Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-015 HPC Vane Actuating Crankshaft Bearing Housings - Replace The Bearing In The Front Housing, Repair-015 (VRS6239)

Material of component

The front bearing housing is made of jethete.

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-34, Inspection.

This Repair can only be done five times. If the part is identified as VRS6239/4, it can not be repaired.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines.

Related repairs

HP Compressor Front and Rear Housing Assembly - Replacement of Surface Protection. Refer to TASK 72-41-34-300-033 (VRS6356).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Milling machine | LOCAL | Milling machine | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Paint brush | LOCAL | Paint brush | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Drill | LOCAL | Drill | 0.114 in. (2.9 mm) Dia. | |

| Reamer | LOCAL | Reamer | 0.118 in. (3.0 mm) Dia. | |

| End mill | LOCAL | End mill | 0.472 in. (12.0 mm) Dia. |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-131 INDICATOR | LOCAL | CoMat 01-131 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-031 STOPPING-OFF CRAYON | LOCAL | CoMat 03-031 | ||

| CoMat 03-124 FLAME SPRAY NICKEL-ALUMINUM(78 Ni-22 Al) | 39918 | CoMat 03-124 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 | ||

| CoMat 10-110 HIGH TEMPERATURE ANTI-SEIZE COMPOUND | K6835 | CoMat 10-110 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Retaining Ring | RRN362 | 1 | ||

| Pin | AS20643 | 1 | ||

| Bearing | 03-413-40E001 | 1 | ||

| Bearing | 03-413-45E001 | 1 |

Safety Requirements

NONEProcedure

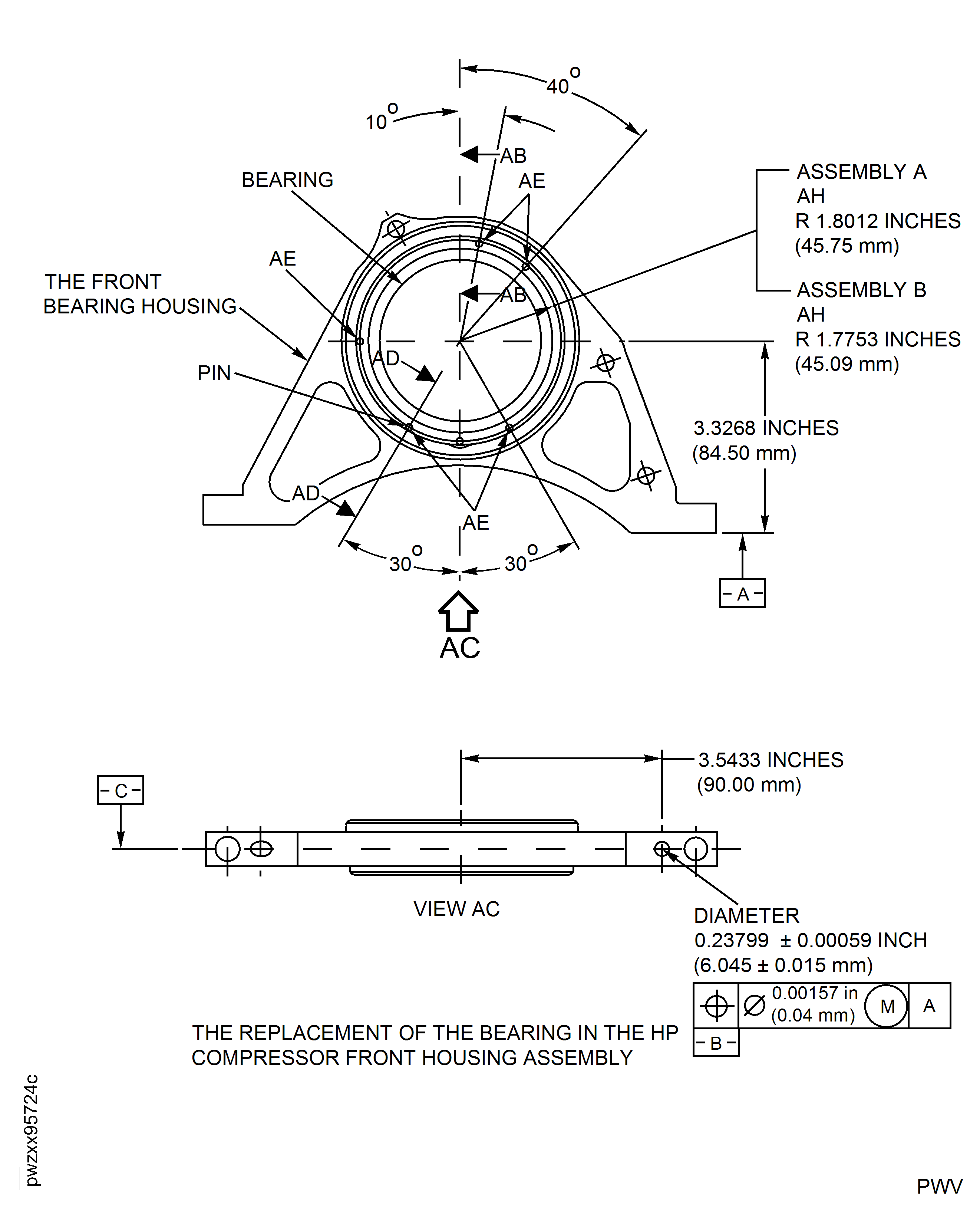

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

Use a CoMat 02-099 LINT-FREE CLOTH, made moist with CoMat 01-131 INDICATOR, or CoMat 01-124 ISOPROPYL ALCOHOL to make the mating surfaces clean.

Chemically clean the mating surfaces of the bearing and front housing assembly.

SUBTASK 72-41-34-110-070 Clean the Bearing and Front Housing Assembly

Refer to Figure.

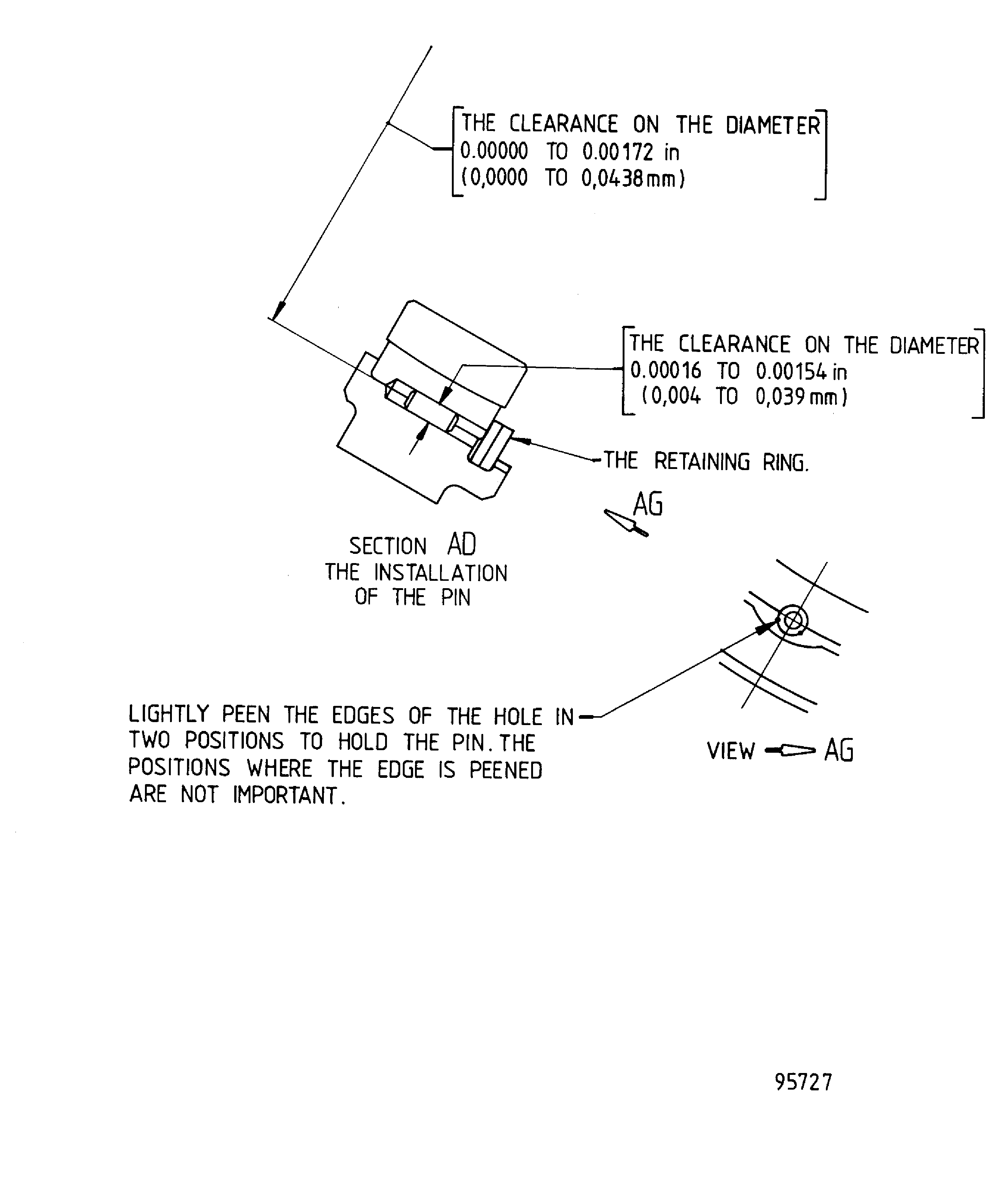

SUBTASK 72-41-34-350-106 Install the Bearing to the Front Housing Assembly

Drill at the position AE, as milled in Step.

Use a 0.114 in. (2.9 mm) diameter drill and a 0.118 in. (3.0 mm) diameter reamer.

Drill and ream the hole for the pin.

SUBTASK 72-41-34-323-051 Drill and Ream the Pin Hole

Refer to VRS6356, TASK 72-41-34-300-033.

Replace any damaged enamel.

SUBTASK 72-41-34-380-061 Replace any Damaged Enamel

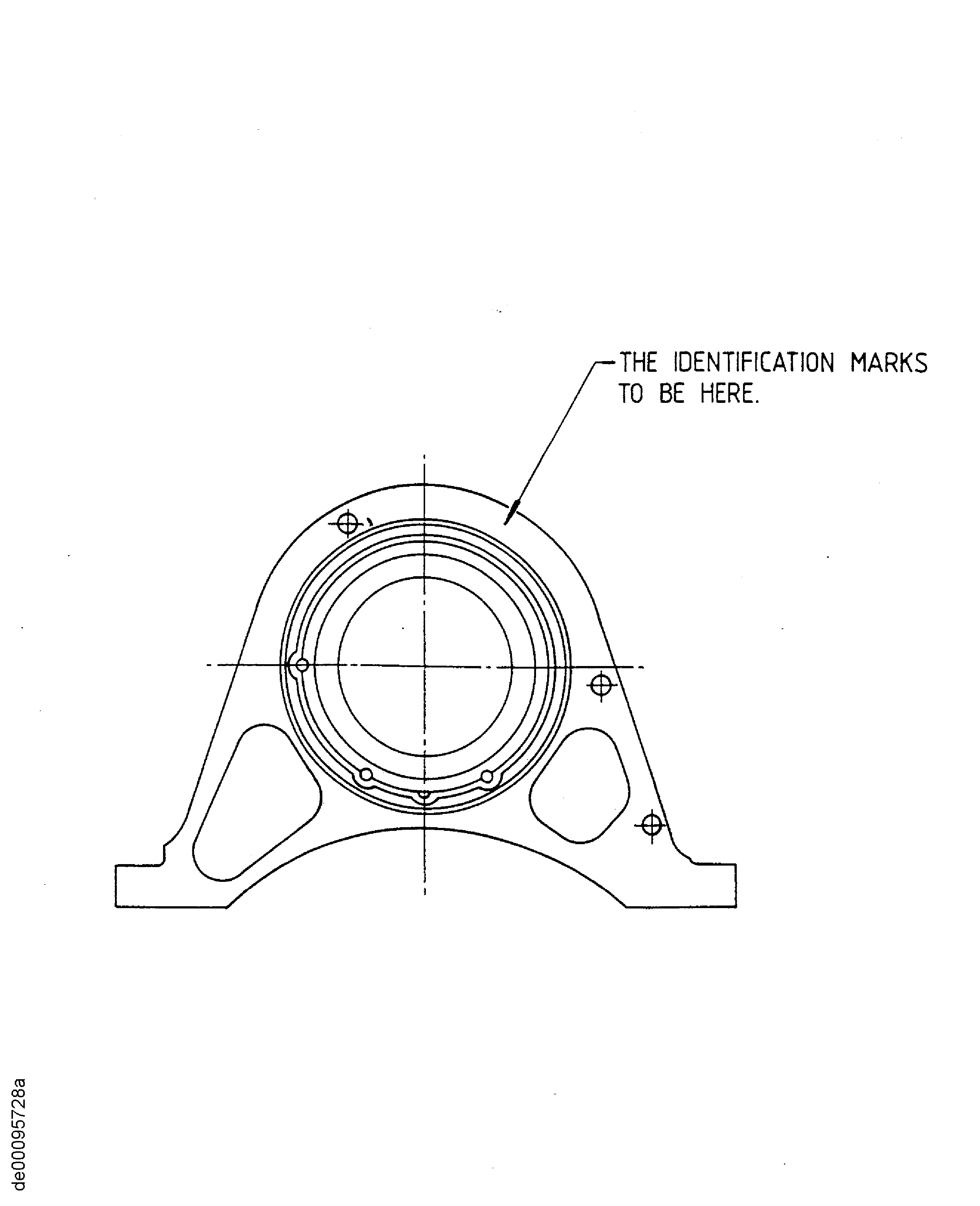

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

For second applications of this Repair, mark /1 after VRS6239.

For third applications of this Repair, mark /2 after VRS6239.

For fourth application of this Repair, mark /3 after VRS6239.

For the fifth application of this Repair, mark /4 after VRS6239.

Use CoMat 06-073 INK, METAL MARKING and CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR aerolac metal protective varnish applied with a paint brush.

Make a mark VRS6239 adjacent to existing markings which are under the surface protection.

SUBTASK 72-41-34-350-108 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

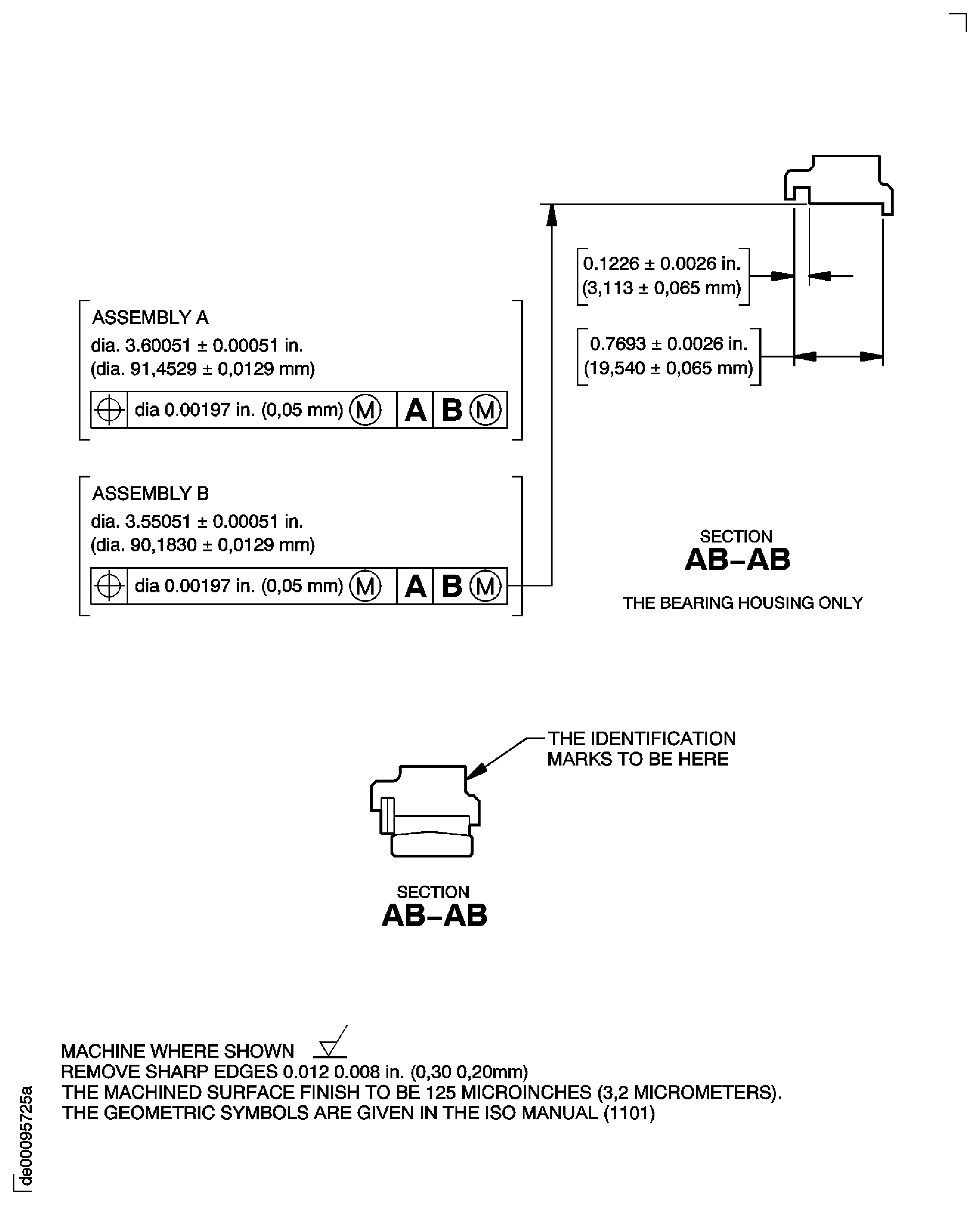

Figure: Repair Details and Dimensions

Repair Details and Dimensions

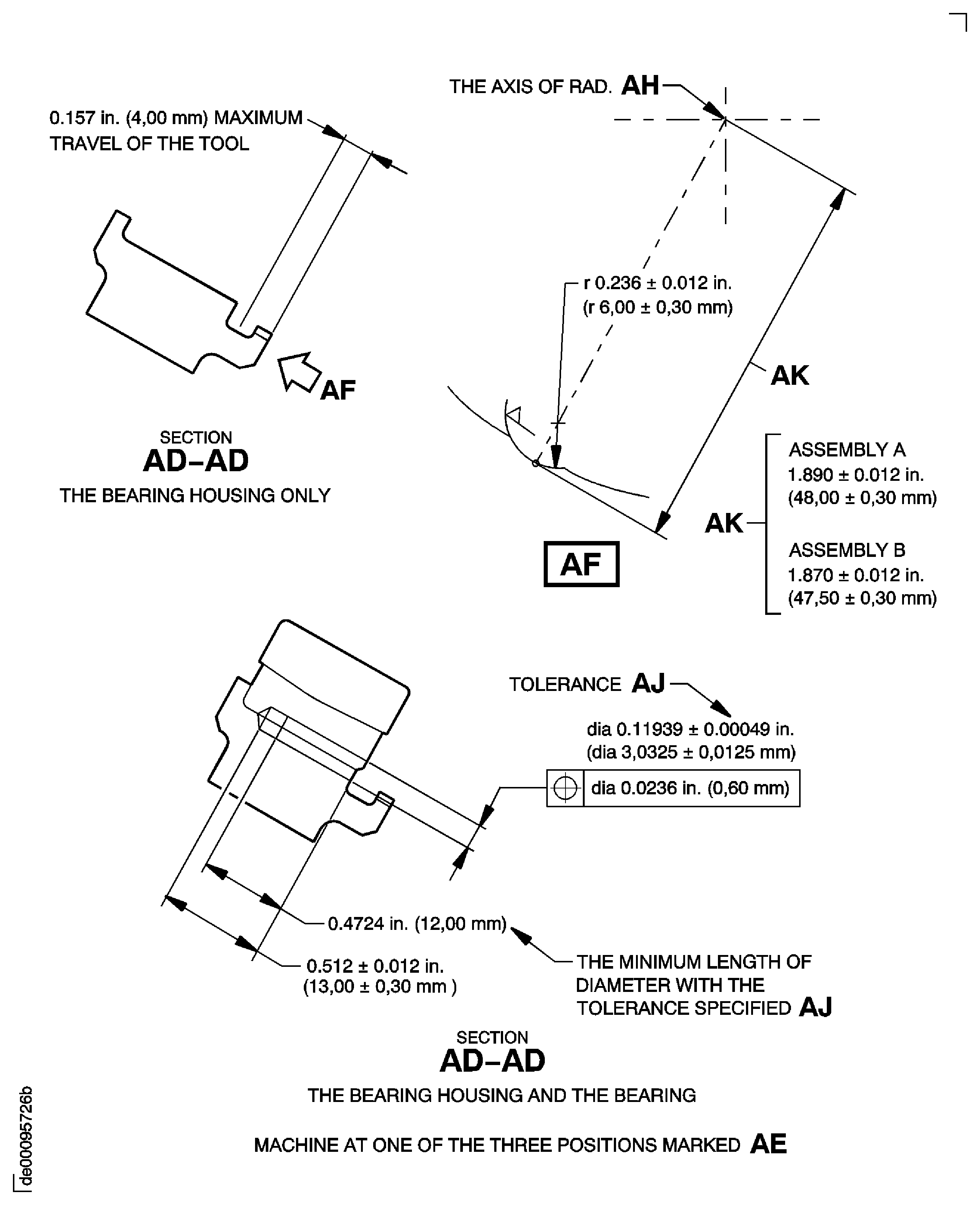

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions