Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-053 HPC Stage 3 Rotor Blade - Remove The Clapper Coating, Repair-053 (VRS6635)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-200 | 6A3513 | A |

01-200 | 6A3938 | A |

Deleted | Deleted | Deleted |

Deleted | Deleted | Deleted |

Deleted | Deleted | Deleted |

01-200 | 6A8353 | D |

Deleted | Deleted | Deleted |

01-200 | 6A8688 | E |

NOTE

General

This repair must only be done when the instructions to do so is given in 72-41-15, INSPECTION.

This Repair removes the tungsten carbide coating on the clapper abutment faces of the HP compressor stage 3 rotor blades. The tungsten carbide 15 percent cobalt metal spray coating is applied by flame detonation deposition process or high velocity oxy-fuel deposition process.

The practices and processes are referred to in the procedure by the TASK/SUBTASK numbers in the SPM.

Price and Availability

Refer to International Aero Engines

Related Repairs

HP Compressor Rotor Blade - Stage 3 - Repair Damaged or Worn Clapper Abutment Face by Weld, refer to Repair, VRS6616 TASK 72-41-15-300-052 (REPAIR-052).

HP Compressor Stage 3 Rotor Blade - Replace Clapper Coating, refer to Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR-035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Degreasing equipment | LOCAL | Degreasing equipment | ||

| Rochelle carbonate tank | LOCAL | Rochelle carbonate tank | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| IAE 3R19363 Inspection fixture | 0AM53 | IAE 3R19363 | 1 | |

| IAE 3R19366 Inspection Block | 0AM53 | IAE 3R19366 | 1 | |

| IAE 3R19367 Inspection block | 0AM53 | IAE 3R19367 | 1 | |

| IAE 3R19372 Stop block | 0AM53 | IAE 3R19372 | 2 | |

| IAE 3R19777 Inspection kit | 0AM53 | IAE 3R19777 | 1 | |

| IAE 3R19815 Clapper width checking fixture | 0AM53 | IAE 3R19815 | 1 | |

| IAE 3R19816 Inspection jaws | 0AM53 | IAE 3R19816 | 1 | |

| IAE 3R19817 Master blade | 0AM53 | IAE 3R19817 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-017 WAX | LOCAL | CoMat 02-017 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | X222X | CoMat 05-003 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-03-300-503.

Use degreasing equipment.

Remove the grease.

SUBTASK 72-41-15-110-153 Clean the Blade

Refer to Figure.

Use CoMat 02-017 WAX.

Put the blade fully into hot wax.

SUBTASK 72-41-15-330-056 Mask the Blade

Refer to Figure.

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-006.

Hang the blade from the tip with a clamp to make electrical contact.

Use rochelle carbonate tank.

Remove hard facings by anodically etching the blade.

SUBTASK 72-41-15-330-057 Remove Hard Facings

Refer to the SPM TASK 70-23-04-230-501.

Cracks are not permitted.

Use penetrant crack test equipment.

Do a penetrant crack test on clapper abutment faces.

SUBTASK 72-41-15-230-121 Do a Crack Test

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Lightly abrasive blast struts and airfoil to remove staining.

SUBTASK 72-41-15-120-071 Abrasive Blast

Use IAE 3R19777 Inspection kit 1 off, with IAE 3R19363 Inspection fixture 1 off, IAE 3R19366 Inspection Block 1 off, IAE 3R19367 Inspection block 1 off and IAE 3R19372 Stop block 2 off.

Measure the dimensions of the clapper abutment faces in relation to the blade.

Do Repair, VRS6616 TASK 72-41-15-300-052 (REPAIR-052).

Blades that are not to the limits in A.

Do Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR 035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

Blades that are to the limits in A.

SUBTASK 72-41-15-220-406-A00 Examine the Repair, Assembly A

Use IAE 3R19815 Clapper width checking fixture 1 off, IAE 3R19816 Inspection jaws 1 off, and IAE 3R19817 Master blade 1 off.

Measure the dimensions of the clapper abutment faces in relation to the blade.

Do Repair, VRS6616 TASK 72-41-15-300-052 (REPAIR-052).

Blades that are not to the limits in A.

Do Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR-035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

Blades that are to the limits in A.

SUBTASK 72-41-15-220-406-B00 Examine the Repair, Assembly D and Assembly E

Refer to the SPM TASK 70-11-03-300-503.

Use degreasing equipment.

Remove the grease.

SUBTASK 72-41-15-110-156 Clean the Blade

Refer to Repair, VRS6616 TASK 72-41-15-300-052 (REPAIR-052).

Repair damaged or worn clapper abutment faces by weld, as necessary.

SUBTASK 72-41-15-310-062 Repair Damaged or Worn Clapper Abutment Faces by Weld

Refer to Repair, VRS6236 TASK 72-41-15-300-035 (REPAIR-035) or Repair, VRS9297 TASK 72-41-15-300-058 (REPAIR-058).

Replace the clapper coating.

SUBTASK 72-41-15-340-058 Replace the Clapper Coating

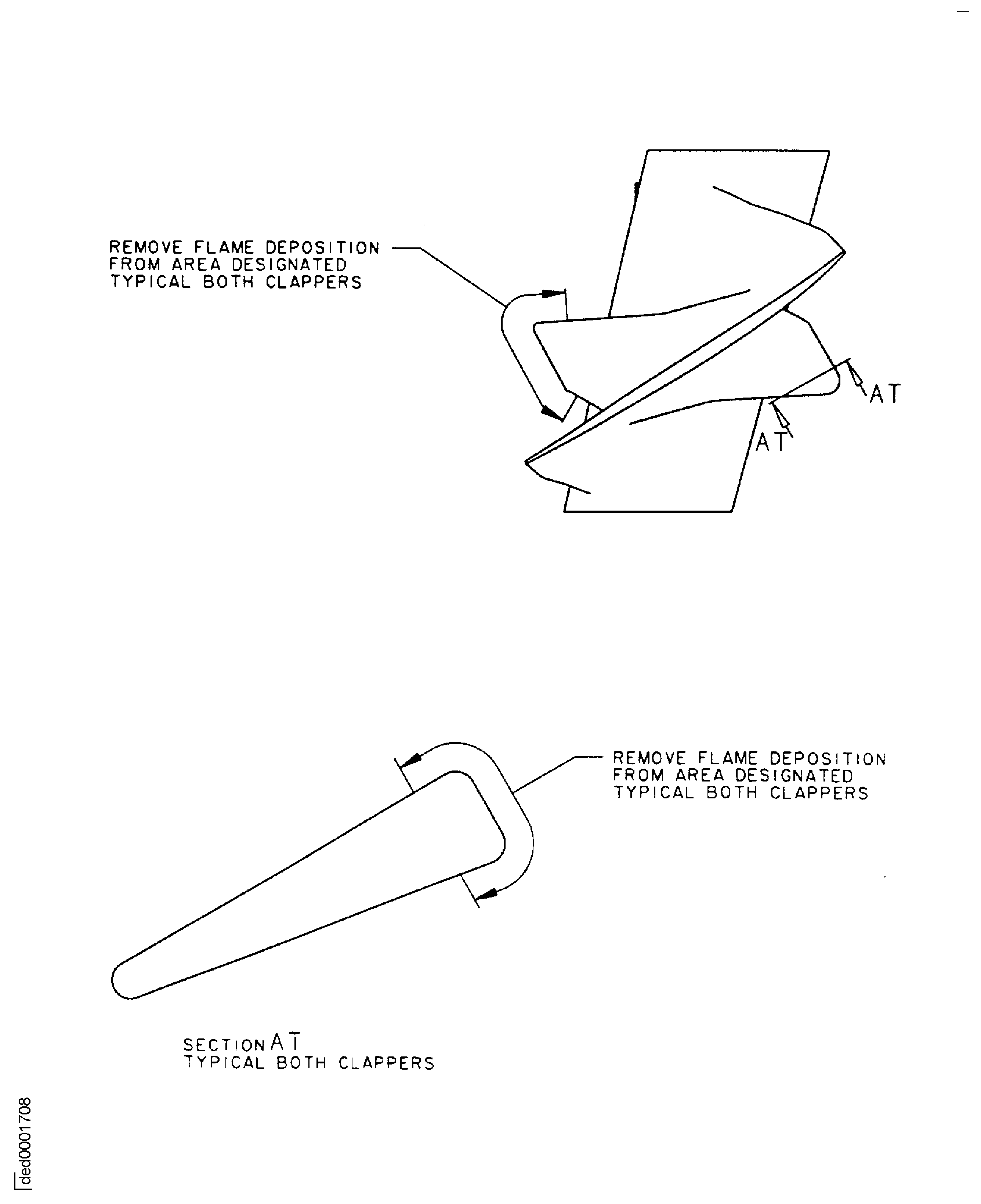

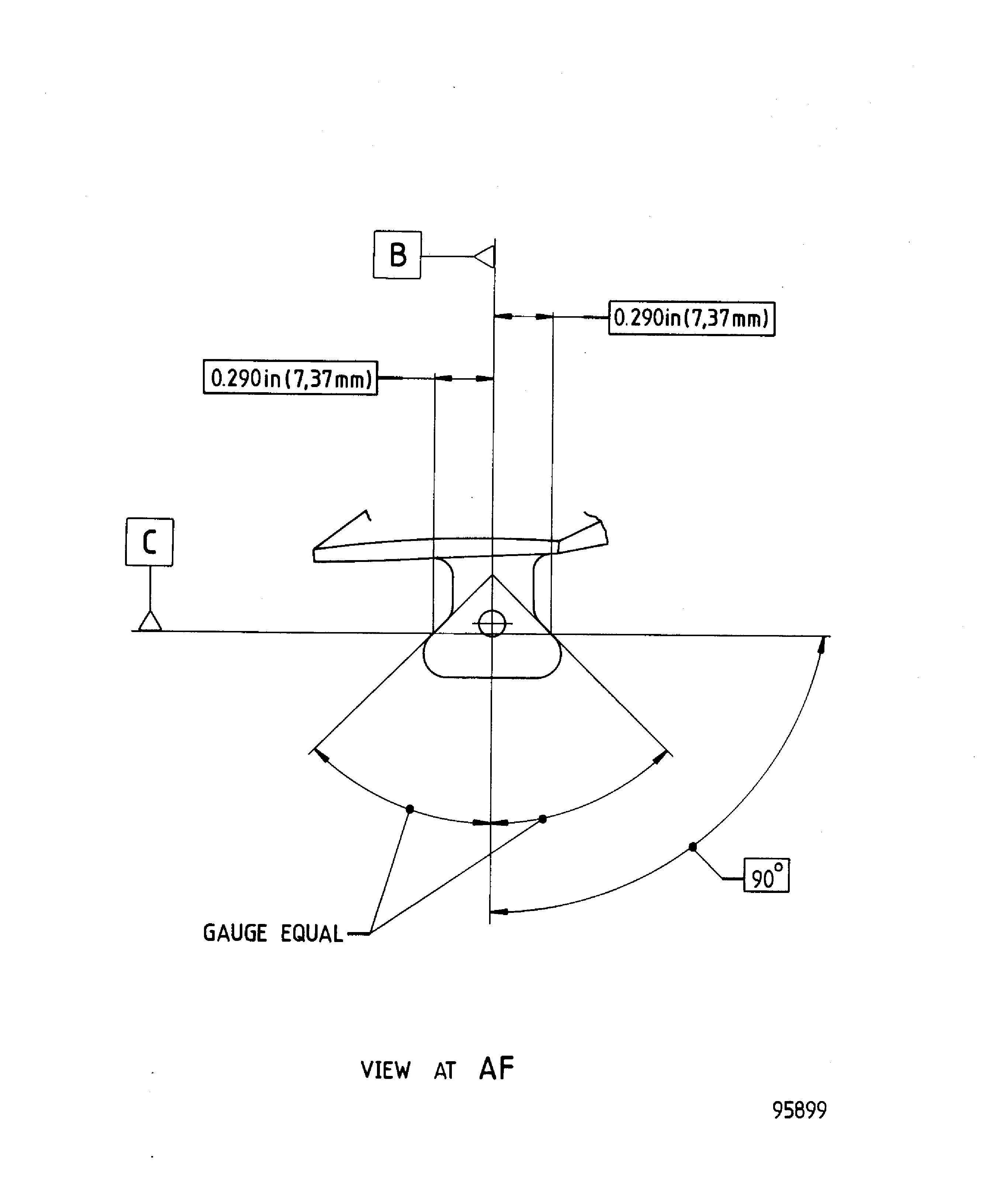

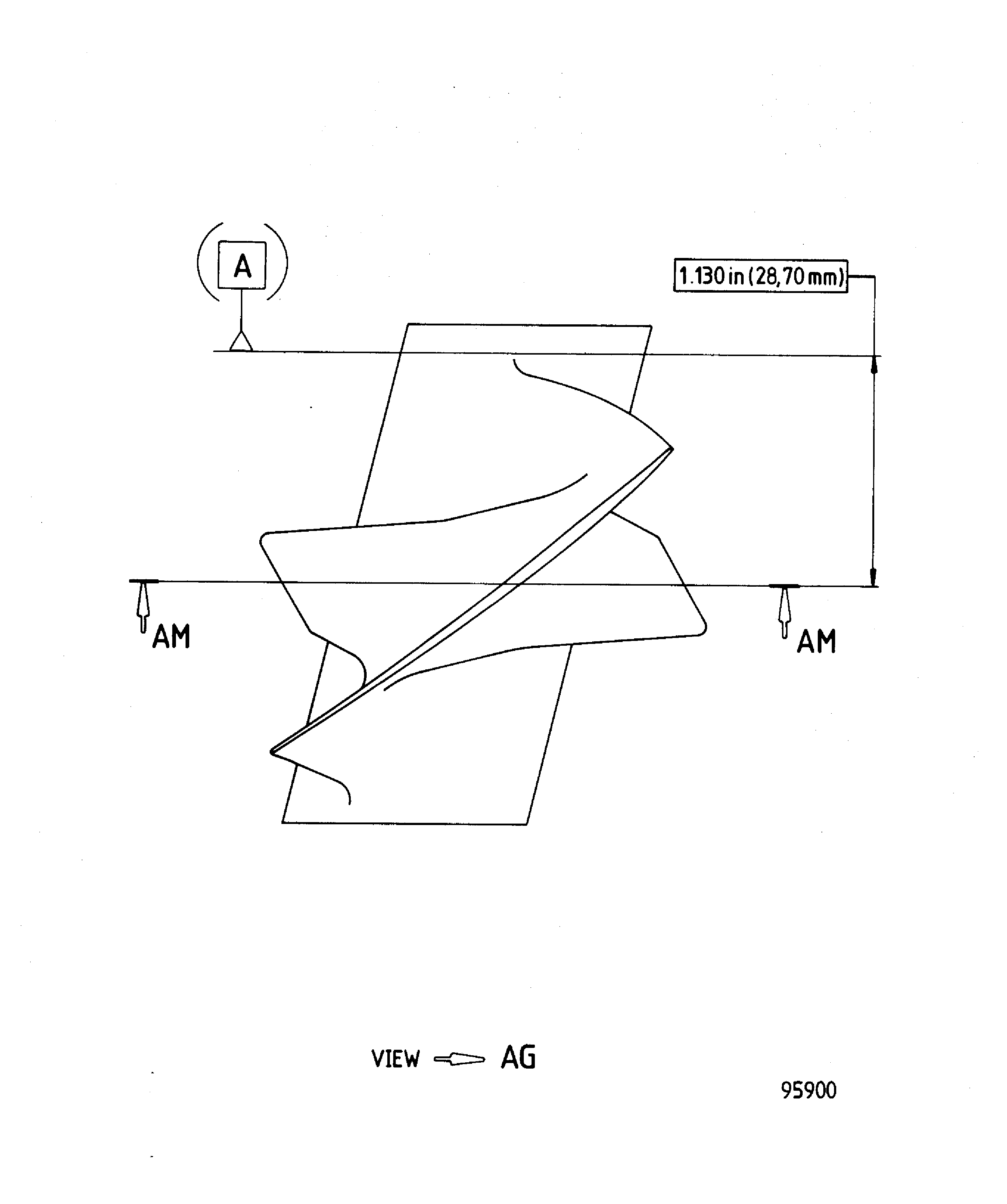

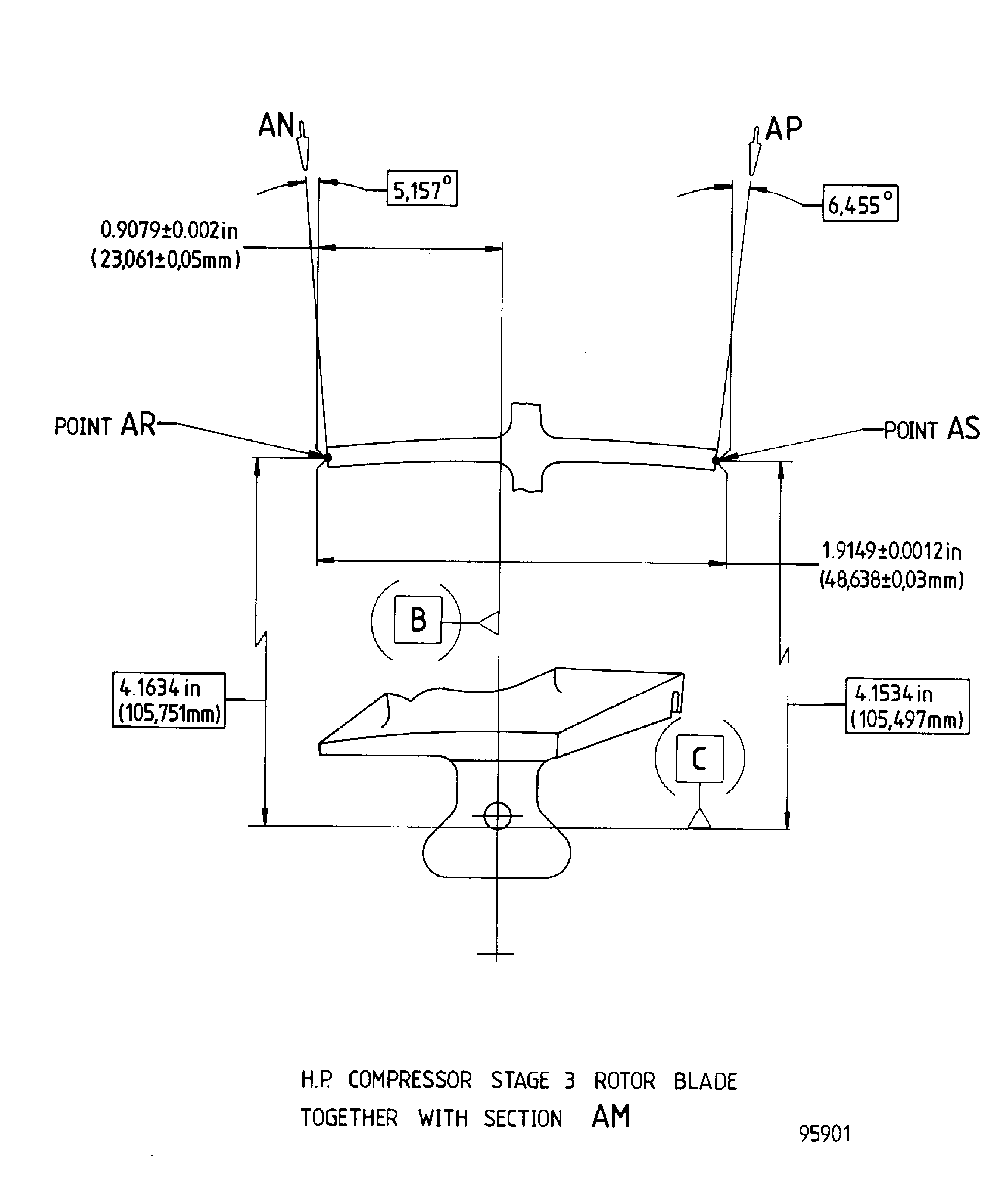

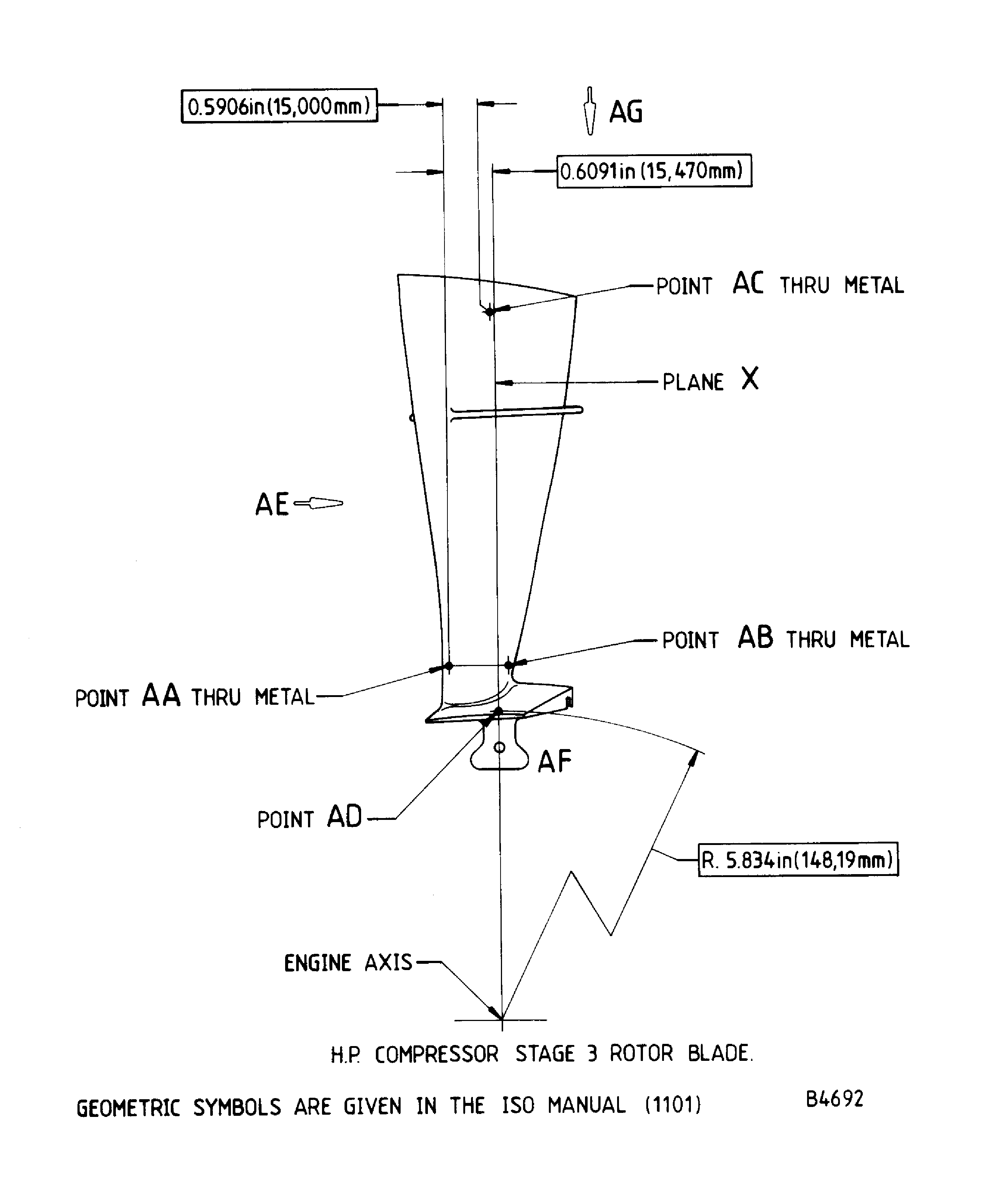

Figure: Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

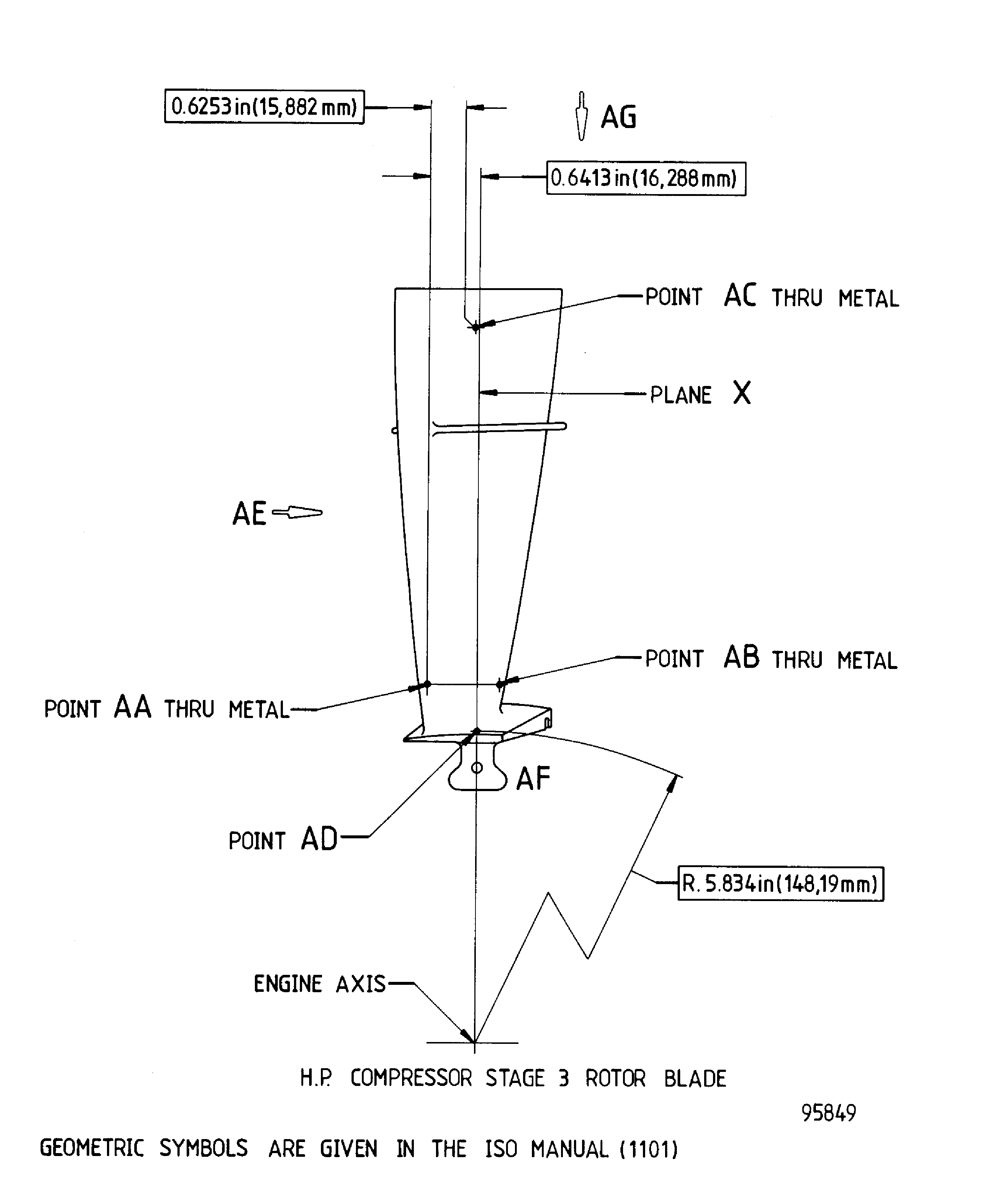

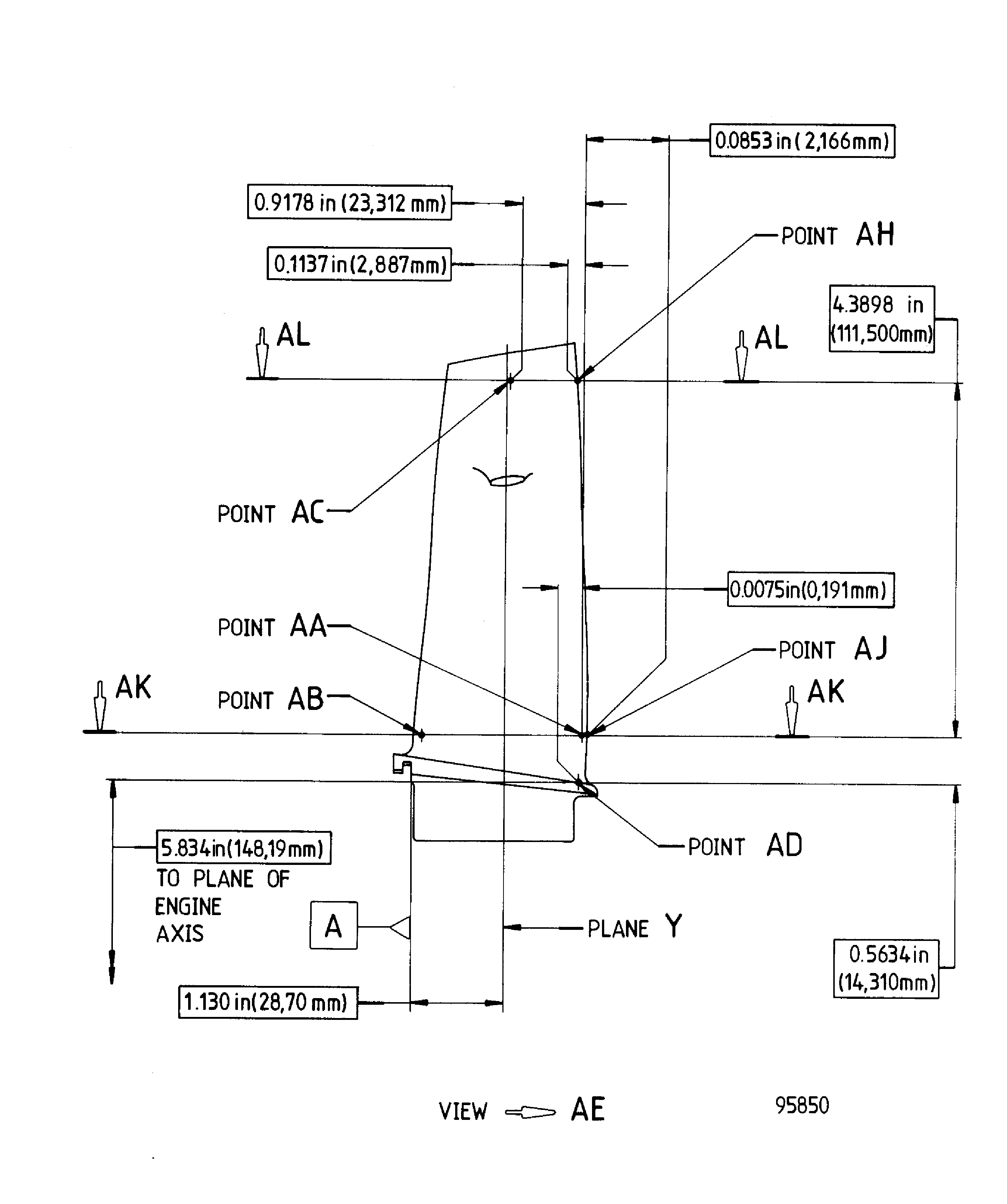

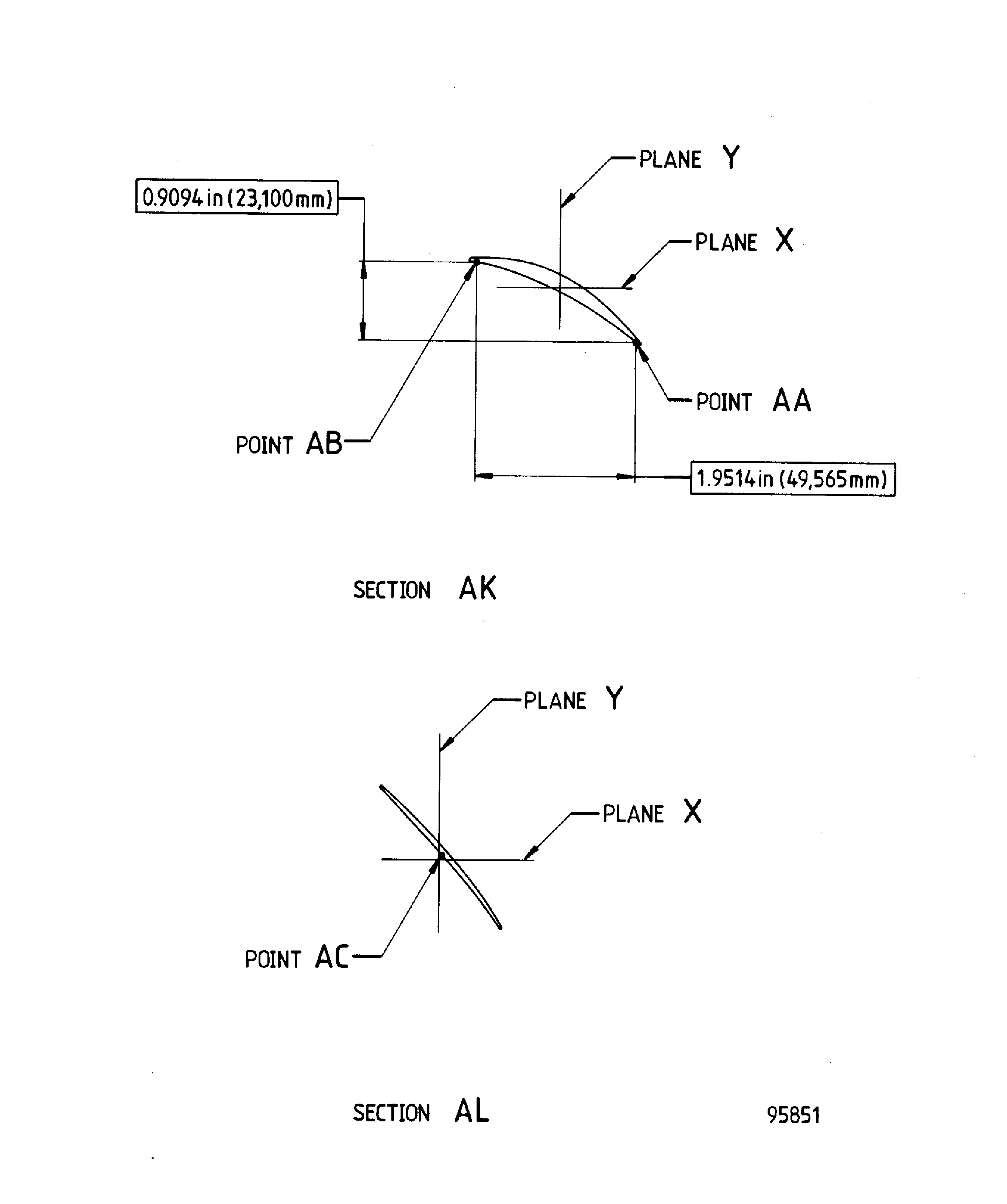

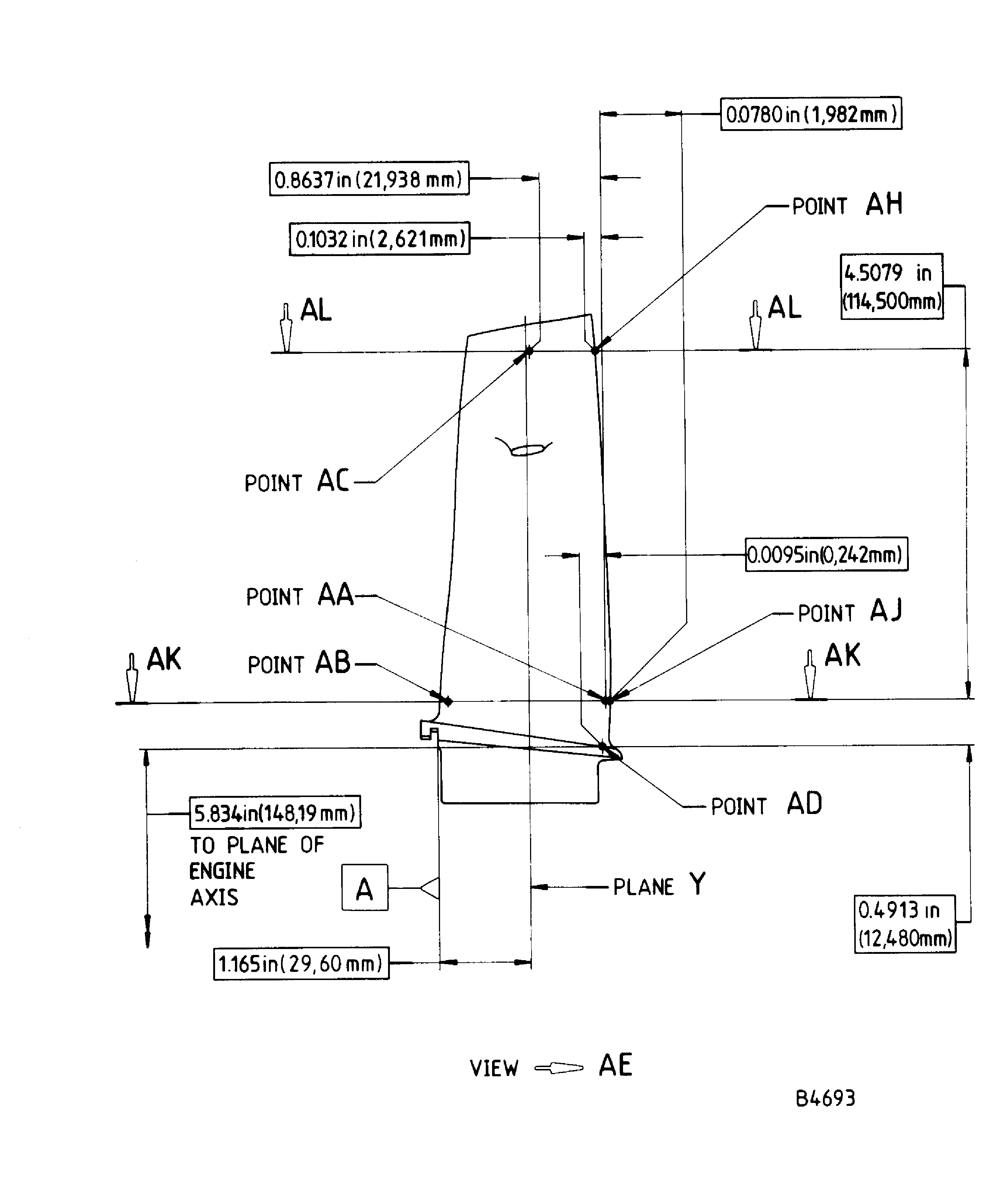

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

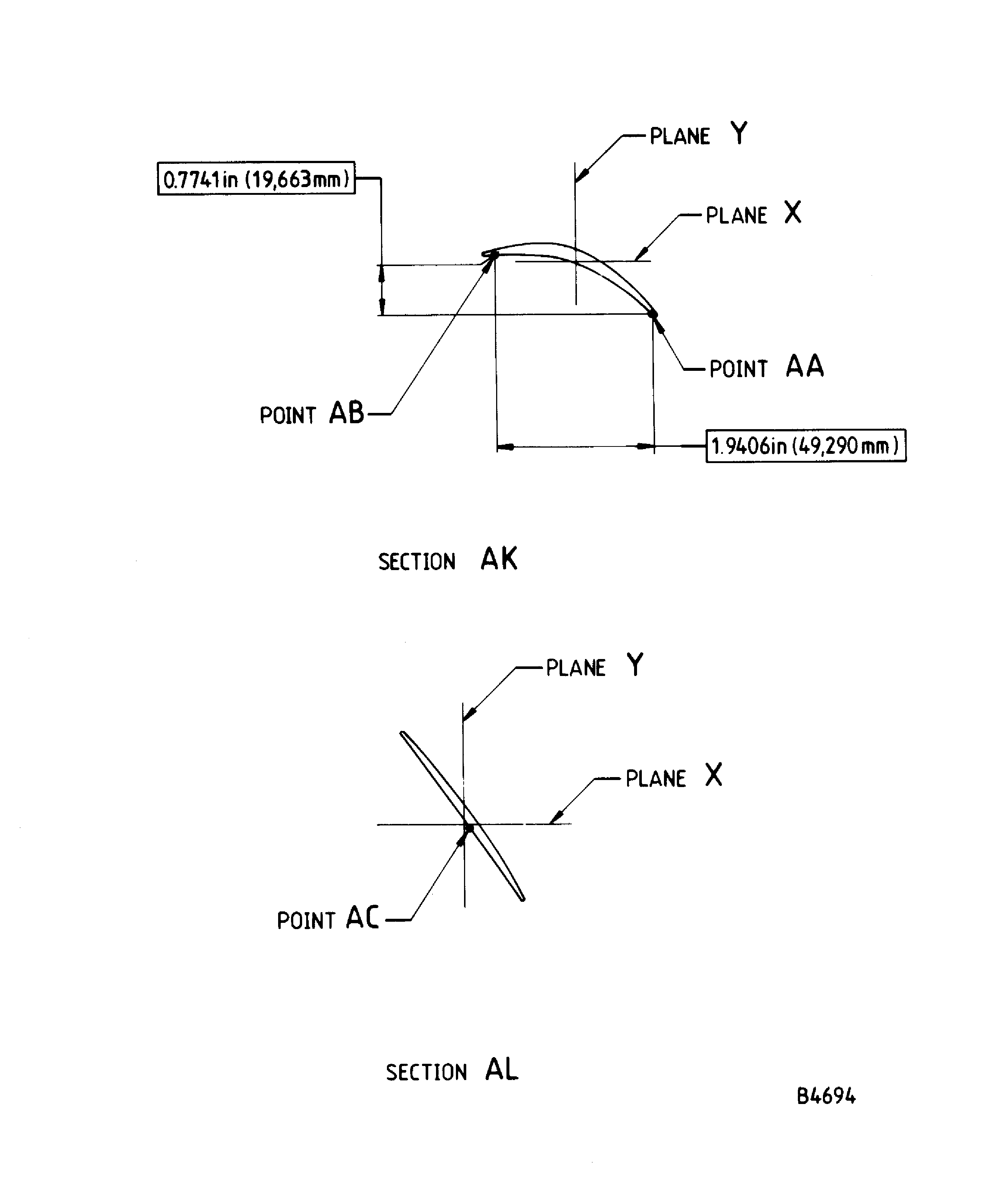

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

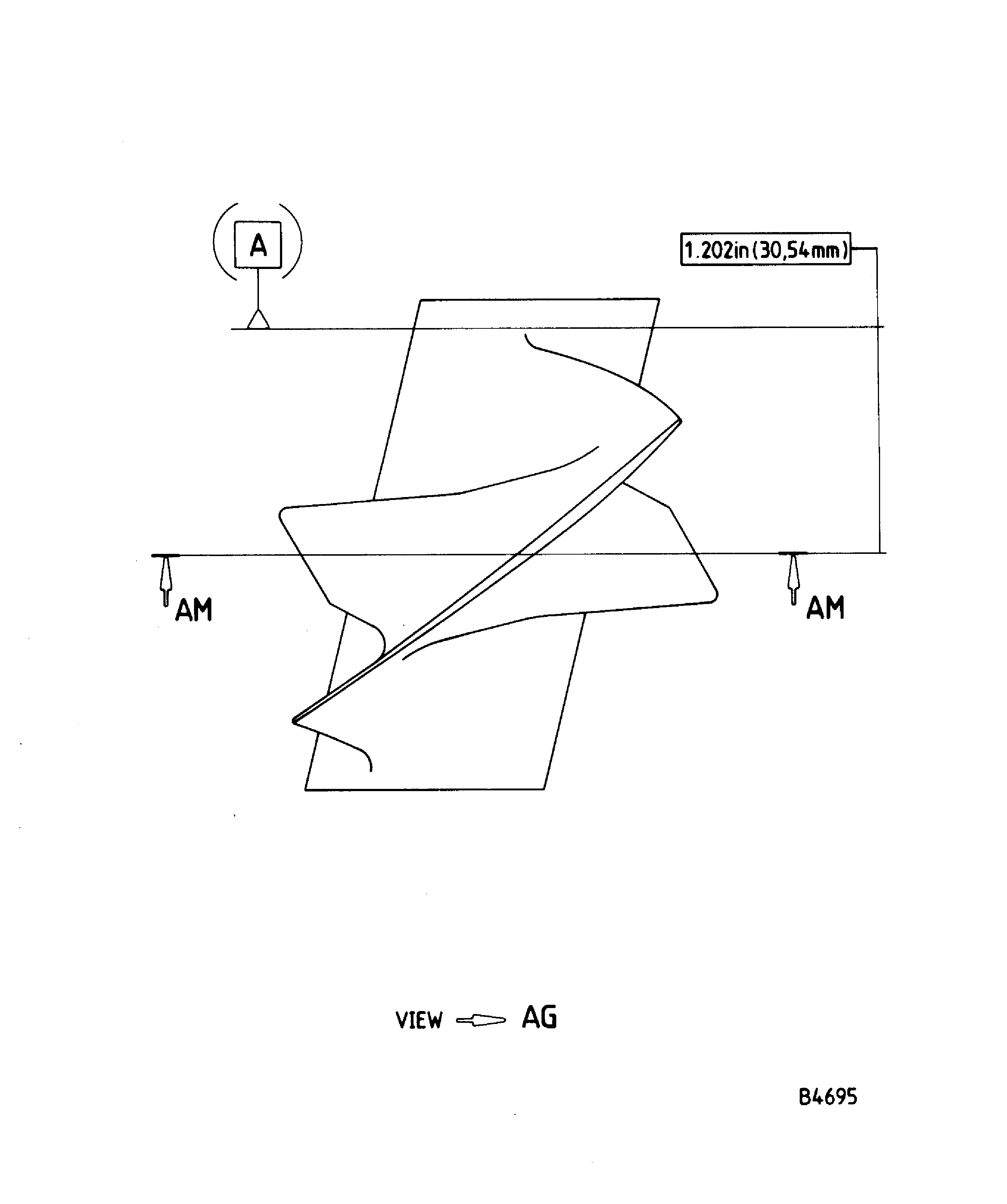

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

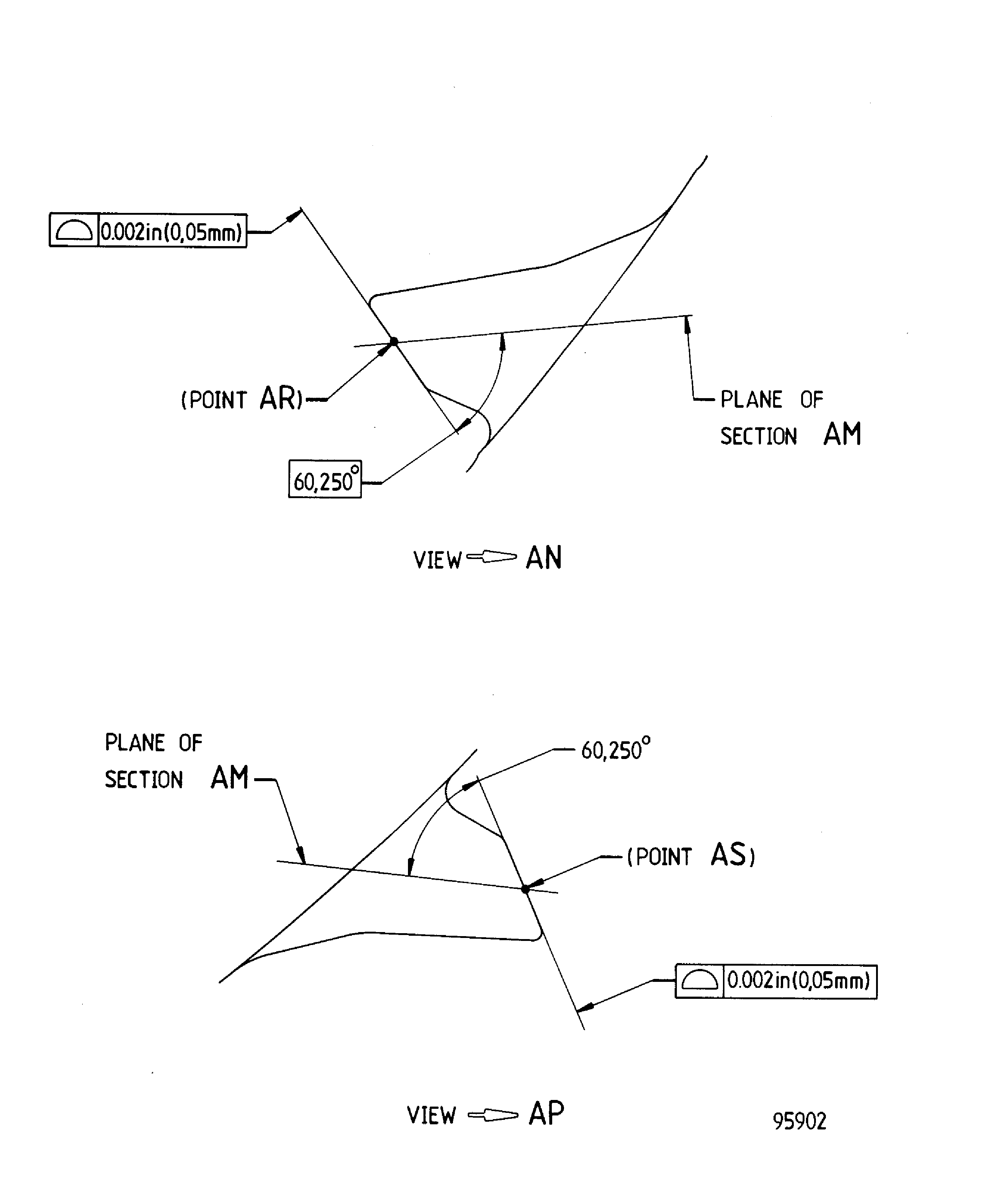

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

Repair Details And Dimensions - Assembly A, Assembly D And Assembly E

Figure: Repair Details And Dimensions - Assembly D And Assembly E

Repair Details And Dimensions - Assembly D And Assembly E

Figure: Repair Details And Dimensions - Assembly D And Assembly E

Repair Details And Dimensions - Assembly D And Assembly E

Figure: Repair Details And Dimensions - Assembly D And Assembly E

Repair Details And Dimensions - Assembly D And Assembly E

Figure: Repair Details And Dimensions - Assembly D And Assembly E

Repair Details And Dimensions - Assembly D And Assembly E

Figure: Repair Details And Dimensions - Assembly B And Assembly C (Deleted)

Repair Details And Dimensions - Assembly B And Assembly C (Deleted)

Figure: Repair Details And Dimensions - Assembly D And Assembly E

Repair Details And Dimensions - Assembly D And Assembly E