Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-047 HPC Inlet Variable Stator Vane Unison Rings - Replace The Bushes And Loose Fittings, Repair-047 (VRS6265)

Material of component

The HP compressor VIGV actuating ring connector assembly is manufactured from titanium alloy.

The bushes are manufactured from polymide resin.

The bracket assemblies and dowels are manufactured from corrosion resistant steel.

General

This repair must only be done when the instruction to do so is given in TASK 72-41-34 Inspection.

The practices and processes referred to in the procedure by TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs

HP compressor VIGV and stage 3 to 5 actuating ring assemblies and related housing assemblies - replacement of 0.250-28 wire screw thread inserts. Repair-014, refer to TASK 72-41-34-300-014 (VRS6156).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling machine | LOCAL | Drilling machine | ||

| Drill | LOCAL | Drill | 0.346 in. (8.80 mm) dia | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Manual welding equipment | LOCAL | Manual welding equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 03-366 WELDING FILLER WIRE | LOCAL | CoMat 03-366 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| VIGV Upper Variable Vane Actuating Ring Assembly | 6A3535 | A | ||

| VIGV Upper Variable Vane Actuating Ring Assembly | 6A7580 | B | ||

| VIGV Upper Variable Vane Actuating Ring Assembly | 6A7849 | C | ||

| VIGV Upper Variable Vane Actuating Ring Assembly | 6A7899 | D | ||

| VIGV Upper Variable Vane Actuating Ring Assembly | 6A8075 | E | ||

| Bush | UP11069 | 32 | A | |

| Bush | UP11069 | 32 | B | |

| Bush | UP11069 | 32 | C | |

| Bush | BRR12496 | 16 | D | |

| Bush | BRR12496 | 16 | E | |

| Spacer | 6A2860 | 4 | A | |

| Spacer | 6A2860 | 4 | B | |

| Spacer | 6A2860 | 4 | C | |

| Spacer | 6A2860 | 4 | D | |

| Spacer | 6A2860 | 4 | E | |

| Bracket Assembly | 6A2861 | 1 | A | |

| Bracket Assembly | 6A2863 | 1 | A | |

| VIGV Lower Variable Vane Actuating Ring Assembly | 6A3537 | A | ||

| VIGV Lower Variable Vane Actuating Ring Assembly | 6A7584 | B | ||

| VIGV Lower Variable Vane Actuating Ring Assembly | 6A7851 | C | ||

| VIGV Lower Variable Vane Actuating Ring Assembly | 6A7901 | D | ||

| VIGV Lower Variable Vane Actuating Ring Assembly | 6A8077 | E | ||

| Bush | UP11069 | 32 | A | |

| Bush | UP11069 | 32 | B | |

| Bush | UP11069 | 32 | C | |

| Bush | BRR12496 | 16 | D | |

| Bush | BRR12496 | 16 | E | |

| Spacer | 6A2860 | 4 | A | |

| Spacer | 6A2860 | 4 | B | |

| Spacer | 6A2860 | 4 | C | |

| Spacer | 6A2860 | 4 | D | |

| Spacer | 6A2860 | 4 | E | |

| Bracket Assembly | 6A2863 | 1 | A | |

| Bracket Assembly | 6A2861 | 1 | A |

Safety Requirements

NONEProcedure

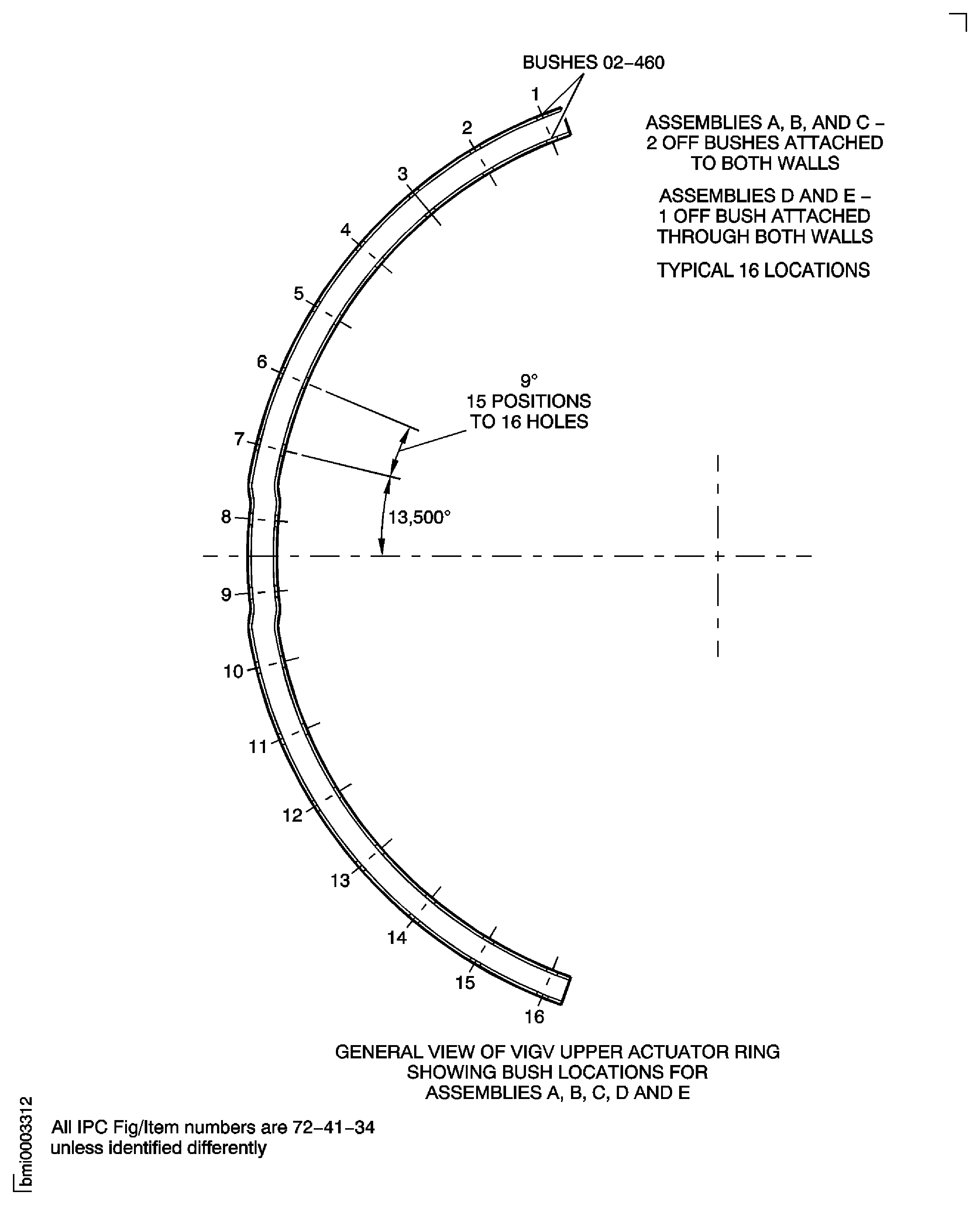

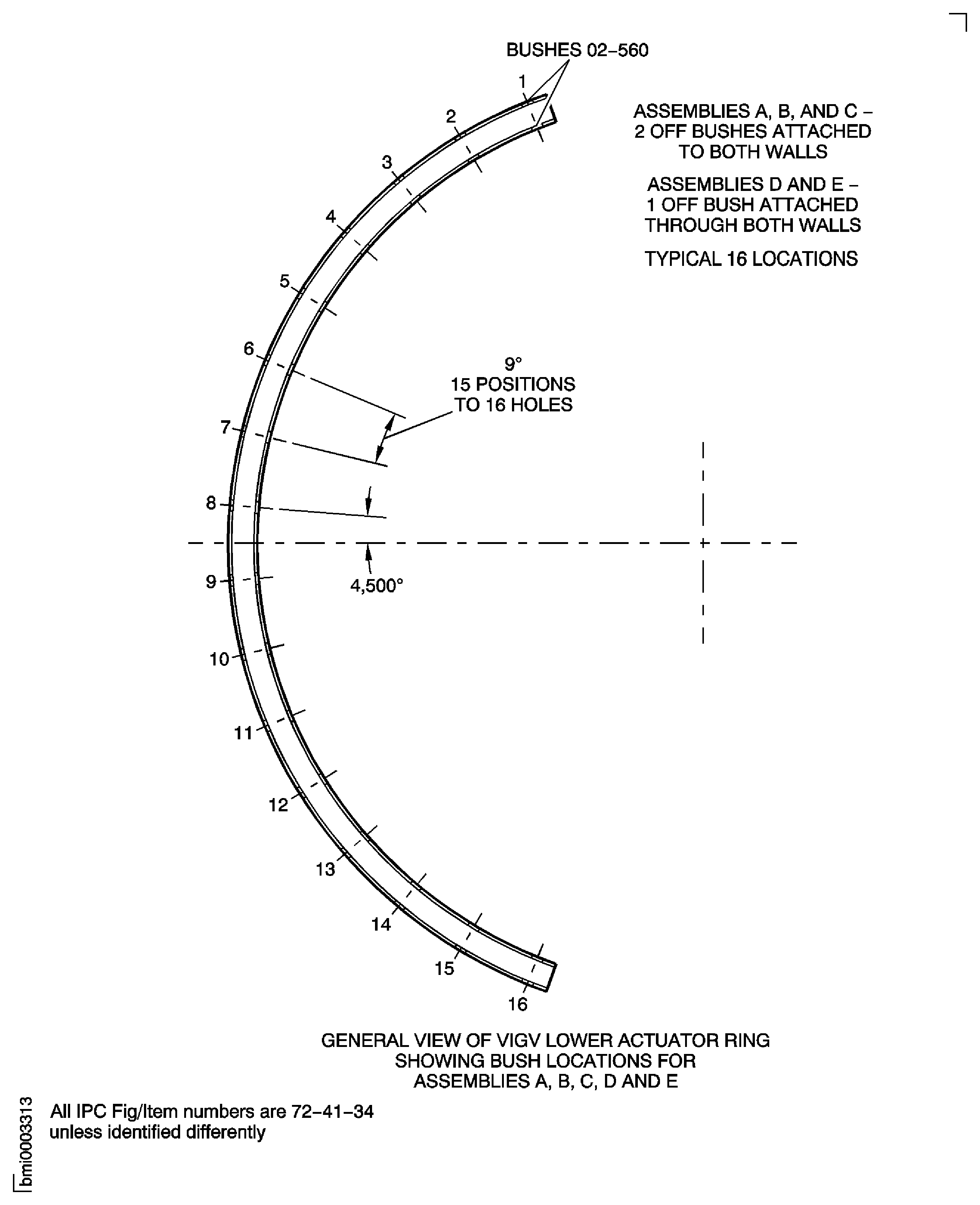

Drill the head of the bush until the head is released to remove the bushes HPC Variable Stator Vane Actuation System (72-41-34,02-460) and HPC Variable Stator Vanes (72-41-32,02-560) (32 off).

Drift out to remove the spacers HPC Variable Stator Vane Actuation System (72-41-34,02-462) and HPC Variable Stator Vane Actuation System (72-41-34,02-562) (4 off).

Remove and retain loose bracket assemblies HPC Variable Stator Vane Actuation System (72-41-34,02-470), HPC Variable Stator Vane Actuation System (72-41-34,02-490), HPC Variable Stator Vane Actuation System (72-41-34,02-570) and HPC Variable Stator Vane Actuation System (72-41-34,02-590) from inside the actuator ring.

SUBTASK 72-41-34-350-086-A00 Remove the Worn Bushes, Brackets, Dowel Assemblies and Spacers of Assembly A, from Upper and Lower VIGV Actuating Ring Assemblies

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU HAND DRESS TO REMOVE LOCATION PIN HEAD, OR BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED, MASK ADJACENT AREA TO REPAIR IF NECESSARY.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Drill the head of the bush until the head is released to remove the bushes HPC Variable Stator Vane Actuation System (72-41-34,02-460) and HPC Variable Stator Vane Actuation System (72-41-34,02-560) (32 off).

Drift out to remove the spacers HPC Variable Stator Vane Actuation System (72-41-34,02-462) and HPC Variable Stator Vane Actuation System (72-41-34,02-562) (4 off).

SUBTASK 72-41-34-350-086-B00 Remove the Worn Bushes, Brackets, Dowel Assemblies and Spacers of Assembly B and Assembly C, from Upper and Lower VIGV Actuating Ring Assemblies

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU HAND DRESS TO REMOVE LOCATION PIN HEAD, OR BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED, MASK ADJACENT AREA TO REPAIR IF NECESSARY.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.SBE 72-0418: Drill the head of the bush until the head is released to remove the bushes HPC Variable Stator Vane Actuation System (72-41-34,02-460) and HPC Variable Stator Vane Actuation System (72-41-34,02-560) (16 off).

Drift out to remove the spacers HPC Variable Stator Vane Actuation System (72-41-34,02-462) and HPC Variable Stator Vane Actuation System (72-41-34,02-562) (4 off).

SUBTASK 72-41-34-350-086-C00 Remove the Worn Bushes, Brackets, Dowel Assemblies and Spacers of Assembly D and Assembly E, from Upper and Lower VIGV Actuating Ring Assemblies

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU HAND DRESS TO REMOVE LOCATION PIN HEAD, OR BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED, MASK ADJACENT AREA TO REPAIR IF NECESSARY.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to the SPM TASK 70-11-26-300-503.

Remove sharp edges around the holes.

Use standard workshop equipment.

Use air blast to remove debris.

Swab degrease to clean the holes.

Clean the location holes in the actuating ring.

SUBTASK 72-41-34-160-063 Clean the Location Holes

Refer to VRS6156, TASK 72-41-34-300-014 for the replacement of damaged inserts.

Replace damage wire screw thread inserts.

SUBTASK 72-41-34-220-218 Examine the Retained Bracket Assembly A

Refer to the SPM TASK 70-23-02-230-501.

Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the repair area.

SUBTASK 72-41-34-230-088 Do a Crack Test

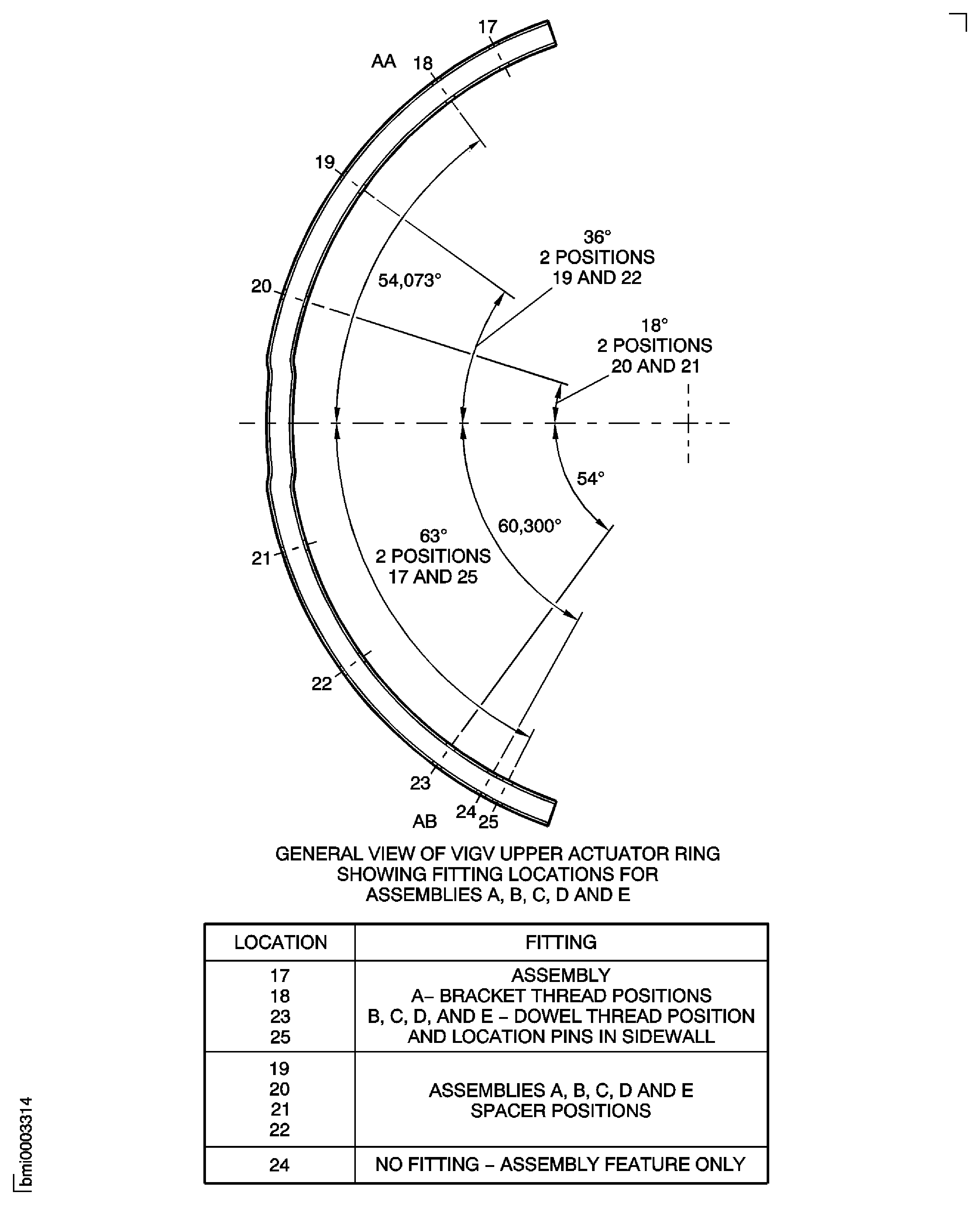

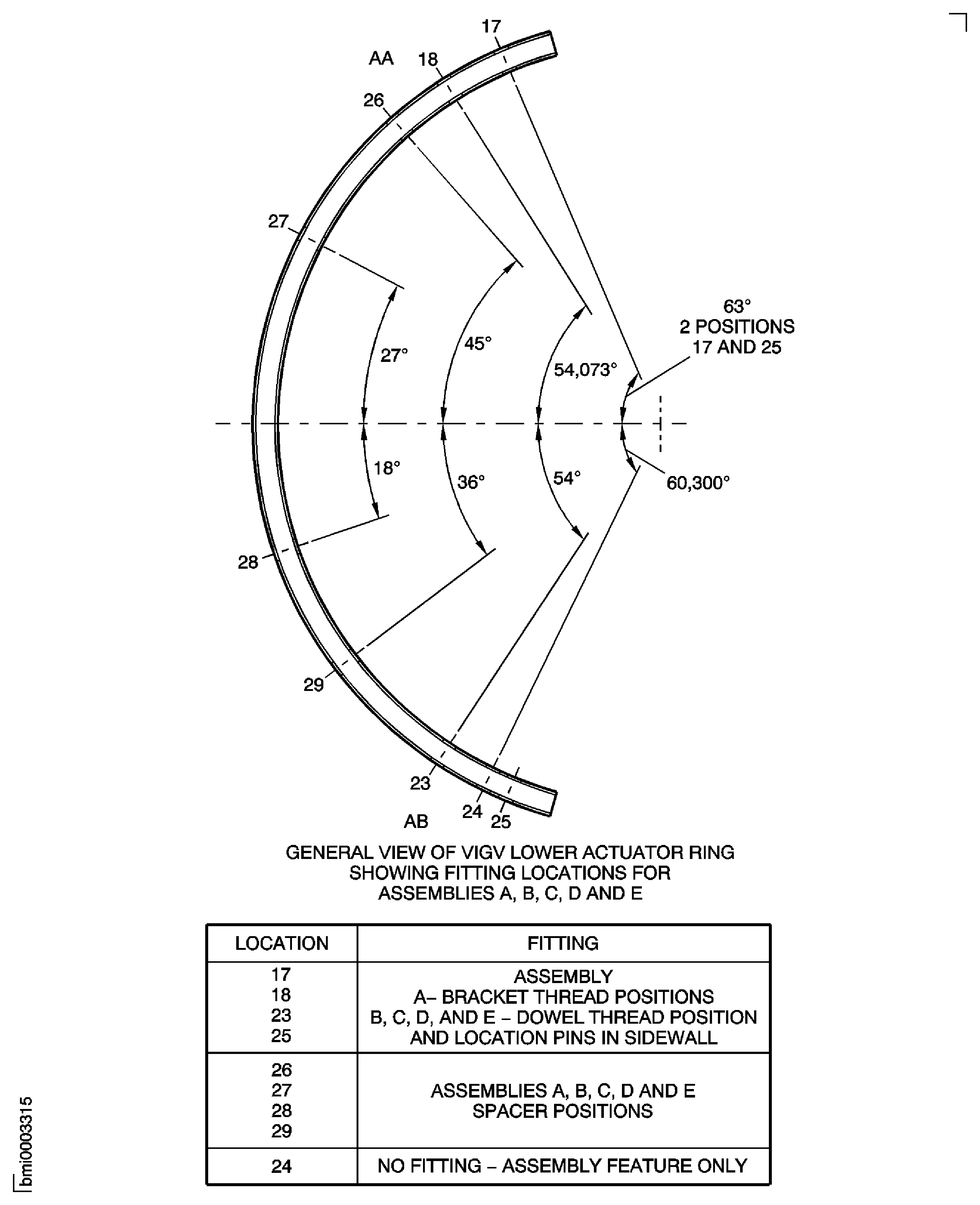

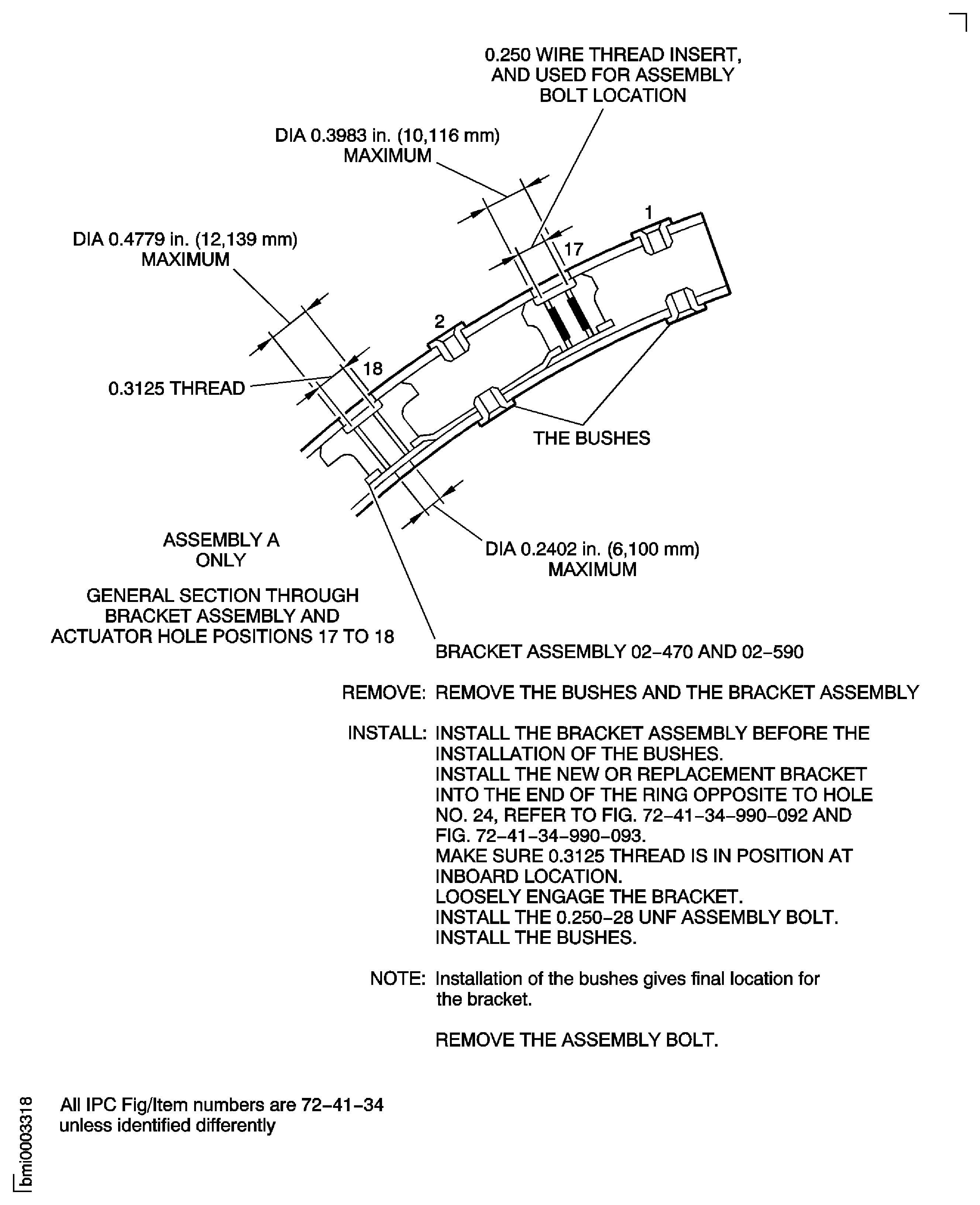

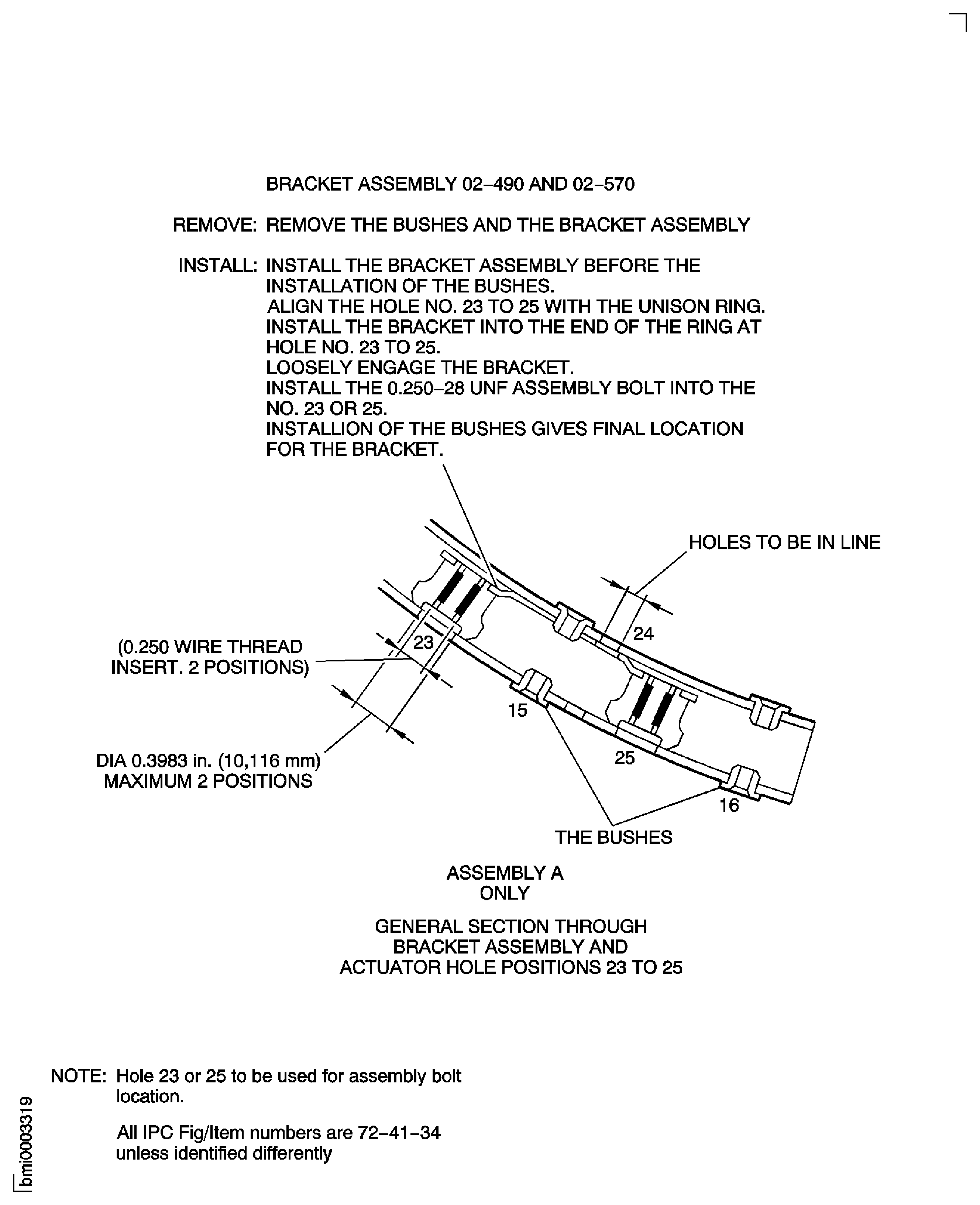

Use hand tightened 0.250-28 UNF bolts, as assembly aids for fitting of bracket assemblies HPC Variable Stator Vane Actuation System (72-41-34,02-470) and HPC Variable Stator Vane Actuation System (72-41-34,02-490) into their respective actuator ring locations.

For correct installation of bracket assembly at hole positions 23 and 25, check ring to bracket hole alignment at hole 24.

Check 0.3125 thread is located at hole 18 position.

Install the existing or replacement bracket assemblies in upper and lower actuating rings. Loosely fit and retain in position before installing the replacement bushes.

SUBTASK 72-41-34-350-087 Temporary Install Brackets, Assembly A

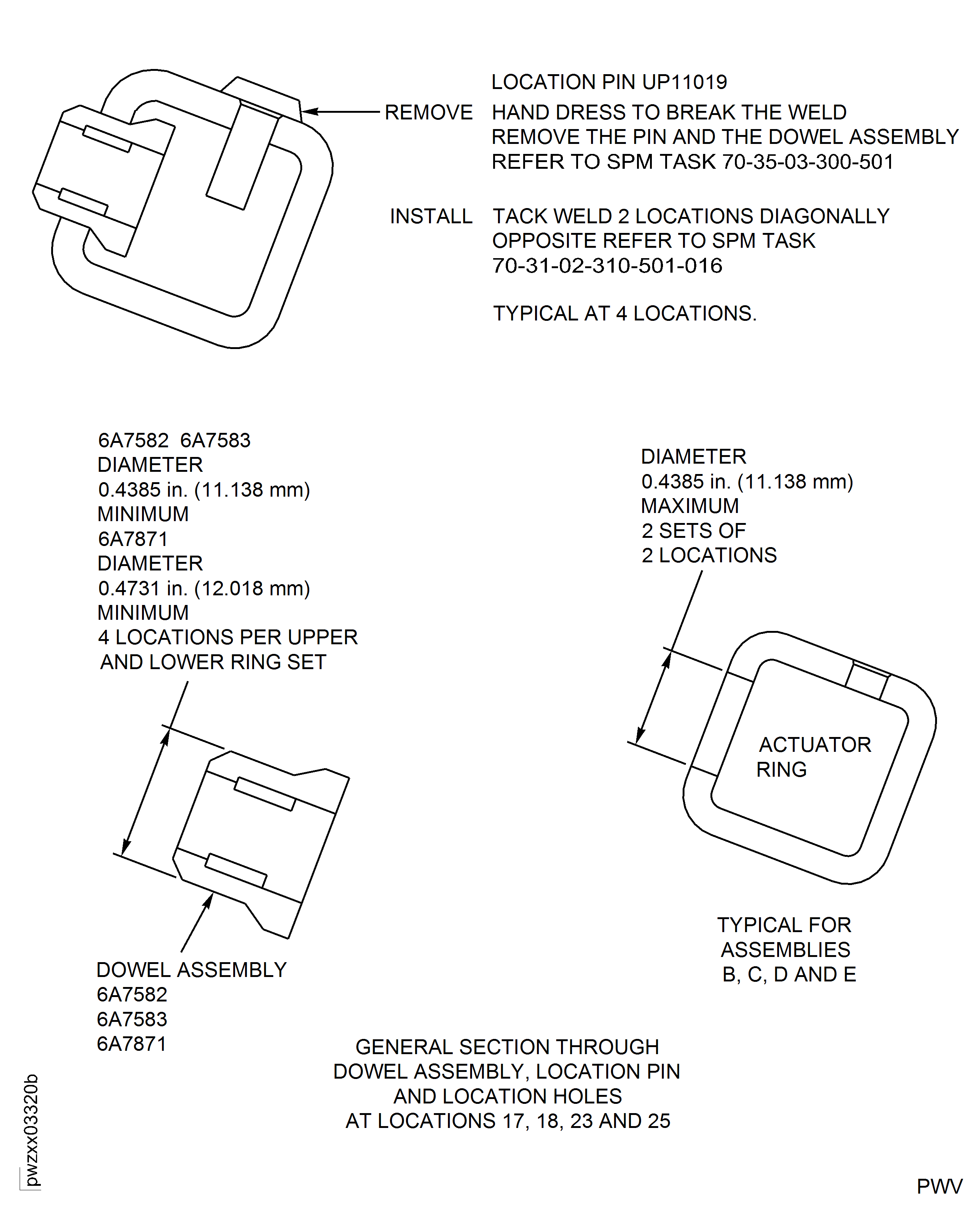

Refer to the SPM TASK 70-31-02-310-501-001.

Procedure to tack weld location pin (UP11019) 4 off positions, to capture respective dowel assemblies in actuating ring.

Install replacement location pins in upper and lower actuating rings, to retain dowel assemblies (4 off).

Refer to the SPM TASK 70-31-02-310-501-001, SUBTASK 70-31-02-220-002 and SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

Cracks are not permitted.

Inspection of welds.

SUBTASK 72-41-34-350-139 Install Dowels, Assembly B, Assembly C, Assembly D and Assembly E

Press fit the bush HPC Variable Stator Vane Actuation System (72-41-34,02-560) until retaining feature engages in 2 sets of 16 locations.

Install the new bushes.

Remove the bolts used in Step.

SUBTASK 72-41-34-350-140-A00 Install the Bushes in Upper and Lower Actuating Rings, Assembly A, Assembly B and Assembly C

Remove the bolts used in Step.

SUBTASK 72-41-34-350-140-B00 Install the Bushes in Upper and Lower Actuating Rings, Assembly D and Assembly E

Freeze fit the spacer HPC Variable Stator Vane Actuation System (72-41-34,02-562).

Freeze the spacers.

SUBTASK 72-41-34-350-088 Install the Spacers

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions