Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-031 HPC Stage 4 Rotor Blade - Replace The Seal Strip, Repair-031 (VRS6214)

Effectivity

FIG/ITEM | PART NO | ASSEMBLY |

|---|---|---|

01-500 | 6A3333 | A |

01-500 | 6A3635 | A |

01-500 | 6A3939 | A |

01-500 | 6A4254 | B |

01-500 | 6A7635 | C |

01-500 | 6A8738 | C |

Material of component

PART IDENT | MATERIAL |

|---|---|

HP compressor stage 4 rotor blade | Titanium alloy |

Seal strip | Silicone rubber sheet |

General

This repair must only be done when the instruction to do so is given in 72-41-15 Inspection/Check.

The dry film lubricant where applicable must be applied before the sealing strips are bonded in to position.

The area used for bonding shall be segregated from normal workshop conditions, and shall be kept clean. Refer to SPM TASK 70-36-07-360-501.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | LOCAL | DELETED | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 08-012 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-012 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | LOCAL | CoMat 08-014 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Seal strip | 6A1032 | 1 | ||

| Seal strip | 6A4256 | 1 | ||

| Seal strip | 6A7646 | 1 |

Safety Requirements

NONEProcedure

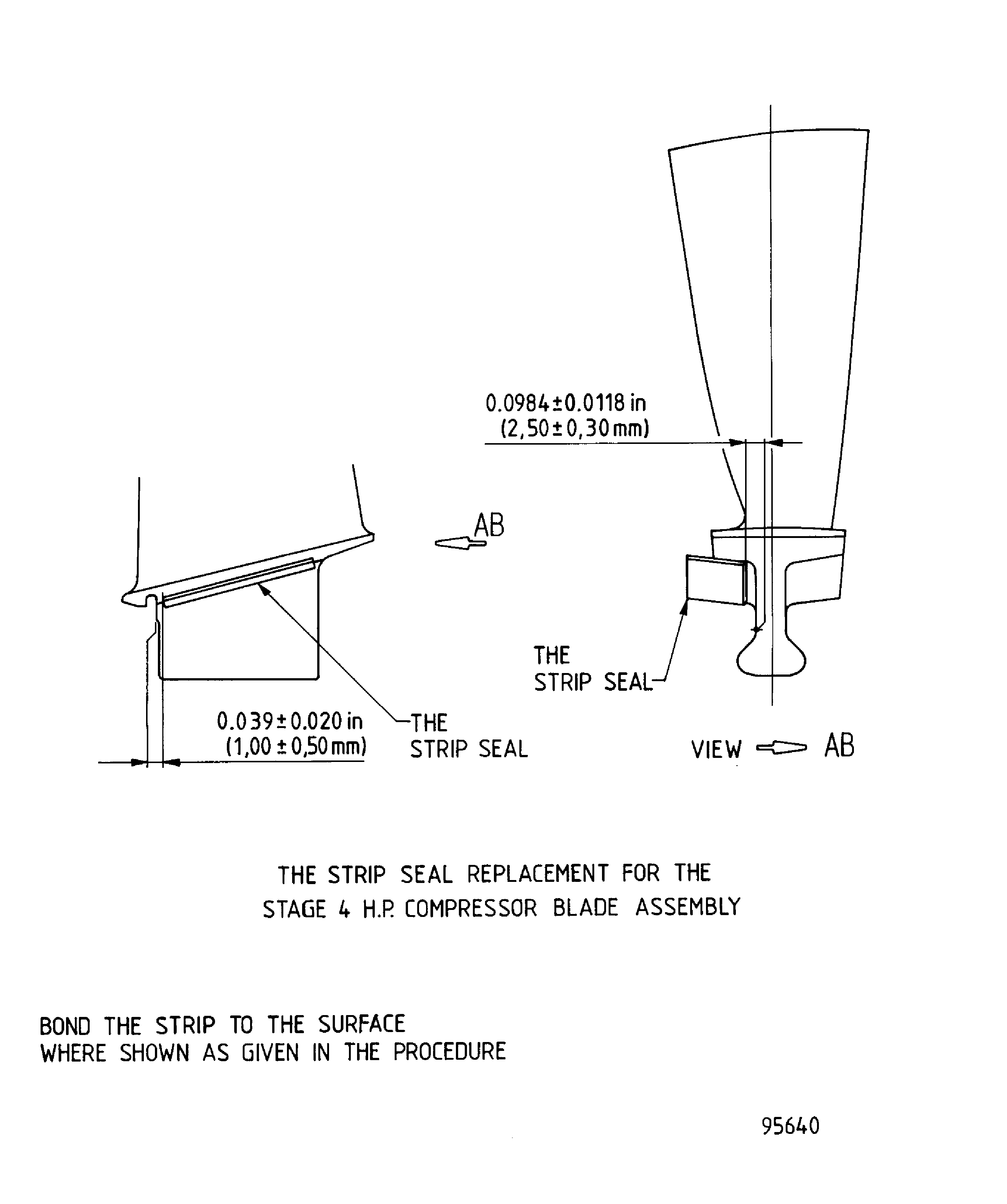

Refer to Figure.

Use CoMat 05-016 GARNET PAPER, 80-GRIT or CoMat 05-017 GARNET PAPER, 60 GRIT to abrade the surface.

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-110-003.

Prepare the blade for bonding.

Use 6A1032 6A1032 .

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11- 26-110-003.

Prepare the seal for bonding.

SUBTASK 72-41-15-110-076-A00 Prepare the Parts for Bonding, Assembly A

Refer to Figure.

Use CoMat 05-016 GARNET PAPER, 80-GRIT or CoMat 05-017 GARNET PAPER, 60 GRIT to abrade the surface.

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-110-003.

Prepare the blade for bonding.

Use 6A4256 6A4256 .

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-110-003.

Prepare the seal for bonding.

SUBTASK 72-41-15-110-076-B00 Prepare the Parts for Bonding, Assembly B

Refer to Figure.

Use CoMat 05-016 GARNET PAPER, 80-GRIT or CoMat 05-017 GARNET PAPER, 60 GRIT to abrade the surface.

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-110-003.

Prepare the blade for bonding.

Use 6A7646 6A7646 .

Clean the repair area with a solvent. Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-110-003.

Prepare the seal for bonding.

SUBTASK 72-41-15-110-076-C00 Prepare the Parts for Bonding, Assembly C

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Dry in air for 30 minutes.

Apply a thin layer of primer to the mating surface on the blade.

Use 6A1032 6A1032 .

Apply the compound to the mating surfaces on the blade and the seal.

Make sure that the compound can be seen around the seal edges.

Remove excess compound from the adjacent areas.

Cure at 60 deg F to 80 deg F (16 deg C to 27 deg C) for 48 hours. The relative humidity must be controlled at a minimum of 50 percent at 75 deg F (24 deg C) or equivalent moisture level. To find equivalent moisture levels, see Figure.

Assemble the seal to the blade.

SUBTASK 72-41-15-360-051-A00 Apply the Adhesive, Assembly A

Refer to the SPM TASK 70-36-02-360-501 SUBTASK 70-36-02-360-020.

Dry in air for 30 minutes.

Apply a thin layer of primer to the mating surface on the blade.

Use 6A4256 6A4256 .

Apply the compound to the mating surfaces on the blade and the seal.

Make sure that the compound can be seen around the seal edges.

Remove excess compound from the adjacent areas.

Cure at 60 deg F to 80 deg F (16 deg C to 27 deg C) for 48 hours. The relative humidity must be controlled at a minimum of 50 percent at 75 deg F (24 deg C) or equivalent moisture level. To find equivalent moisture levels, see Figure.

Assemble the seal to the blade.

SUBTASK 72-41-15-360-051-B00 Apply the Adhesive, Assembly B

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Dry in air for 30 minutes.

Apply a thin layer of primer to the mating surface on the blade.

Use 6A7646 6A7646 .

Apply the compound to the mating surfaces on the blade and the seal.

Make sure that the compound can be seen around the seal edges.

Remove excess compound from the adjacent areas.

Cure at 60 deg F to 80 deg F (16 deg C to 27 deg C) for 48 hours. The relative humidity must be controlled at a minimum of 50 percent at 75 deg F (24 deg C) or equivalent moisture level. To find equivalent moisture levels, see Figure.

Assemble the seal to the blade.

SUBTASK 72-41-15-360-051-C00 Apply the Adhesive, Assembly C

Refer to Figure.

SUBTASK 72-41-15-220-190-A00 Examine the Seal, Assembly A

Refer to Figure.

SUBTASK 72-41-15-220-190-B00 Examine the Seal, Assembly B

Refer to Figure.

SUBTASK 72-41-15-220-190-C00 Examine the Seal, Assembly C

Figure: Repair details and dimensions - Assemblies A and B

Repair details and dimensions - Assemblies A and B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Equivalent Relative Humidity

Equivalent Relative Humidity