Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-038 HPC Stage 8 Case - Replace The Boroscope Access Port And/or Rivets, Repair-038 (VRS6249)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Stage 8 Compressor Case Assembly | QRK | Nickel cobalt alloy |

Boroscope access port | EAK | Corrosion resistant steel |

Rivet | Heat resistant alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-21 Inspection/Check.

When any of the rivet(s) which secure the boroscope access port require to be replaced, go to SUBTASK 72-41-21-350-137.

When the boroscope access port requires to be replaced, go to Step.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

DELETED

More equipment and materials necessary to do this Repair are given in the SPM TASKS that follow: SPM TASK 70-09-00-400-501,

SPM TASK 70-09-01-400-501,,

and SPM TASK 70-39-03-390-501.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vertical drilling machine | LOCAL | Vertical drilling machine | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Dial indicator | LOCAL | Dial indicator | ||

| Drill | LOCAL | Drill | ||

| Cold squeeze riveting equipment | LOCAL | Cold squeeze riveting equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rivet, solid CSK head | AS16688 | 4 | ||

| Rivet, solid CSK head | AS16729 | 4 | (oversize) | |

| Boss, boroscope access port | 6A4187 | 1 | (Assembly A) | |

| Adaptor, boroscope access port | 6A5870 | 1 | (Assembly B, Assembly C and Assembly D) |

Safety Requirements

NONEProcedure

Refer to SPM TASK 70-09-01-400-501.

Identify the damaged holes.

SUBTASK 72-41-21-220-349-A00 Examine the Rivet Holes on the HP Compressor Stage 8 Case Assembly, Assembly A

Refer to SPM TASK 70-09-01-400-501.

Identify the damaged holes.

SUBTASK 72-41-21-220-349-B00 Examine the Rivet Holes on the HP Compressor Stage 8 Case Assembly, Assembly B

Refer to SPM TASK 70-09-01-400-501.

Identify the damaged holes.

SUBTASK 72-41-21-220-349-C00 Examine the Rivet Holes on the HP Compressor Stage 8 Case Assembly, Assembly C and Assembly D

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant test equipment.

Cracks are not permitted.

Do a local penetrant crack test of the drilled holes.

SUBTASK 72-41-21-230-142 Do a Crack Test

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant test equipment.

Cracks are not permitted.

Do a penetrant crack test on the rivets.

SUBTASK 72-41-21-230-143 Do a Crack Test

Refer to SPM TASK 70-39-03-390-501, SUBTASK 70-39-03-390-005.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the assembly.

SUBTASK 72-41-21-220-450-B00 Examine the HP Compressor Stage 8 Case Assembly, Assembly B

Refer to SPM TASK 70-39-03-390-501, SUBTASK 70-39-03-390-005.

Useworkshop inspection equipment.

Visually examine and measure the dimensions of the assembly.

SUBTASK 72-41-21-220-450-C00 Examine the HP Compressor Stage 8 Case Assembly, Assembly C and Assembly D

Refer to SPM TASK 70-09-00-400-501.

Use vibro-engraving equipment.

Make a mark VRS6249/1 adjacent to the assembly number when the boroscope access port has been replaced.

SUBTASK 72-41-21-350-139 Identify the Repair

Refer to TASK 72-41-21-100-000.

Use chemical cleaning equipment.

Chemically clean the assembly.

SUBTASK 72-41-21-110-165 Chemically Clean

Refer to TASK 72-41-21-200-000.

Use penetrant crack test equipment.

Do a penetrant crack test.

SUBTASK 72-41-21-230-188 Do a Crack Test

Refer to SPM TASK 70-09-01-400-501.

Identify damaged hole(s).

SUBTASK 72-41-21-220-351-A00 Examine the Rivet Hole(s) on the HP Compressor Stage 8 Case Assembly and Boroscope Access Port, Assembly A

Refer to SPM TASK 70-09-01-400-501.

Identify damaged hole(s).

SUBTASK 72-41-21-220-351-B00 Examine the Rivet Hole(s) on the HP Compressor Stage 8 Case Assembly and Boroscope Access Port, Assembly B

Refer to SPM TASK 70-09-01-400-501.

Identify damaged hole(s).

SUBTASK 72-41-21-220-351-C00 Examine the Rivet Hole(s) on the HP Compressor Stage 8 Case Assembly and Boroscope Access Port, Assembly C and Assembly D

Refer to SPM TASK 70-09-01-400-501.

Identify which holes have been drilled for the larger rivets.

SUBTASK 72-41-21-220-352-A00 Examine the Rivet Hole(s), Assembly A

Refer to SPM TASK 70-09-01-400-501.

Identify which holes have been drilled for the larger rivets.

SUBTASK 72-41-21-220-352-B00 Examine the Rivet Hole(s), Assembly B

Refer to SPM TASK 70-09-01-400-501.

Identify which holes have been drilled for the larger rivets.

SUBTASK 72-41-21-220-352-C00 Examine the Rivet Hole(s), Assembly C and Assembly D

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the rivet hole(s).

SUBTASK 72-41-21-230-144 Do a Crack Test

Refer to SPM TASK 70-39-03-390-501.

Use cold squeeze riveting equipment.

Cold squeeze the rivets.

SUBTASK 72-41-21-390-054-A00 Install the Rivet(s), Assembly A

Refer to SPM TASK 70-39-03-390-501.

Use cold squeeze riveting equipment.

Cold squeeze the rivets.

SUBTASK 72-41-21-390-054-B00 Install the Rivet(s), Assembly B

Refer to SPM TASK 70-39-03-390-501.

Use cold squeeze riveting equipment.

Cold squeeze the rivets.

SUBTASK 72-41-21-390-054-C00 Install the Rivet(s), Assembly C and Assembly D

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the rivets.

SUBTASK 72-41-21-230-145 Do a Crack Test

Refer to SPM TASK 70-39-03-390-501, SUBTASK 70-39-03-390-005.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the assembly.

SUBTASK 72-41-21-220-451-A00 Examine the HP Compressor Stage 8 Case Assembly, Assembly A

Refer to SPM TASK 70-39-03-390-501, SUBTASK 70-39-03-390-005.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the assembly.

SUBTASK 72-41-21-220-451-B00 Examine the HP Compressor Stage 8 Case Assembly, Assembly B

Refer to SPM TASK 70-39-03-390-501, SUBTASK 70-39-03-390-005.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the assembly.

SUBTASK 72-41-21-220-451-C00 Examine the HP Compressor Stage 8 Case Assembly, Assembly C and Assembly D

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Make a mark VRS6249/2 adjacent to the assembly number when the damaged rivet(s) have been replaced.

SUBTASK 72-41-21-350-142 Identify the Repair

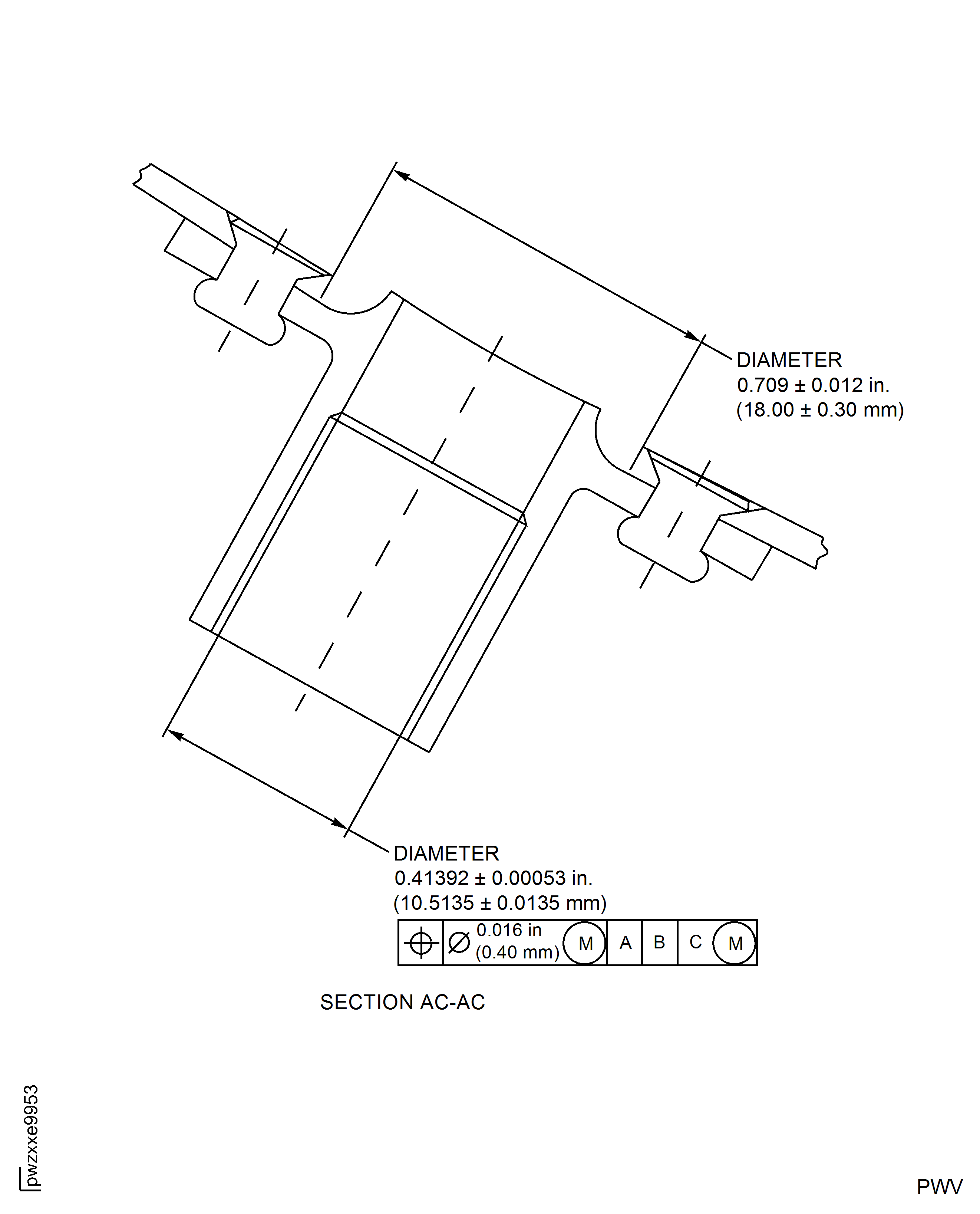

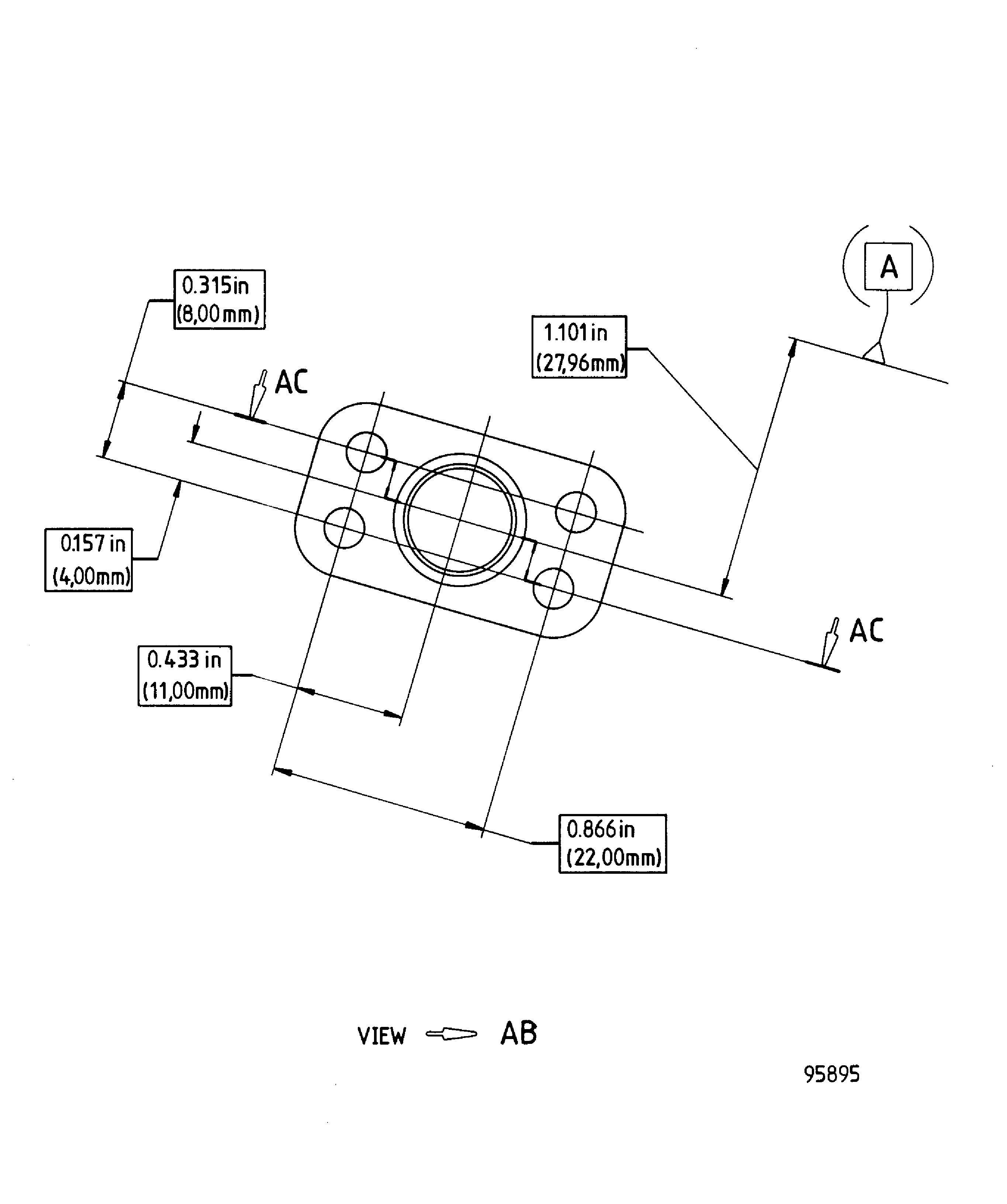

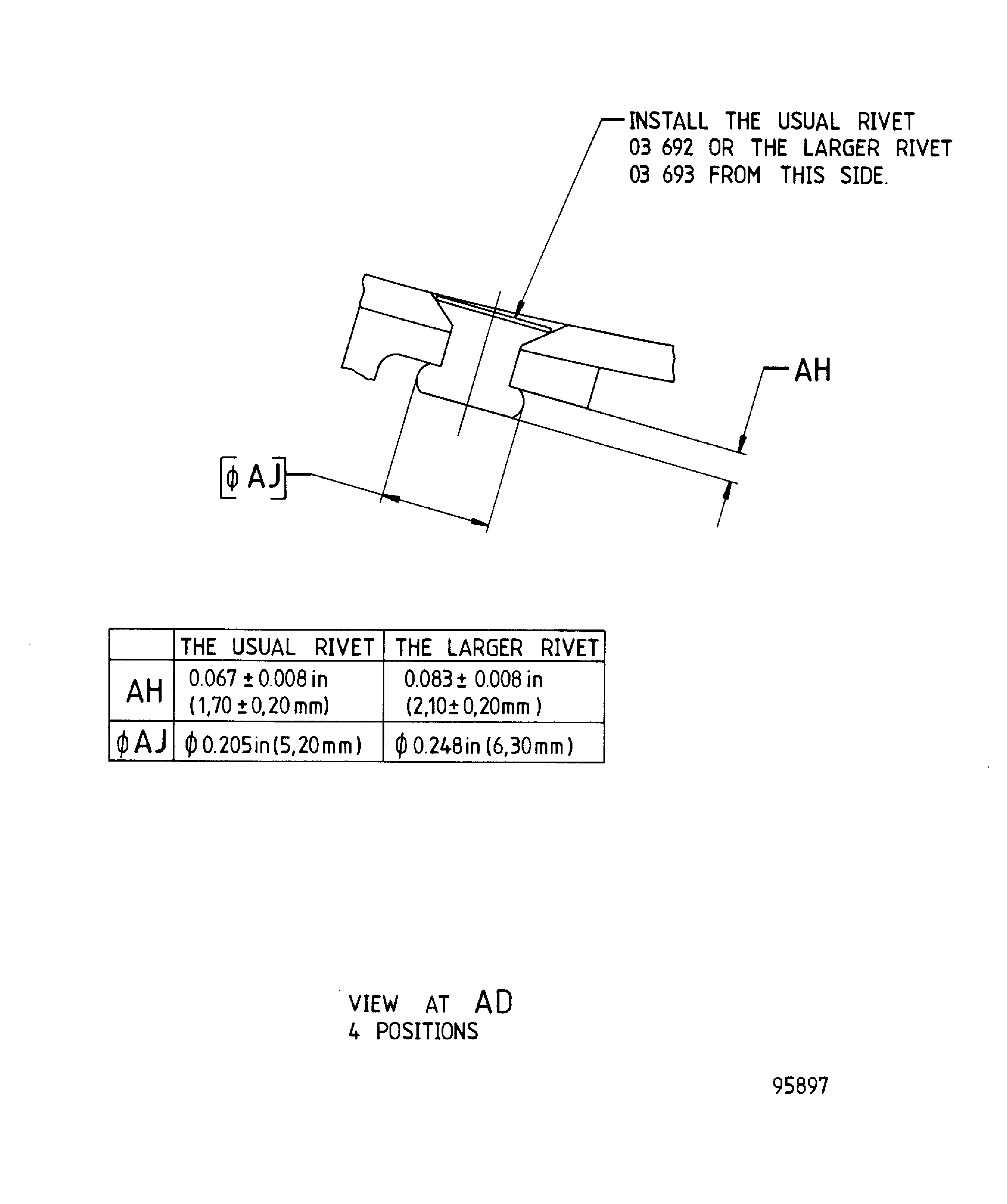

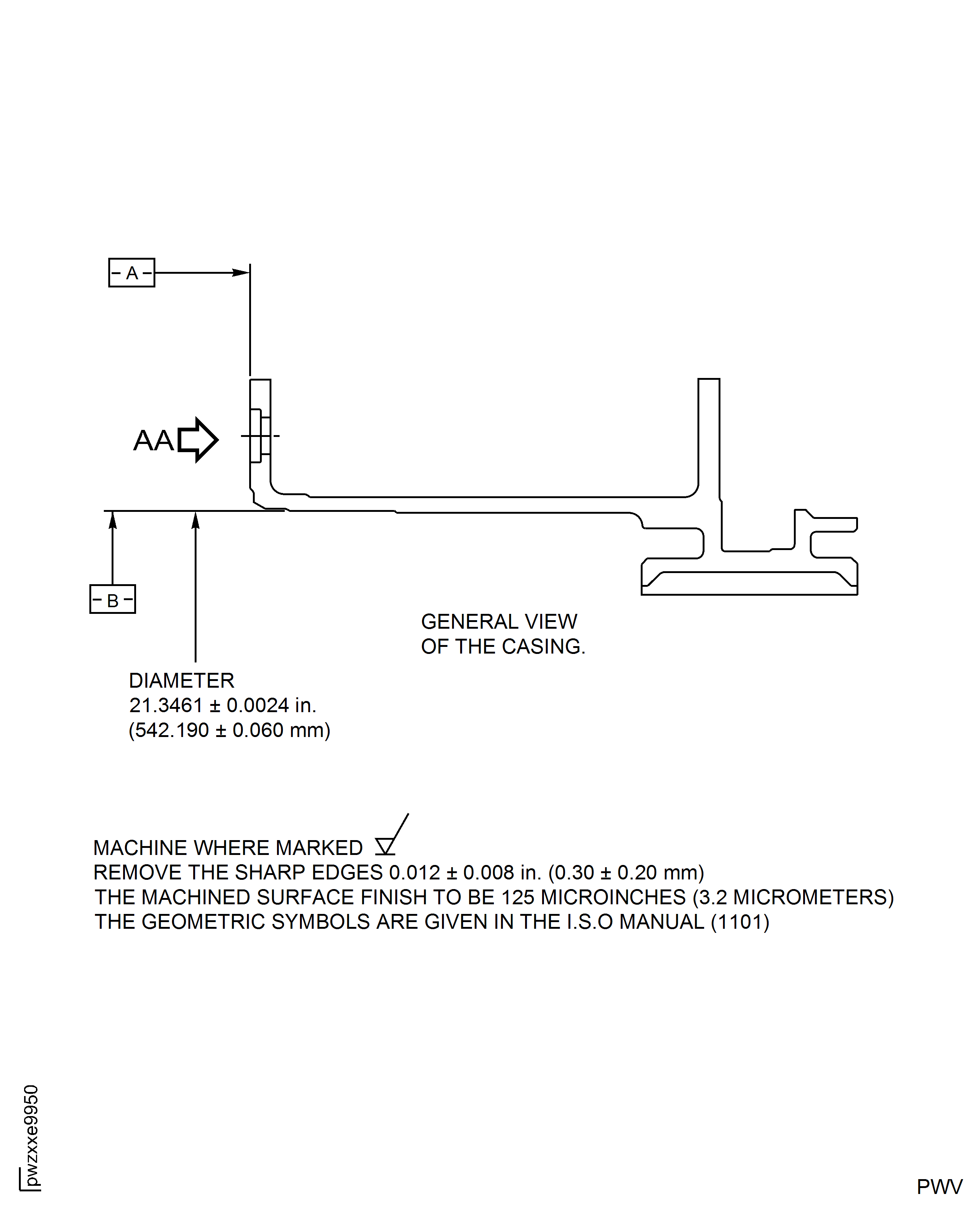

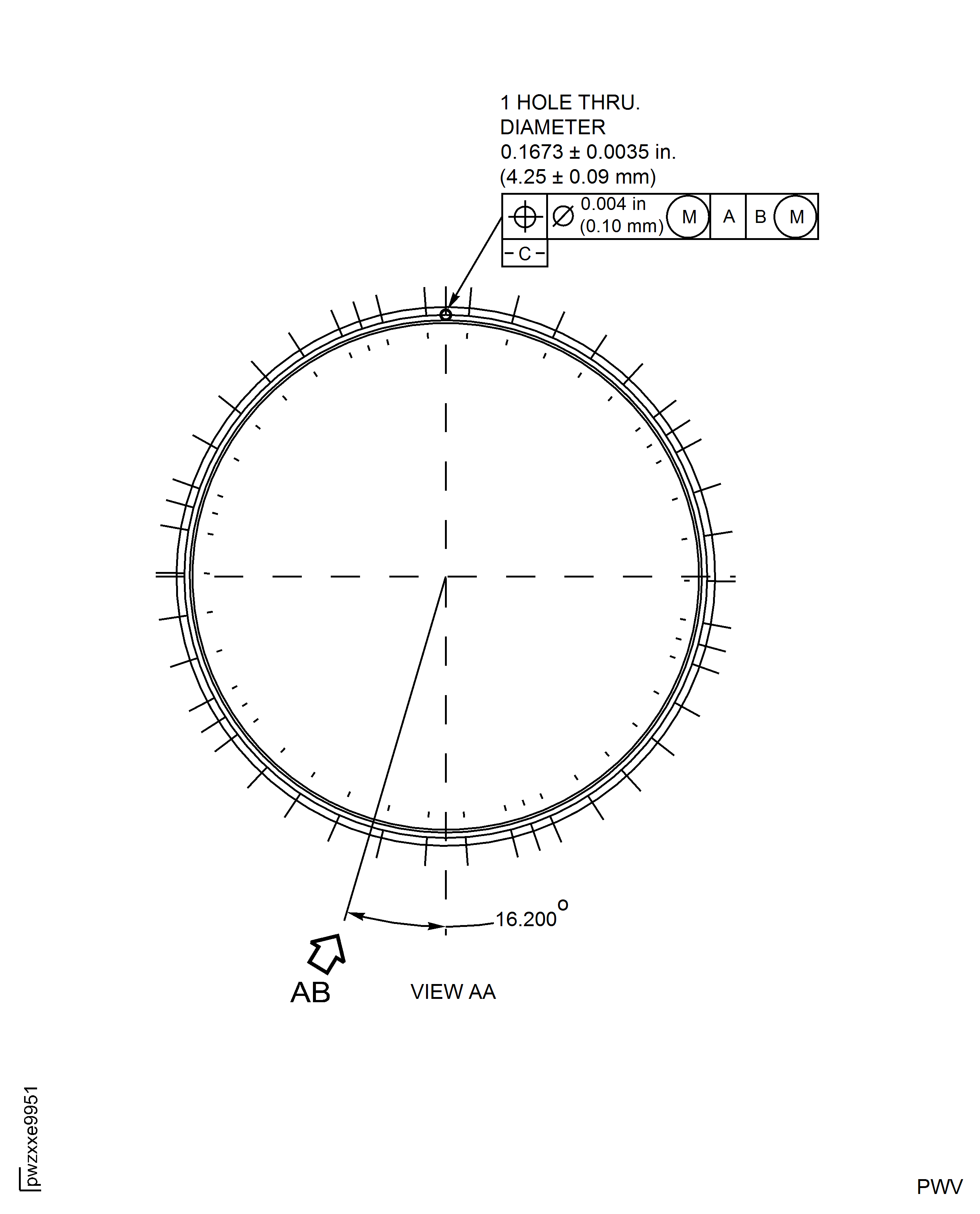

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

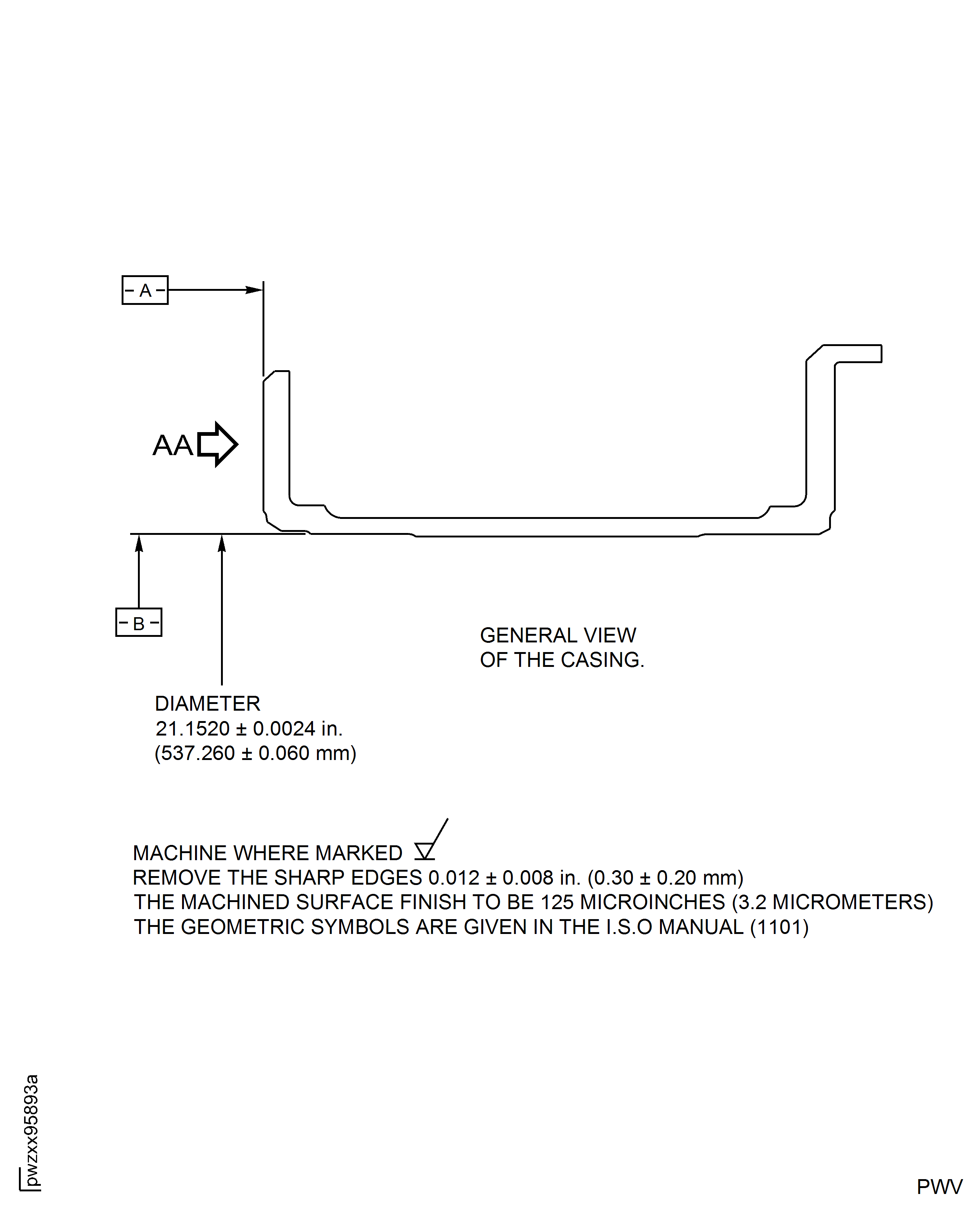

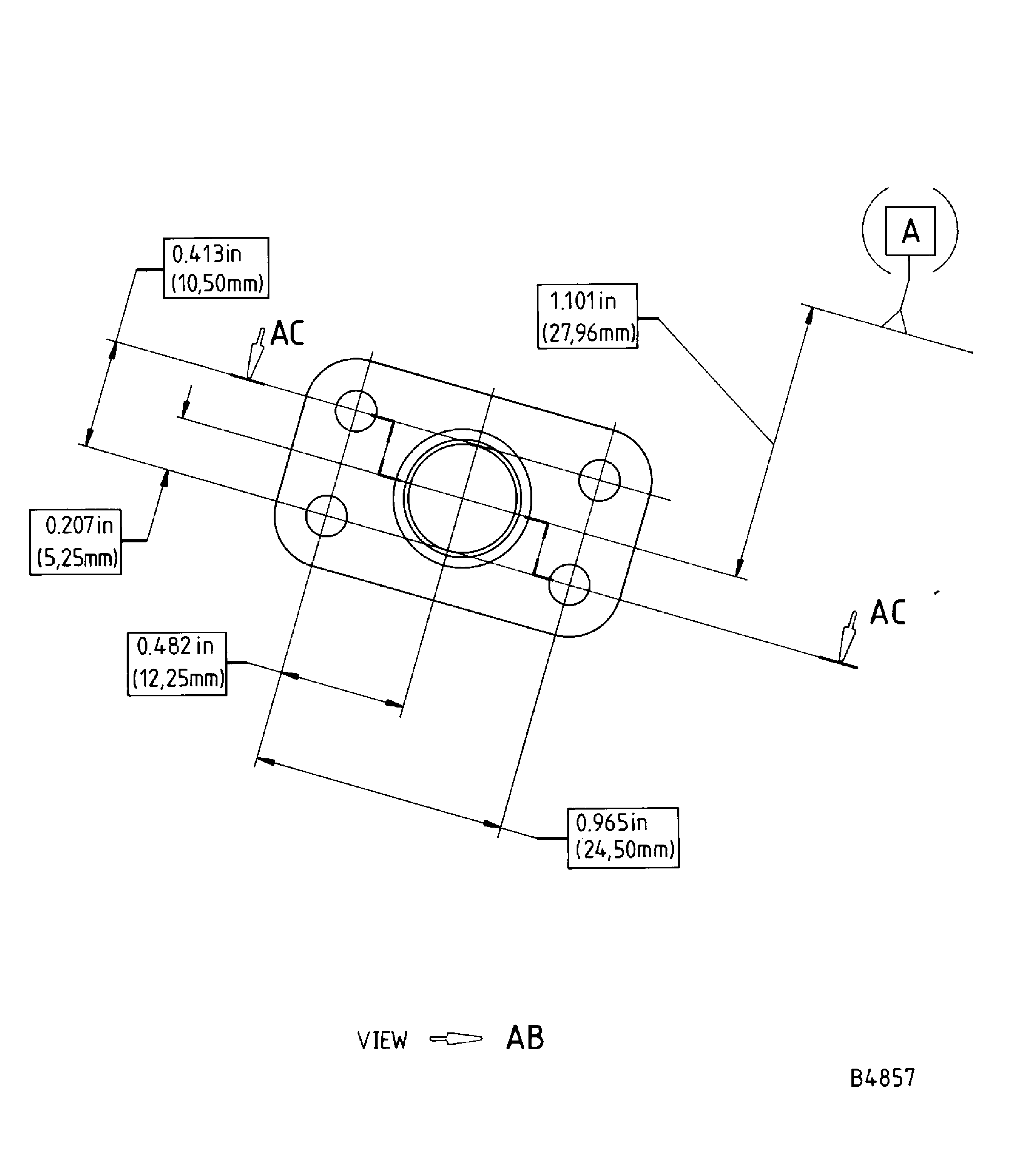

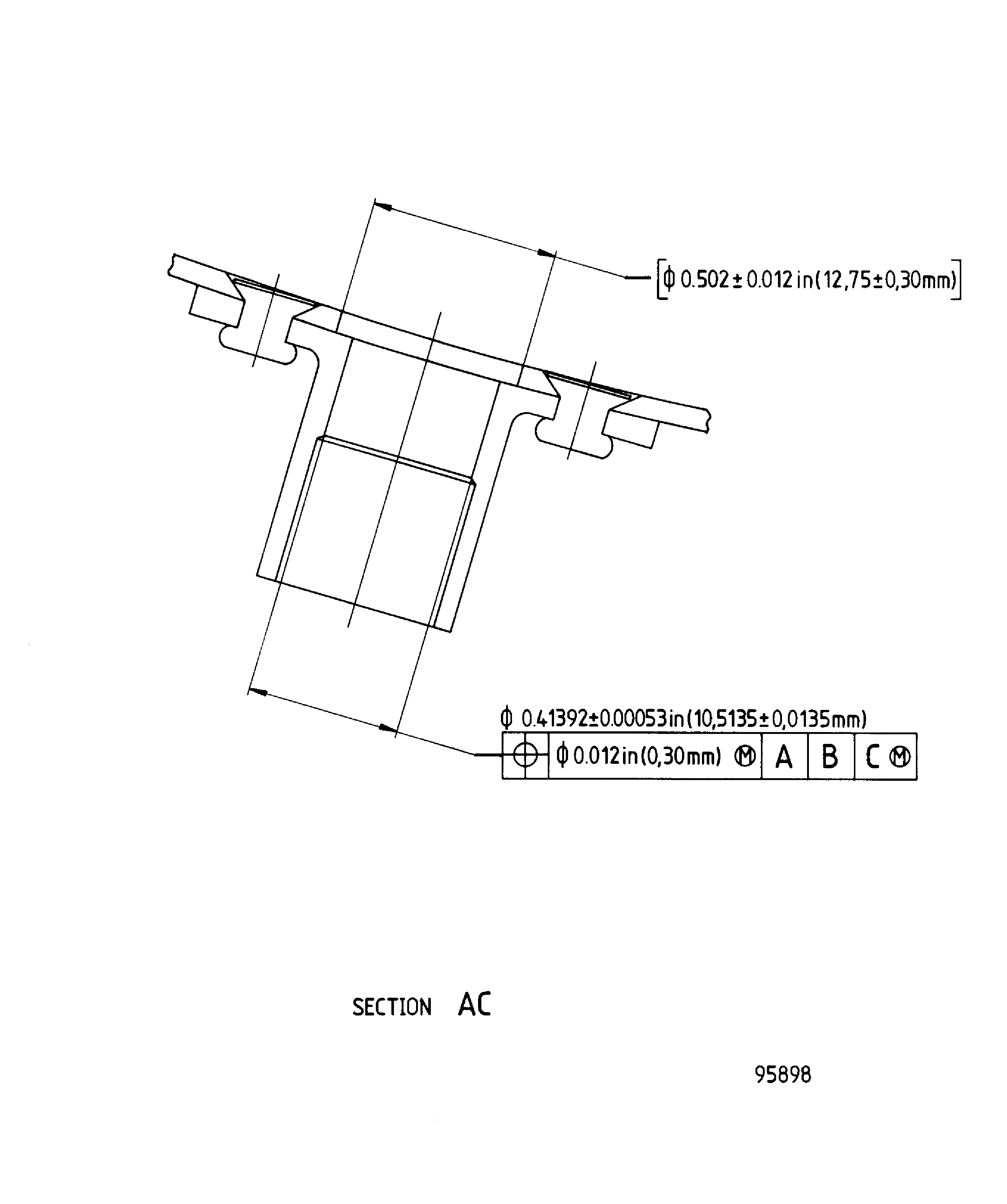

Figure: Repair Details And Dimensions - Assembly B And Assembly C

Repair Details And Dimensions - Assembly B And Assembly C

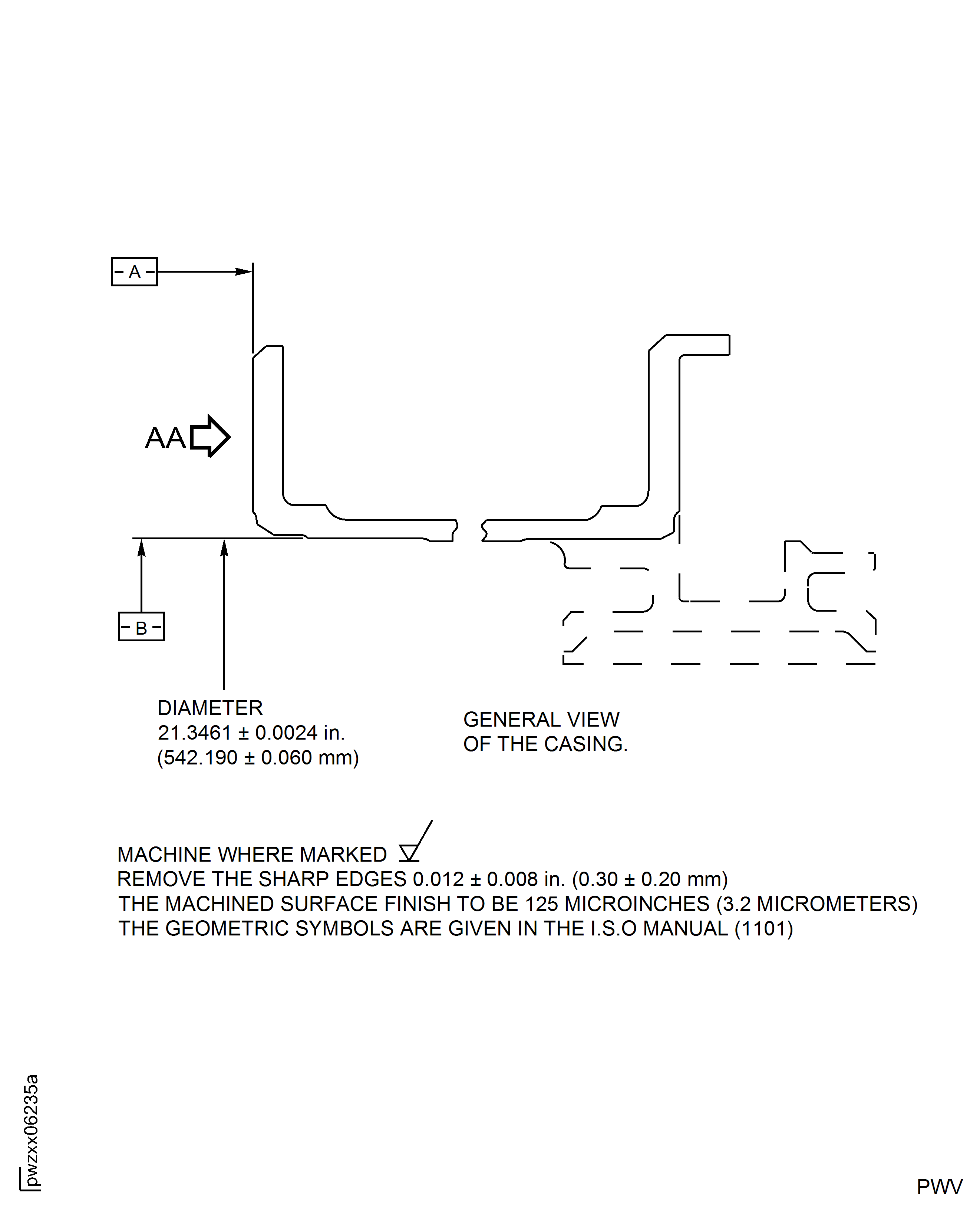

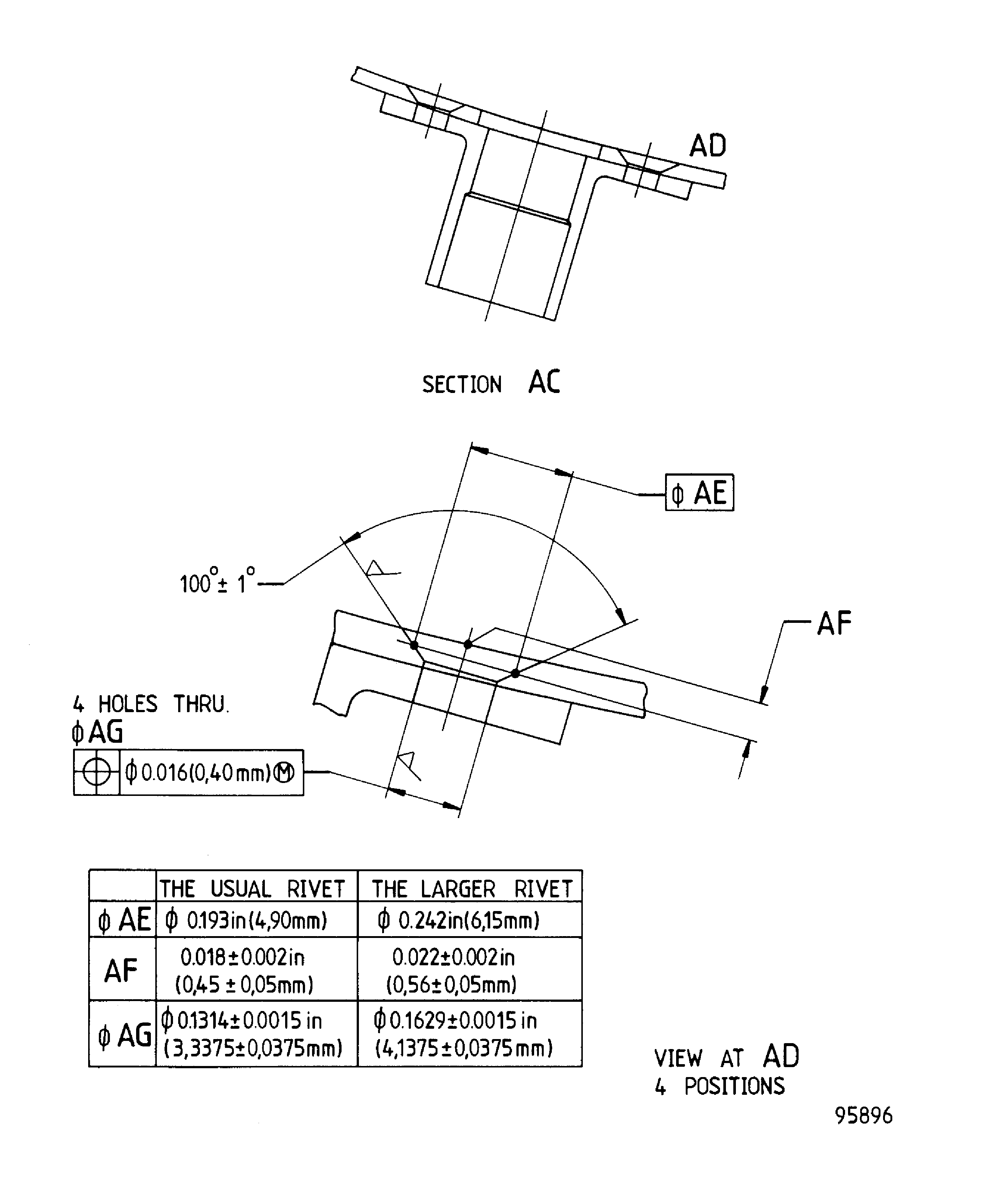

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

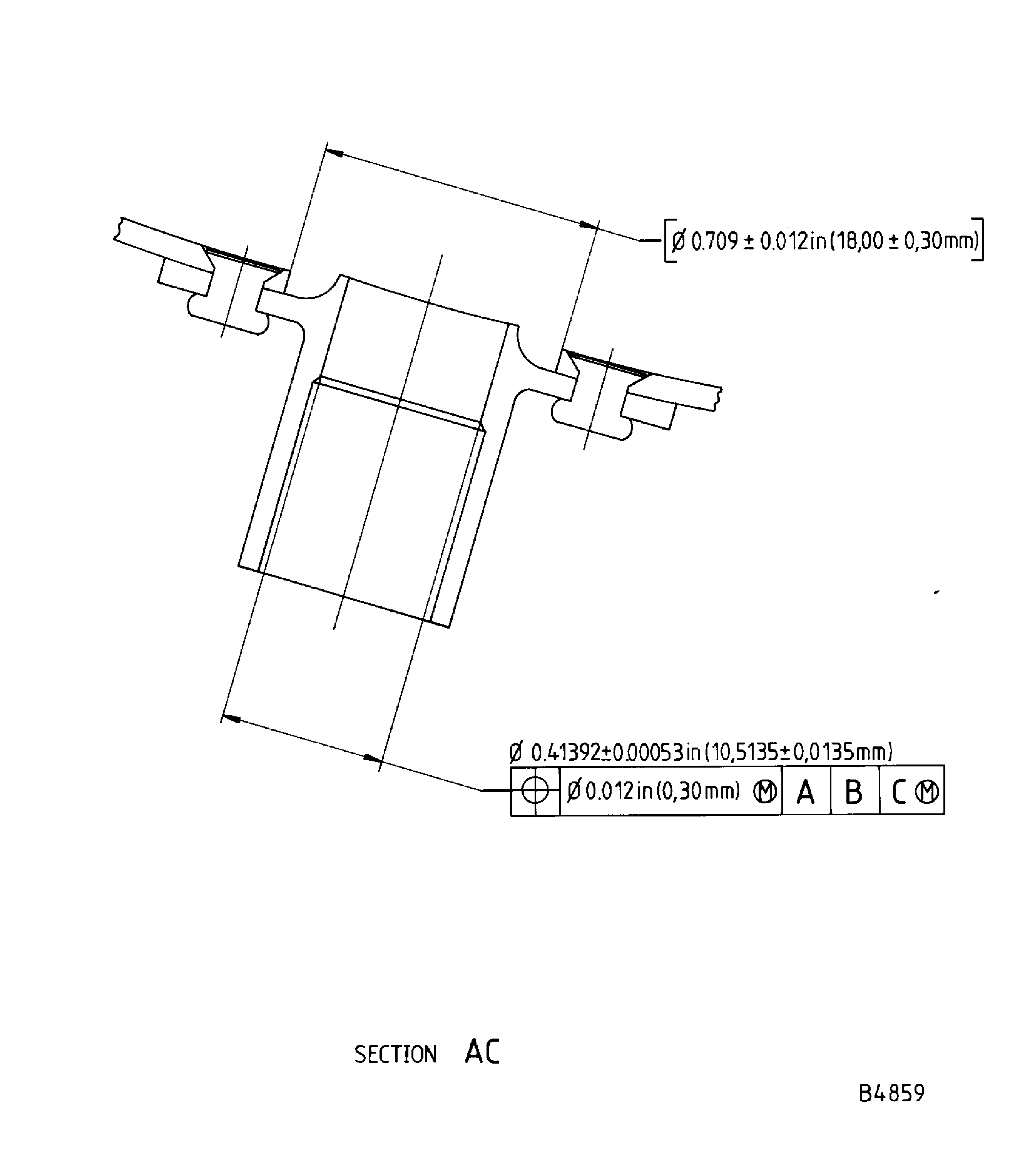

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B

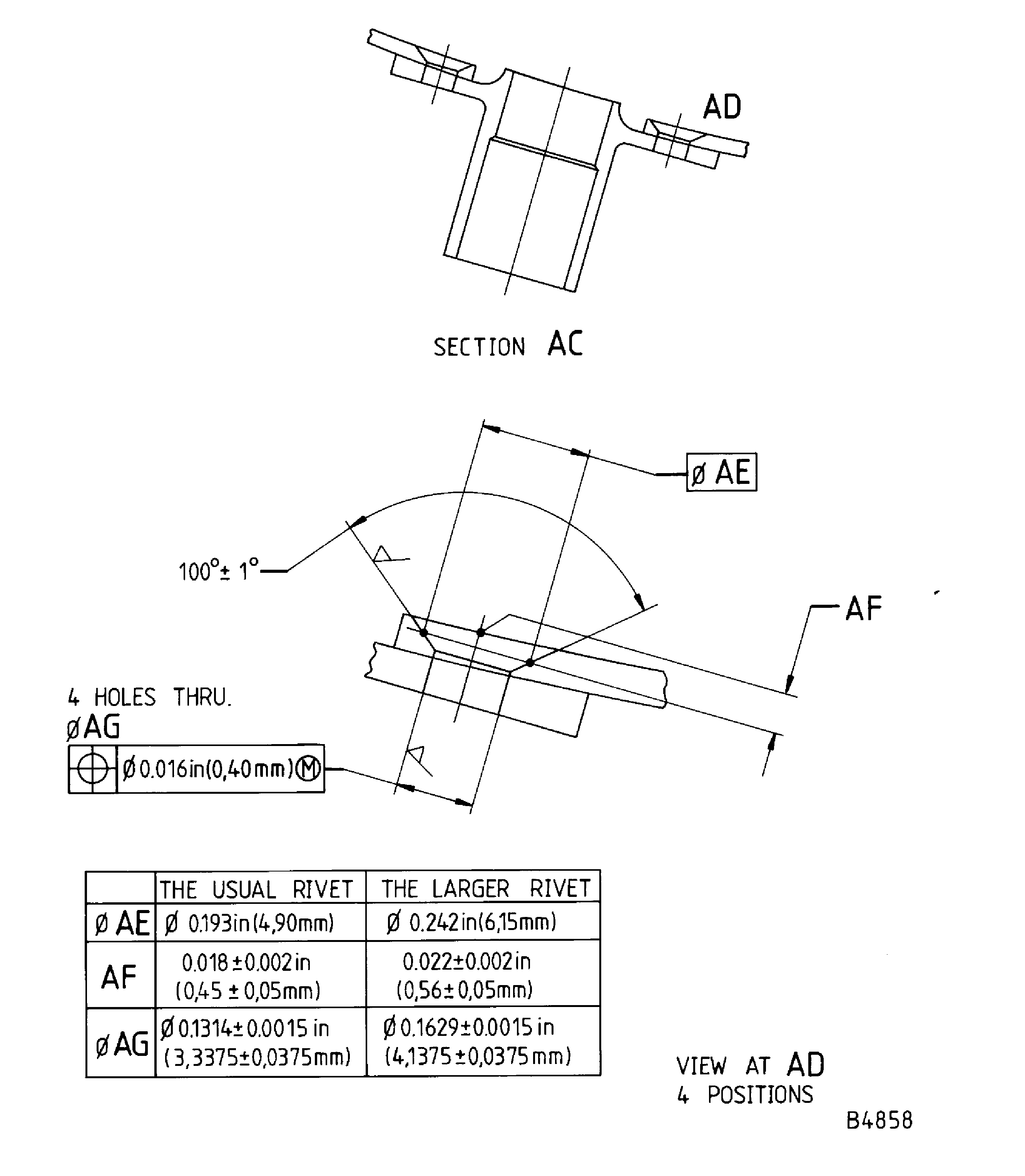

Figure: Repair Details And Dimensions - Assembly C And Assembly D

Repair Details And Dimensions - Assembly C And Assembly D

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly B, Assembly C And Assembly D

Repair Details And Dimensions - Assembly B, Assembly C And Assembly D

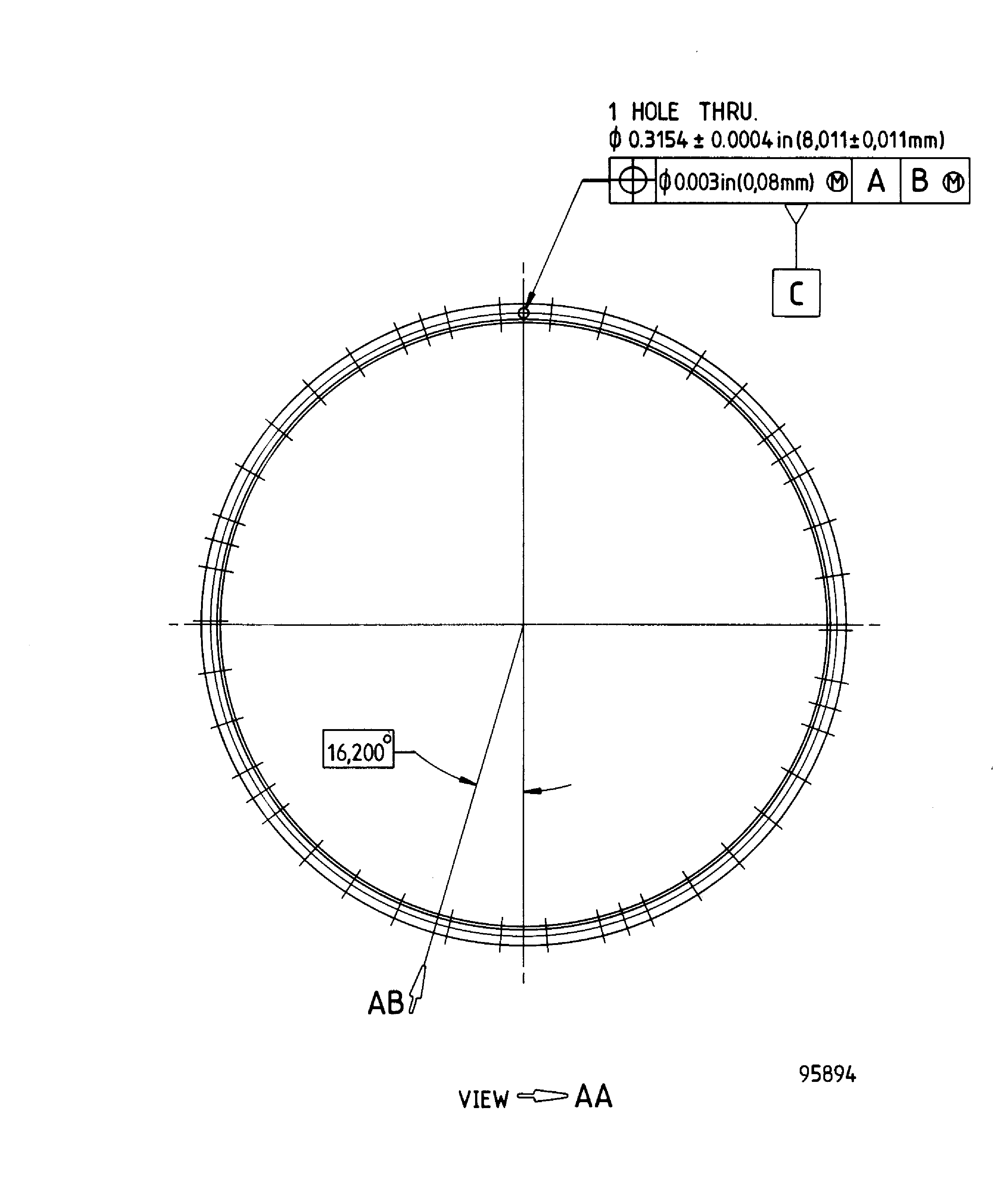

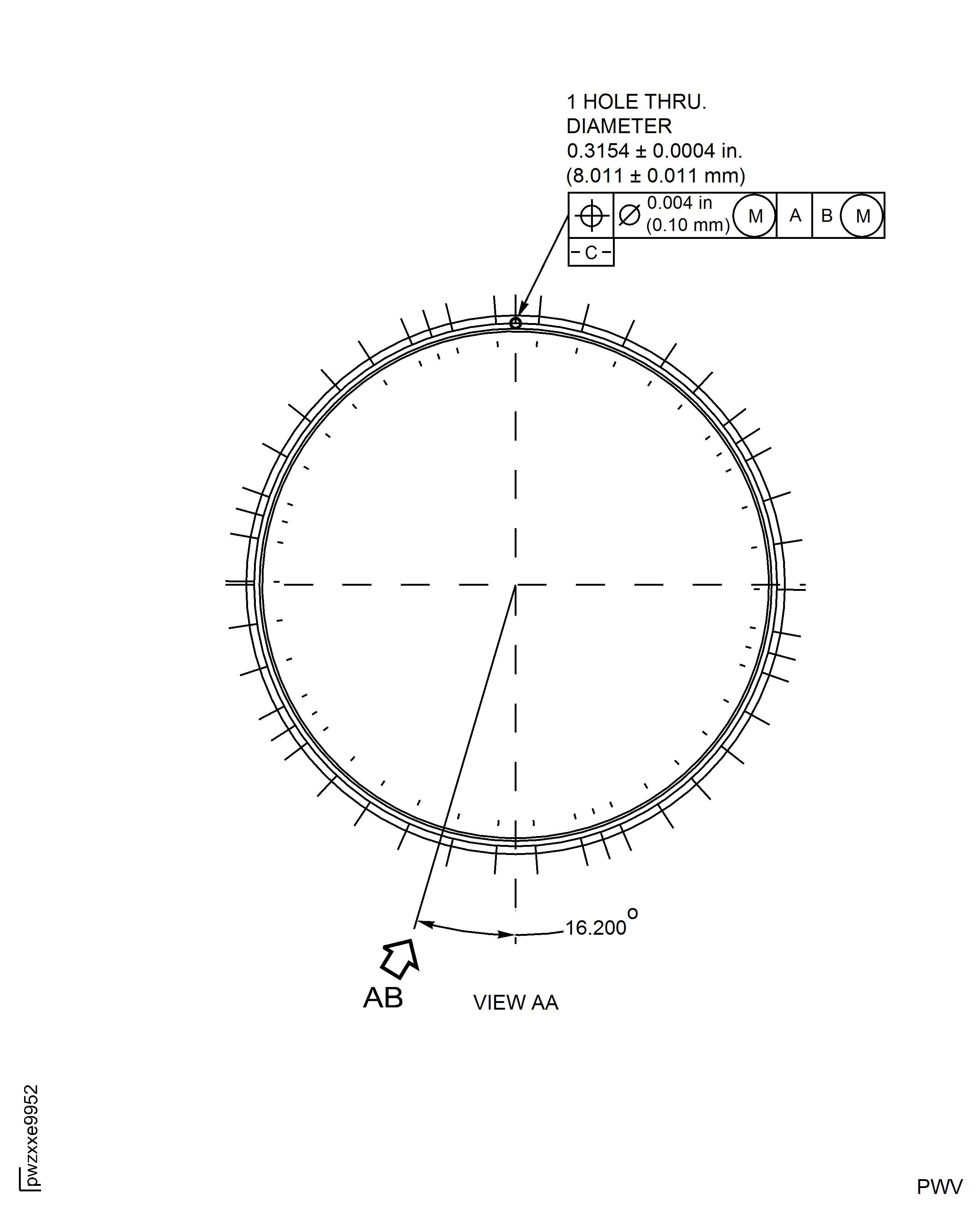

Figure: Repair Details And Dimensions - Assembly A, Assembly B, Assembly C And Assembly D

Repair Details And Dimensions - Assembly A, Assembly B, Assembly C And Assembly D

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly B And Assembly C

Repair Details And Dimensions - Assembly B And Assembly C

Figure: Repair Details And Dimensions - Assembly C

Repair Details And Dimensions - Assembly C

Figure: Repair Details And Dimensions - Assembly D

Repair Details And Dimensions - Assembly D

Figure: Repair Details And Dimensions - Assembly D

Repair Details And Dimensions - Assembly D

Figure: Repair Details And Dimensions - Assembly D

Repair Details And Dimensions - Assembly D