Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

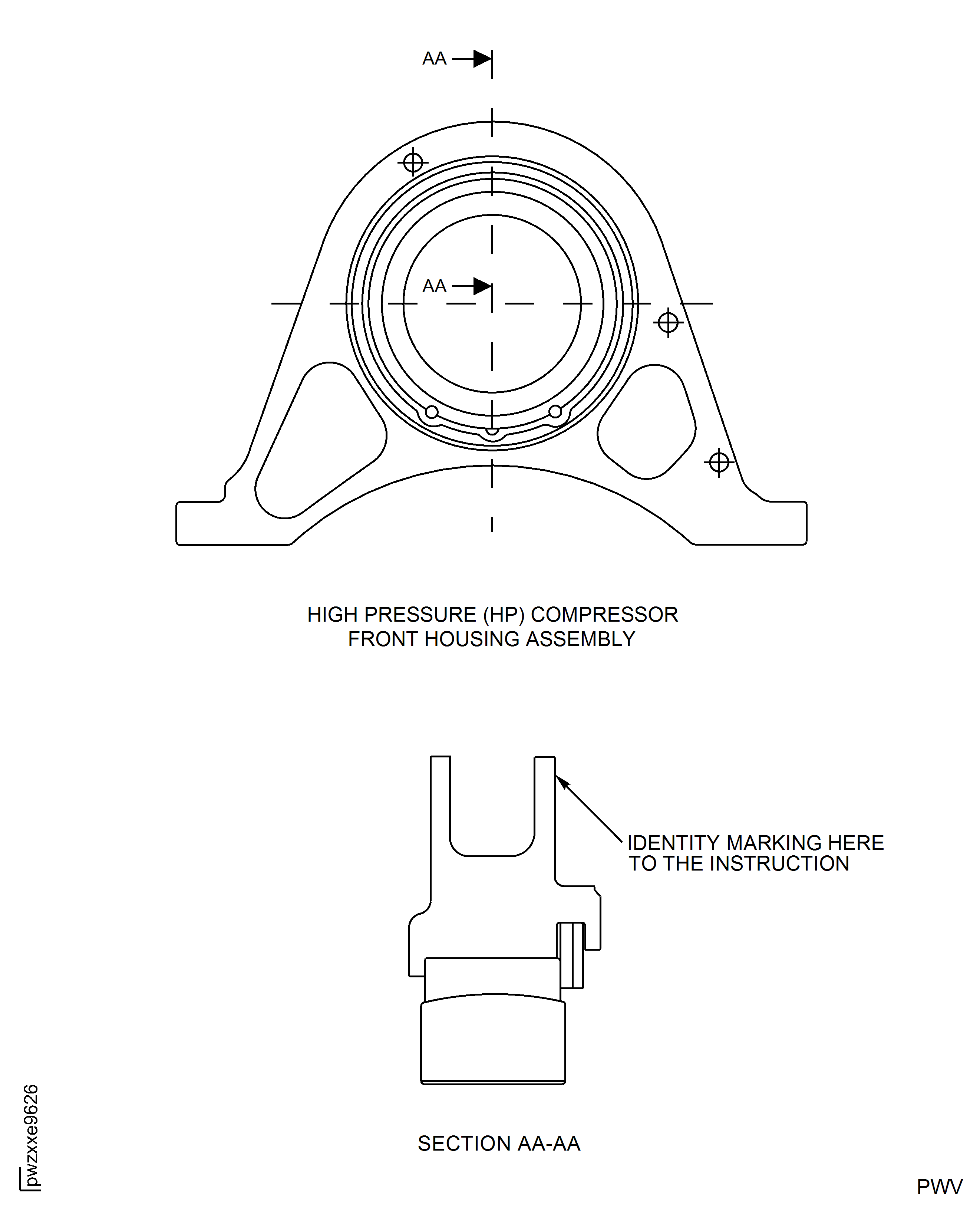

TASK 72-41-34-300-002 High Pressure (HP) Compressor Front Housing Assembly - Repair The Surface Damage By Material Removal, Repair - 002 (VRS6291)

Material of Component

DESCRIPTION | MATERIAL |

|---|---|

HP Compressor Front Housing Assembly | Corrosion Resistant Steel |

General

This TASK gives the procedure to remove surface damage on the HP Compressor Front Housing Assembly by material removal.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the Standard Practices Manual (SPM).

Price and Availability

Refer to International Aero Engines (IAE).

Related Repairs

Replace the surface protection on the HP Compressor Front and Rear Housing Assembly. Refer to repair, VRS6356 TASK 72-41-34-300-033 (REPAIR-033).

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Paint brush | LOCAL | Paint brush | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| Workshop inspection equipment | 0AM53 | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-074 ALUMINIUM OXIDE ABRASIVE PAPER | 06565 | CoMat 05-074 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-111 EMERY POLISHING PAPER | 06565 | CoMat 05-111 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 |

Spares

NONESafety Requirements

NONEProcedure

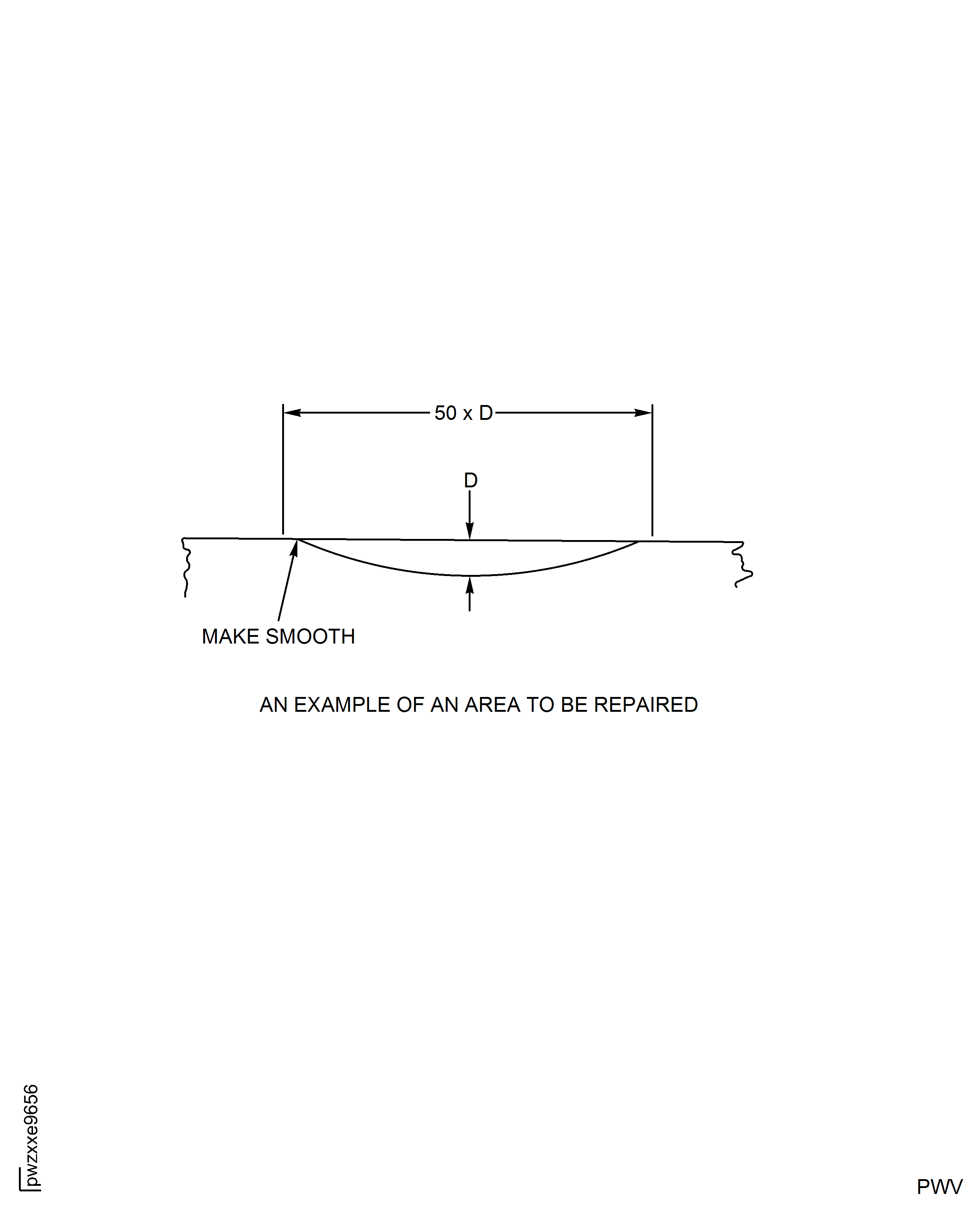

Refer to Figure.

Refer to SPM TASK 70-35-03-300-501.

The maximum depth to remove the damage must not be more than 0.005 in. (0.13 mm).

The diameter of area(s) removed is to be 50 times the depth.

Remove small area(s) of damage as necessary.

Refer to SPM TASK 70-35-03-300-501.

Remove sharp corners.

Blend the area(s) of repair.

Refer to SPM TASK 70-35-03-300-501.

Polish to give a surface finish to the same as the adjacent material.

Polish the area(s) of repair.

SUBTASK 72-41-34-350-001 Remove the Damaged Area(s)

Refer to Figure.

Make sure the surface finish is the same as the adjacent surfaces.

Make sure the maximum depth of the repair is not more than 0.005 in. (0.13 mm).

Reject the part if not in the limits given.

Do a visual and dimensional inspection.

SUBTASK 72-41-34-220-001 Inspect the Repair

Refer to SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-300-001.

Swab etch the repaired area(s).

SUBTASK 72-41-34-110-002 Do a Swab Etch

Refer to SPM TASK 70-23-02-230-501.

Cracks are not permitted.

Reject the part if cracked.

Do a penetrant crack test on the repaired area(s).

SUBTASK 72-41-34-230-002 Do a Crack Test

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibropeen VRS6291 adjacent to the assembly number.

SUBTASK 72-41-34-350-002 Identify the Repair

Refer to repair, VRS6356 TASK 72-41-34-300-033 (REPAIR-033).

Apply surface protection locally to the repaired areas.

SUBTASK 72-41-34-380-001 Apply Surface Protection to Repaired Areas

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Put the part number adjacent to the existing markings which are under the surface protection.

Use a Paint brush.

Re-identify the part.

SUBTASK 72-41-34-350-173 Identify the Repair

Figure: An Example of an Area to be Repaired

An Example of an Area to be Repaired

Figure: High Pressure (HP) Compressor Front Housing Assembly

High Pressure (HP) Compressor Front Housing Assembly