939 | 72-0035 | B |

01-500 | 6A4254 | 70-0726 | B |

01-500 | 6A7504 | 70-0714 | B |

01-500 | 6A7635 | 72-0295 | B |

01-500 | 6A8738 | 72-0560 | B |

01-800 | 6A3941 | 72-0035 | C |

01-800 | 6A4198 | 70-0726 | C |

01-800 | 6A7506 | 70-0714 | C |

01-800 | 6A8449 | 72-0490 | C |

01-800 | 6A8451 | 72-0490 | C |

01-800 | 6B1346 | 72-0587 | C |

General Data

The dry film lubricant must be applied before the sealing strips are bonded into position.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | LOCAL | DELETED | ||

| CoMat 07-009 THINNER | LOCAL | CoMat 07-009 | ||

| CoMat 10-002 DRY FILM LUBRICANT | LOCAL | CoMat 10-002 |

Spares

NONESafety Requirements

NONEProcedure

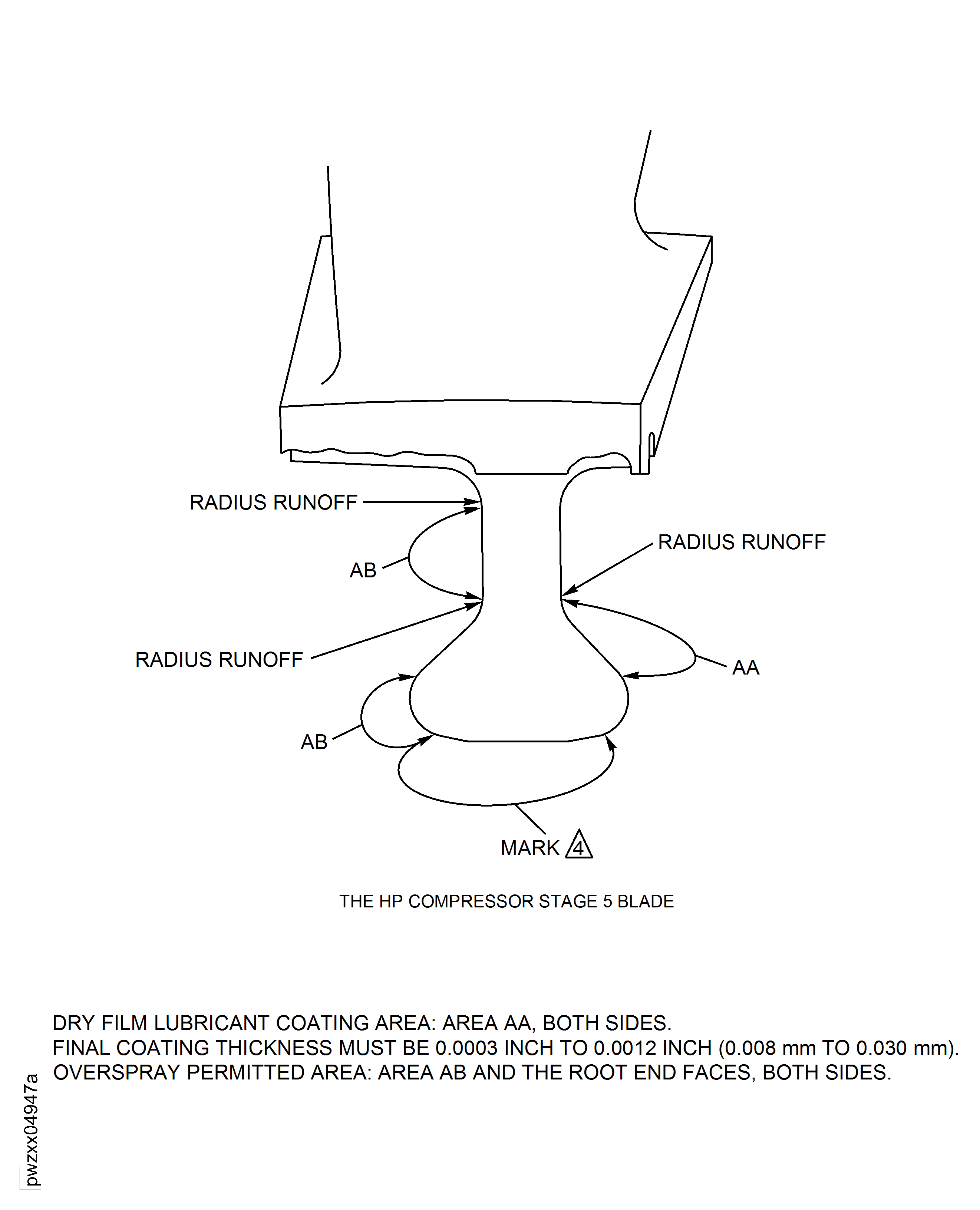

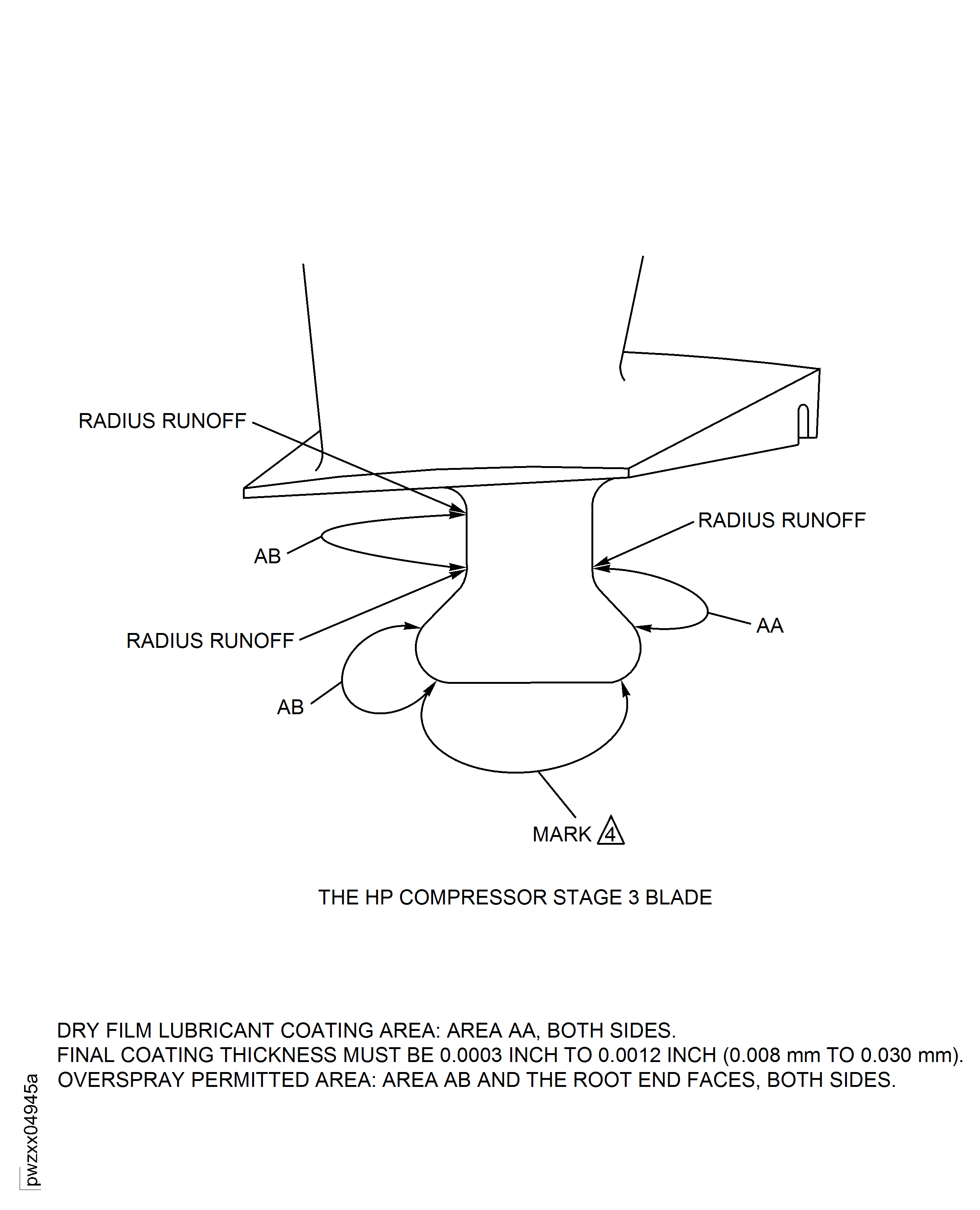

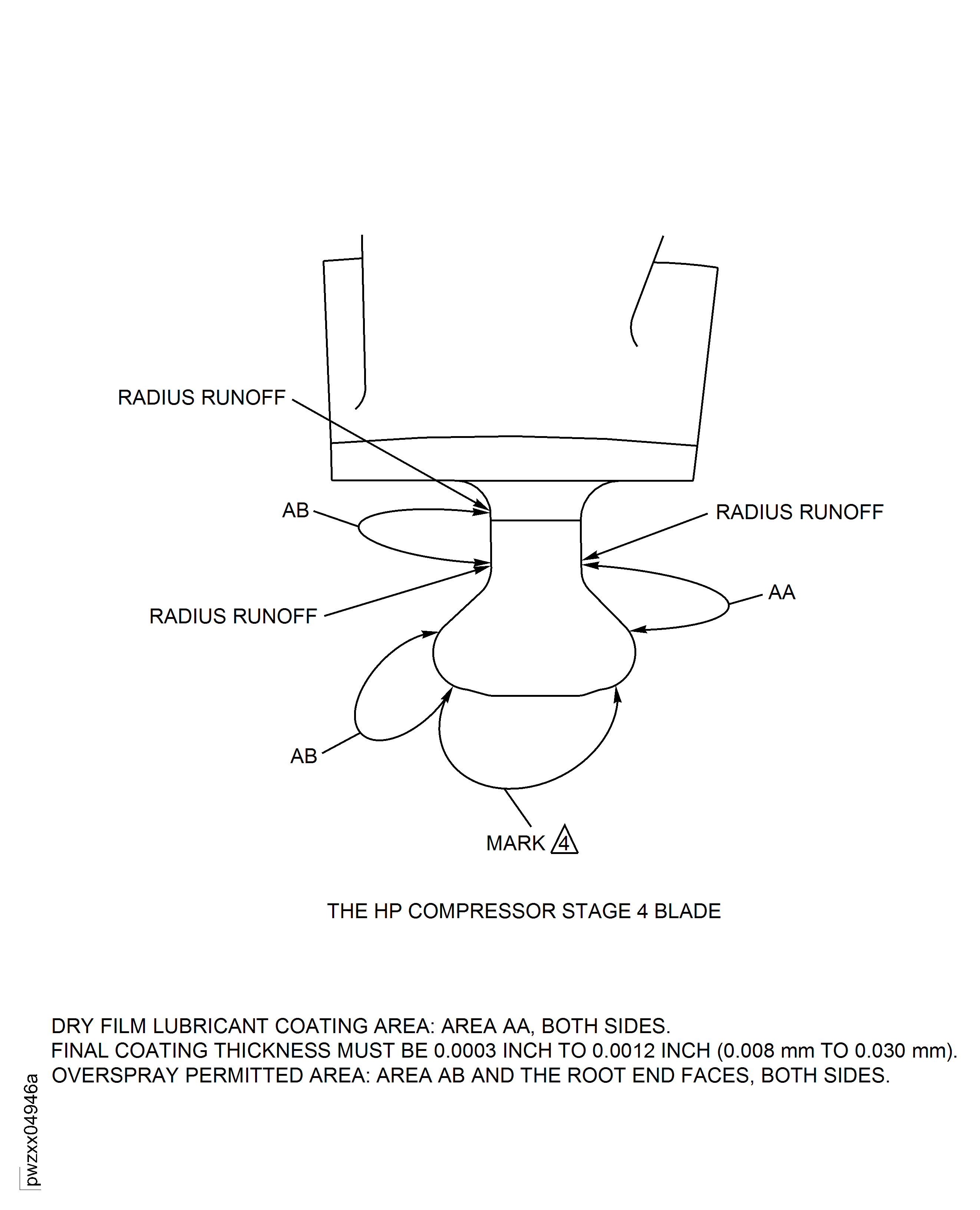

Mask the areas of the blade not to be coated with dry film lubricant.

Apply a total coat thickness of 0.0003 inch to 0.0012 inch (0.008 mm to 0.030 mm).

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

Apply the Dry Film Lubricant to the dovetail roots on areas identified AA

SUBTASK 72-41-15-380-096 Apply the Dry Film Lubricant to the Dovetail Roots of the Stage 3, 4 and 5 Rotor Blades

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-005.

Heat cure the rotor blades.

SUBTASK 72-41-15-380-097 Heat Cure the Rotor Blades

If the dry film lubricant coat is satisfactory, continue with this repair.

If the dry film lubricant coat is not satisfactory, do this repair from Step.

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-220-001 for inspection standards.

Visually examine the dry film lubricant coat.

SUBTASK 72-41-15-220-239 Examine the Dry Film Lubricant

Refer to VRS6214, TASK 72-41-15-300-031 (REPAIR-031) and VRS6215, TASK 72-41-15-300-032 (REPAIR-032) as applicable.

Bond the sealing strips.

SUBTASK 72-41-15-360-056 Bond the Sealing Strips to the Stage 4 and 5 Rotor Blades

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibration peen the code symbol as shown in Figure, Figure and Figure adjacent to the assembly number.

SUBTASK 72-41-15-350-126 Identify the Repair

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C