Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-016 HPC Vane Actuating Crankshaft Bearing Housings - Replace The Bearing In The Rear Housing, Repair-016 (VRS6240)

Material of component

PART IDENT | SYMBOL | MATERIAL | Assembly |

Rear Bearing Housing (Pre SBE 72-0564) | EAD or EAK | Jethete | A |

Rear Bearing Housing (SBE 72-0564) | MSRR6601 | 17-4 PH | B |

Bearing | AMS 5643 | 16% Chrome, 45% Nickel Steel | A and B |

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-34 Inspection.

This repair can only be done five times. If the part is identified as VRS6240/4, it can not be repaired.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability:

Refer to International Aero Engines.

Related repairs

HP Compressor Front and Rear Housing Assembly - Replacement of Surface Protection, refer to TASK 72-41-34-300-033 (VRS6356).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Milling Machine | LOCAL | Milling Machine | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Paint brush | LOCAL | Paint brush | ||

| Drilling Machine | LOCAL | Drilling Machine | ||

| Drill | LOCAL | Drill | 0.114 in. (2.9 mm) Dia. | |

| Reamer | LOCAL | Reamer | 0.118 in. (3.0 mm) Dia. | |

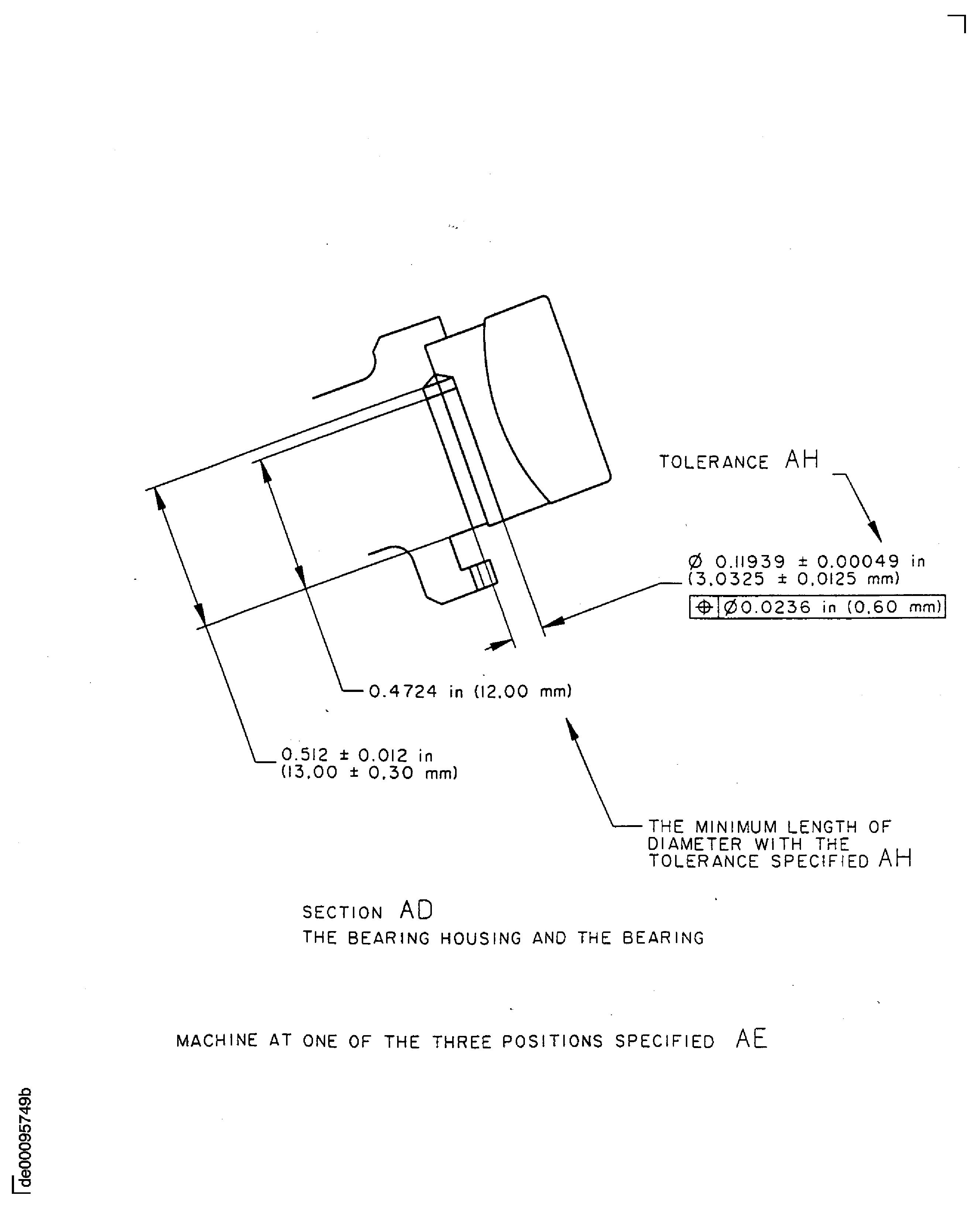

| End mill | LOCAL | End mill | 0.472 in. (12.0 mm) Dia. |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-031 STOPPING-OFF CRAYON | LOCAL | CoMat 03-031 | ||

| CoMat 03-124 FLAME SPRAY NICKEL-ALUMINUM(78 Ni-22 Al) | 39918 | CoMat 03-124 | ||

| CoMat 04-014 THIXOTROPIC DRY FILM LUBRICANT | 0AM53 | CoMat 04-014 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Retaining Ring | RRN362 | 1 | ||

| Pin | AS20643 | 1 | ||

| Bearing | 03-413-40E002 | 1 | ||

| BEARING | Z5H62 | 03-413-45E002 | 1 |

Safety Requirements

NONEProcedure

Use a clean CoMat 02-099 LINT-FREE CLOTH and blast with air.

Clean the bearing location and the retaining ring recess to remove all unwanted material.

SUBTASK 72-41-34-350-110 Remove the Burrs

Refer to the SPM TASK 70-23-01-230-501.

Do a penetrant crack test.

SUBTASK 72-41-34-230-098 Do a Crack Test

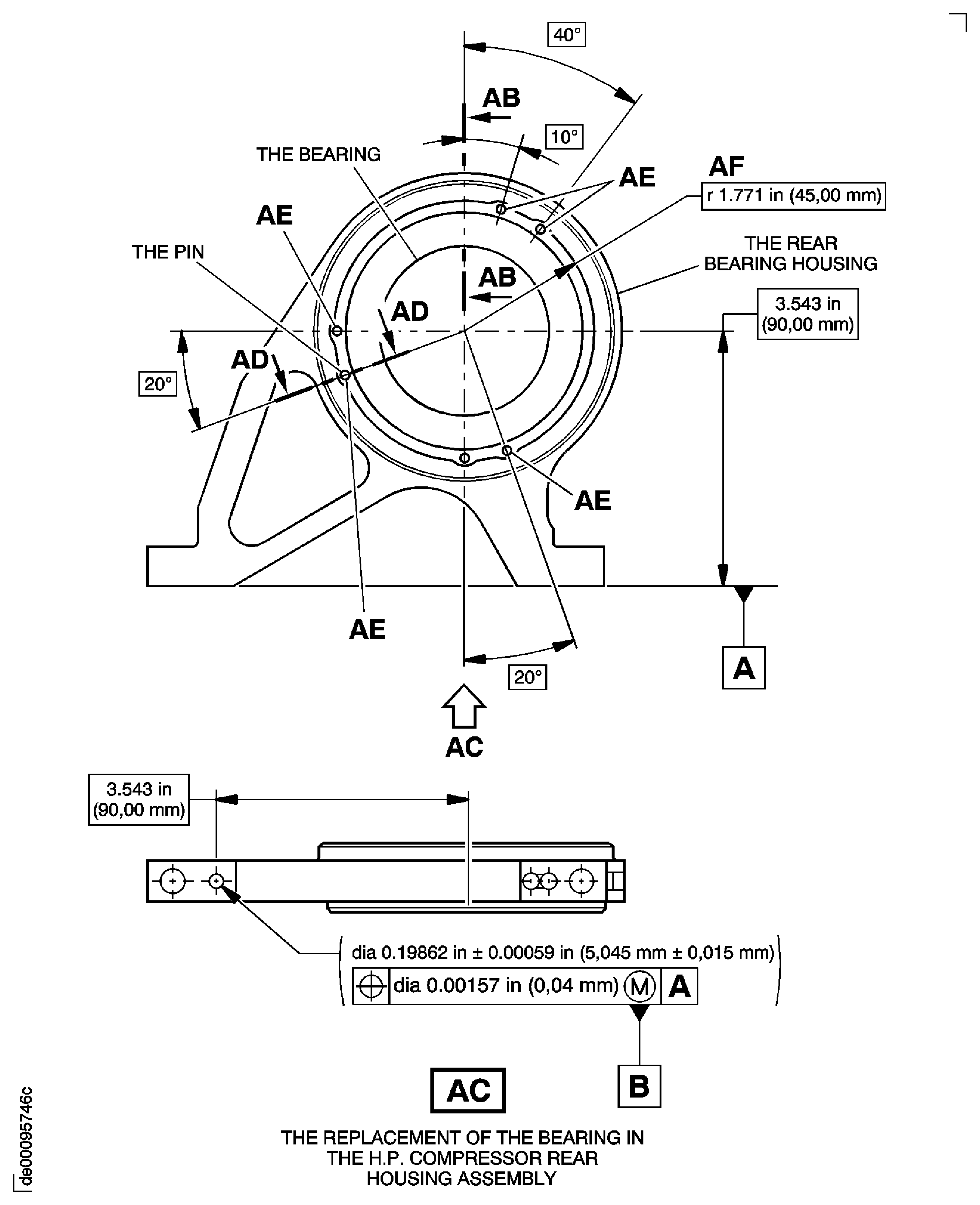

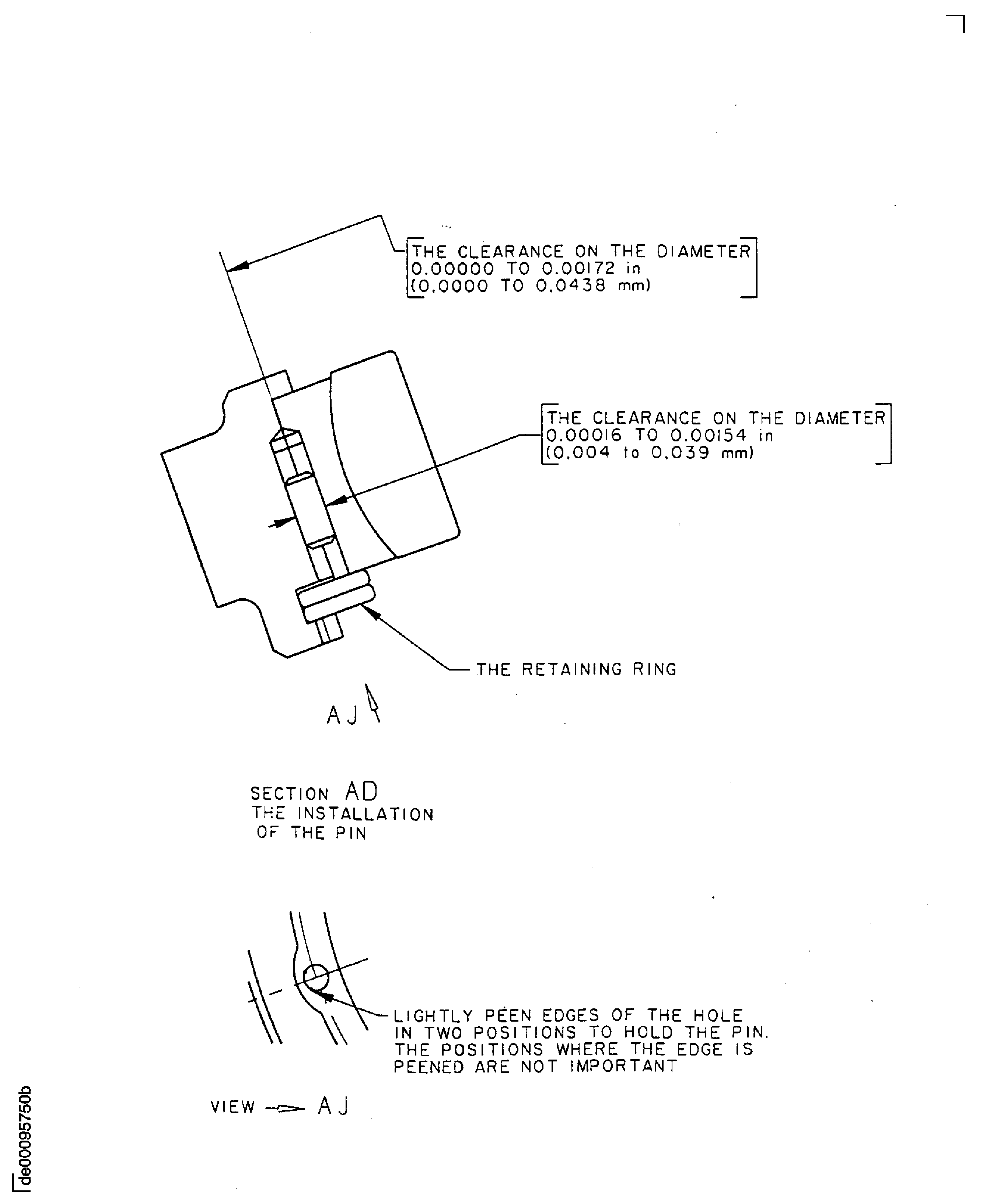

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

Use a clean CoMat 02-099 LINT-FREE CLOTH, made moist with CoMat 01-031 ACETONE (CH3)2CO, or CoMat 01-124 ISOPROPYL ALCOHOL to make the mating surfaces clean.

Chemically clean the mating surfaces of the bearing and rear housing assembly.

SUBTASK 72-41-34-110-071-B00 Clean the Bearing and Rear Housing Assembly

Refer to Figure.

SUBTASK 72-41-34-350-111 Install the Bearing in the Rear Housing Assembly

Drill at the position AE, as milled in Step.

Use a 0.114 in. (2.9 mm) diameter drill and 0.118 in. (3.0 mm) diameter reamer.

Drill and ream the hole for the pin.

Use a clean CoMat 02-099 LINT-FREE CLOTH and blast with air.

Clean the hole.

SUBTASK 72-41-34-323-052 Drill and Ream the Pin Hole

Refer to VRS6356, TASK 72-41-34-300-033.

Replace any damaged enamel.

SUBTASK 72-41-34-380-062 Replace any Damaged Enamel

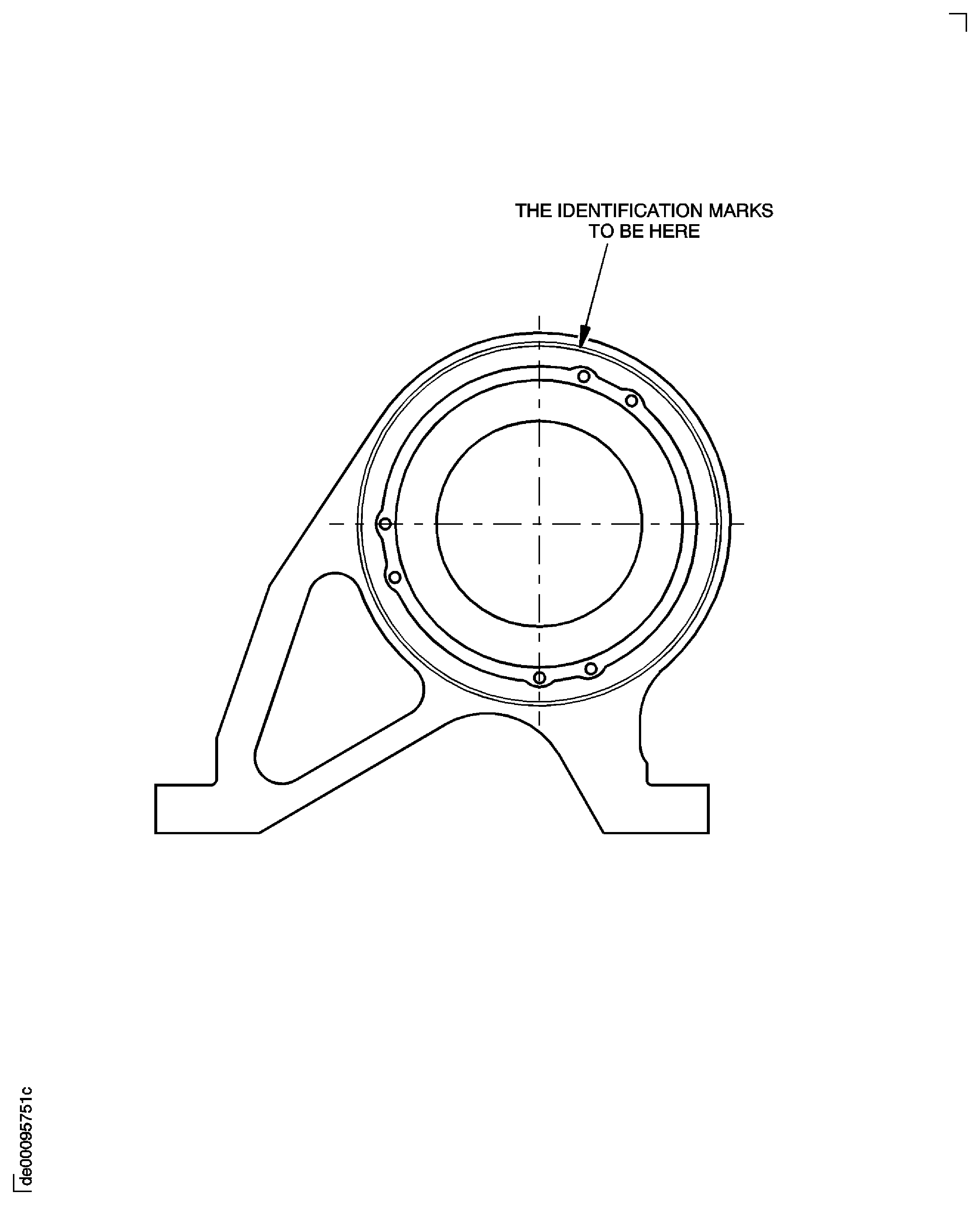

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

For second application of this repair, mark /1 after VRS6240.

For third application of this repair, mark /2 after VRS6240.

For fourth application of this repair, mark /3 after VRS6240.

For fifth application of this repair, mark /4 after VRS6240.

Use CoMat 06-073 INK, METAL MARKING and CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR aerolac metal protective varnish applied with a paint brush.

Make a mark VRS6240 adjacent to existing marks which are under the surface protection.

SUBTASK 72-41-34-350-113 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

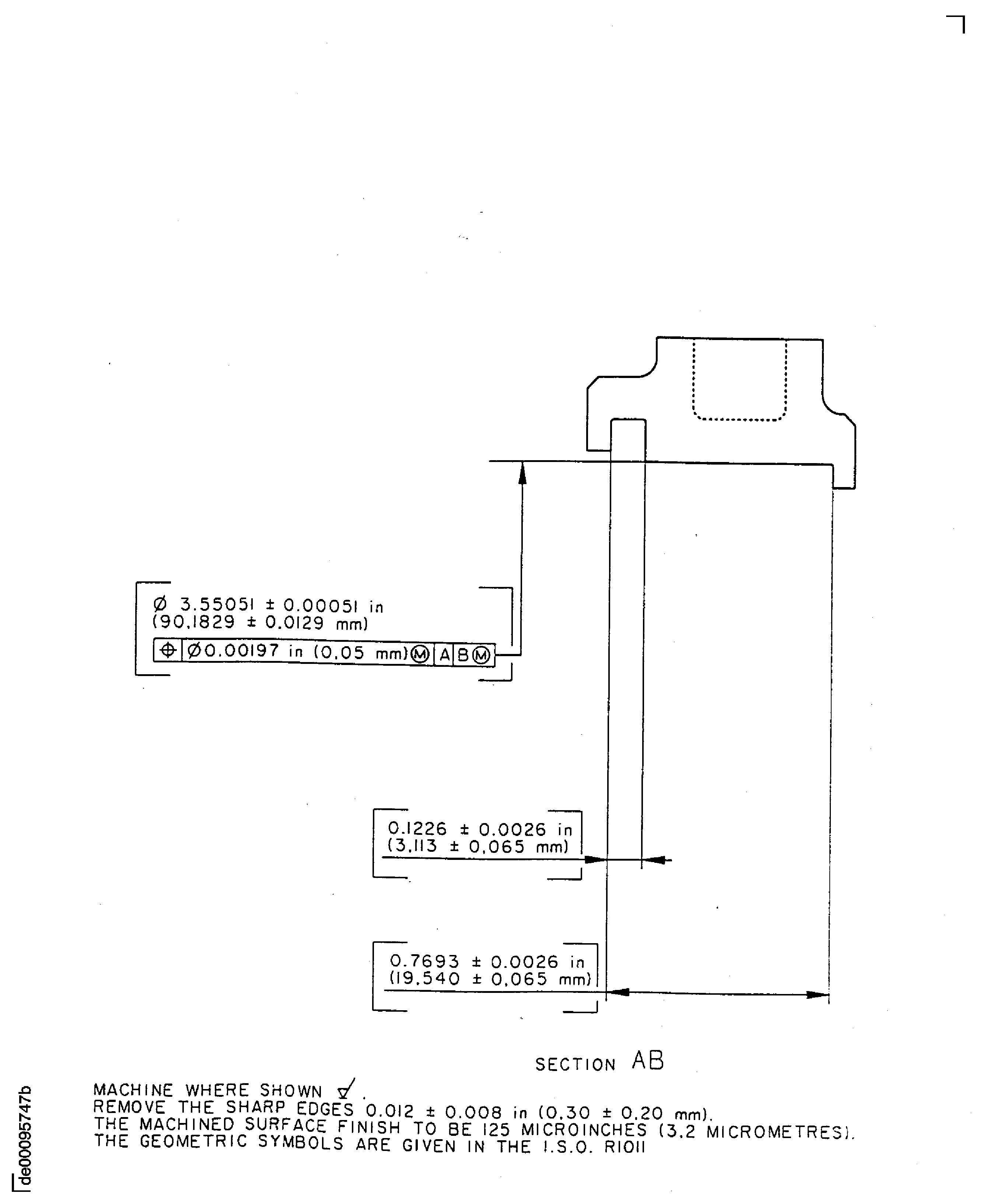

Figure: Repair Details and Dimensions

Repair Details and Dimensions

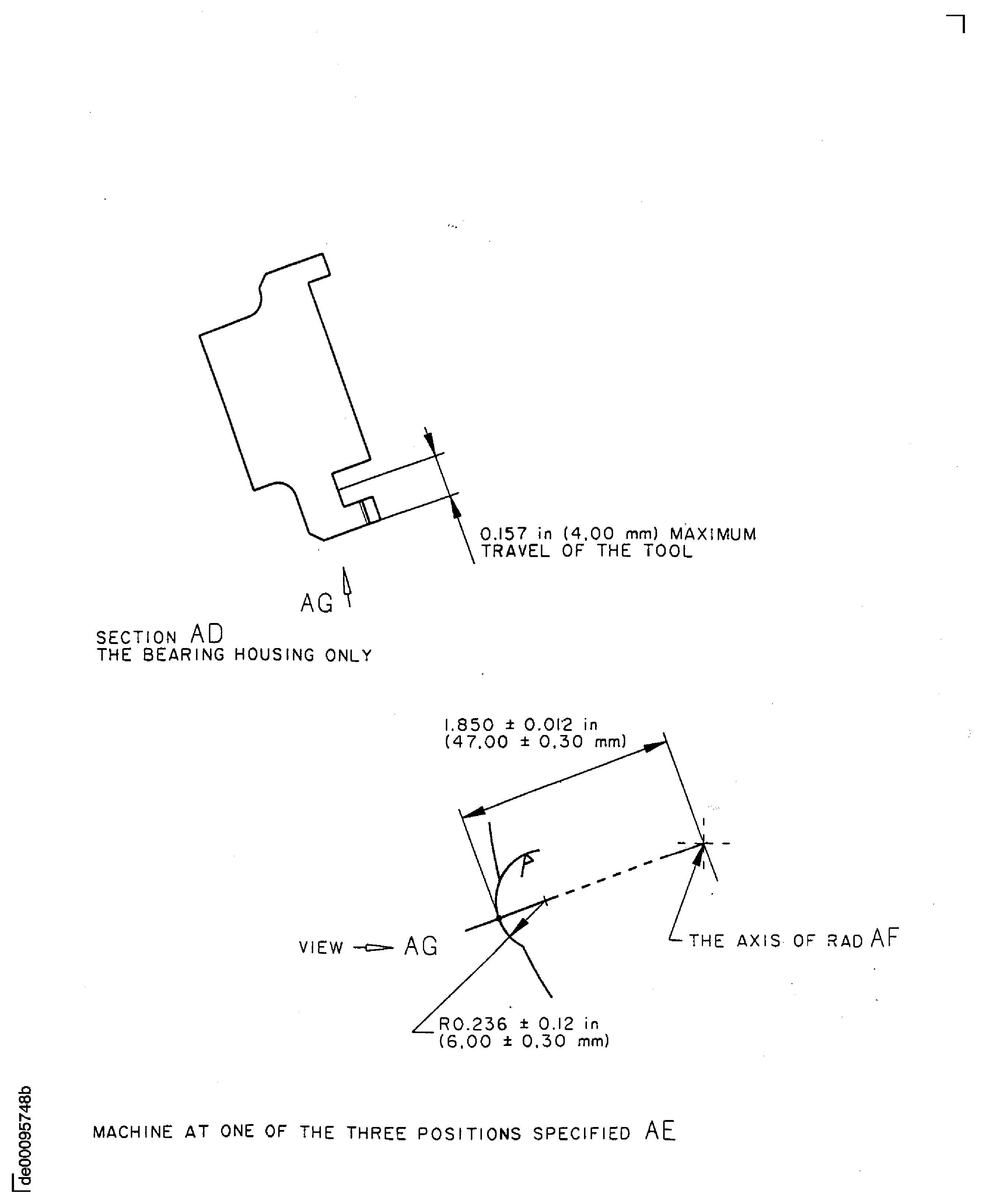

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions