Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-33-300-007 HPC Stage 4 Variable Stator Vane Shroud - Replace The Lining On The Shroud Or The Half Seal, Repair-007 (VRS6039)

Material of component

PART IDENT | MATERIAL |

|---|---|

HP compressor stage 4 half ring seal or half shroud assembly | Aluminium alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-33, Inspection/Check.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-057 ALUMINIUM ALLOY/POLYESTERCOMPOSITE | LOCAL | CoMat 03-057 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| DELETED | LOCAL | DELETED |

Spares

NONESafety Requirements

NONEProcedure

Remove the bond coat by a chemical strip process. Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-002 and SUBTASK 70-33-59-300-008 or SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-005.

Remove the bond coat by dry single-point machining.

Remove the remaining bond coat by one of the methods that follow.

SUBTASK 72-41-33-350-081 Remove the Bond Coat

CAUTION

THE CHEMICAL STRIP PROCESS CAN CAUSE DAMAGE TO THE PART.Refer to the SPM TASK 70-11-03-300-503.

SUBTASK 72-41-33-110-067 Chemically Clean the Part

Cracks are not permitted.

Do a fluorescent penetrant inspection of the repair area by the applicable part number task in TASK 72-41-33-200-000 (INSPECTION-000).

SUBTASK 72-41-33-230-065 Do a Crack Test

For powder feed plasma spray gun use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for wire feed combustion spray use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Apply a thickness of 0.0030 in. to 0.0050 in. (0.076 mm to 0.127 mm).

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-010.

Apply the bond coat.

Apply sufficient thickness to allow for machining.

Also spray a test piece to check the spray hardness.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-020.

Apply the lining.

Refer to the SPM TASK 70-11-26-300-503.

After the coat is applied and the part is cooled, remove the mask.

SUBTASK 72-41-33-340-051-A00 Apply the Lining, Assembly A and Assembly B

For powder feed plasma spray gun use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for wire feed combustion spray use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Apply a thickness of 0.0030 in. to 0.0050 in. (0.076 mm to 0.127 mm).

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-010.

Apply the bond coat.

Apply sufficient thickness to allow for machining.

The thickness of the abradable lining must not be more than a maximum of 0.126 in. (3.20 mm).

Also spray a test piece to examine the spray hardness.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-020.

Apply the lining.

Refer to the SPM TASK 70-11-26-300-503.

After the coat is applied and the part is cooled, remove the mask.

SUBTASK 72-41-33-340-051-B00 Apply the Lining, Assembly C

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the lining.

The average hardness must be 55 to 85 R15Y with the outer limits of 50 minimum to 90 maximum.

Refer to the SPM TASK 70-34-01-340-501.

Do a hardness test on the test piece.

SUBTASK 72-41-33-220-114 Examine the Lining

Refer to the SPM TASK 70-34-01-340-501.

Visually and dimensionally examine the lining.

SUBTASK 72-41-33-220-115 Examine the Lining

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibration peen VRS6039 adjacent to the part number.

SUBTASK 72-41-33-350-058 Identify the Repair

Refer to the SPM TASK 70-38-02-300-503.

Apply the corrosion protection as required.

SUBTASK 72-41-33-380-054 Apply the Corrosion Protection

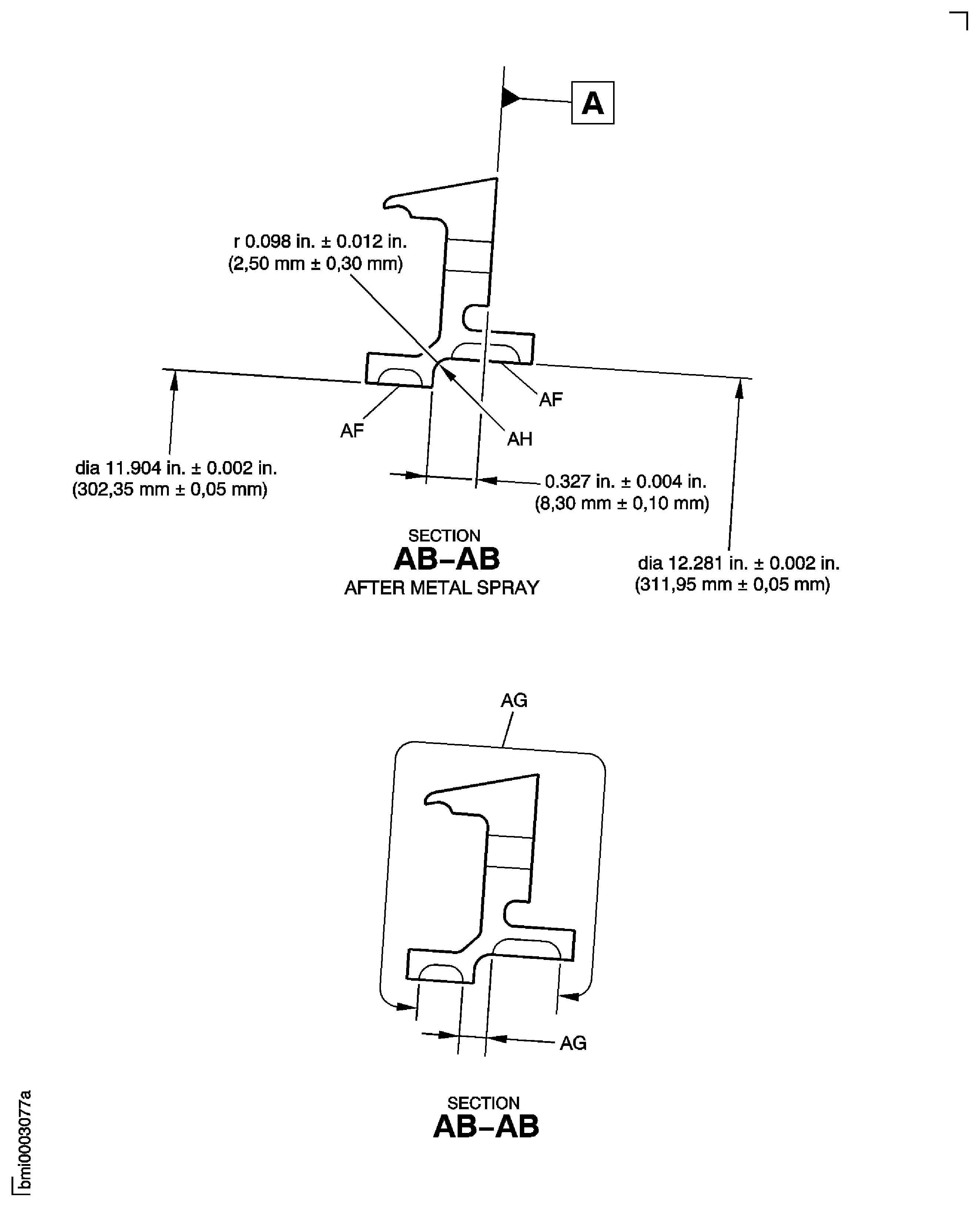

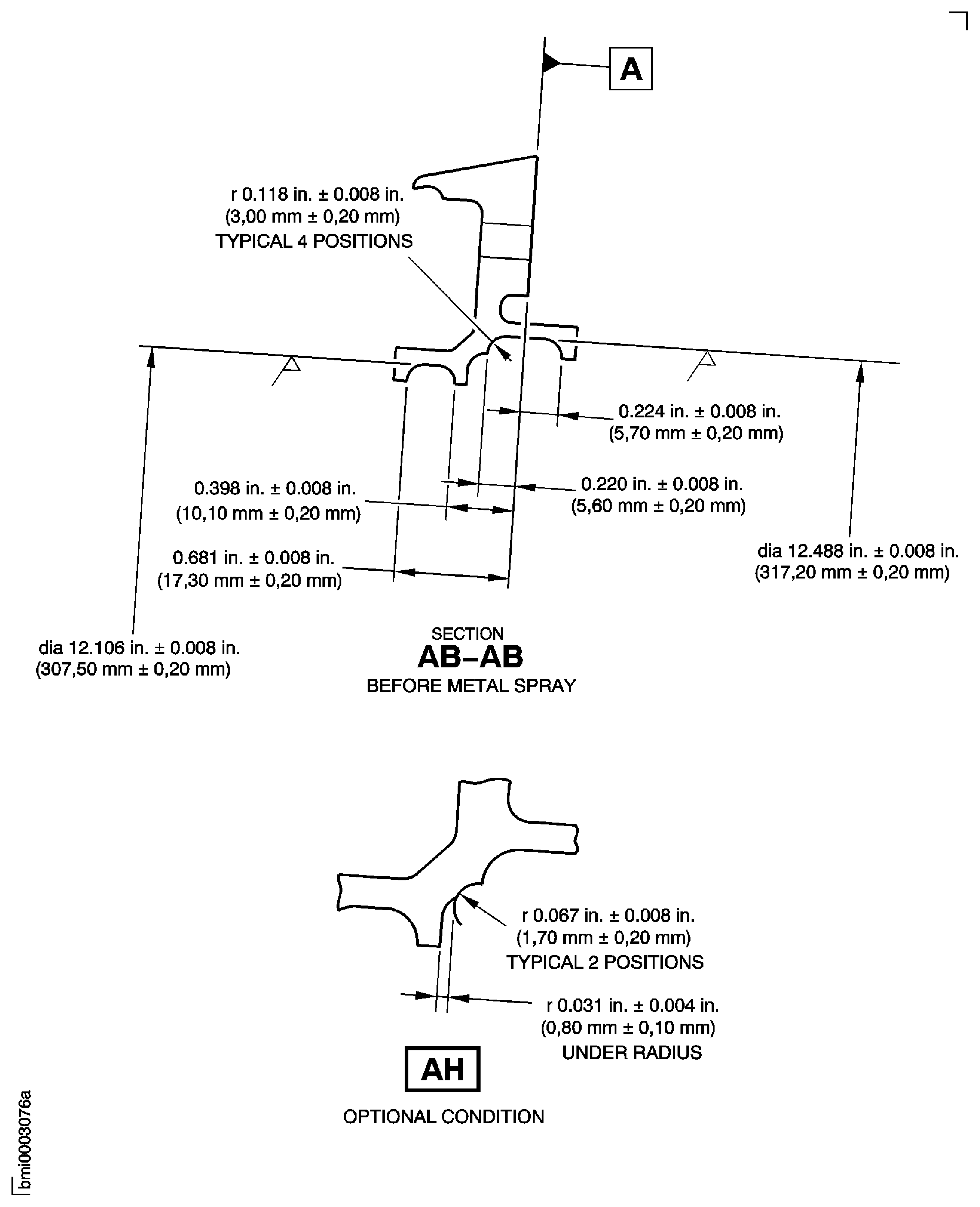

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Sheet 1

Figure: Repair Details and Dimensions - Assembly A

Sheet 2

Figure: Repair Details and Dimensions - Assembly A

Sheet 3

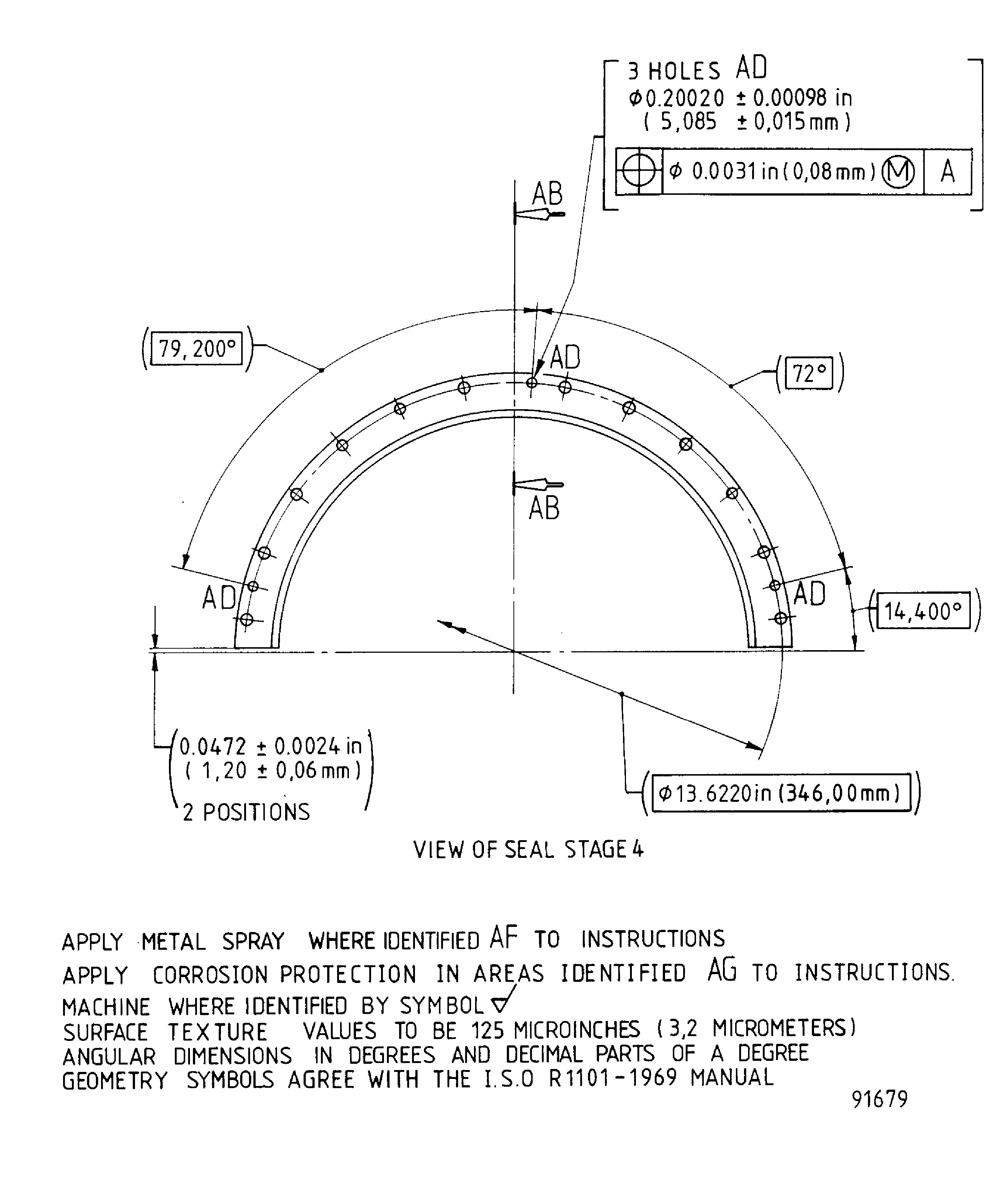

Figure: Repair Details and Dimensions - Assembly B

Sheet 4

Figure: Repair Details and Dimensions - Assembly C

Sheet 5

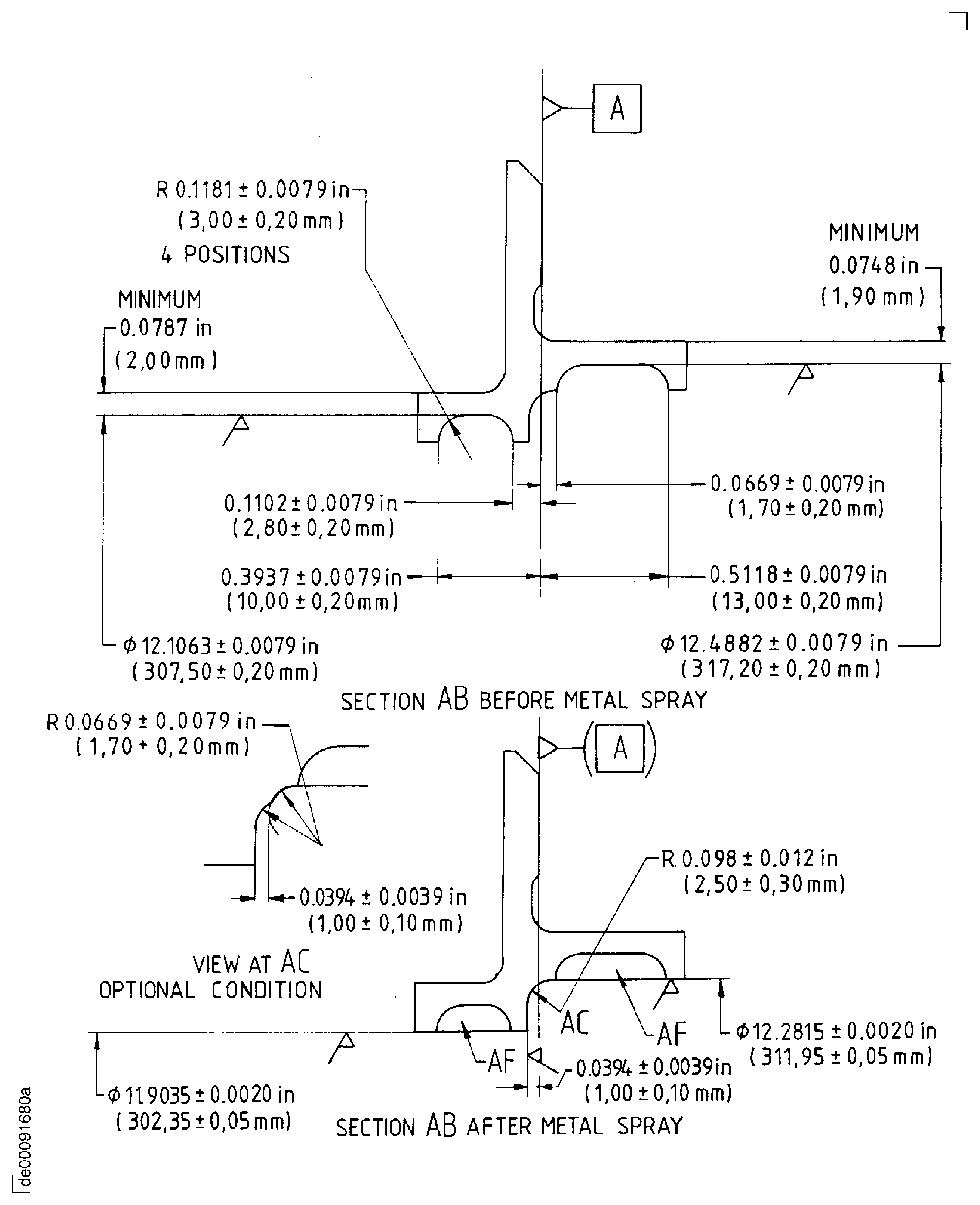

Figure: Repair Details and Dimensions - Assembly B

Sheet 6

Figure: Repair Details and Dimensions - Assembly C

Sheet 7

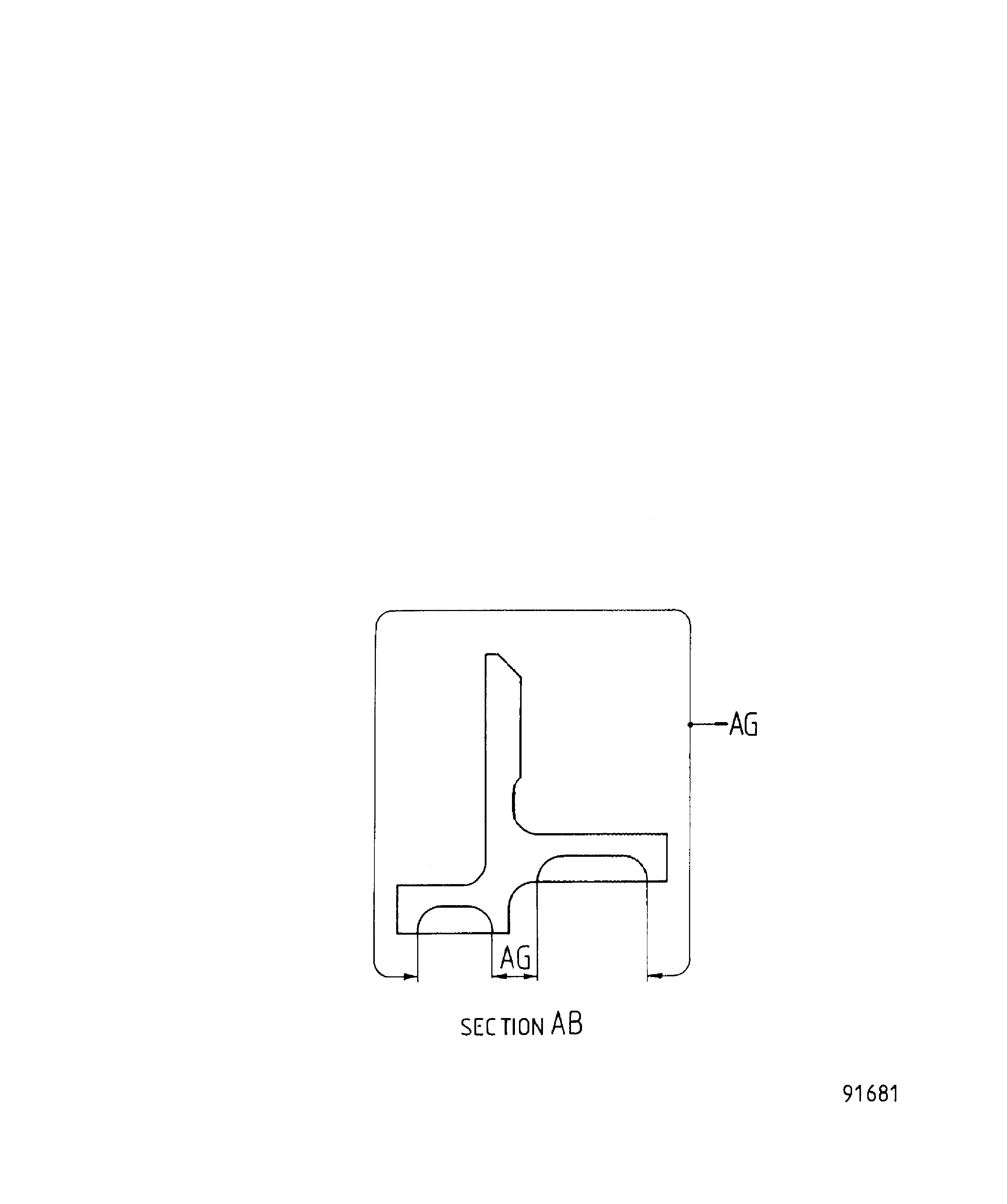

Figure: Repair Details and Dimensions - Assembly B and Assembly C

Sheet 8