Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-40-300-005 HPC Exit Guide Vane Stator - Repair Damaged Vane(s) By Replacement, Repair-005 (VRS6619)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor OGV Assembly - Stage 12 | QNP or QTB | Nickel base alloy |

Vane, Outlet Guide - HP Compressor Stage 12 Front | QNP or QTB | Nickel base alloy |

Vane, Outlet Guide - HP Compressor Stage 12 Rear | QNP or QTB | Nickel base alloy |

General

This Repair must only be done when the instruction to do so is given in 72-42-40 Inspection/Check.

This Repair repairs damaged HP Compressor OGV Assemblies - Stage 12, by Vane replacement, with new and/or serviceable vane(s) made from a donor HP Compressor OGV Assembly.

To keep the HP Compressor efficiency, Stage 12 OGV Assemblies are repaired as near to the new OGV condition as possible.

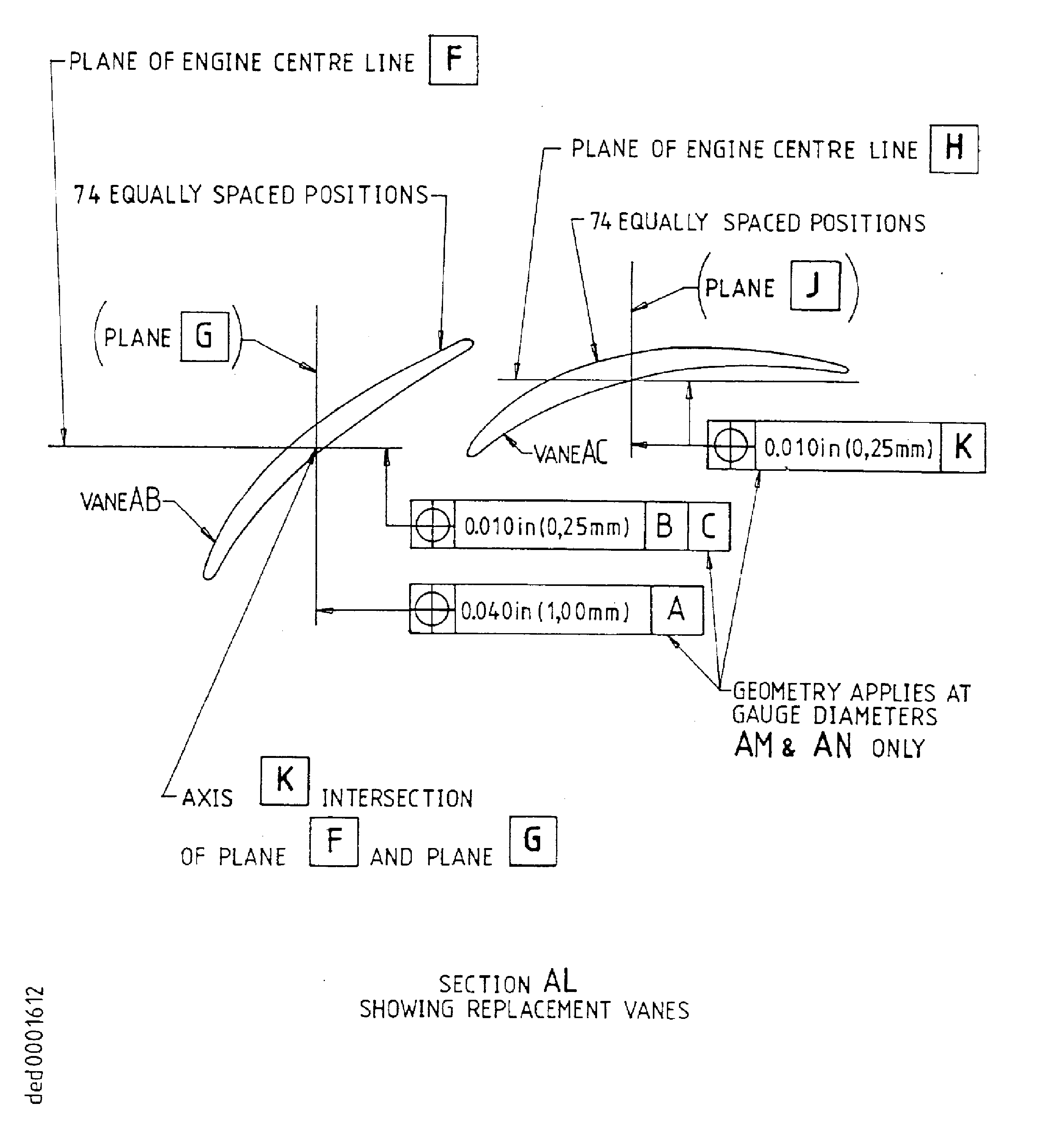

This Repair will permit a limit of 50 percent vane replacement on airfoil AB and airfoil AC, refer to Figure.

This is a Source Demonstration Repair which can only be done by approved vendors.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability - Refer to International Aero Engines

Related repairs - none

Repair Facilities

The Source Demonstration requirements of this Repair means that any facility not authorized to accomplish this Repair either, utilize the Authorized Repair Vendors listed below or cntact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG,

C/O ROLLS-ROYCE COMMERCIAL AERO ENGINES LTD.,

P.O. BOX 31,

DERBY DE24 8BJ,

ENGLAND

ATTN: Manager Technical Services

Authoirized Repair Vendors for Repair VRS6619 are listed below:

Chromalloy Connecticut,

601 Marshall Phelps Road,

Windsor,

Connecticut 06095,

USA

ATTN: Technical Director

The designation by IAE of an Authorized Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualification or quality standards of the Repair Vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorized Repair Vendors do not act as agents or representatives of IAE.

NOTE

DELETED

More equipment and materials necessary to do this Repair are in the SPM TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Nickel plate equipment | LOCAL | Nickel plate equipment | ||

| Lint free white cotton gloves | LOCAL | Lint free white cotton gloves | ||

| Argonarc welding equipment | LOCAL | Argonarc welding equipment | ||

| Wire brush | LOCAL | Wire brush | Stainless steel | |

| Furnace brazing equipment | LOCAL | Furnace brazing equipment | ||

| Heat treatment equipment | LOCAL | Heat treatment equipment | ||

| Hardness tester | LOCAL | Hardness tester | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 03-150 DELETED | 0AM53 | CoMat 03-150 | ||

| CoMat 03-250 BRAZING FILLER MATERIAL,Ni-BASE | 01FK3 | CoMat 03-250 | ||

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-109 SILICON CARBIDE ABRASIVETAPE | 44197 | CoMat 05-109 | ||

| CoMat 05-110 EMERY POLISHING PAPER | 0AM53 | CoMat 05-110 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vane, Outlet Guide - HP Compressor | 6A7390 | |||

| Vane, Outlet Guide - HP Compressor | 6A7391 |

Safety Requirements

NONEProcedure

Refer to TASK 72-42-40-200-000 (72-42-40 (INSPECTION-000)).

Make a record of all dimensions, to allow dimensions before and after repair, to be checked.

Measure the dimensions of the HP Compressor OGV Assembly, Stage 12, prior to the removal of the damaged vane(s).

SUBTASK 72-42-40-220-062 Examine the HP Compressor OGV Assembly, Stage 12

Use 6A7390 Stage 12 Front, 01-220 and/or 6A7391 Stage 12 Rear, 01-221 and/or serviceable vane(s) made from a donor HP Compressor OGV Assembly.

Make sure the vane(s) can be located correctly in the outer and inner platform surfaces.

Make sure there is sufficient clearance, for brazing, up to a maximum of 0.010in. (0.254 mm).

Visually inspect the fit of the replacement vane(s).

SUBTASK 72-42-40-220-063 Examine the Outer and Inner Platform Surfaces, for Vane Fit

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-001-001.

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-42-40-110-061 Chemically Clean

Refer to 4. Repair Facilities, Para B., for approved vendor masks or use CoMat 02-001 ADHESIVE TAPE (MASKING).

Mask areas of the HP Compressor OGV Assembly, Stage 12 not to be repaired.

Refer to the SPM TASK 70-12-09-120-501.

Use 6A7390 Stage 12 Front, 01-220, 74 off and/or 6A7391 Stage 12 Rear, 01-221, 74 off and/or serviceable vane(s) made from the donor HP Compressor OGV Assembly, as necessary.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE, with abrasive blast equipment.

Abrasive blast areas of the HP Compressor OGV Assembly, Stage 12 to be repaired and the replacement vanes.

SUBTASK 72-42-40-120-052 Abrasive Blast the HP Compressor OGV Assembly, Stage 12

Refer to the SPM TASK 70-31-16-310-501, SUBTASK 70-31-16-310-004.

Use 6A7390 Stage 12 Front, 01-220, 74 off and/or 6A7391 12 Rear, 01-221, 74 off and/or serviceable vane(s) made from the donor HP Compressor OGV Assembly, as necessary.

Nickel plate must be 0.0001 in. to 0.0006 in. (0.003 mm to 0.015 mm) thick.

Use nickel plate equipment.

Nickel plate the HP Compressor OGV Assembly, Stage 12 and the replacement vane(s).

SUBTASK 72-42-40-330-051 Nickel Plate the HP Compressor OGV Assembly, Stage 12 and the Replacement Vane(s)

Use 6A7390 Stage 12 Front, 01-220, 74 off and/or 6A7391 Stage 12 Rear, 01-221, 74 off and/or serviceable vane(s) made from the donor HP Compressor OGV Assembly.

Place tang end first through the outer platform and seat it in to the pocket on the inner platform.

Make sure the tang portion of the vane(s) is completely through the inner platform and located correctly.

Repeat for all vane(s), both rows, as necessary.

Install the new vane(s) as necessary.

SUBTASK 72-42-40-350-059 Install Replacement Vane(s) in the HP Compressor OGV Assembly, Stage 12

CAUTION

WEAR LINT FREE WHITE COTTON GLOVES WHEN YOU DO THIS PROCEDURE.Refer to the SPM TASK 70-31-02-310-501-001.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE with argonarc welding equipment.

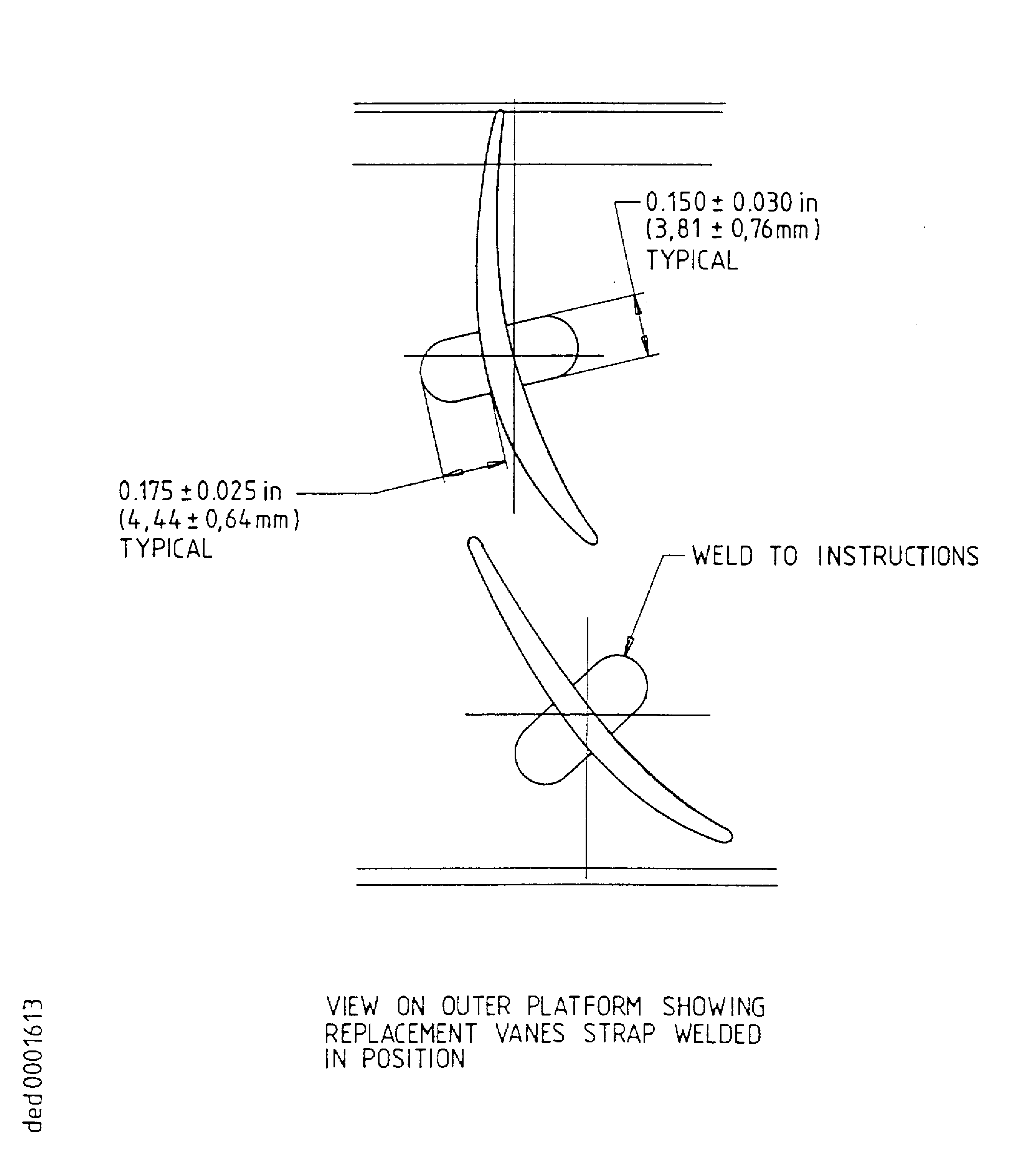

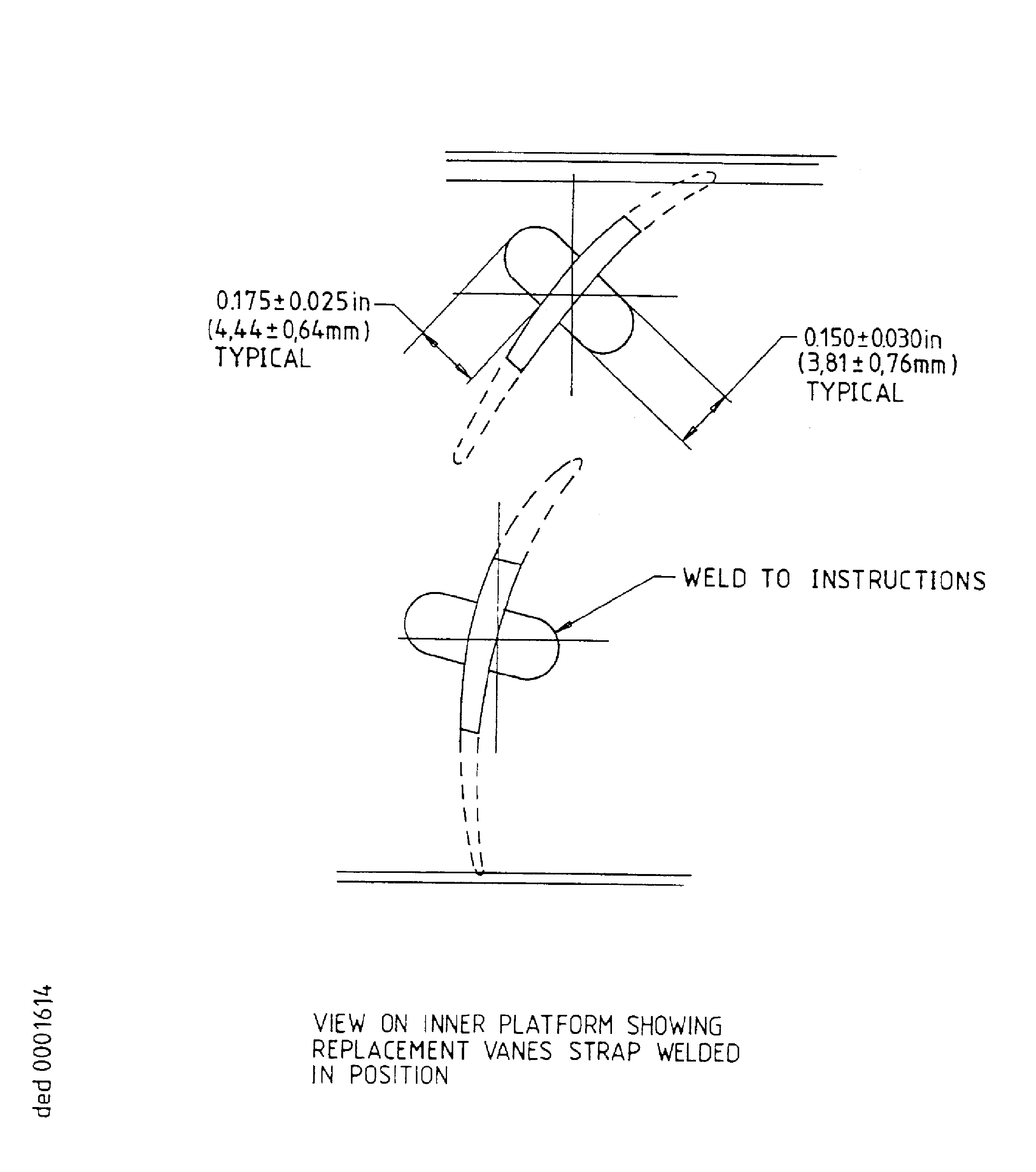

Strap weld the replacement vane(s) to the non-gas-path side of the inner and outer platform at the mid chord position.

Refer to the SPM TASK 70-31-02-310-501-001.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE, with argonarc welding equipment.

Weld Data

Refer to approved vendor in 4. Repair Facilities, Para B., for weld parameters.

NOTE

This weld is to prevent the trailing edge thin wall from cracking due to expansion and contraction during the braze cycle.

Fusion weld the trailing edge only of the replacement vane(s) AC, to the outer platform.

SUBTASK 72-42-40-310-051 Safety the Replacement Vane(s) in Position

Refer to the SPM TASK 70-31-16-310-501.

Use CoMat 03-150 DELETED.

Use an applicable needle to apply the brazing filler powder.

Apply braze alloy paste to the vane joint(s) on both the inner and outer platform.

Refer to the SPM TASK 70-31-16-310-501.

When you use the wide gap filler material, apply the filler to the joint, then trim any excess material smooth with the adjacent outer and/or inner platform surface.

On completion apply CoMat 03-150 DELETED to cover the joint completely.

Fill wide gaps, as necessary.

Refer to the SPM TASK 70-31-16-310-501.

Use furnace brazing equipment.

Braze data

Refer to approved vendor in 4. Repair Facilities, Para B., for braze parameters.

Furnace braze the HP Compressor OGV Assembly, Stage 12.

SUBTASK 72-42-40-310-052 Braze the Replacement Vane(s) in Position

Refer to the SPM TASK 70-31-16-310-501.

The brazed joint must show the presence of a fillet and must show no recess or through voids.

Visually examine the brazed joint(s) of the replacement vane(s).

SUBTASK 72-42-40-220-066 Examine the Brazed Joint(s)

Refer to 4. Repair Facilities, Para B., for approved vendor tools.

Heat-Treat Data

Heat to a temperature of 1400 deg F (760 deg C) and hold for 2 hours in a vacuum or argon.

Furnace cool at a rate of 100 deg F (56 deg C) per hour to 1150 deg F (621 deg C) and hold for 4 hours.

Cool down to room temperature in air.

Heat-treat the HP Compressor OGV Assembly, Stage 12 in a vacuum or controlled atmosphere.

SUBTASK 72-42-40-370-051 Heat-Treat the HP Compressor OGV Assembly, Stage 12

Use a sample piece of OGV.

The hardness check must be within RC34 to RC43, with RC32 minimum.

This ia a guide for quality control and is not an absolute limit.

Use a hardness tester.

NOTE

If the sample OGV piece is outside the hardness variation limits, additional OGV's must be sampled, if more than 10 percent variation in hardness is experienced, then the cause must be investigated.

Do a hardness check on a sample of HP Compressor OGV Assembly, Stage 12.

SUBTASK 72-42-40-220-066 Do a Hardness Check

Refer to 4. Repair Facilities, Para B., for approved vendor tools.

Make sure the vane(s) are still brazed in position.

Make sure the vane angle(s) is/are to the dimensions given, adjust the vane(s), as necessary.

Compare before and after repair dimensions, refer to Step.

Use workshop inspection equipment.

Visually examine and measure the vane angle(s).

SUBTASK 72-42-40-220-067 Examine

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-001-001.

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-42-40-110-064 Chemically Clean

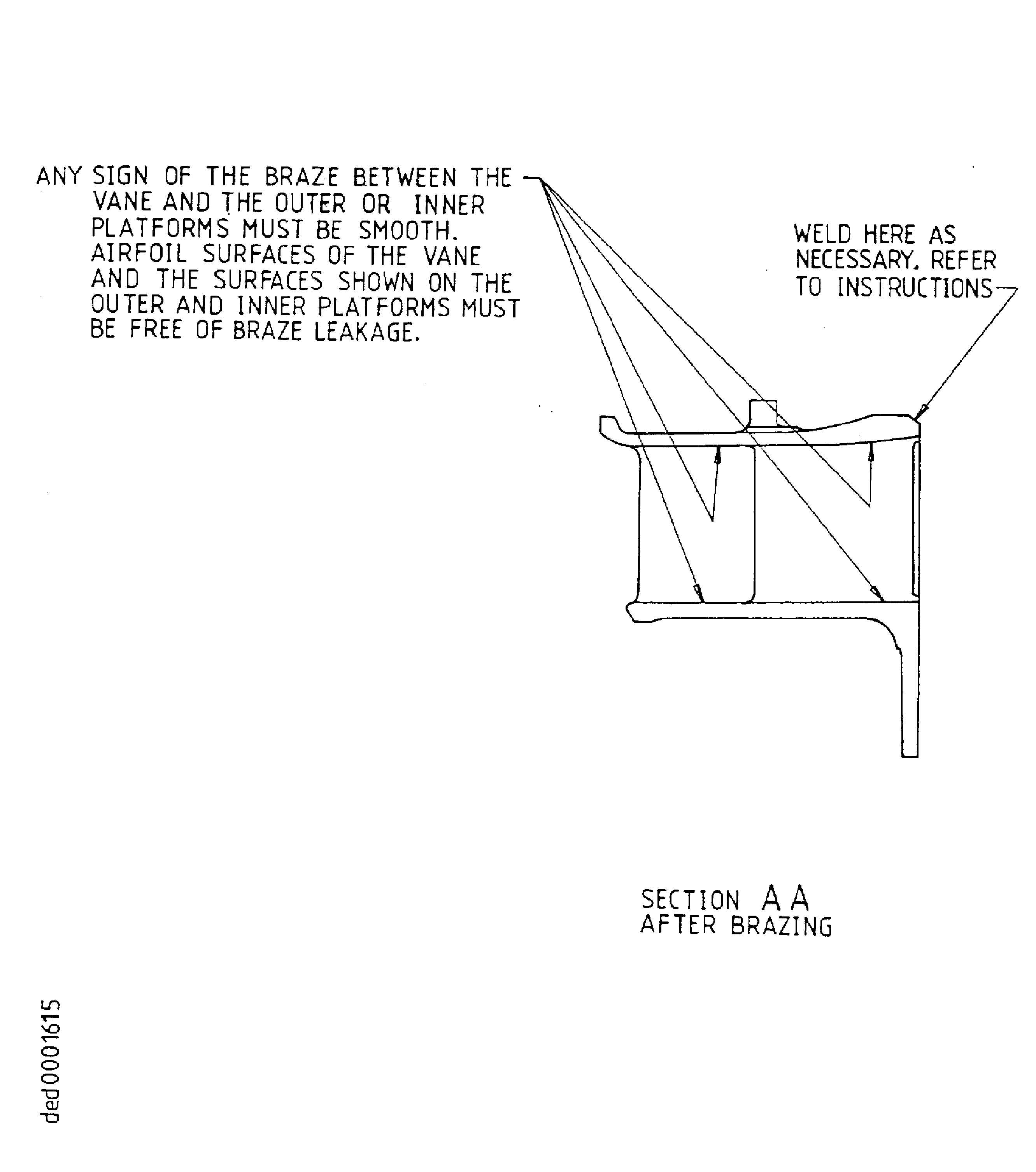

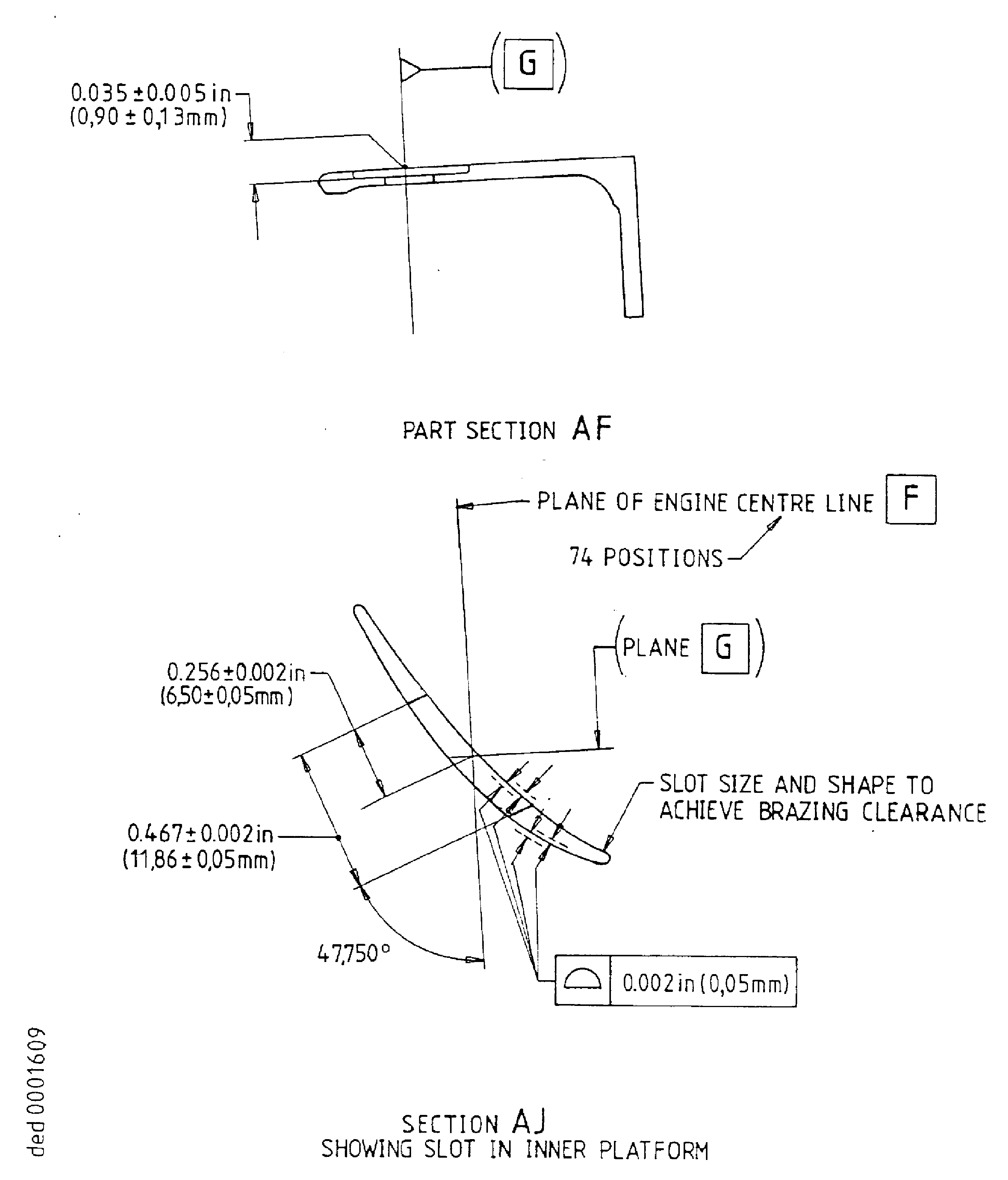

Figure: Repair details and dimensions

Repair details and dimensions

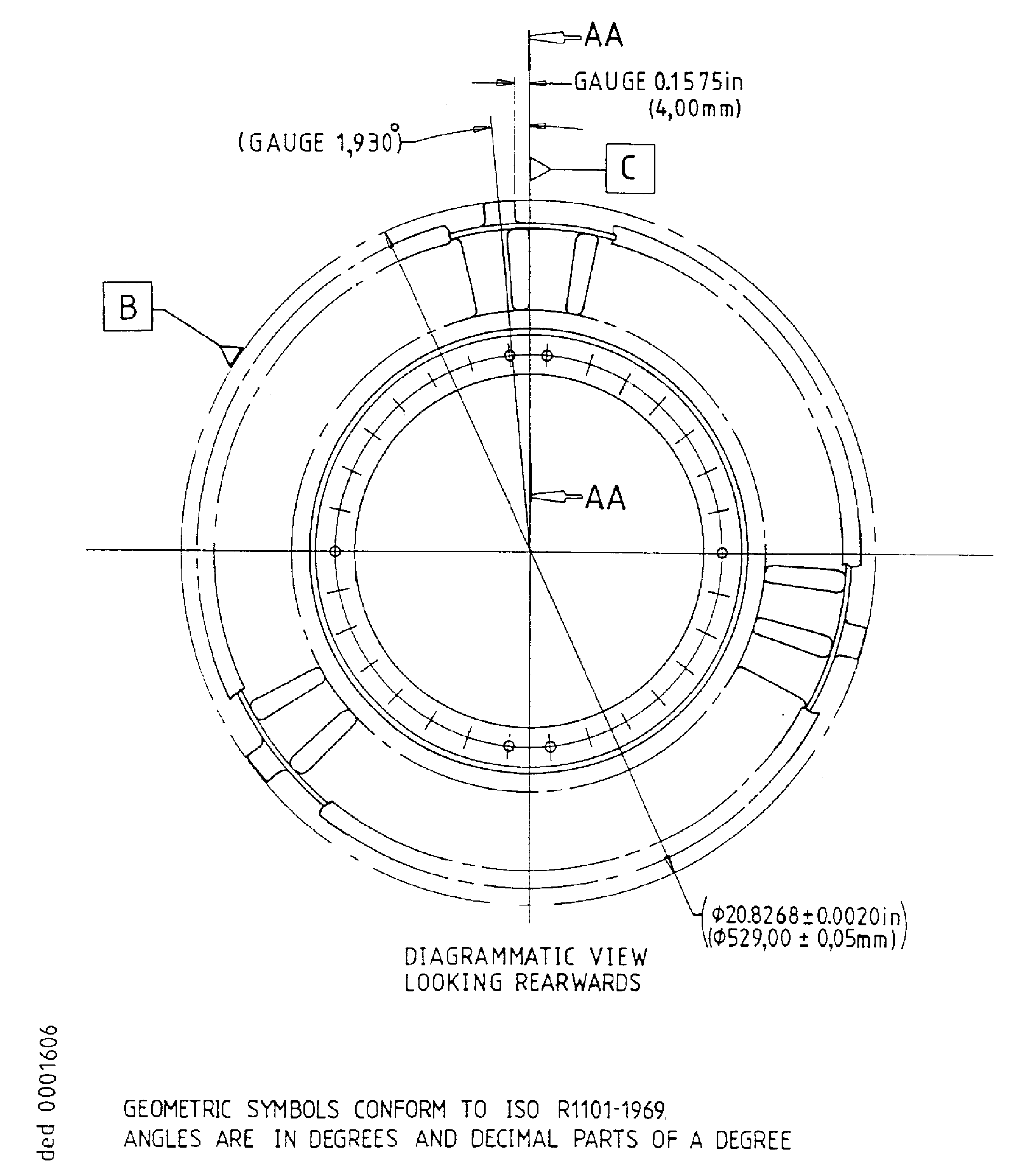

Figure: Repair details and dimensions

Repair details and dimensions

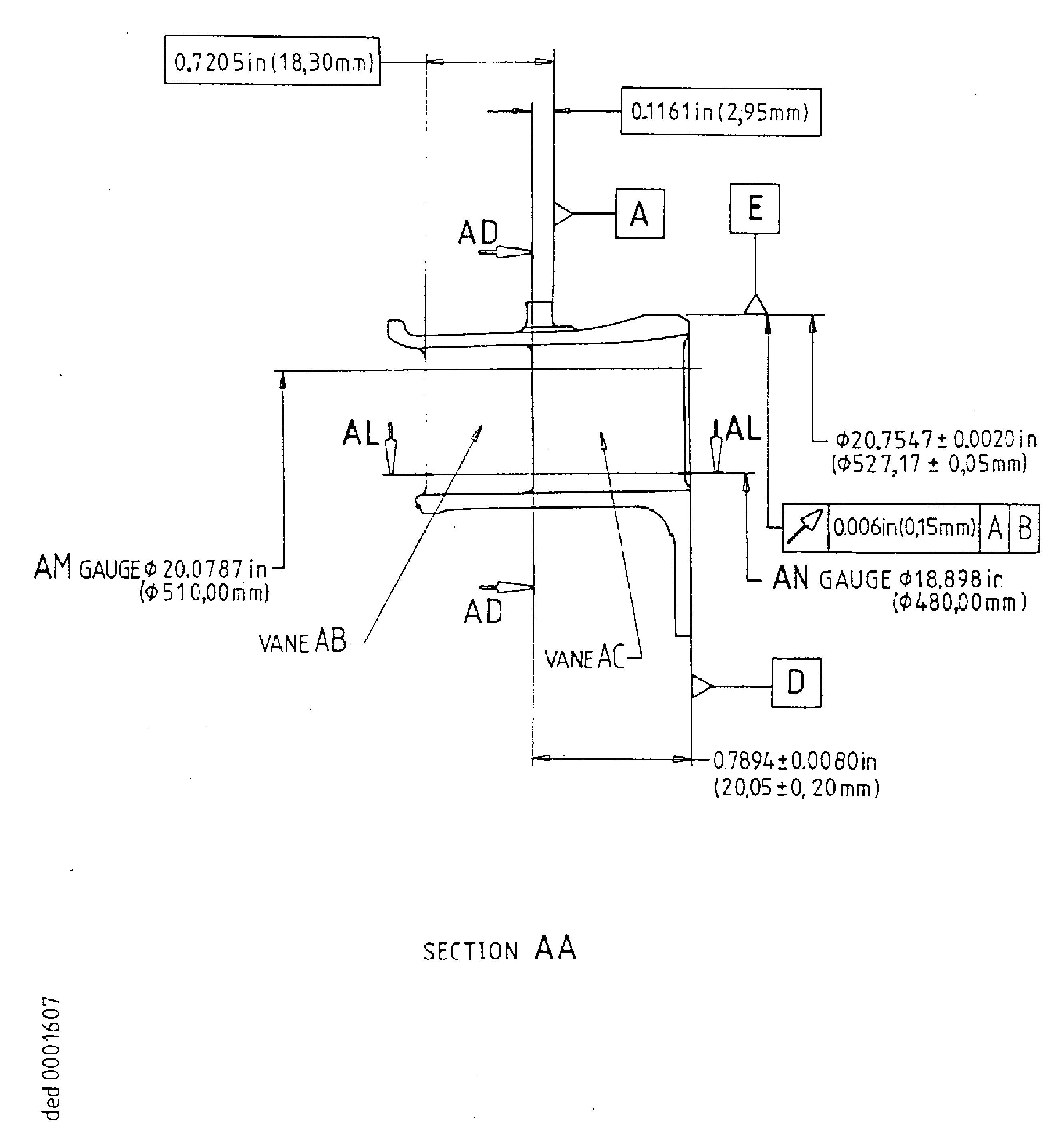

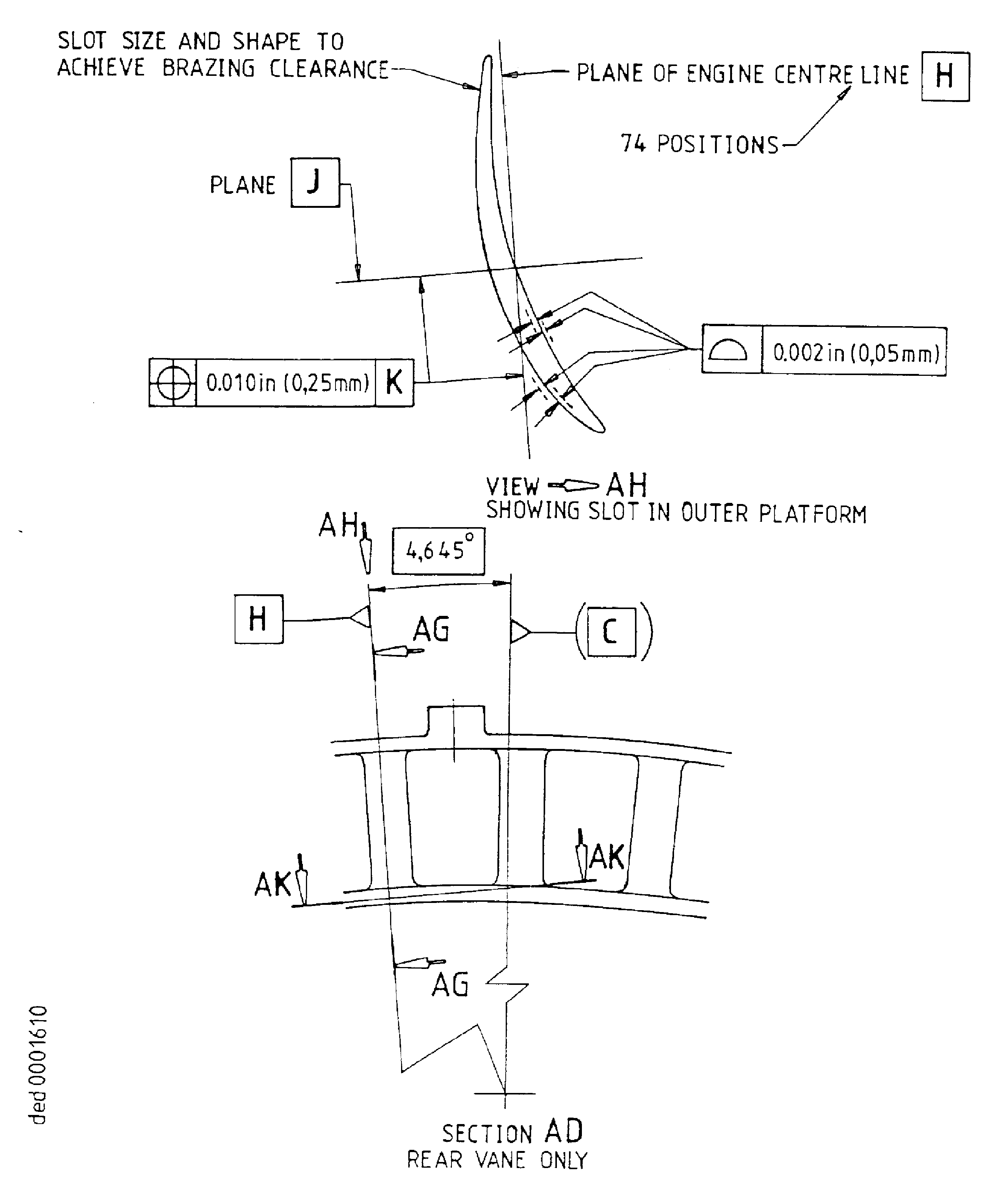

Figure: Repair details and dimensions

Repair details and dimensions

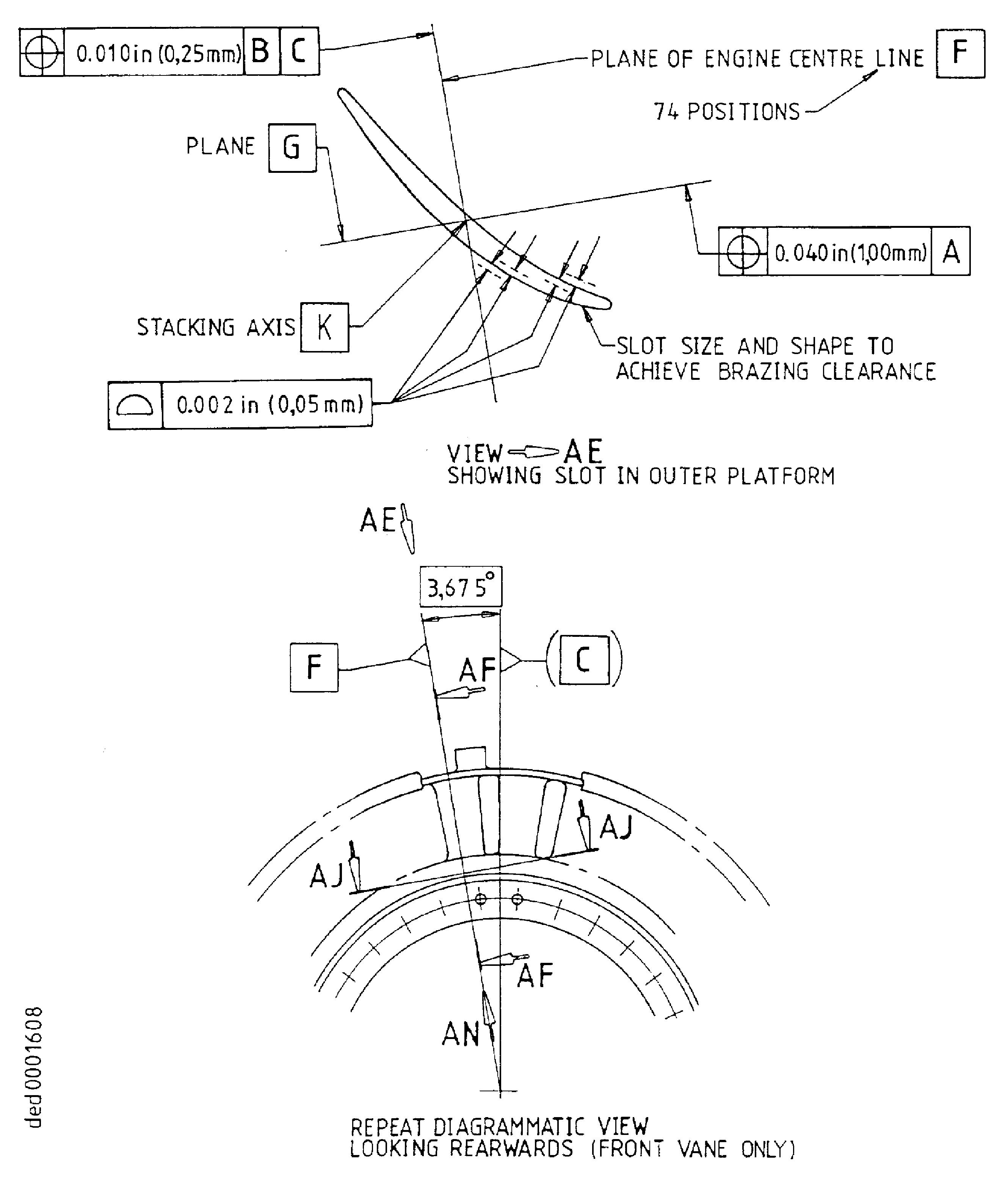

Figure: Repair details and dimensions

Repair details and dimensions

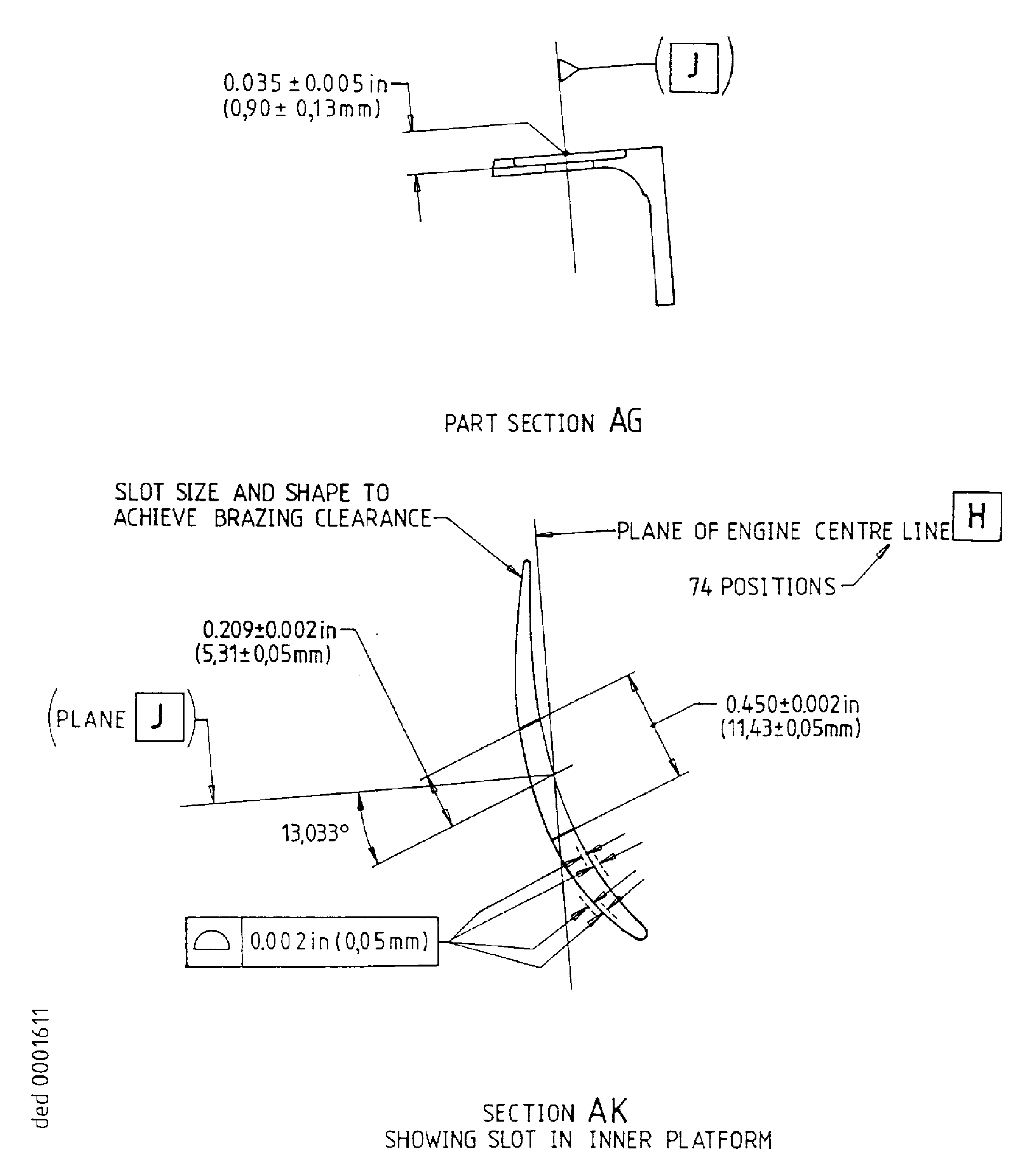

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions