Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-012 HPC Inlet Variable Stator Vane - Repair Worn/Damaged Inner And/or Outer Pivot Journal By Metal Spray, Repair-012 (VRS6181)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-500 | 6A3690 | A |

01-500 | 6A4201 | A |

01-500 | 6A5653 | B |

01-500 | 6A7723 | C |

01-500 | 6A8058 | J |

01-500 | 6A8405 | D |

01-600 | 6A3692 | B |

01-600 | 6A4203 | E |

01-600 | 6A5655 | F |

01-600 | 6A7725 | G |

01-600 | 6A8060 | K |

01-600 | 6A8407 | H |

Special tools - none

Expendable parts - none

Repair parts - none

General

This repair must only be done when the instruction to do so is given in 72-41-32 Inspection/Check.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before the repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-320 METAL SPRAYING POWDER,WC/Co | LOCAL | CoMat 03-320 | ||

| CoMat 03-456 METAL SPRAY POWDER WC-17CO | 39918 | CoMat 03-456 | ||

| DELETED | LOCAL | DELETED |

Spares

NONESafety Requirements

CAUTION

Procedure

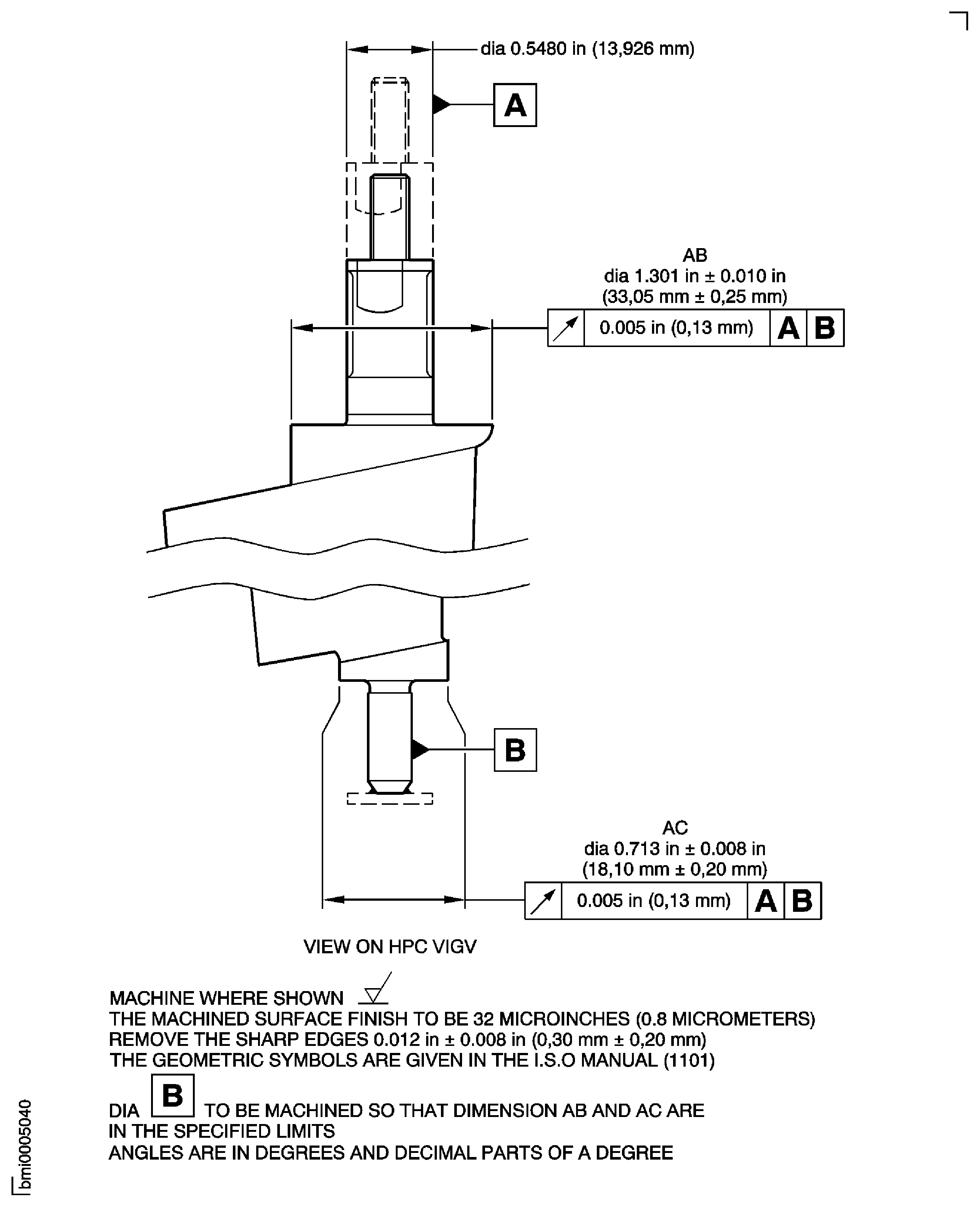

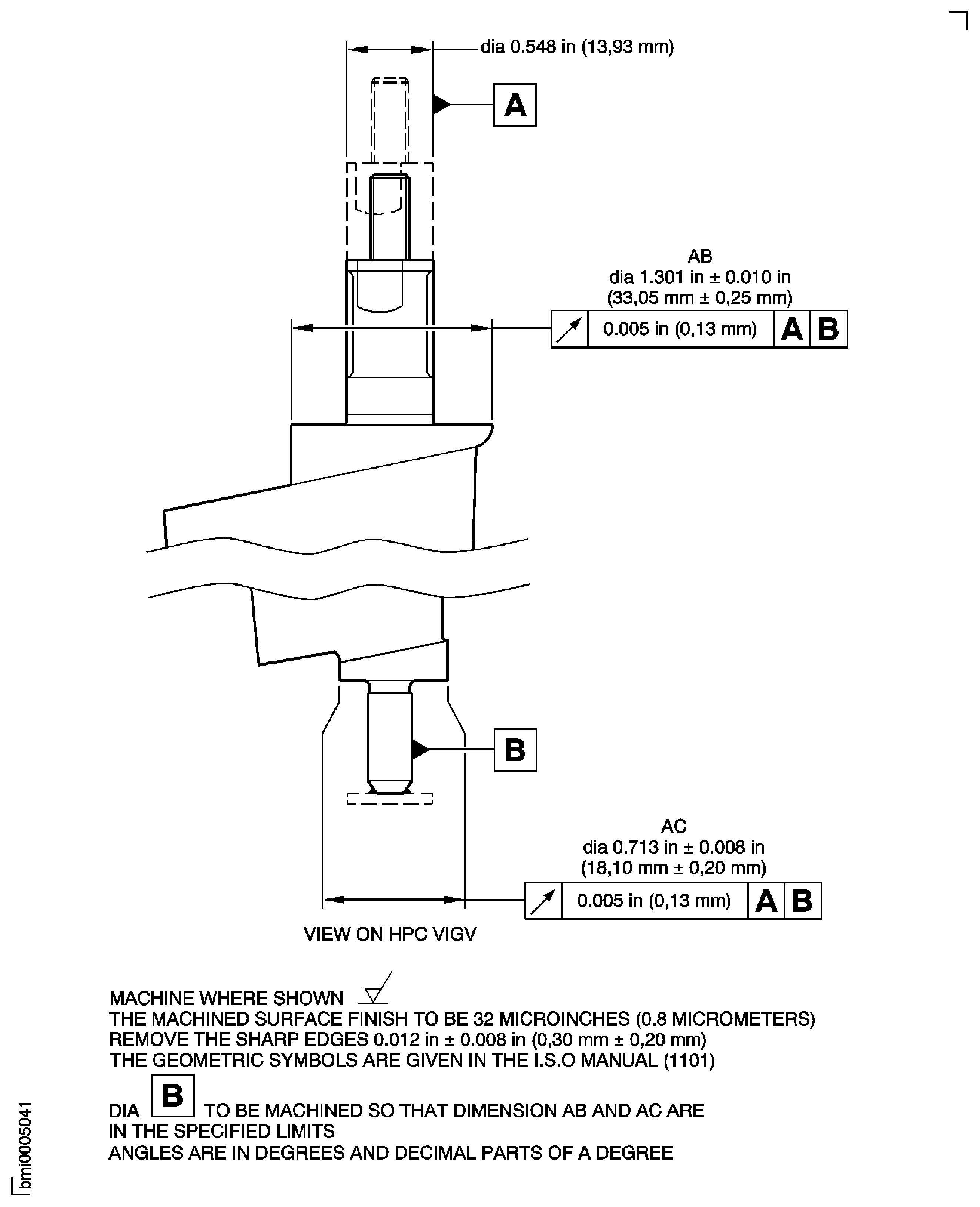

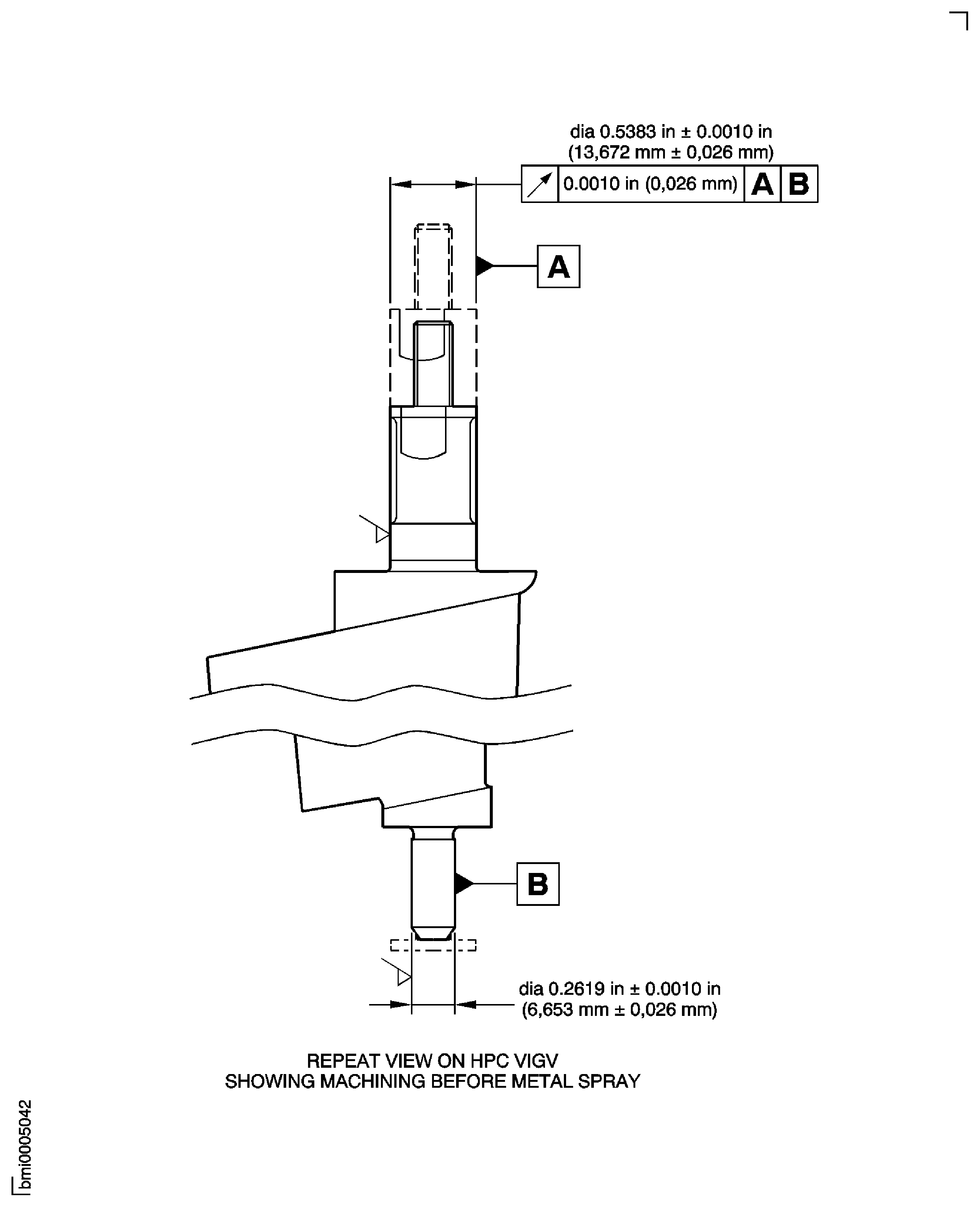

Single-point machine to remove wear from the inner and/or outer pivot journal.

NOTE

The minimum diameter of the inner pivot journal after you have removed wear and/or damage is 0.2609 in. (6.627 mm).NOTE

The minimum diameter of the outer pivot journal after you have removed wear and/or damage is 0.5373 in. (13.647 mm).

SUBTASK 72-41-32-325-055 Remove Damage from the HP Compressor Variable Inlet Guide Vane

CAUTION

DO NOT REMOVE MATERIAL FROM THE HP COMPRESSOR VARIABLE INLET GUIDE VANE INNER AND OUTER RADII.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to SPM TASK 70-11-03-300-503.

Clean the HP Compressor Variable Inlet Guide Vane

SUBTASK 72-41-32-110-091 Clean the HP Compressor Variable Inlet Guide Vane

Do not touch surface(s) to be repaired after cleaning the part.

Grit blast outside of the repair area is not permitted.

Use masks or maskants.

Refer to SPM TASK 70-34-18-380-501.

Prepare the part for coat.

SUBTASK 72-41-32-120-061 Prepare the Surfaces for Repair

CAUTION

DO NOT TOUCH SURFACE(S) TO BE REPAIRED AFTER THEY ARE CLEANED.

CAUTION

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE REPAIRED SURFACE CONDITION AND MUST BE PREVENTED.Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-014.

Apply a layer of sufficient thickness to get the correct dimensions after the component is machined.

Apply the metal spray to the HP compressor variable inlet guide vane, inner and/or outer pivot journal.

Refer to SPM TASK 70-11-26-300-503.

After the coat is applied and the part is cool remove the masks or maskants and tape residue.

SUBTASK 72-41-32-340-001 Apply the Metal Spray Coat

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Make sure there is a layer of sufficient thickness to get the correct dimensions after the component is machined.

Visually examine and measure the dimensions of the sprayed coating.

SUBTASK 72-41-32-220-151 Examine the HP Compressor Variable Inlet Guide Vane

Refer to SPM TASK 70-11-03-300-503.

Chemically clean.

SUBTASK 72-41-32-110-090 Chemically Clean

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibration peen VRS6181 adjacent to the assembly number.

SUBTASK 72-41-32-350-087 Identify the Repair

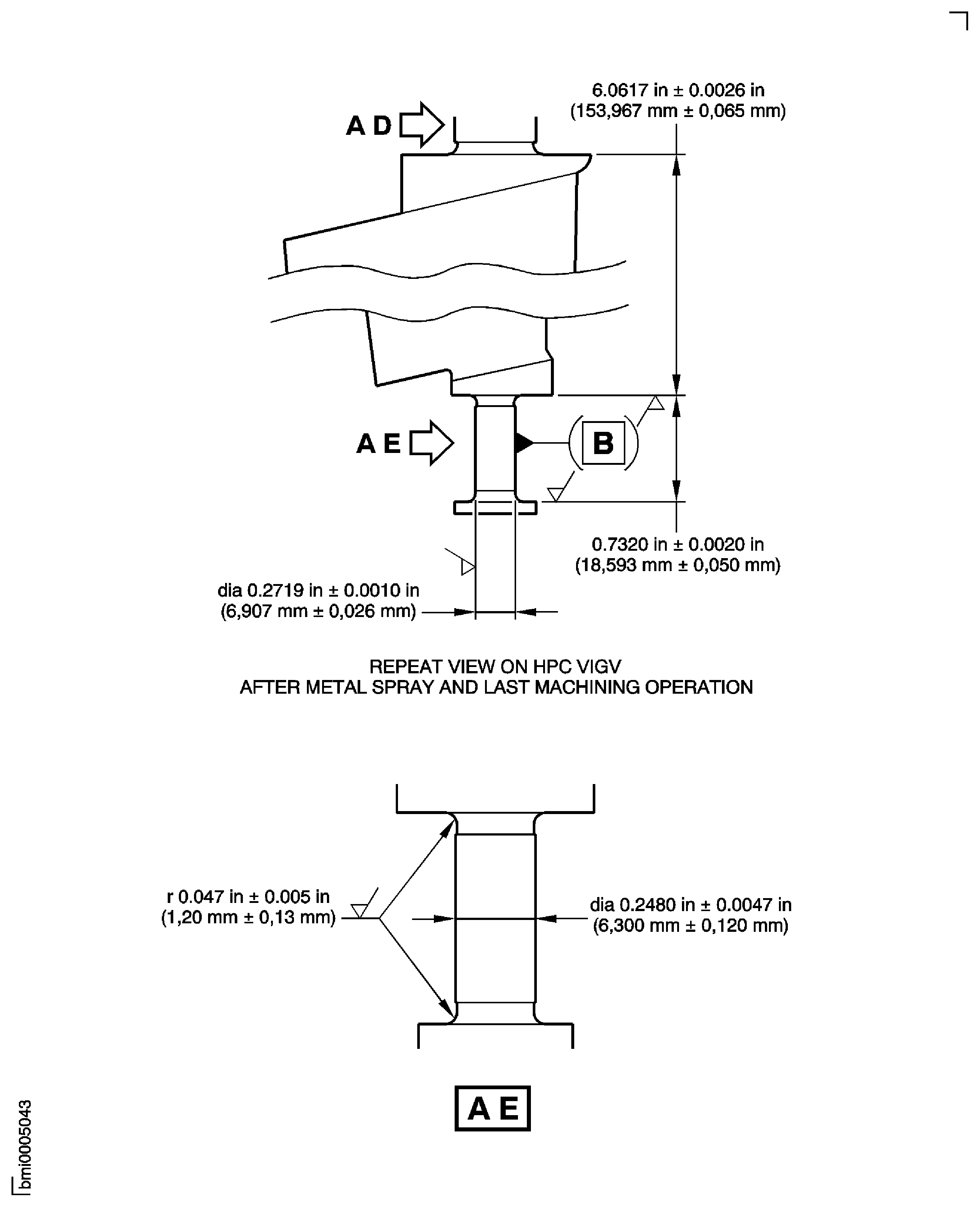

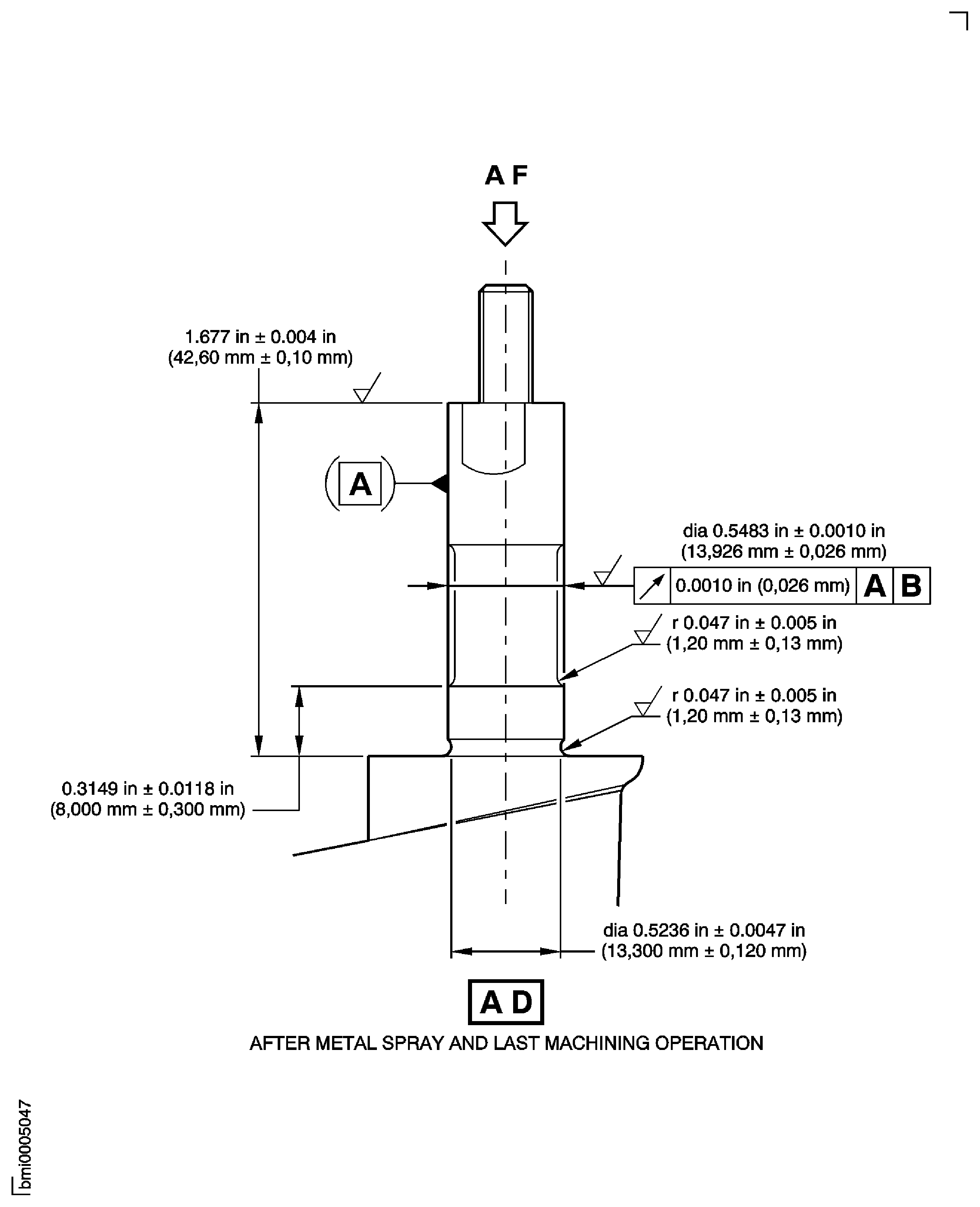

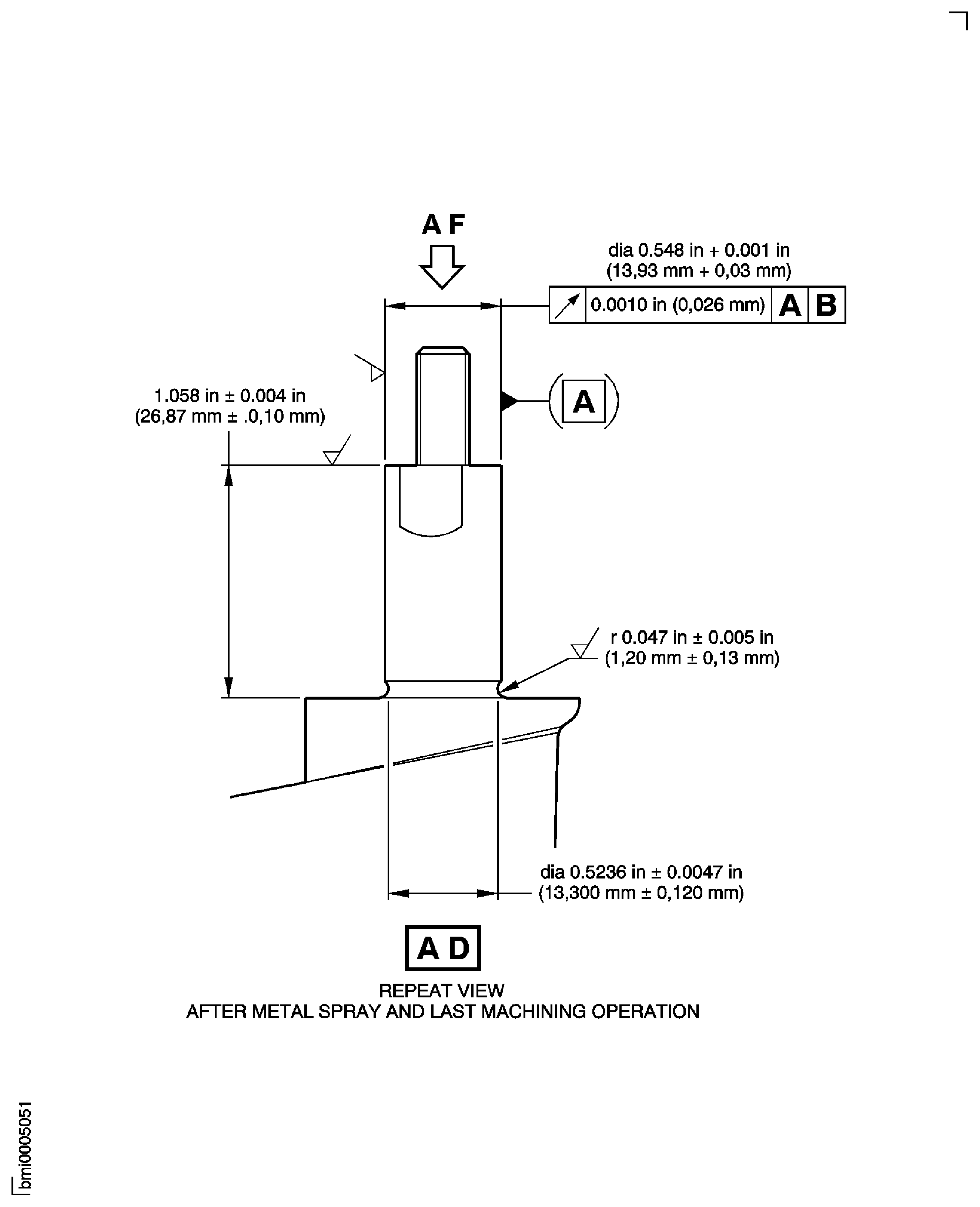

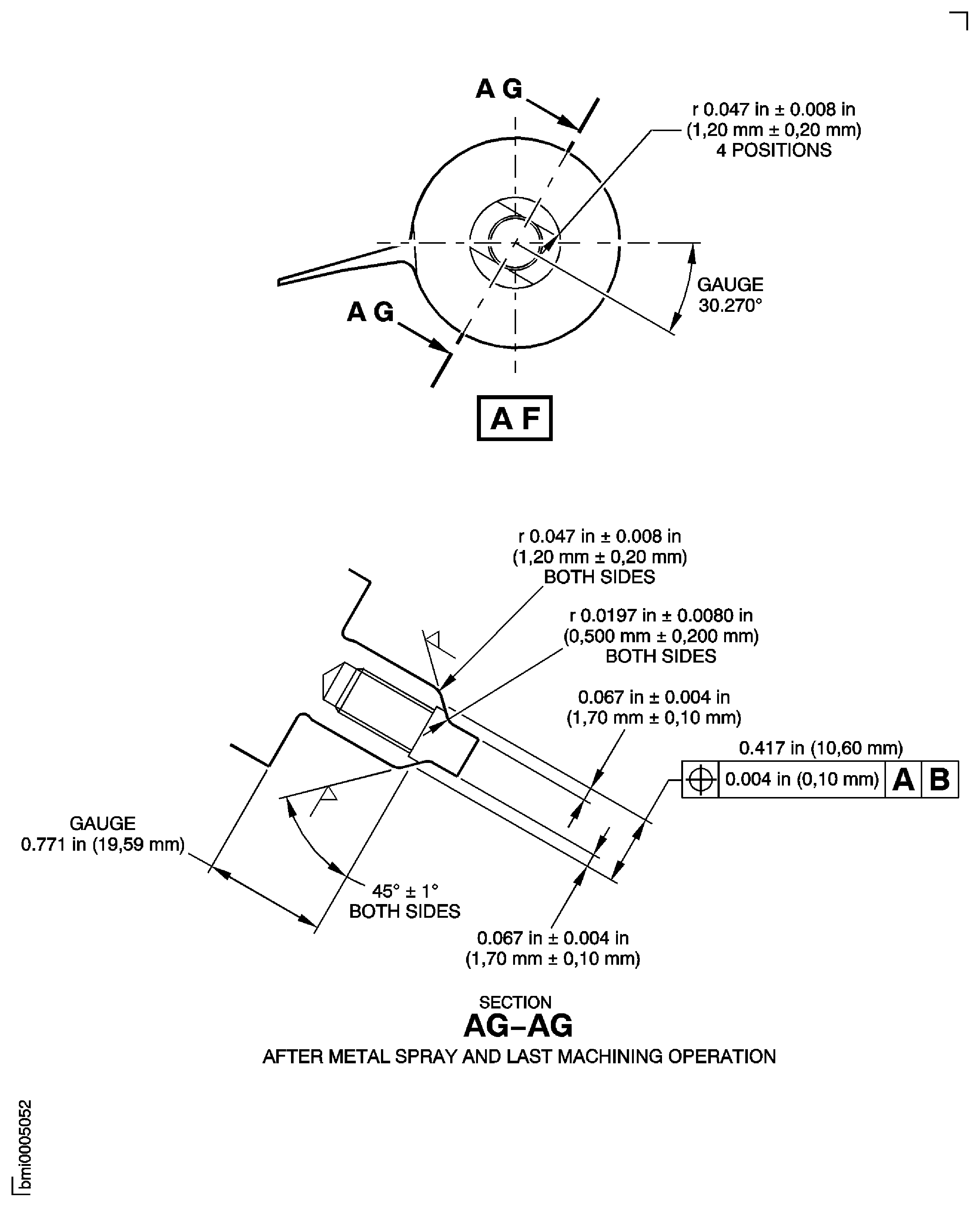

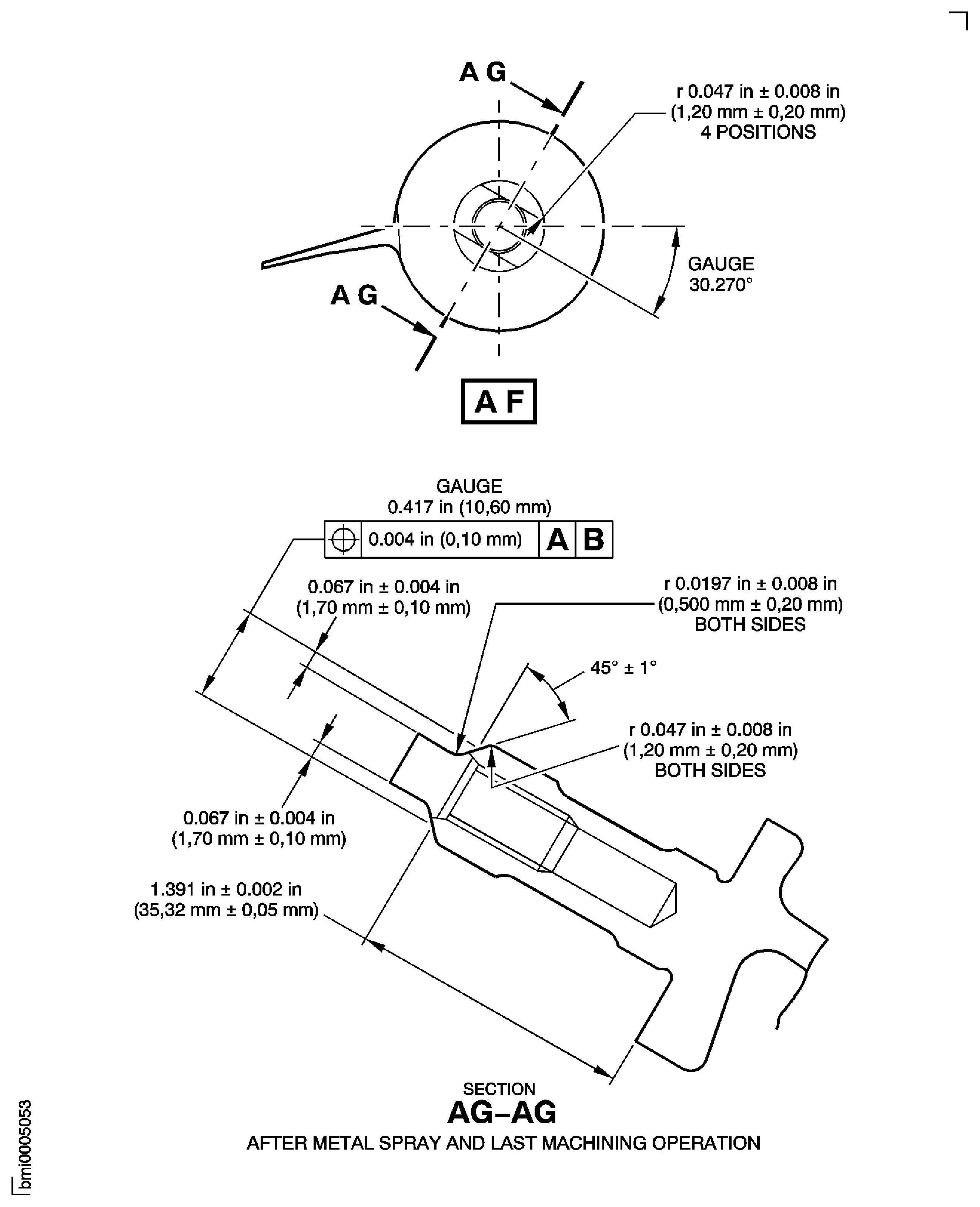

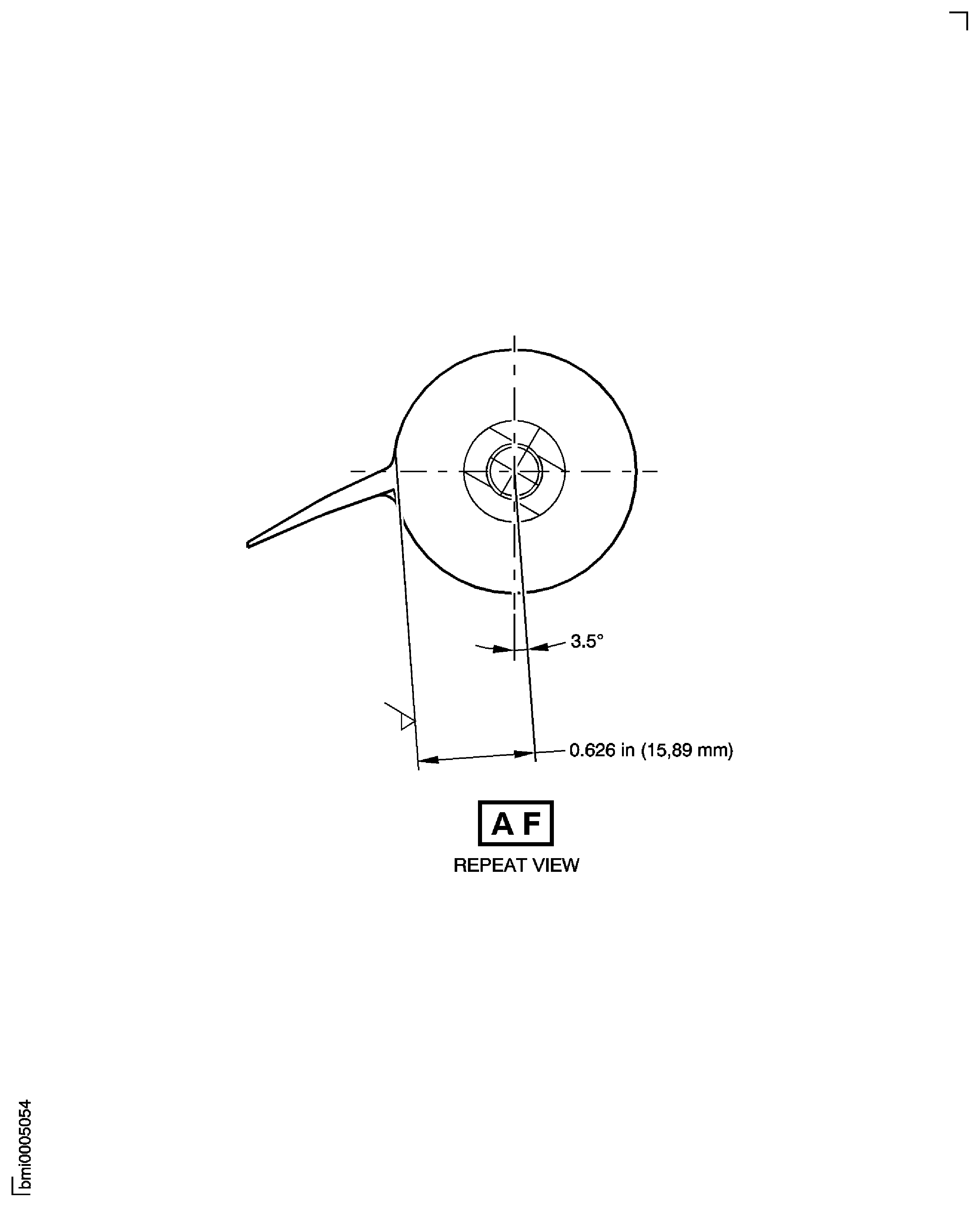

Figure: Repair Details and Dimensions - Assembly A, Assembly C, Assembly E, Assembly G, Assembly J and Assembly K

Repair Details and Dimensions - Assembly A, Assembly C, Assembly E, Assembly G, Assembly J and Assembly K

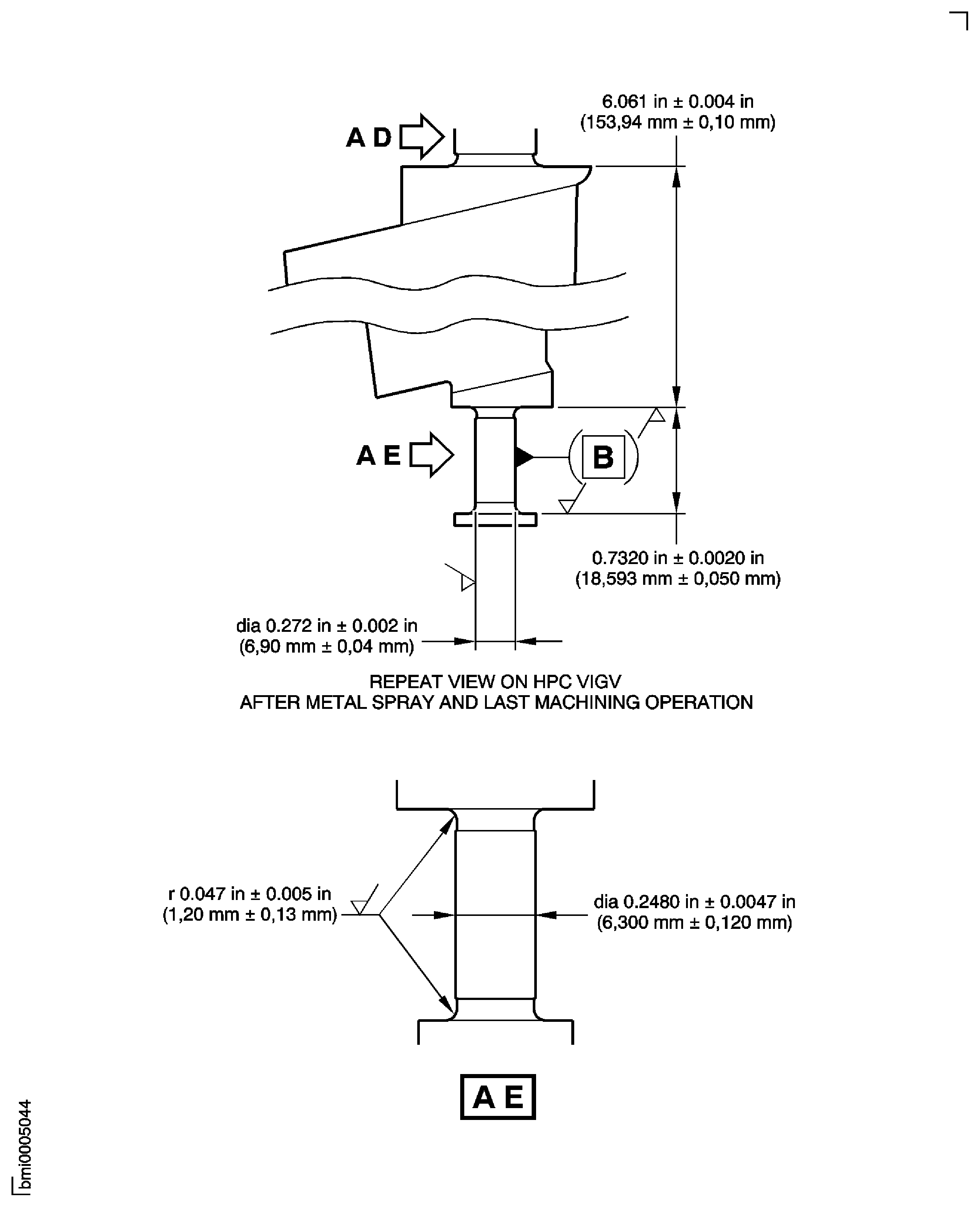

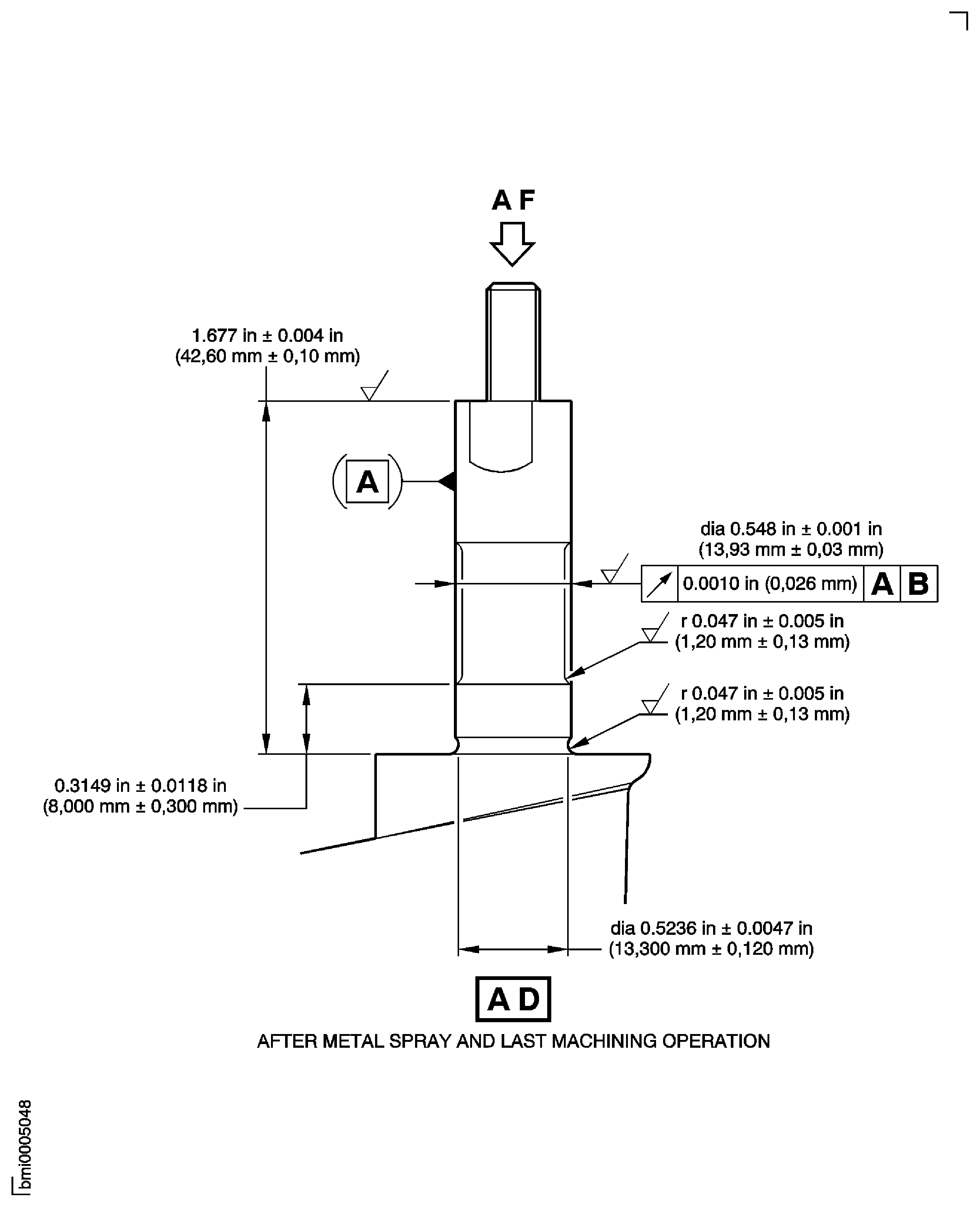

Figure: Repair Details and Dimensions - Assembly B, Assembly D, Assembly F and Assembly H

Repair Details and Dimensions - Assembly B, Assembly D, Assembly F and Assembly H

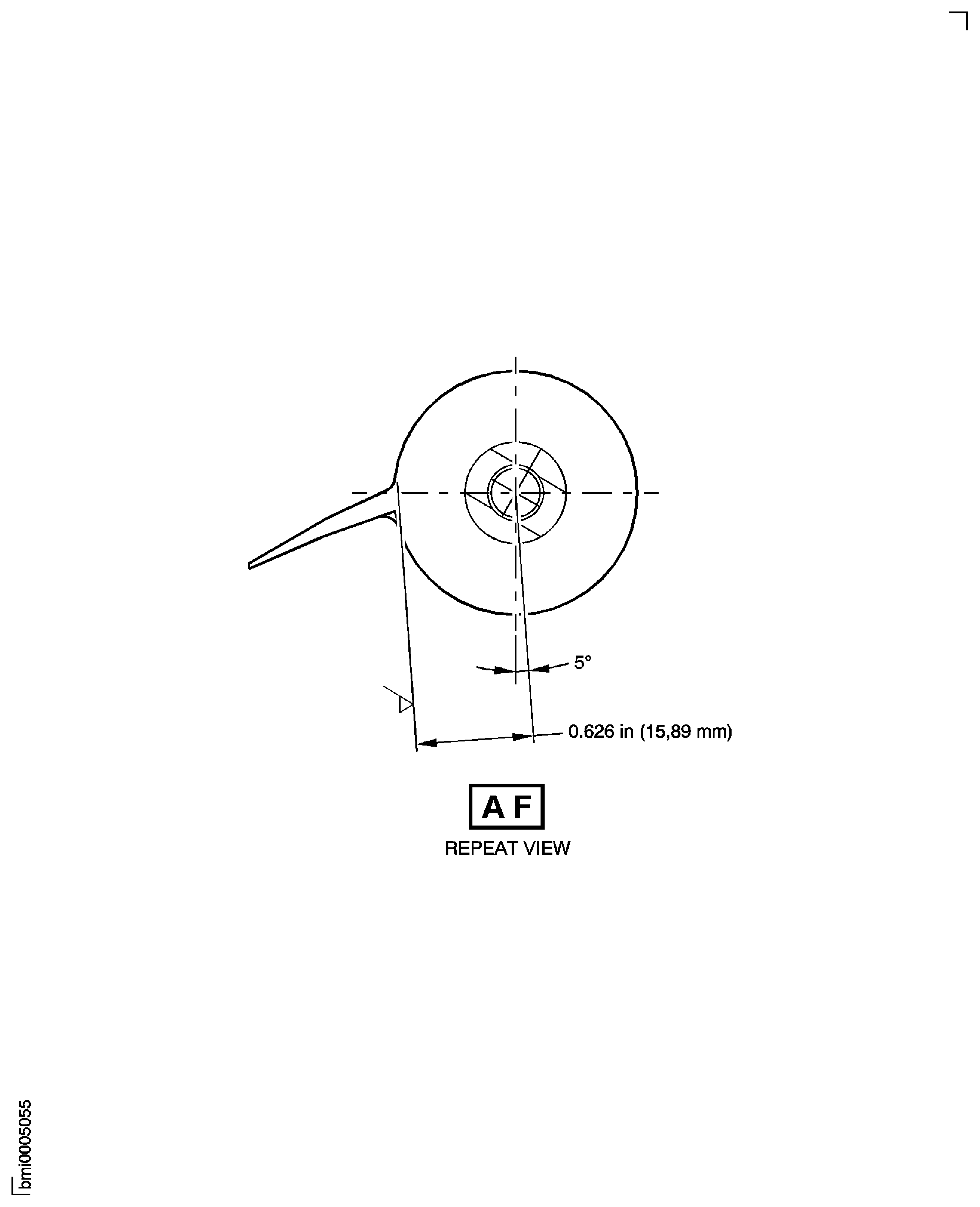

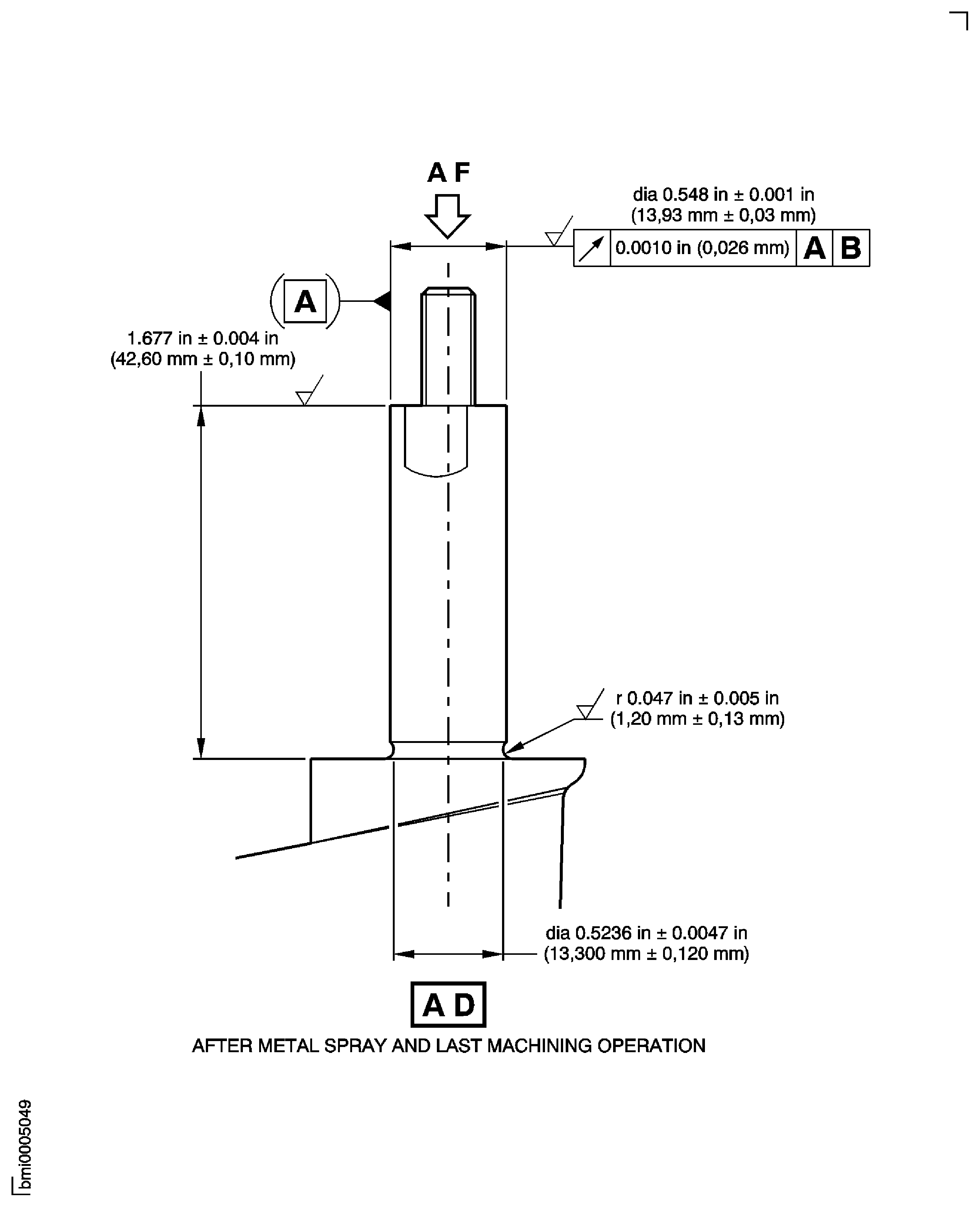

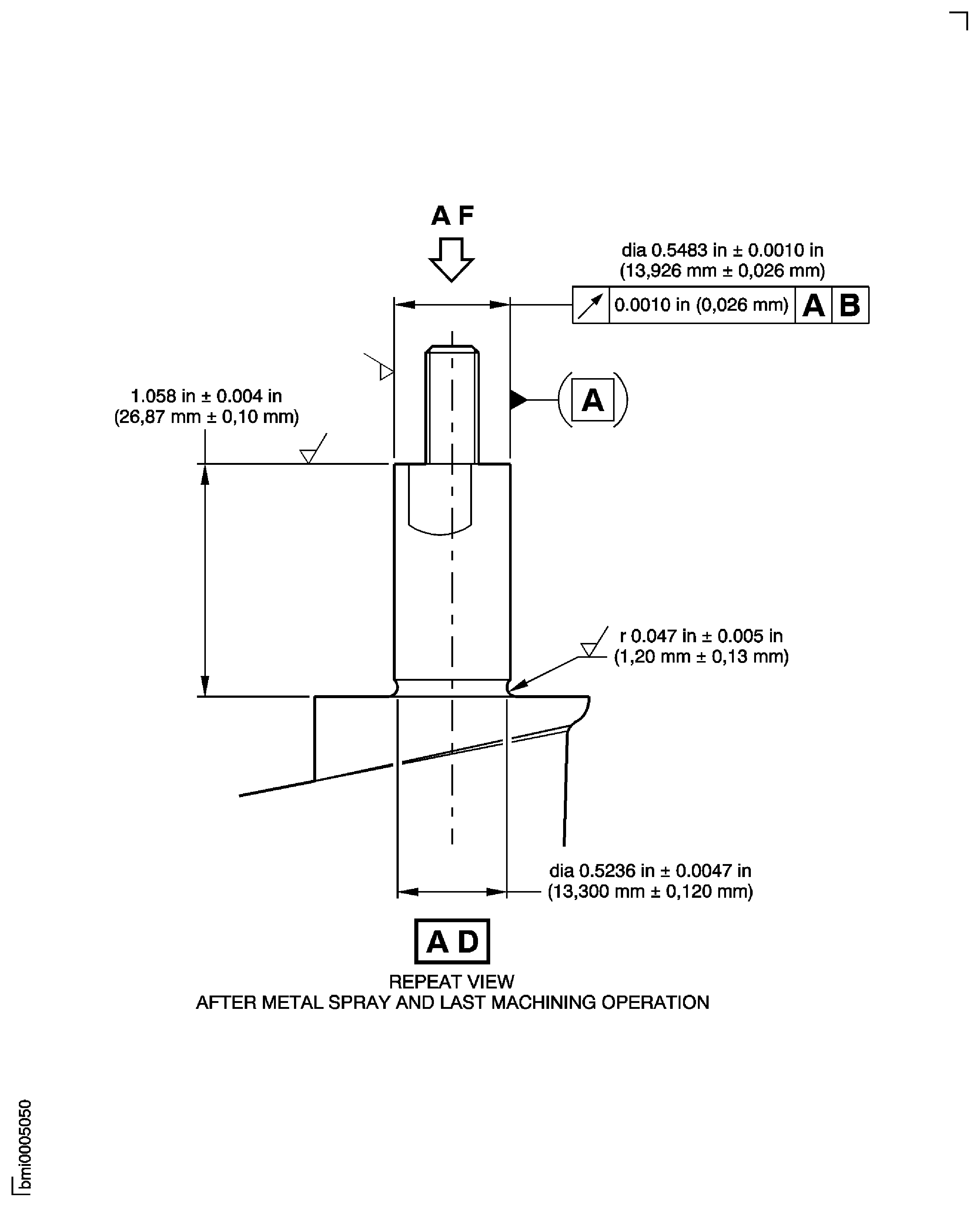

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions - Assembly A and Assembly E

Repair Details and Dimensions - Assembly A and Assembly E

Figure: Repair Details and Dimensions - Assembly B and Assembly F

Repair Details and Dimensions - Assembly B and Assembly F

Figure: Repair Details and Dimensions - Assembly C, Assembly G, Assembly J and Assembly K

Repair Details and Dimensions - Assembly C, Assembly G, Assembly J and Assembly K

Figure: Repair Details and Dimensions - Assembly D and Assembly H

Repair Details and Dimensions - Assembly D and Assembly H

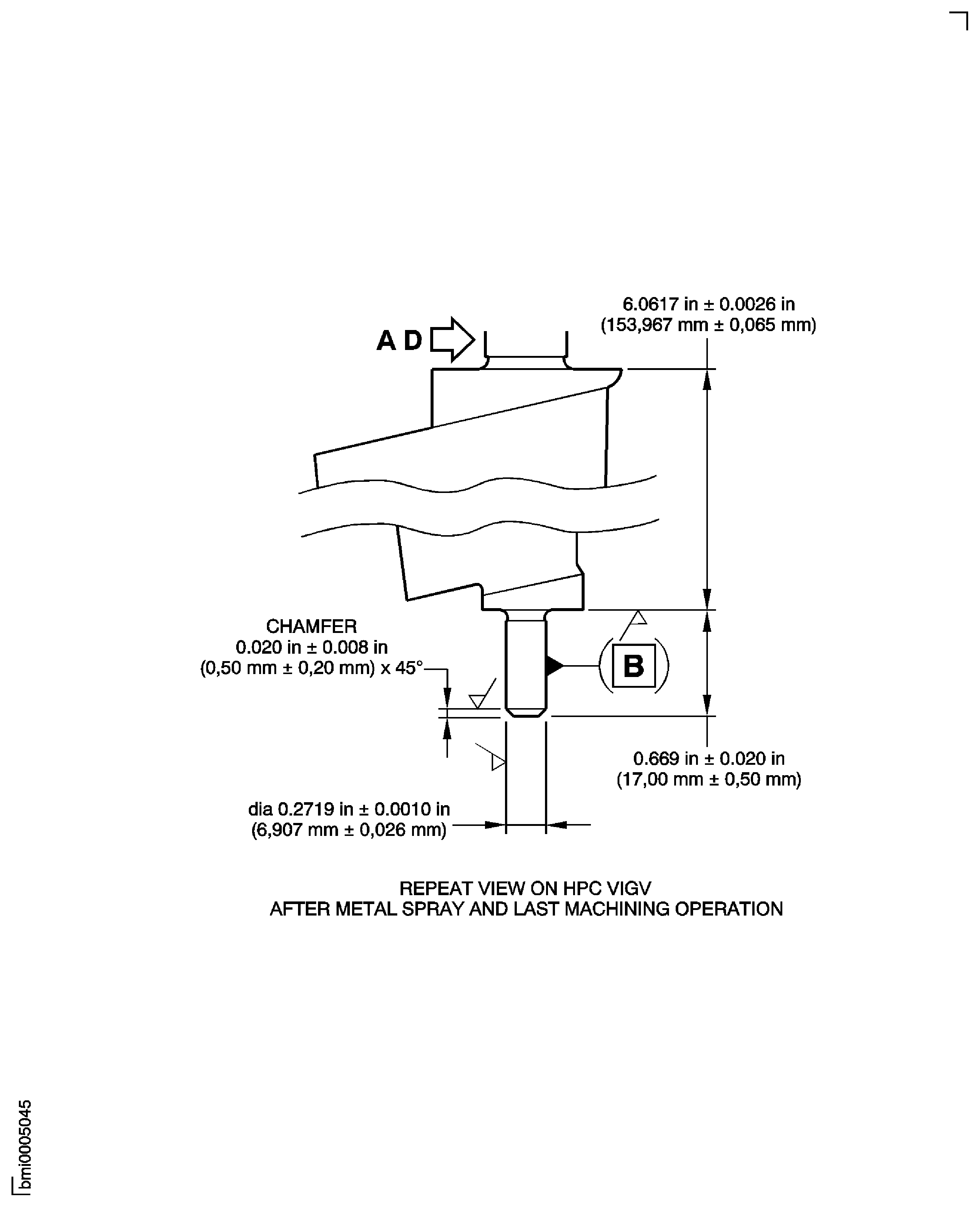

Figure: Repair Details and Dimensions - Assembly A, Assembly C and Assembly J

Repair Details and Dimensions - Assembly A, Assembly C and Assembly J

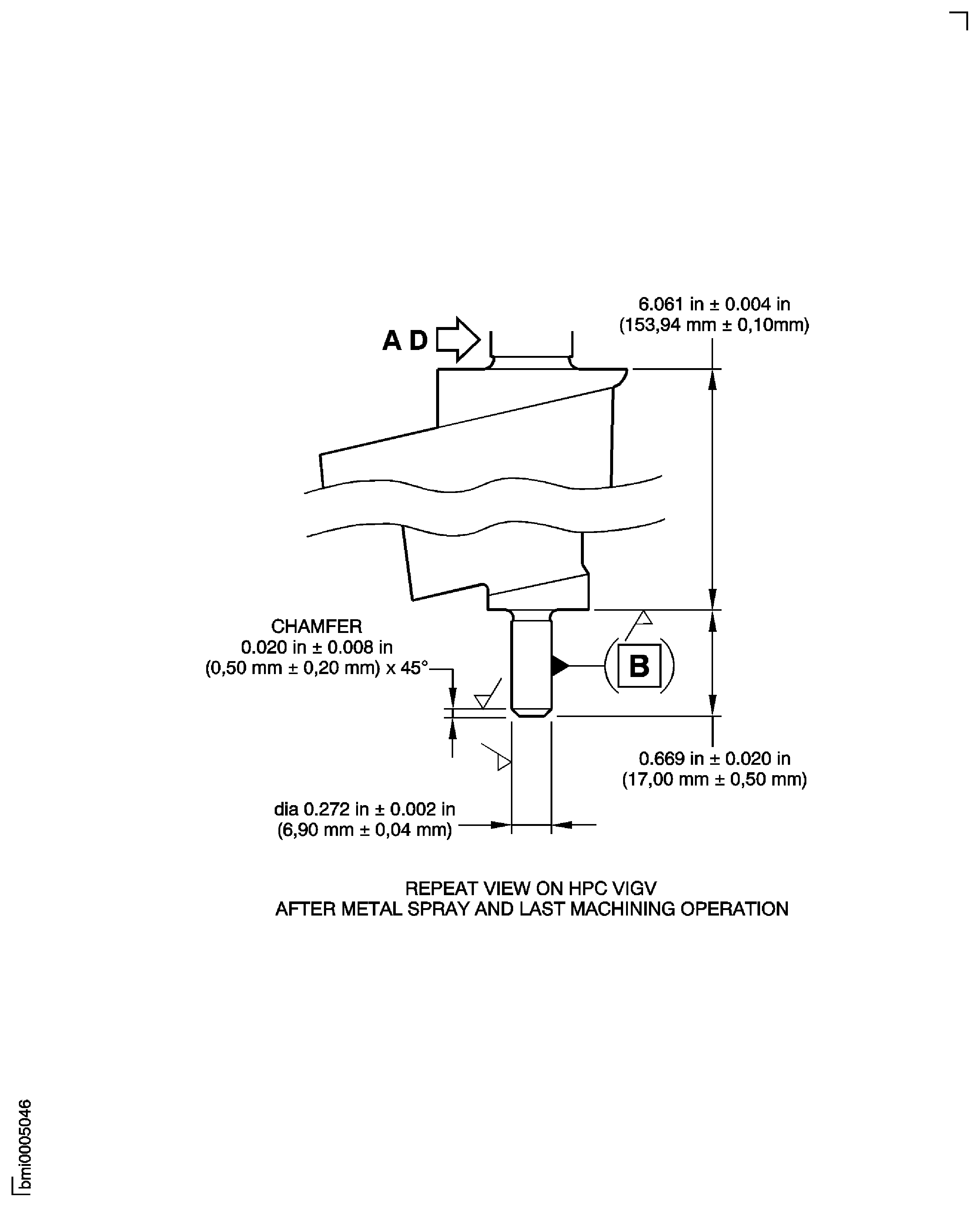

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly D

Repair Details and Dimensions - Assembly D

Figure: Repair Details and Dimensions - Assembly E, Assembly G and Assembly K

Repair Details and Dimensions - Assembly E, Assembly G and Assembly K

Figure: Repair Details and Dimensions - Assembly F and Assembly H

Repair Details and Dimensions - Assembly F and Assembly H

Figure: Repair Details and Dimensions - Assembly E, Assembly F, Assembly G, Assembly H and Assembly K

Repair Details and Dimensions - Assembly E, Assembly F, Assembly G, Assembly H and Assembly K

Figure: Repair Details and Dimensions - Assembly A, Assembly B, Assembly C, Assembly D and Assembly J

Repair Details and Dimensions - Assembly A, Assembly B, Assembly C, Assembly D and Assembly J

Figure: Repair Details and Dimensions - Assembly A, Assembly B, Assembly C, Assembly D, Assembly E, Assembly F, Assembly G and Assembly H

Repair Details and Dimensions - Assembly A, Assembly B, Assembly C, Assembly D, Assembly E, Assembly F, Assembly G and Assembly H

Figure: Repair Details and Dimensions - Assembly J and Assembly K

Repair Details and Dimensions - Assembly J and Assembly K