Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-11-300-026 Diffuser Case - Repair The Oil Supply Inner Case Boss Bushing, Repair-026 (VRS3647)

Effectivity

FIG/ITEM | PART No. |

|---|---|

01-010 | 2A0051 |

01-010 | 2A2081-01 |

01-010 | 2A2581-01 |

01-010 | 2A2883-01 |

01-010 | 2A2889-01 |

01-010 | 2A2896-01 |

01-010 | 2A2885-01 |

01-010 | 2A2891-01 |

01-010 | 2A2897-01 |

01-010 | 2A3132 |

General

Price and availability - refer to IAE

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 | ||

| Nickel Alloy (Inconel 718) | LOCAL | AMS 5663 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-03-300-503.

Clean the diffuser case.

SUBTASK 72-42-11-110-074 Clean the Diffuser Case After Machining

Refer to the SPM TASK 70-23-05-230-501. Use high sensitivity level. No indications permitted.

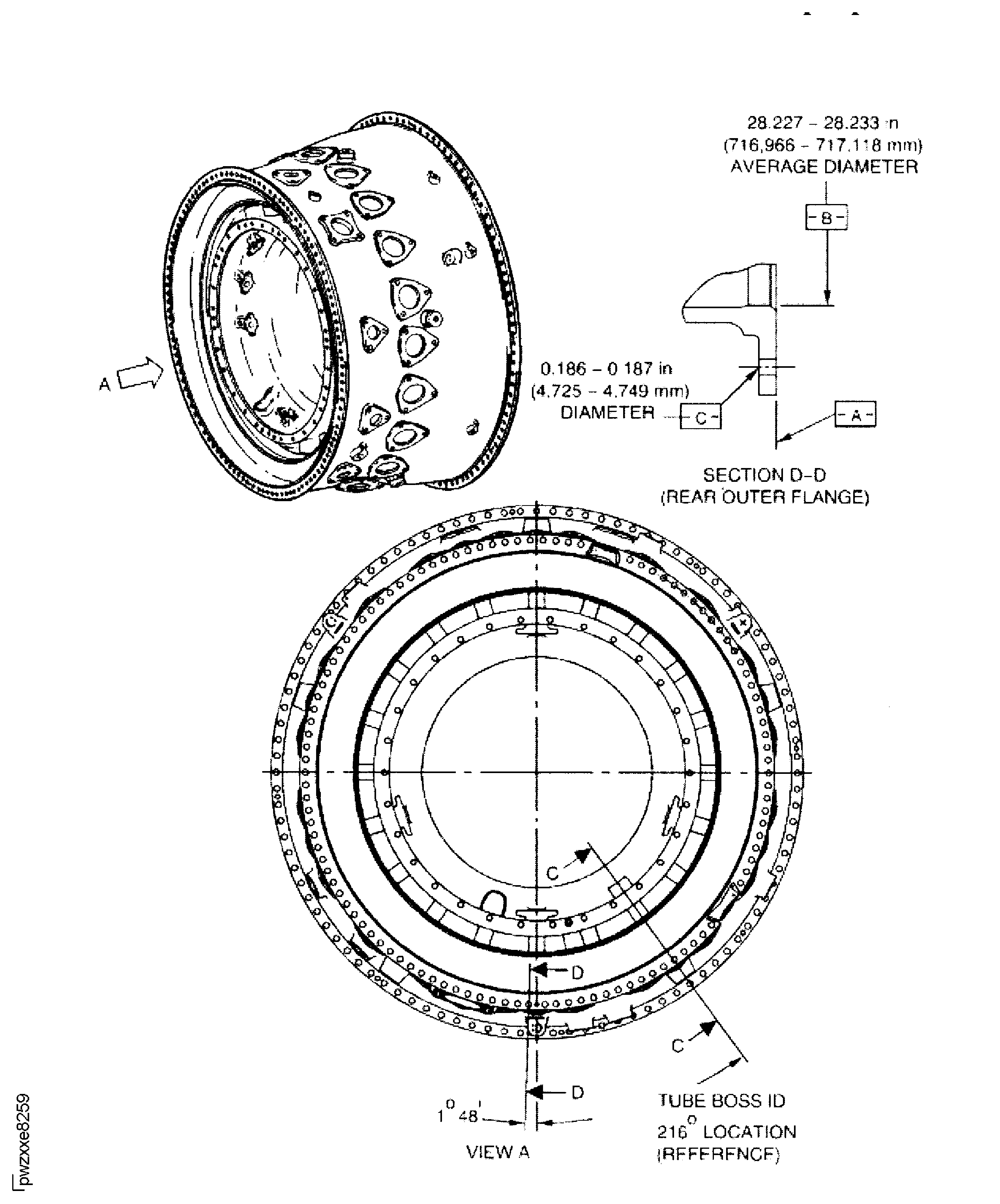

Fluorescent penetrant examine the surface of the oil supply inner boss.

SUBTASK 72-42-11-230-070 Examine the Oil Supply Inner Boss Surface for Indications

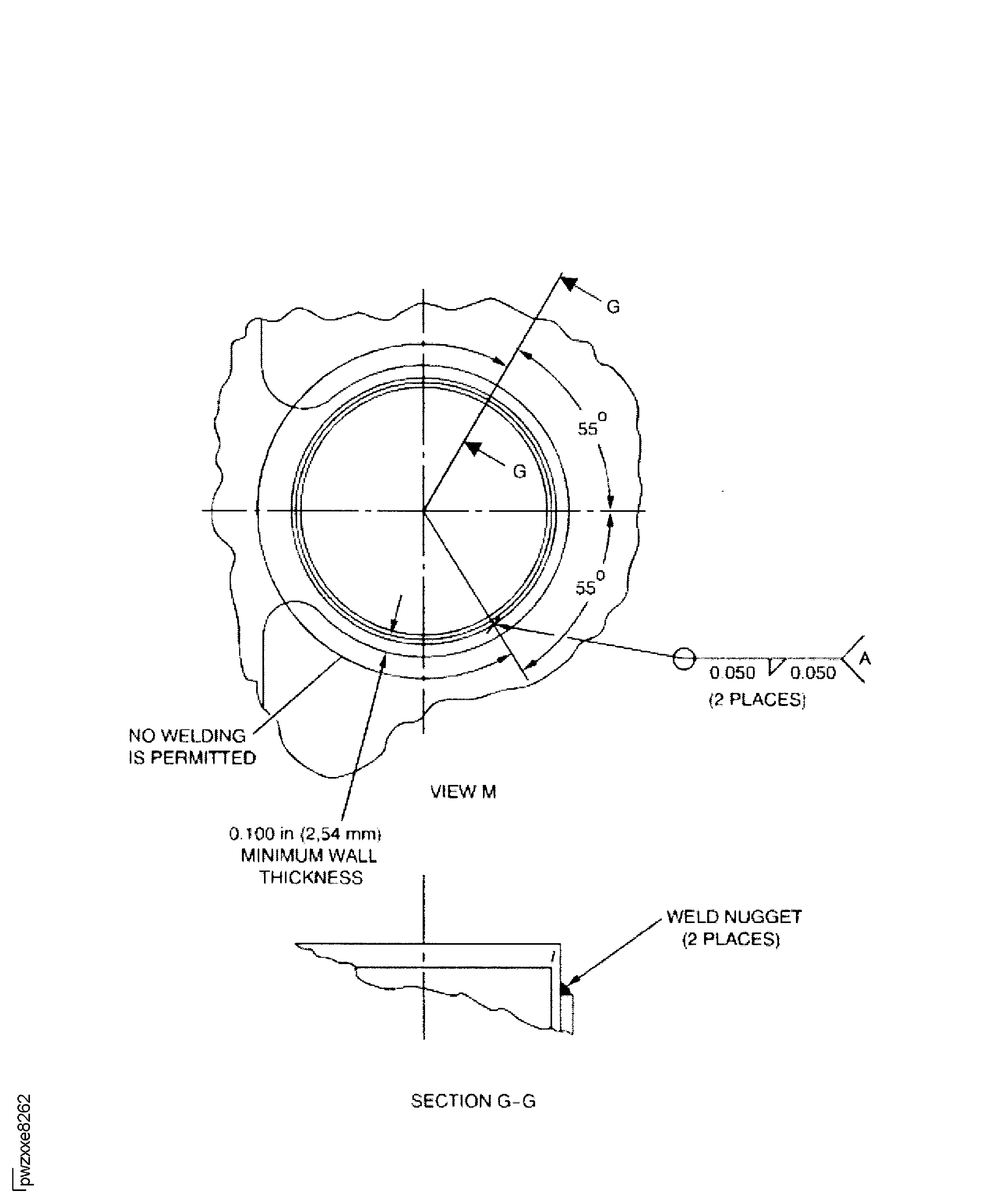

Refer to Figure.

Refer to Figure.

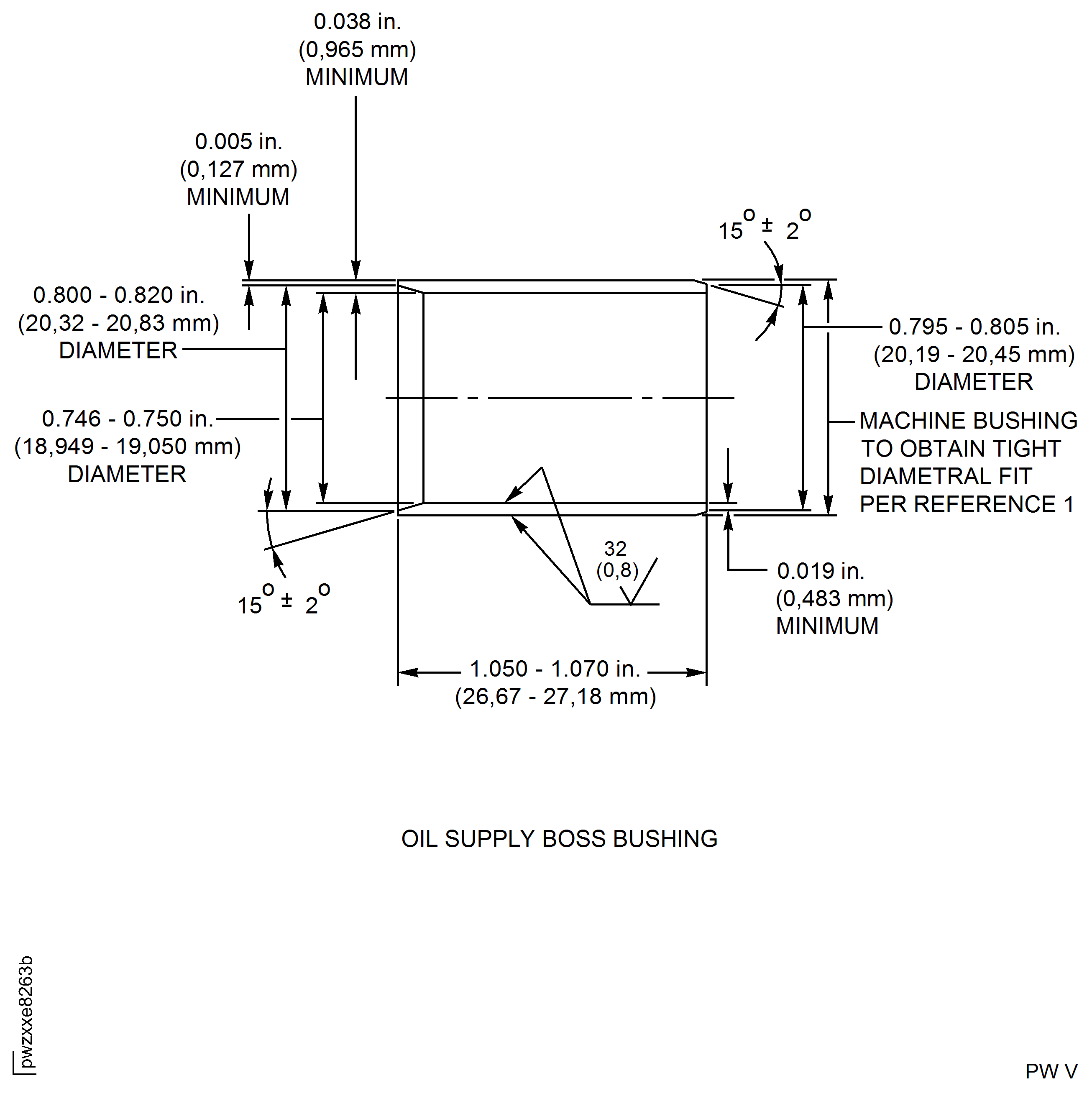

Surface texture must be as given in SPM TASK 70-35-09-350-501.

All surfaces must be 125 microinches (3.2 micrometers) unless specified differently.

Use Nickel Alloy (Inconel 718) to machine bushing.

Refer to the SPM TASK 70-11-03-300-503.

Clean the bushing.

Refer to the SPM TASK 70-23-02-230-501. No cracks permitted.

Fluorescent penetrant examine the bushing.

SUBTASK 72-42-11-330-001 Make the Bushing Locally for the Oil Supply Boss

Refer to Figure.

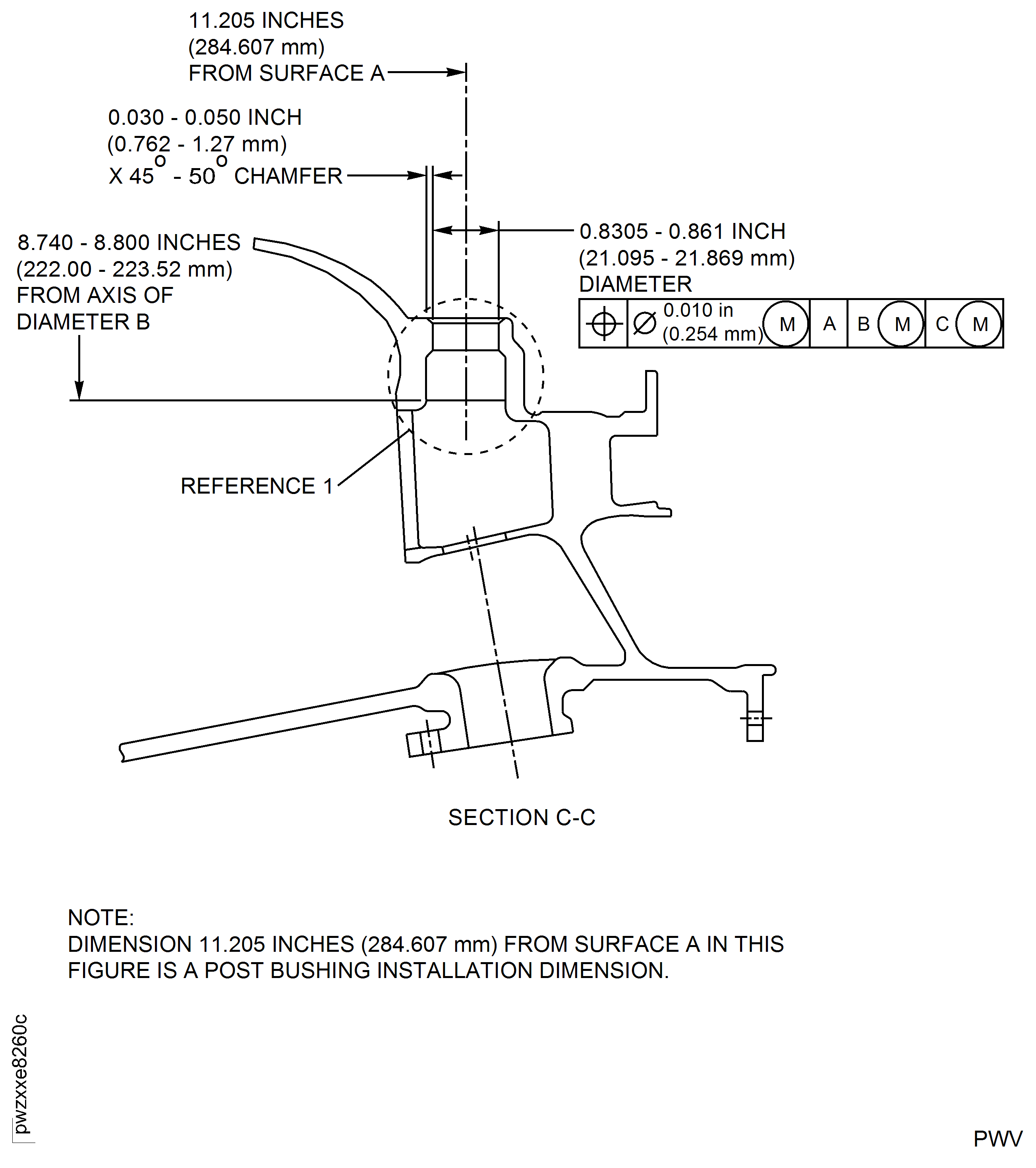

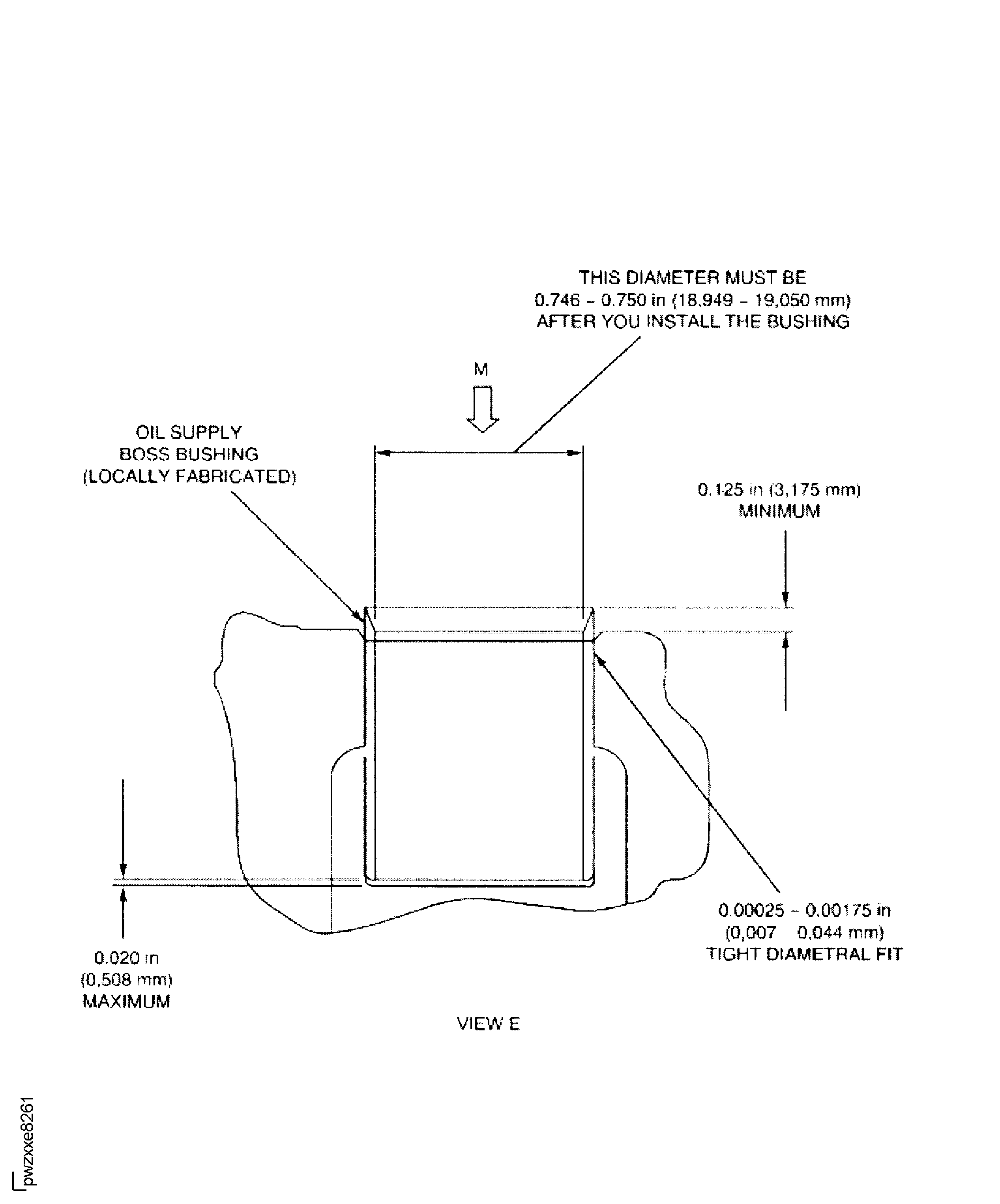

Install bushing in the inside diameter of the machined boss.

SUBTASK 72-42-11-350-084 Install the Bushing into the Oil Supply Boss

Refer to the SPM TASK 70-31-13-310-501.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE welding filler wire.

Refer to Figure.

Stress-relief after welding is not necessary.

CAUTION

DO NOT USE THIS WELD PROCESS FOR ANY OTHER DIFFUSER CASE REPAIRS UNLESS SPECIFICALLY INSTRUCTED.Tack weld bushing to diffuser case.

SUBTASK 72-42-11-310-052 Tack Weld the Bushing to the Boss

Refer to the SPM TASK 70-23-05-230-501.

No cracks are permitted in weld, bushing or diffuser case.

Fluorescent penetrant inspect tack welds.

SUBTASK 72-42-11-230-056 Inspect the Tack Welds

Make a permanent mark by procedure given in SPM TASK 70-09-00-400-501.

Use vibro-peen method.

Remove raised metal caused by marking.

Make a mark VRS3647 adjacent to part number.

SUBTASK 72-42-11-350-085 Identify the Repair

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4

Figure: Repair Details and Dimensions

Repair Details and Dimensions