Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-028 HPC Front Cases - Stage 6 Rotor Path Ring Slots And Forward Location Face, Metal Spray, Repair-028 (VRS6634)

General

This repair must only be done when the instruction to do so is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-31.

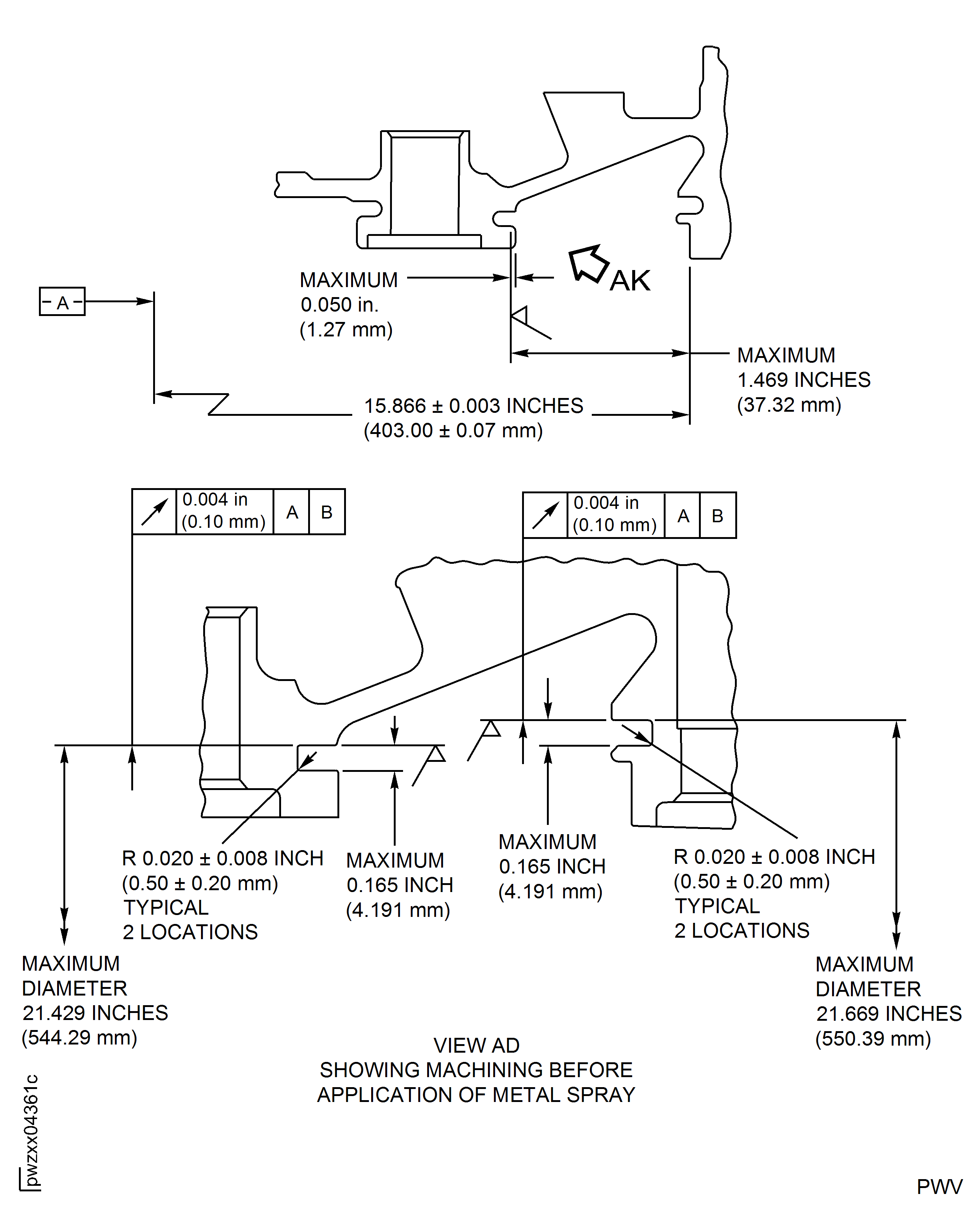

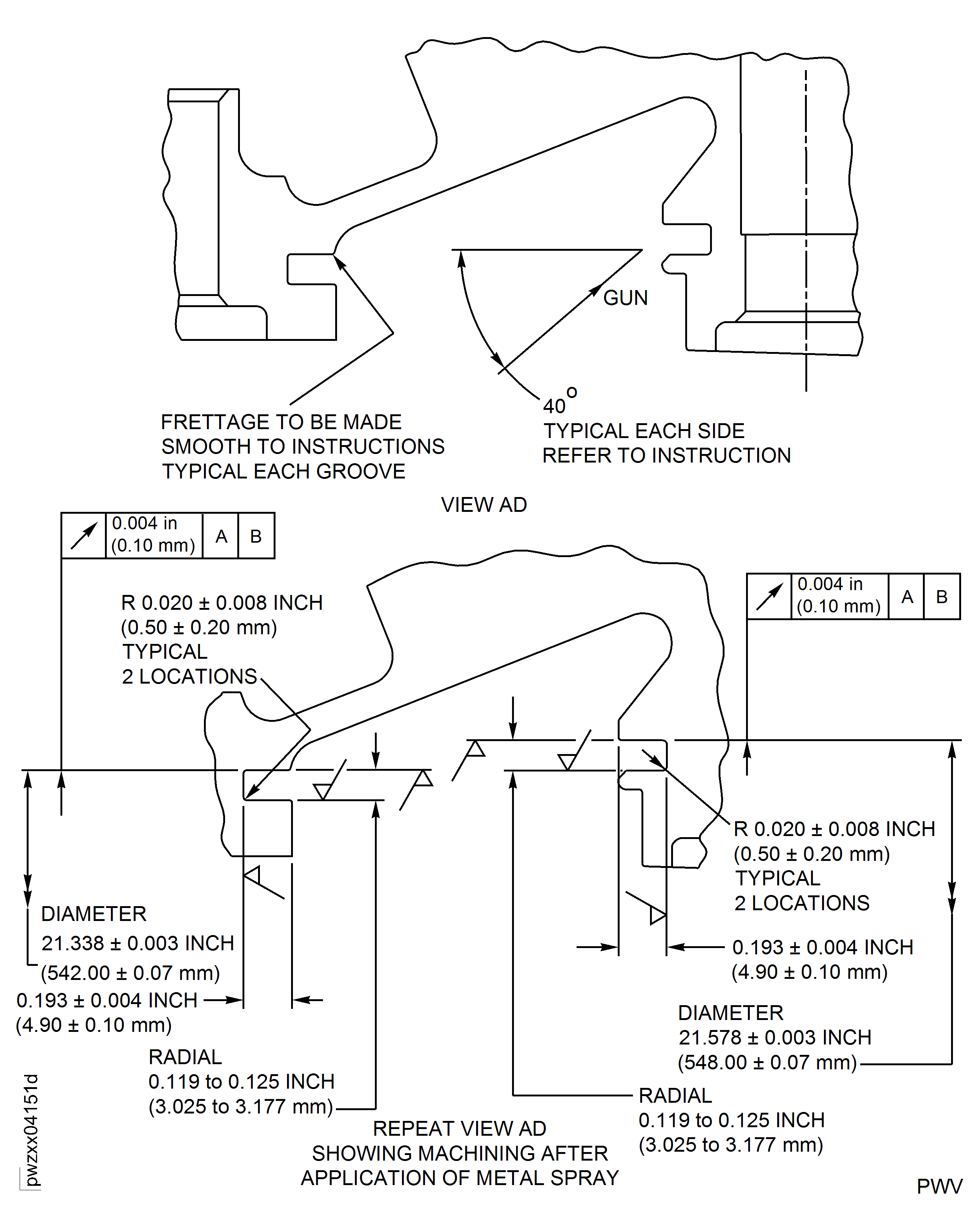

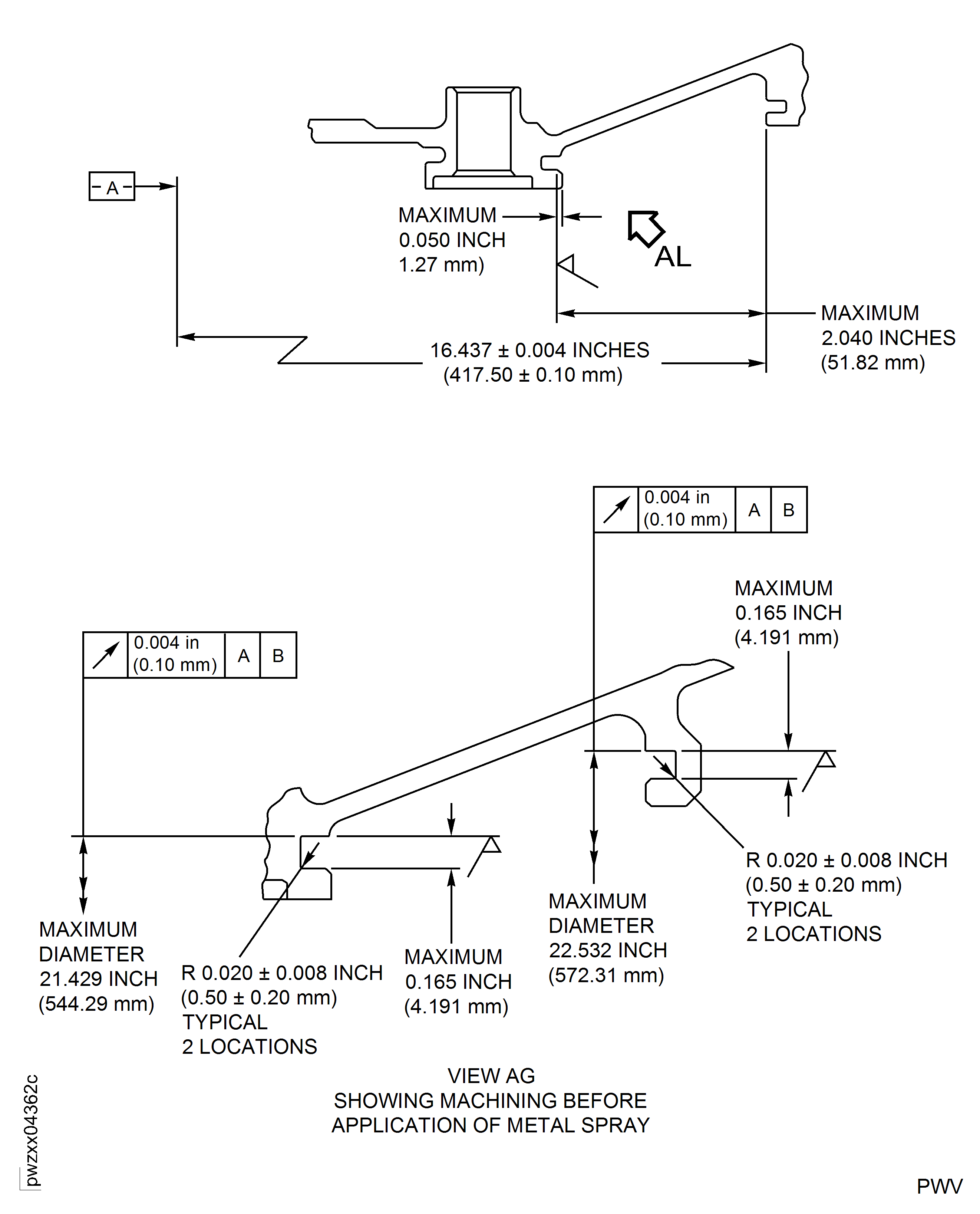

The maximum slot width before repair must not be more than 0.165 in. (4.191 mm). The maximum depth of damage on the forward location face before repair must not be more than 0.050 in. (1.27 mm).

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | X111X | DELETED | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-33-59-300-503.

Make sure that all metal spray has been removed from the slots and forward location face. It is possible that metal spray exists on other locations of the front case. Make sure all other metal spray locations are sufficiently masked.

Remove the metal spray from the HP compressor front case stage 6 rotor path ring slots and forward location face only.

SUBTASK 72-41-31-110-114 Remove the Metal Spray from the HP Compressor Front Case Stage 6 Rotor Path Ring Slots and Forward Location Face

Refer to SPM TASK 70-35-03-300-501.

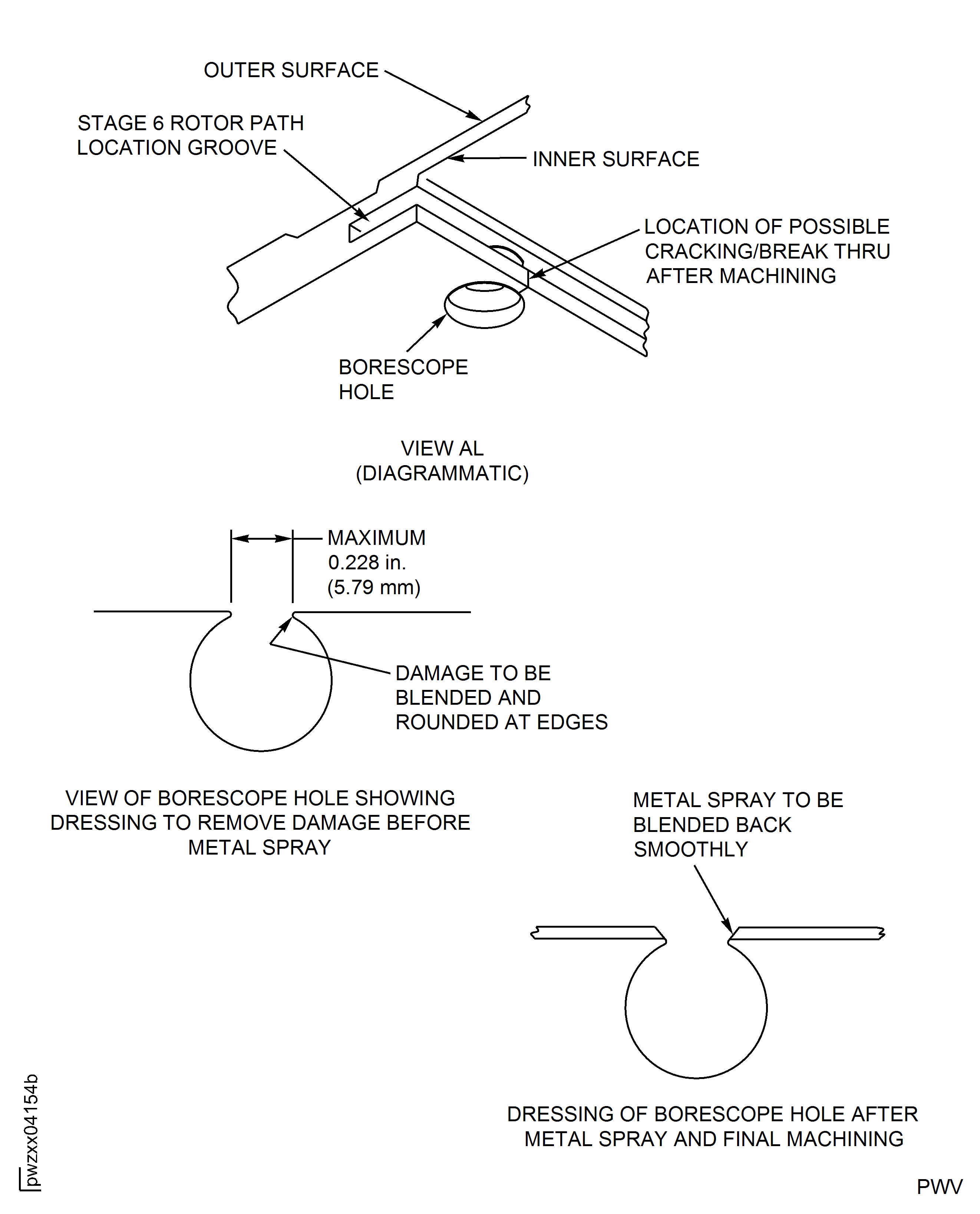

Blend damage to depth, remove no more material than is necessary to make sure a smooth surface.

NOTE

The maximum amount of material removal permitted from the forward location face is 0.050 in. (1.27 mm).

Blend to remove damage.

SUBTASK 72-41-31-350-097 Remove Damaged Area(s) from the HP Compressor Front Case Stage 6 Rotor Path Ring Slots and Forward Location Face by Blending

Use a locally made fixture.

Remove no more material than is necessary to remove the damage.

The maximum slot width after machining must not be more than 0.165 in. (4.191 mm).

Machine the rotor path ring slots to remove damage.

Use a locally made fixture.

Remove no more material than is necessary to remove the damage.

The maximum amount of material removal permitted is 0.050 in. (1.27 mm).

Machine the rotor path ring slot forward location face to remove damage.

Make sure all traces of damage are removed.

Ensure the maximum material removal limits are not exceeded.

Visually and dimensionally examine the area(s) of material removal.

SUBTASK 72-41-31-350-001 Remove Damaged Area(s) from the HP Compressor Front Case Stage 6 Rotor Path Ring Slots and/or Forward Location Face

Refer to SPM TASK 70-35-03-300-501.

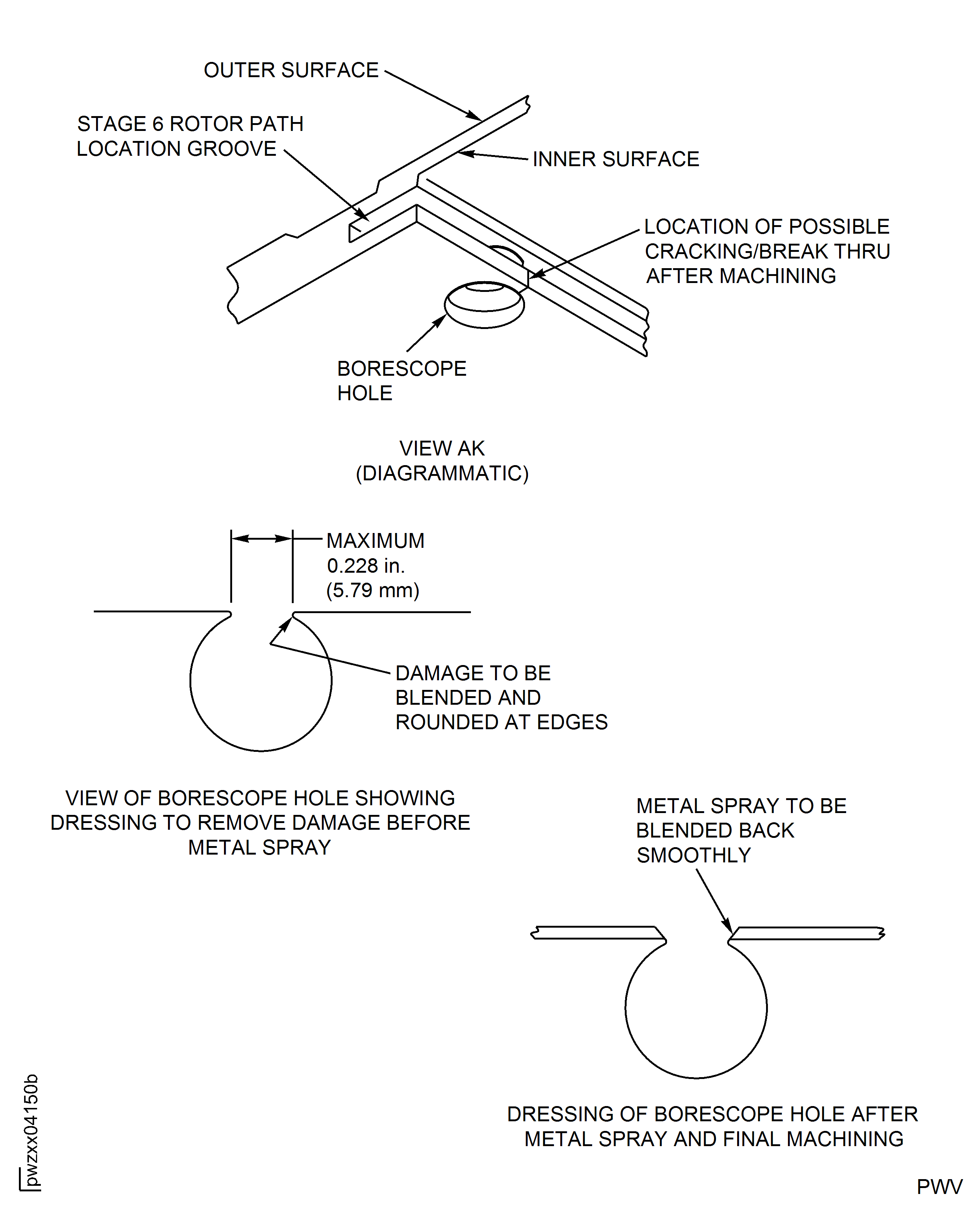

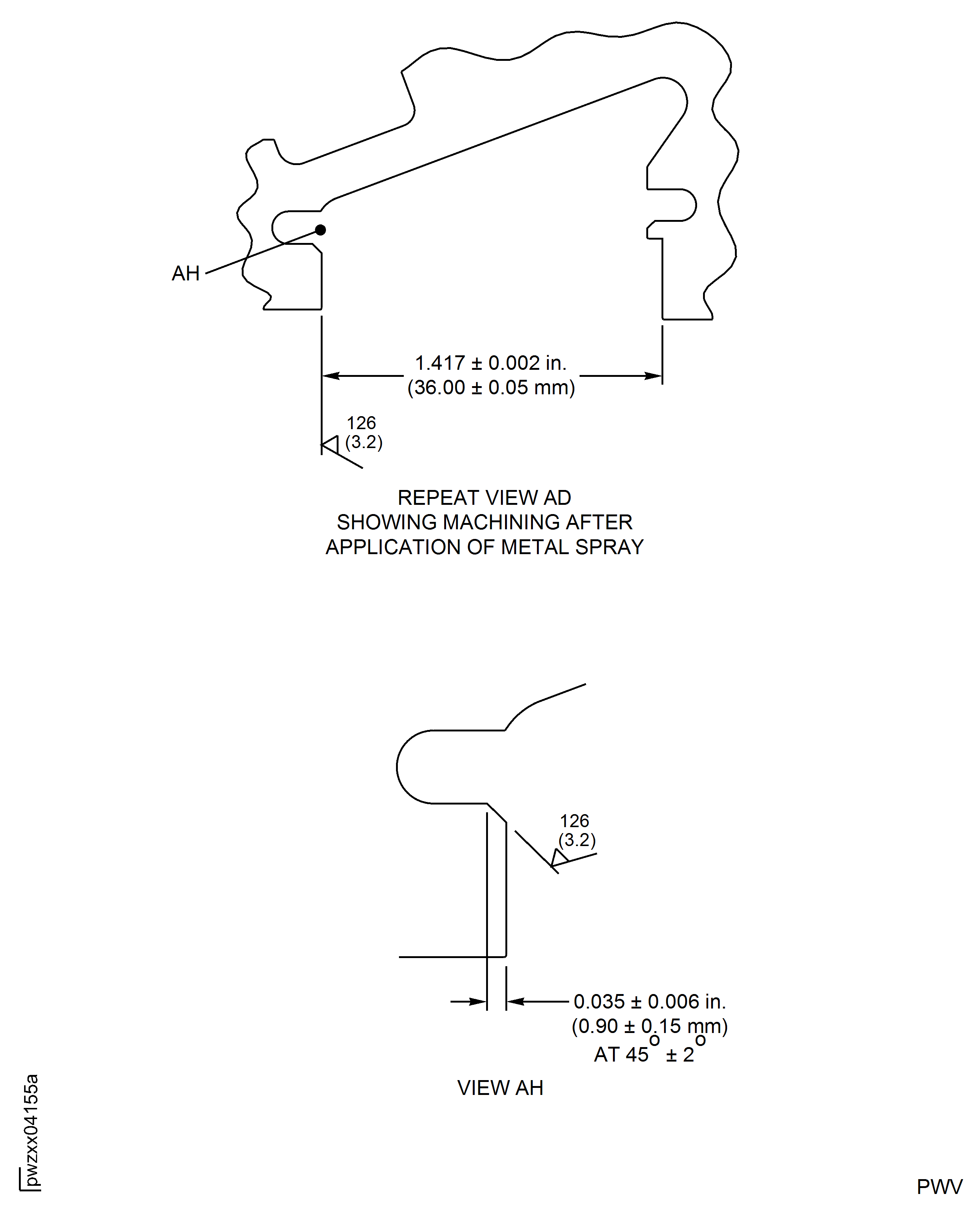

Blend the area to make sure that all sharp edges and burrs are removed.

Blend to remove damage from the borescope hole.

SUBTASK 72-41-31-350-002 Remove Damaged Area from the HP Compressor Front Case Borescope Hole

NOTE

This SUBTASK is only necessary if the borescope hole was repaired in Step.Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Chemically clean the area(s) of material removal.

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Swab etch the area(s) of material removal.

SUBTASK 72-41-31-110-132 Do a Swab Etch

Refer to SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test on the area(s) of material removal using medium sensitivity penetrant.

SUBTASK 72-41-31-230-111 Do a Crack Test

Refer to SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with Abrasive blast equipment.

Abrasive blast the surface to be repaired. Abrasive blast out of repair area is not permitted. Use Mask.

SUBTASK 72-41-31-120-064 Abrasive Blast the Surface to be Repaired

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

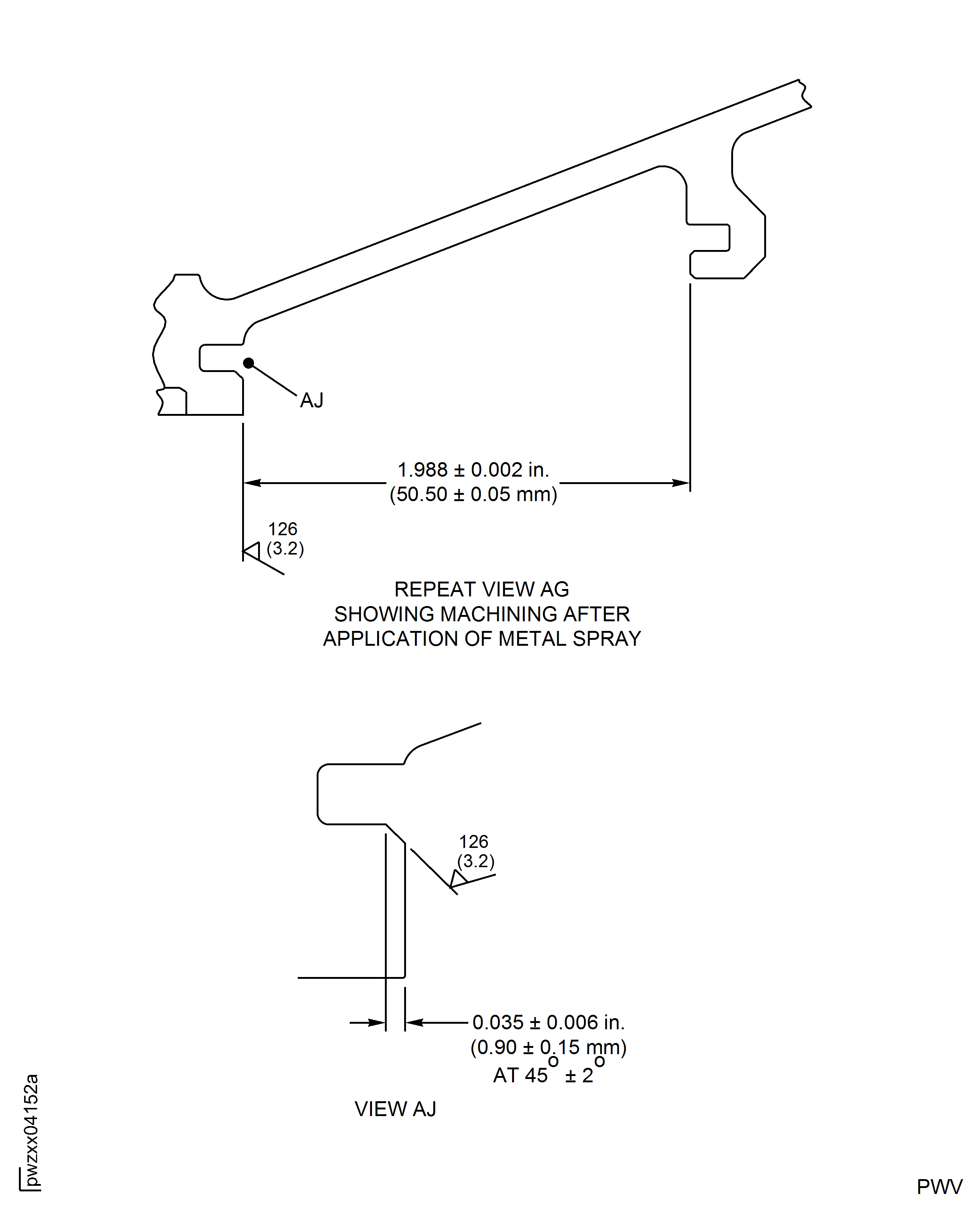

You must apply the metal spray at an angle as close to 45 degrees as possible to get maximum coverage.

A secondary spray at an angle of between 45 and 30 degrees is permissible to get full coverage.

Apply sufficient metal spray to get the final machining dimensions.

Apply metal spray.

Refer to SPM TASK 70-11-26-300-503.

After metal spray is applied and the part is cooled, remove the masking and any tape residue.

SUBTASK 72-41-31-340-058 Metal Spray the HP Compressor Front Case Stage 6 Rotor Path Ring Slots and Forward Location Face

SUBTASK 72-41-31-350-003 Remove Metal Spray from the HP Compressor Front Case Borescope Hole Area

NOTE

This SUBTASK is only necessary if the borescope hole was repaired in Step.Refer to SPM TASK 70-11-03-300-503.

SUBTASK 72-41-31-110-116 Clean the HP Compressor Front Case

Measure the dimensions to make sure they are in the given limits.

NOTE

It is possible that localized areas exist where the slot width more than the final machining dimensions given. This is permitted to a maximum of 0.007 in. (0.18 mm) above a localized arc of not more than 3.00 in. (76.20 mm) at not more than three locations in each half casing.

Measure the dimensions of the stage 6 rotor path ring slots.

SUBTASK 72-41-31-220-241 Examine the HP Compressor Front Case

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibration peen VRS6634 adjacent to the part number.

SUBTASK 72-41-31-350-099 Identify the Repair

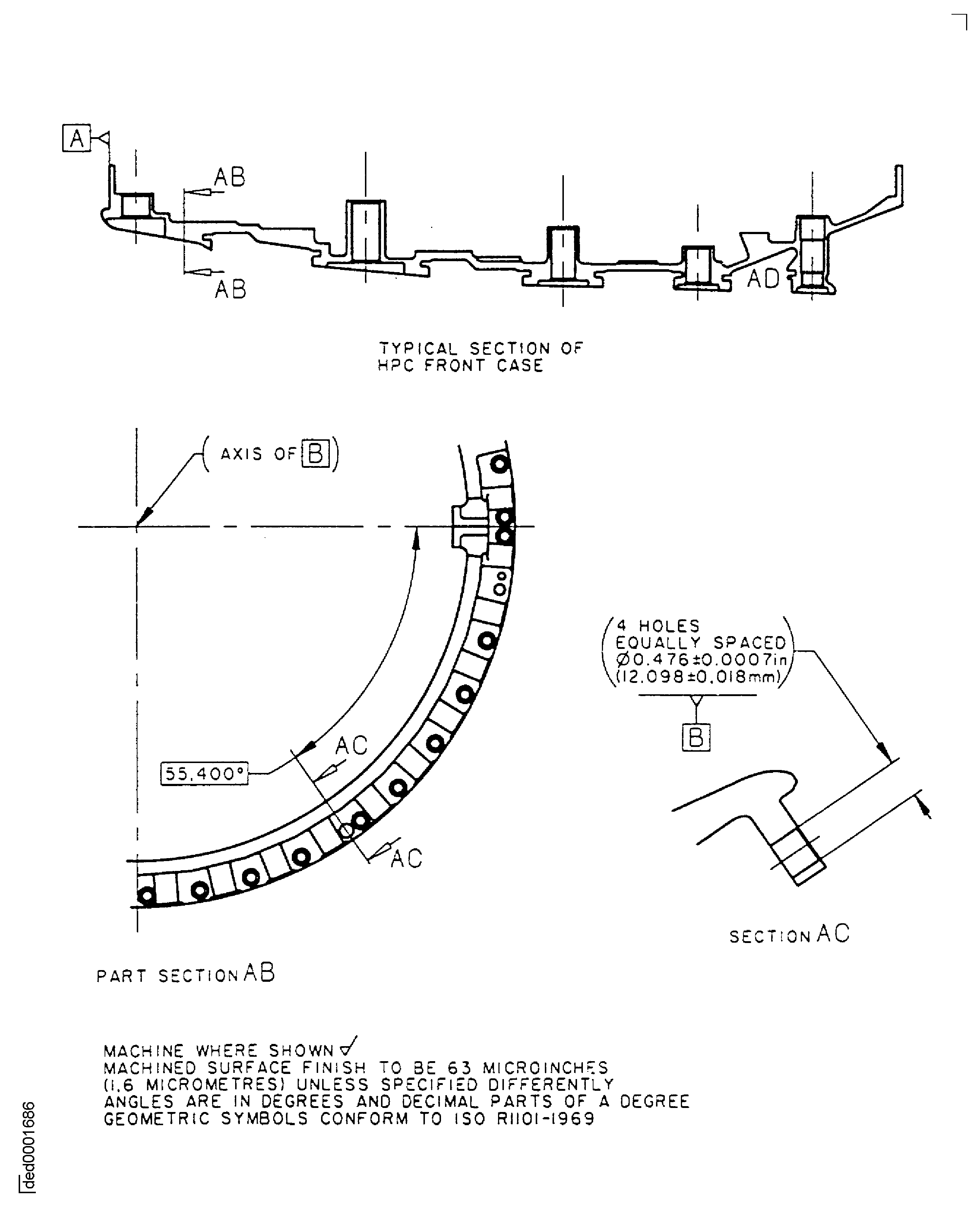

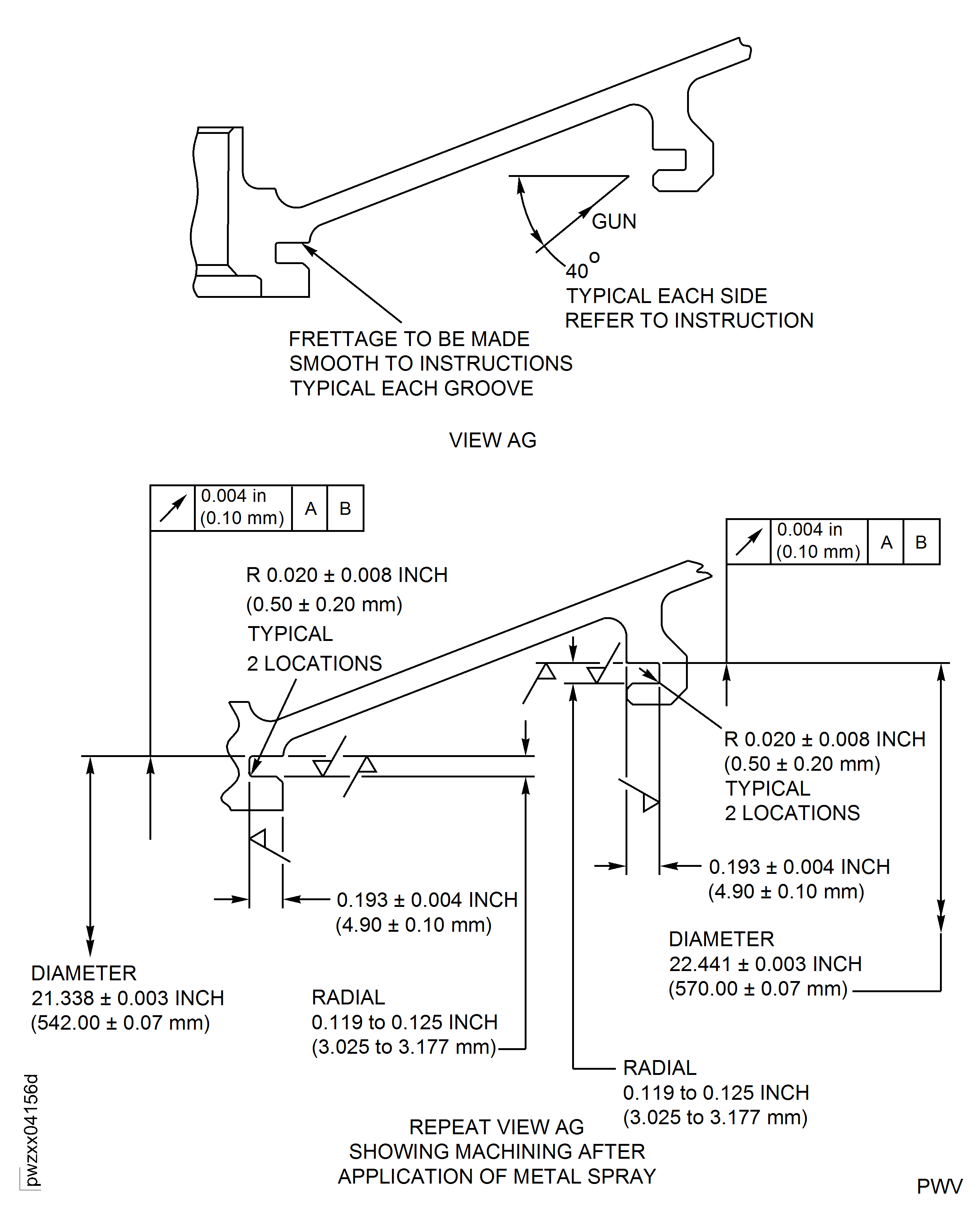

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B