Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-070 HPC Heatshields - Replace Loose Or Damaged Rivets And/or A Damaged Plate On The Stage 9 Front Heatshield Or Stage 10 Rear Heatshield, Repair-070 (VRS6311)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

03-920 | 6A3029 | Assembly A |

04-450 | 6A3029 | Assembly A |

03-920 | 6A4261 | Assembly B |

04-450 | 6A4262 | Assembly B |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Assembly Half Ring Stage 9, Front and Stage 10, Rear (Assembly A) | QRK or | 38 percent Nickel, 14 percent Cobalt, 1.5 percent Titanium, 1 percent Manganese |

Assembly, Half Ring, Stage 10, Rear (Assembly B) | QTX or | Iron, 38 percent Nickel, 14.5 percent Cobalt, 4.75 percent Niobium, 1.6 percent Titanium |

Assembly Half Ring, Stage 9, Front Stage 10, Rear (Assembly A and Assembly B) | QTX or | Iron, 38 percent Nickel, 14.5 percent Cobalt, 4.75 percent Niobium, 1.6 percent Titanium |

Assembly, Half Ring, Stage 9 Front (Assembly B) | TDZ | 5 percent Aluminum, 3 percent Zirconium, 3 percent Tin, 1 percent Niobium |

Plate | EBQ | 11 percent Chromium and 1 percent Molybdenum |

Rivet, solid | QBE or QPK | Nimonic 75 |

General

This Repair must only be done when the instruction to do so is given in 72-41-21 Inspection.

This Repair replaces loose or damage rivits and/or a damaged plate, on the HP Compressor Front Heatshield, Stage 9 and the Rear Heatshield, Stage 10.

When loose or damaged rivet(s) are to be replaced do SUBTASK 72-41-21-323-069.

When a damaged plate is to be replaced do SUBTASK 72-41-21-350-181.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price an availabilty

Refer to International Areo Engines

Related repairs

HP Compressor Stage 9 Front and Stage 10 Rear Heatshield Assemblies - Replace the surface protection, refer to TASK 72-41-21-300-074 (REPAIR-074)

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vertical drilling machine | LOCAL | Vertical drilling machine | ||

| Toolmakers clamp | LOCAL | Toolmakers clamp | or equivalent | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rivet, solid, universal head | AS16246 | 2 | (Assembly A and Assembly B) | |

| Rivet, solid, universal head | AS16287 | 2 | (Assembly A and Assembly B) | |

| Plate | 6A6518 | 1 | (Assembly A and Assembly B) | |

| Rivet, solid universal head | AS16246 | 2 | (Assembly A and Assembly B) | |

| Rivet, solid, universal head | AS16287 | 2 | (Assembly A and Assembly B) | |

| Plate | 6A6518 | 1 | (Assembly A and Assembly B) |

Safety Requirements

NONEProcedure

Refer to TASK 72-41-21-100-000 (CLEANING-000).

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-41-21-110-172 Clean the Assembly

Refer to TASK 72-41-21-200-000 (INSPECTION-000).

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-41-21-230-195 Do a Crack Test

Refer to the SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the plate and around the rivet hole(s).

SUBTASK 72-41-21-110-173 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the plate and around the rivet hole(s).

SUBTASK 72-41-21-230-196 Do a Crack Test

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivet(s) in place.

SUBTASK 72-41-21-390-066-A00 Safety the Rivet(s) in Place, Assembly A

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivet(s) in place.

SUBTASK 72-41-21-390-066-B00 Safety the Rivet(s) in Place, Assembly B

Refer to the SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the rivet heads and plate.

SUBTASK 72-41-21-110-174 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the rivet heads and plate.

SUBTASK 72-41-21-230-197 Do a Crack Test

Refer to the SPM TASK 70-09-00-400-501 , SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Mark VRS6311/1 adjacent to the part number when loose or damaged rivet(s) is/are replaced.

SUBTASK 72-41-21-350-180 Identify the Repair

Refer to VRS6312, TASK 72-41-21-300-074 (REPAIR-074).

Apply the surface protection to the HP Compressor Stage 9 Front and/or Stage 10 rear Heatshield Assembly.

SUBTASK 72-41-21-380-180 Apply the Surface Protection, Assembly A only

Use 6A6518 , 1 off 03-930 or 04-460 with toolmakers clamps or equivalent.

Safety the plate to the heatshield.

SUBTASK 72-41-21-323-071-A00 Drill the Plate and Rivet Hole(s), Assembly A

Use 6A6518 , 1 off 03-930 or 04-460 with toolmakers clamp or equivalent.

Safety the plate to the heatshield.

SUBTASK 72-41-21-323-071-B00 Drill the Plate and Rivet Holes, Assembly B

Refer to the SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the plate and around the rivet holes.

SUBTASK 72-41-21-110-175 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the plate and around the rivet holes.

SUBTASK 72-41-21-230-198 Do a Crack Test

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivet(s) in place.

SUBTASK 72-41-21-390-067-A00 Safety the Rivet(s) in Place, Assembly A

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivet(s) in place.

SUBTASK 72-41-21-390-067-B00 Safety the Rivet(s) in Place, Assembly B

Refer to the SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Chemically clean the rivet heads and plate.

SUBTASK 72-41-21-110-176 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the rivet heads and plate.

SUBTASK 72-41-21-230-199 Do a Crack Test

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Mark VRS6311/2 adjacent to the part number when a damaged plate is replaced.

SUBTASK 72-41-21-350-183 Identify the Repair

Refer to VRS6312, TASK 72-41-21-300-074 (REPAIR-074).

Apply the surface protection to the HP Compressor Stage 9 Rear and/or Stage 10 Rear Heatshield Assembly.

SUBTASK 72-41-21-380-121 Apply the Surface Protection, Assembly A only

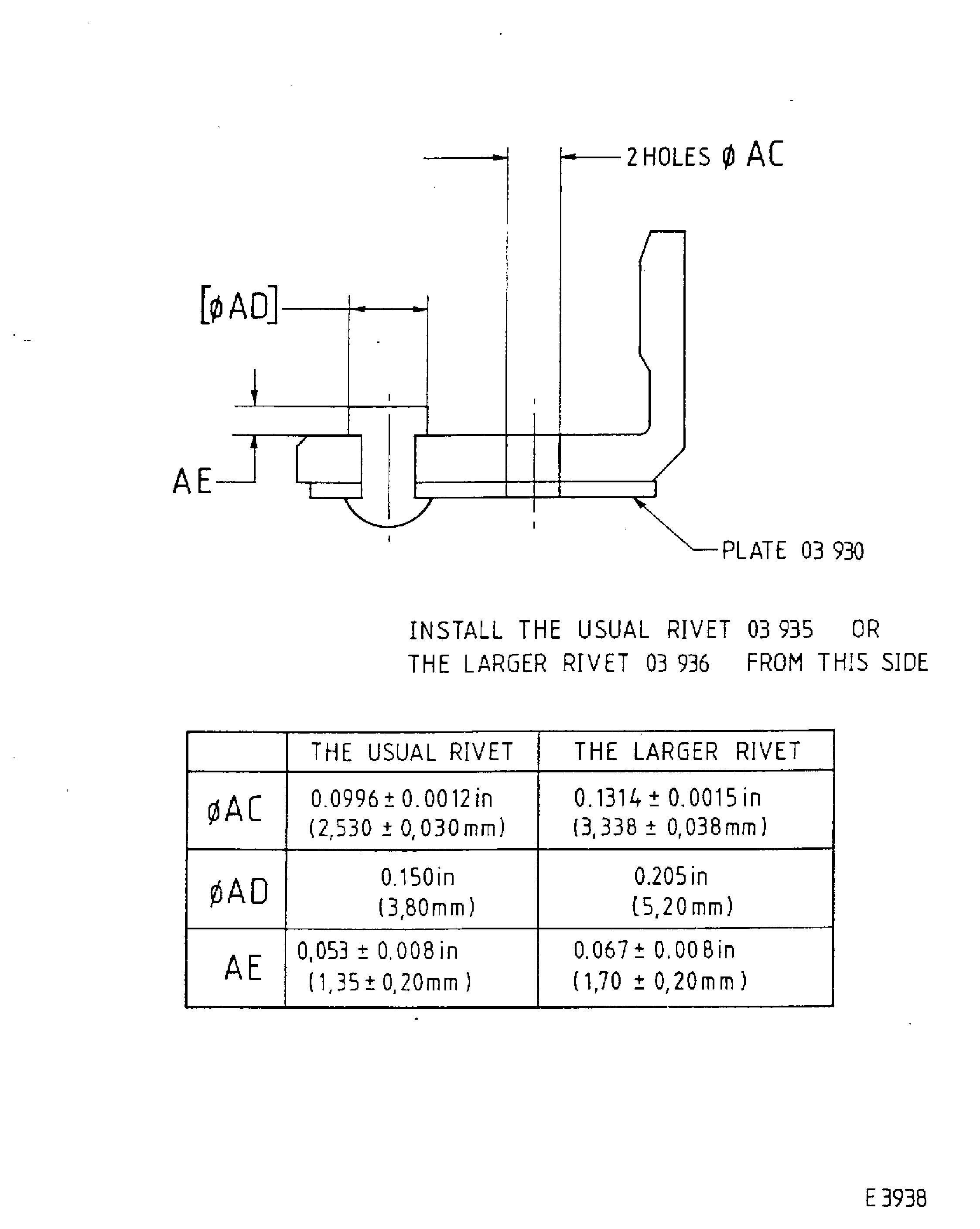

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

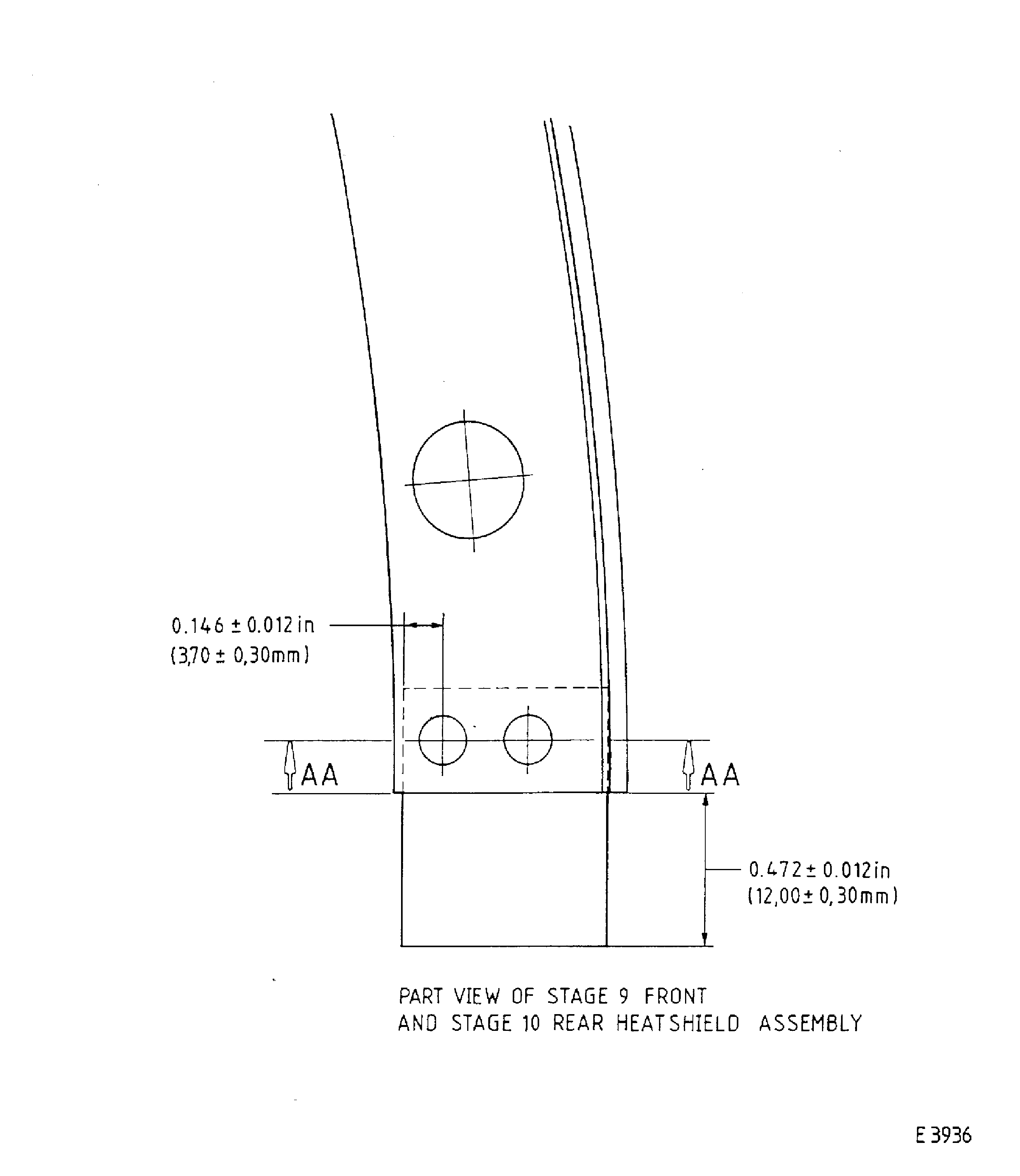

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

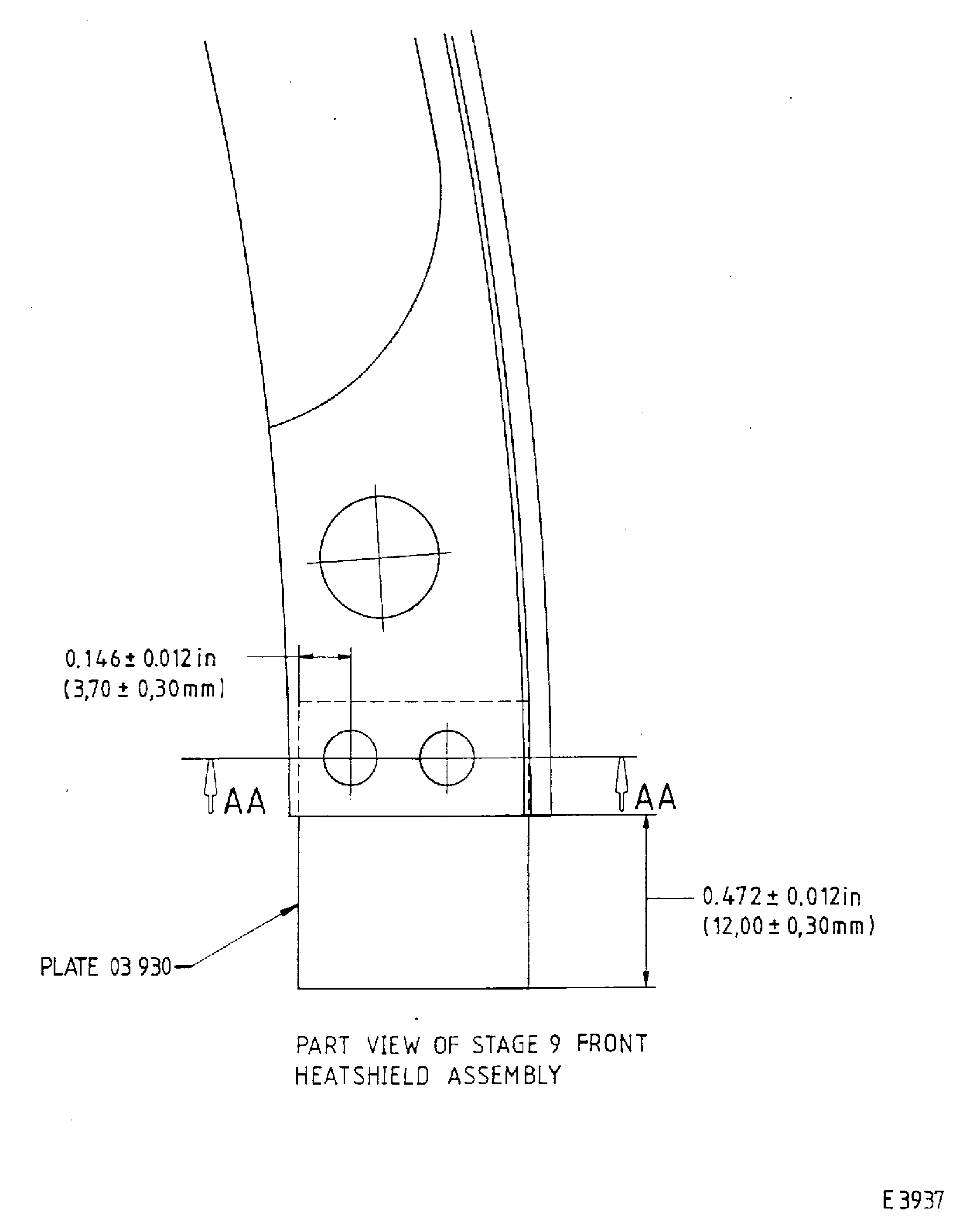

Figure: Repair details and dimensions

Repair details and dimensions