Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-029 HPC Stage 12 Rotor Blade - Vibro Polish To Restore The Surface Finish, Repair-029 (VRS6074)

Effectivity

FIG/ITEM | PART NO | ASSEMBLY |

|---|---|---|

02-770 | 6A3261 | A |

02-770 | 6A4729 | A |

02-770 | 6A5643 | A |

02-770 | 6A5947 | A |

02-770 | 6A6565 | A |

02-770 | 6A8763 | B |

02-785 | 6A3262 | A |

02-785 | 6A4206 | A |

02-785 | 6A5644 | A |

02-785 | 6A5648 | A |

02-785 | 6A8764 | B |

02-800 | 6A3260C01 | A |

02-800 | 6A4207C01 | A |

02-800 | 6A8761 | B |

02-815 | 6A3260C01 | A |

02-815 | 6A4207C01 | A |

02-815 | 6A8761 | B |

02-817 | 6A3260C02 | A |

02-817 | 6A4207C02 | A |

02-817 | 6A8762 | B |

General

This TASK gives the procedure to vibro-polish the HPC Stage 12 Rotor Blades.

The blades must have been repaired, where necessary, and inspected before vibro-polishing.

The blades can only have this repair completed on them three times.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines.

Related Repairs - None

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all cleaning and inspection procedures are done before this repair. | |

| All other repairs must be completed before you apply VRS6074. | |

| Restore the airfoil surface finish before you apply VRS6074. Refer to repair VRS6150 (REPAIR-040). | TASK 72-41-15-300-040 |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3R18556 Mask | 0AM53 | IAE 3R18556 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-093 SUPERFINISHING MEDIA, CERAMIC, ANGLE CUT TRIANGLE | IAE56 | CoMat 05-093 | ||

| CoMat 05-095 LIQUID COMPOUND (VIBROPOLISHING FINISHING FLUID) | IE230 | CoMat 05-095 | ||

| CoMat 05-181 VIBRO POLISHING MEDIA, CERAMIC PIN | LOCAL | CoMat 05-181 | ||

| CoMat 05-182 VIBRO POLISHING COMPOUND, LIQUID | IAE56 | CoMat 05-182 | ||

| CoMat 05-183 VIBRO POLISHING PASTE | IAE56 | CoMat 05-183 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Examine the blade platform underside surface, the dovetail side surface, and the dovetail bottom surface to find, if VRS6074 was done before.

SUBTASK 72-41-15-220-187 Make sure that the Stage 12 Rotor Blade can be Vibro Polished

Refer to SPM TASK 70-38-25-380-501 and/or use IAE 3R18556 Mask.

Apply a mask or maskants to the blade root.

SUBTASK 72-41-15-350-083 Apply the Mask to the Stage 12 Rotor Blade

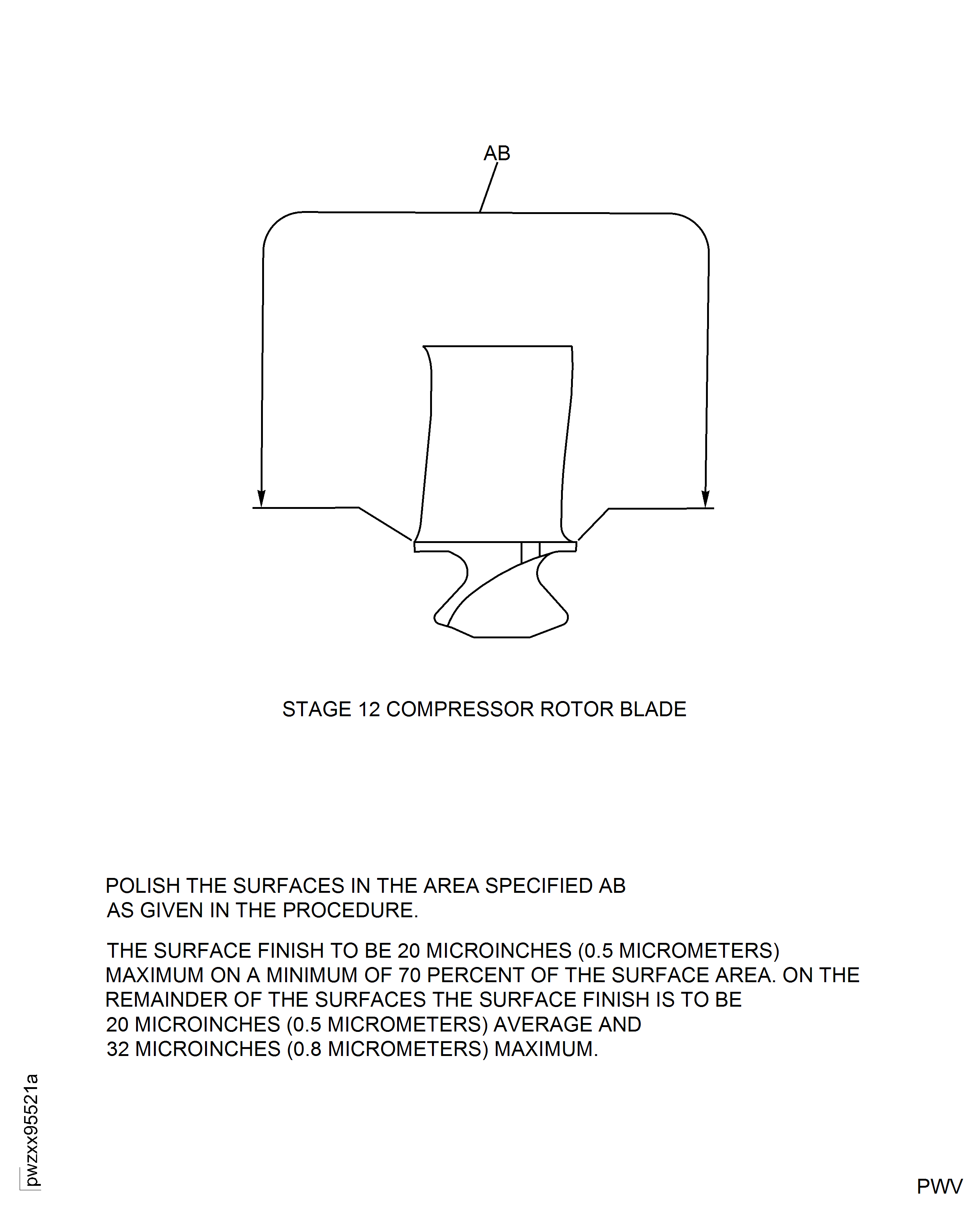

Refer to Figure.

Refer to SPM TASK 70-38-25-380-501.

The surface finish is to be 20 microinches (0.50 micrometers) maximum on a minimum of 70 percent of the surface area.

On the remainder of the blade, the surface finish is to be between 20 microinches (0.50 micrometers) and 32 microinches (0.80 micrometers).

Do not have more than 50 blades for one cubic foot of the superpolishing media.

Option 3: Method Two consumables.

Use one of the following options to get the surface finish limits. The dimension of the superfinishing media is to be 10 mm x 10 mm maximum.

Polish the surfaces in the area specified AB.

Vibro-polish the blade airfoil and adjacent annulus surfaces.

SUBTASK 72-41-15-380-073-A00 Vibro-Polish the Stage 12 Rotor Blade Airfoil, Assembly A

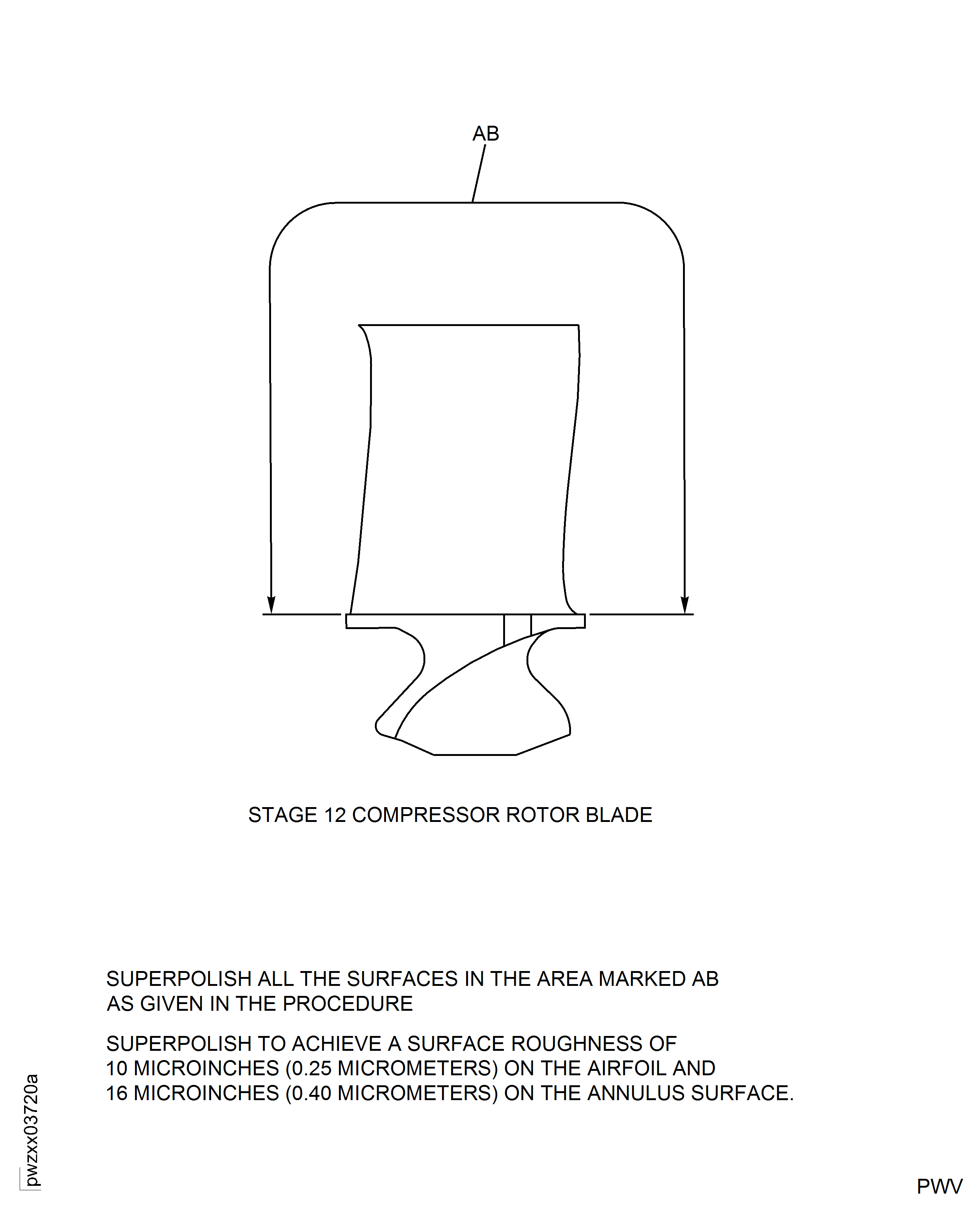

Refer to Figure.

Refer to SPM TASK 70-38-25-380-501.

A maximum of 10 microinches (0.25 micrometers) surface finish is permitted on blade airfoil and fillet surfaces.

On the remainder of the blade, the maximum surface finish is to be 16 microinches (0.40 micrometers).

Do not have more than 50 blades for one cubic foot of the superpolishing media.

Option 3: Method Two consumables.

Use one of the following options to get the surface finish limits. The dimension of the superfinishing media is to be 10 mm x 10 mm maximum.

Polish the surfaces in the area specified AB.

Vibro-polish the blade airfoil and adjacent annulus surfaces.

SUBTASK 72-41-15-380-073-B00 Vibro-Polish the Stage 12 Rotor Blade Airfoil, Assembly B

Remove the mask or maskants.

SUBTASK 72-41-15-350-147 Remove the Mask from the Stage 12 Rotor Blade

Refer to SPM TASK 70-11-03-300-503.

Clean by aqueous degreasing.

SUBTASK 72-41-15-110-206 Clean the Stage 12 Rotor Blade

Refer to Figure.

Refer to SPM TASK 70-38-25-380-501.

The surface finish must obey the limits of Step.

Record each application of vibro-polishing during procedure of VRS6074.

Repair can be applied again, only if the repair identification symbol suffix number will not be more than /2 after the initial application. Each application must be recorded.

If the surface finish is not in the specified limits, do the repair from Step again.

If the surface finish is in the specified limits, continue with the repair.

Examine the surface finish on the each side of the airfoil and the adjacent surfaces in the area specified AB.

Examine the surface finish of the blade.

SUBTASK 72-41-15-220-188-A00 Examine the Stage 12 Rotor Blade Surface Finish, Assembly A

Refer to Figure.

Refer to SPM TASK 70-38-25-380-501.

The surface finish must obey the limits of Step.

Record each application of vibro-polishing during procedure of VRS6074.

Repair can be applied again, only if the repair identification symbol suffix number will not be more than /2 after the initial application. Each application must be recorded.

If the surface finish is not in the specified limits, do the repair from Step again.

If the surface finish is in the specified limits, continue with the repair.

Examine the surface finish on the each side of the airfoil and the adjacent surfaces in the area specified AB.

Examine the surface finish of the blade.

SUBTASK 72-41-15-220-188-B00 Examine the Stage 12 Rotor Blade Surface Finish, Assembly B

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501.

If the blade is already identified with the repair identification symbol, only the suffix number is to be updated.

If this is the first application of VRS6074, mark the repair identification symbol, a 1 in a triangle, on the indicated surface.

If this is the second application of VRS6074, mark /1 adjacent to the repair identification symbol.

If this is the third application of VRS6074, mark /2 adjacent to the repair identification symbol.

Mark the repair identification symbol and the applicable suffix numbers at the indicated location on the blade, use vibration peen method.

SUBTASK 72-41-15-350-084 Identify the Repair

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B

Figure: HPC Stage 12 Rotor Blade - Repair Marking Areas

HPC Stage 12 Rotor Blade - Repair Marking Areas