Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-50-300-001 HPC Rear Static Seal - Replace The Brush Seal Assembly, Repair-001 (VRS6201)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

Support cone | QAW or | Nimonic 80A |

QAL | ||

Seal carrier | QAW or | Nimonic 80A |

QAL | ||

Retaining plate | QAR | C263 |

Rivets | QBE | Nimonic 75 |

General

This repair must only be done when the instruction to do so is given in TASK 72-42-50 Inspection.

This repair replaces the brush seal assembly in the 3 to 8 drum HP compressor static air seal - assembly.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines AG

Related repairs - none

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this repair are in the SPM TASKS that follow:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand grinder | LOCAL | Hand grinder | ||

| Vertical drilling machine | LOCAL | Vertical drilling machine | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Special container for liquid nitrogen | LOCAL | Special container for liquid nitrogen | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Hot squeeze riveting electrodes | LOCAL | Hot squeeze riveting electrodes | ||

| Resistance welding machine | LOCAL | Resistance welding machine | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Plate retaining | 6A4141 | 6 AR | ||

| Rivet, solid | AS16288 | 24 AR | ||

| Rivet, solid | AS16329 | 24 AR | ||

| Rivet, solid | AS16289 | 48 AR | ||

| Rivet, solid | AS16330 | 48 AR | ||

| Brush seal | 6A3933 | 1 AR |

Safety Requirements

NONEProcedure

Refer to Figure

SUBTASK 72-42-50-350-058 Disassemble the Static Seal Assembly

Refer to SPM TASK 70-23-04-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test of the drilled hole(s).

SUBTASK 72-42-50-230-073 Do a Crack Test

Refer to Figure

Use brush seal, 1 off, 01-130, with CoMat 03-026 LIQUID NITROGEN put in a suitable container for liquid nitrogen.

Use protective gloves.

Freeze the brush seal.

SUBTASK 72-42-50-350-059 Assemble the Outer Seal Carrier

Refer to Figure

Refer to SPM TASK 70-39-02-390-501.

Use hot squeeze riveting electrodes with resistance welding machine.

NOTE

Use low voltage for minimum quantity of heat required to give the rivet the correct shape.

Hot squeeze the rivets.

SUBTASK 72-42-50-390-052-001 Safety the Retaining Plates

Refer to Figure

SUBTASK 72-42-50-390-052-002 Safety the Retaining Plates

Refer to SPM TASK 70-23-04-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the rivets.

SUBTASK 72-42-50-230-061 Do a Crack Test

Use CoMat 03-026 LIQUID NITROGEN put in a suitable container for liquid nitrogen.

Use protective gloves.

Freeze the seal carrier.

SUBTASK 72-42-50-350-061 Assemble the Seal Carrier to the Support Cone

Refer to Figure

Refer to SPM TASK 70-39-02-390-501.

Use hot squeeze riveting electrodes with resisting welding machine.

NOTE

Use low voltage for minimum quantity of heat required to give the rivet the correct shape.

Hot squeeze the rivets.

SUBTASK 72-42-50-390-053-001 Safety the Outer Seal Carrier

Refer to Figure

SUBTASK 72-42-50-220-069 Examine the Repair

Do Step.

SUBTASK 72-42-50-230-062 Do a Crack Test

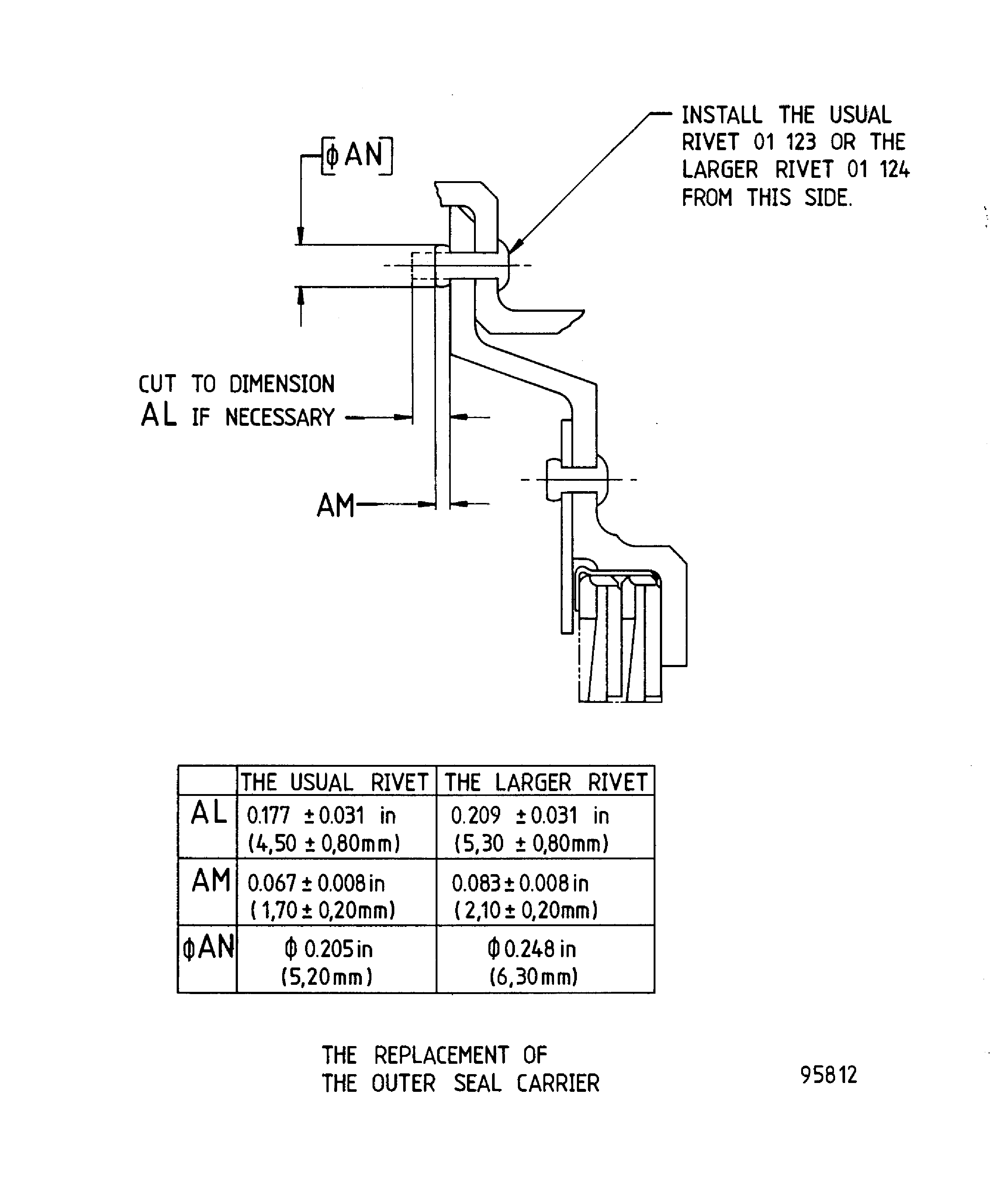

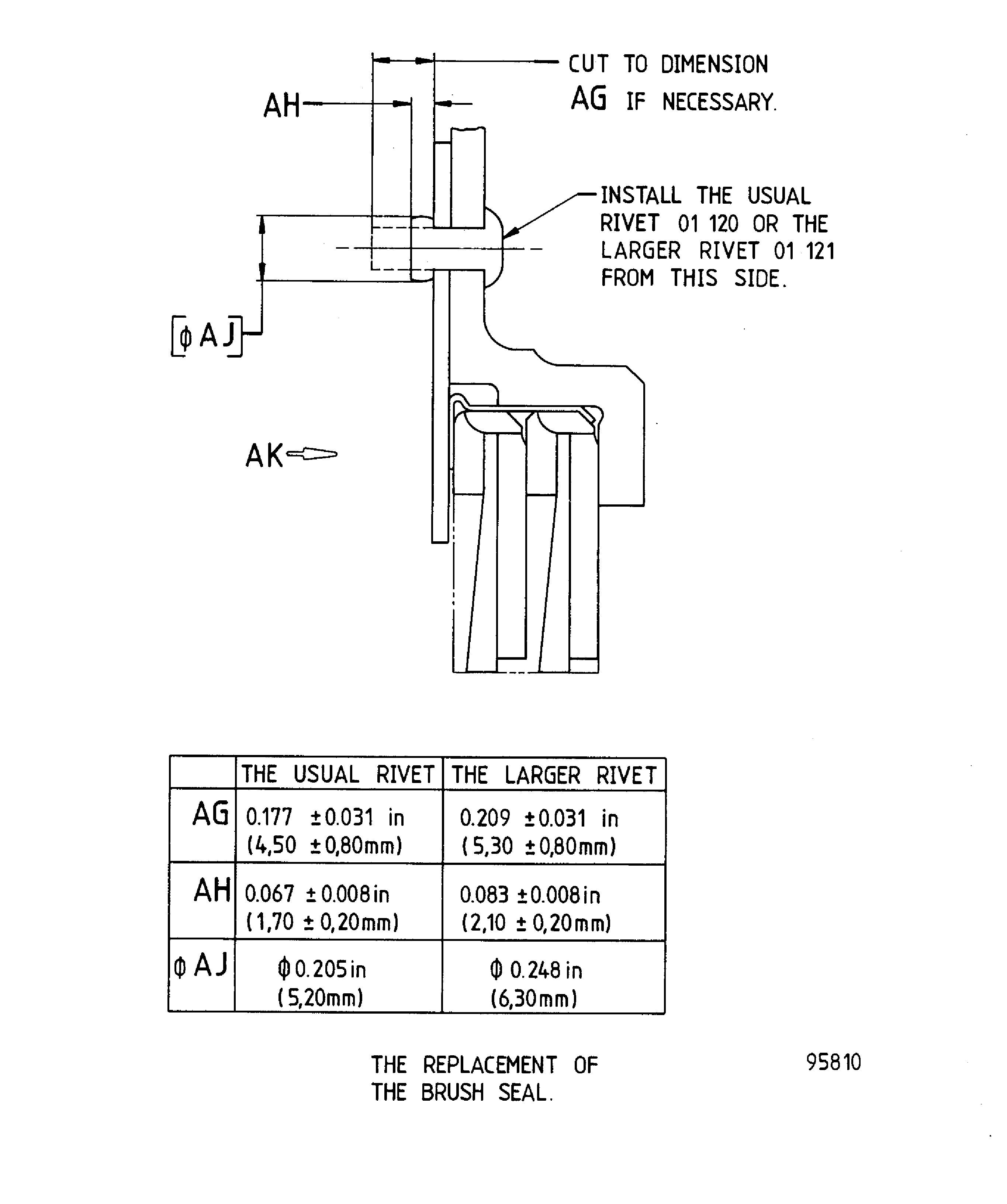

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

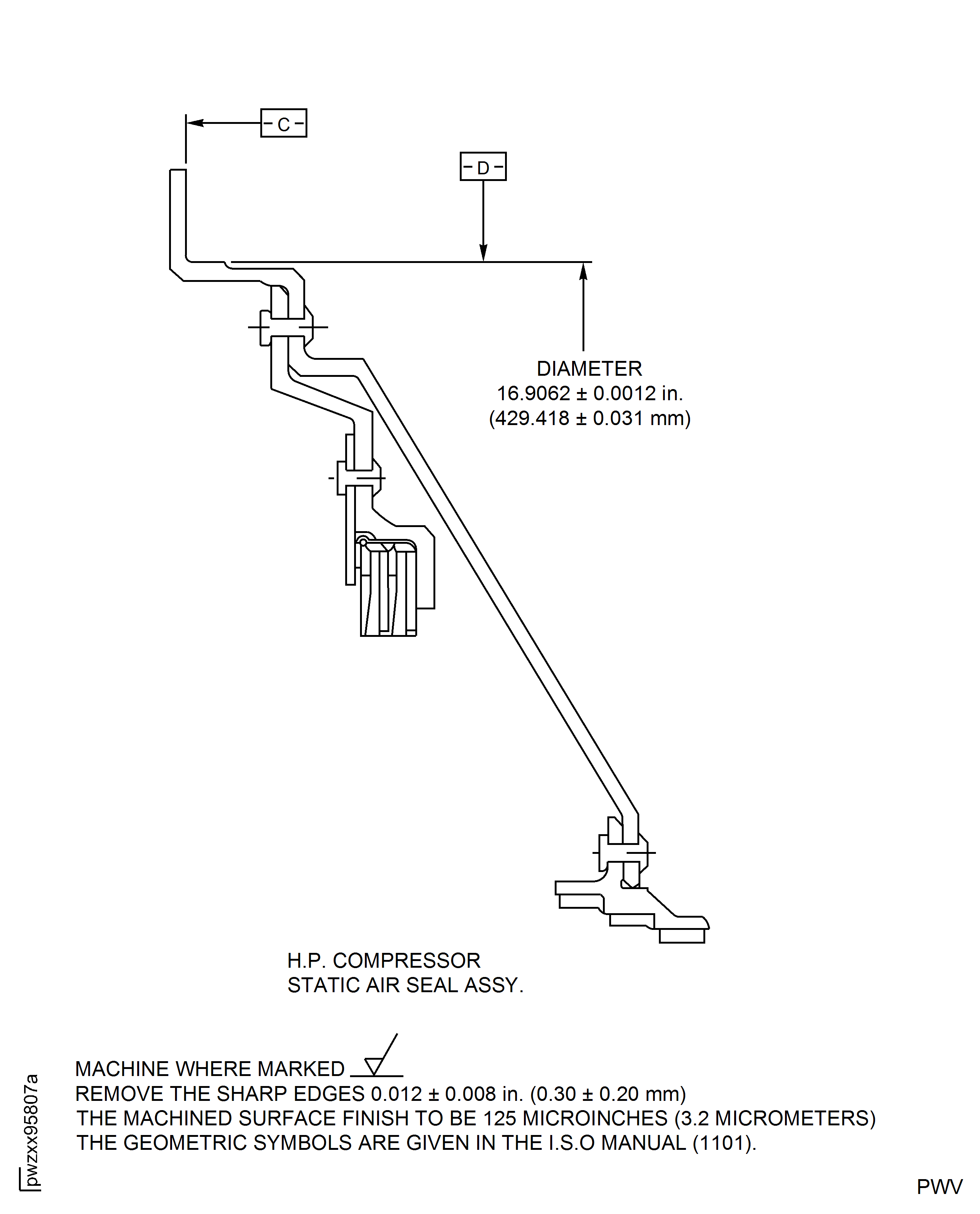

Figure: Repair Details and Dimensions

Repair Details and Dimensions

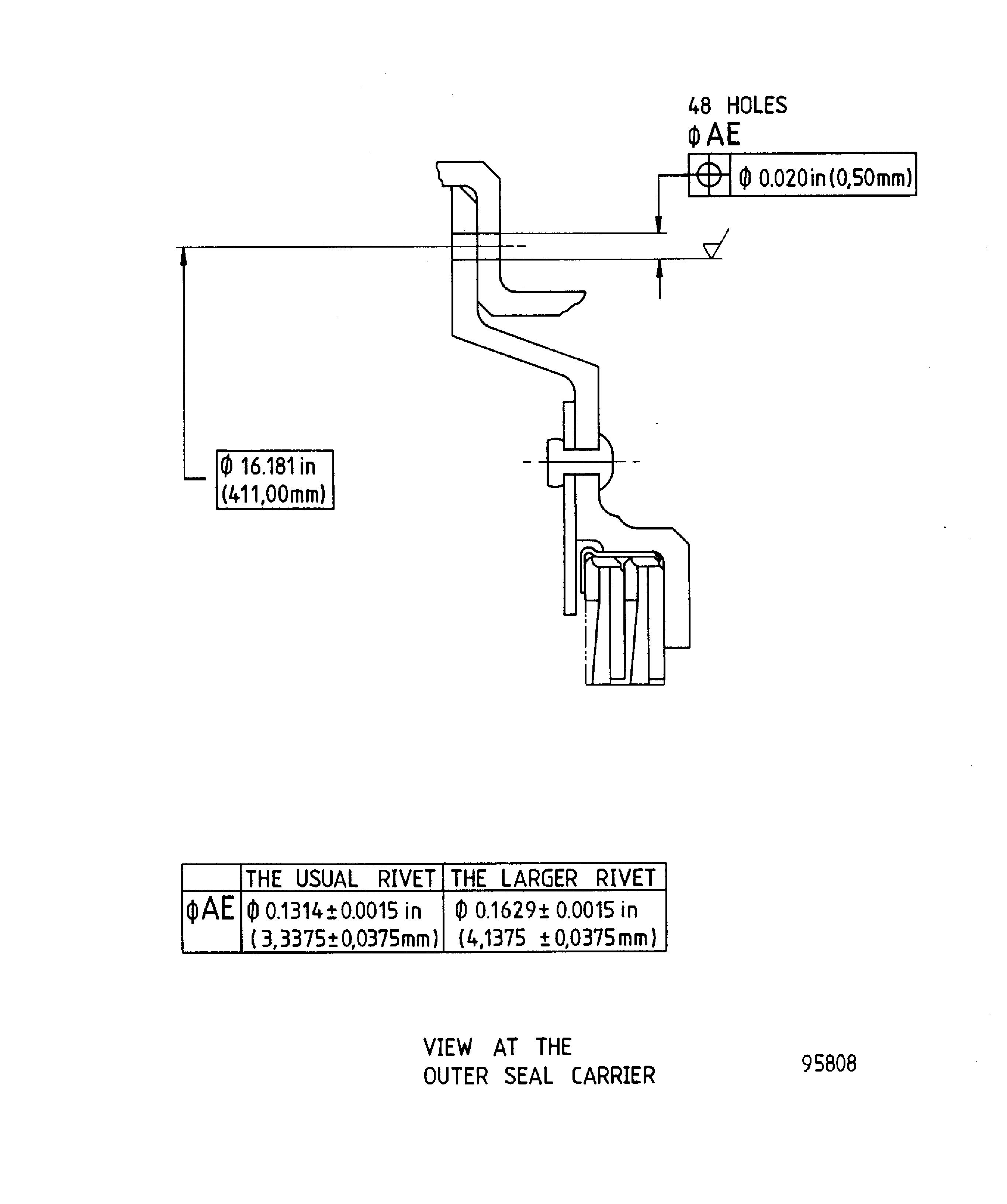

Figure: Repair Details and Dimensions

Repair Details and Dimensions

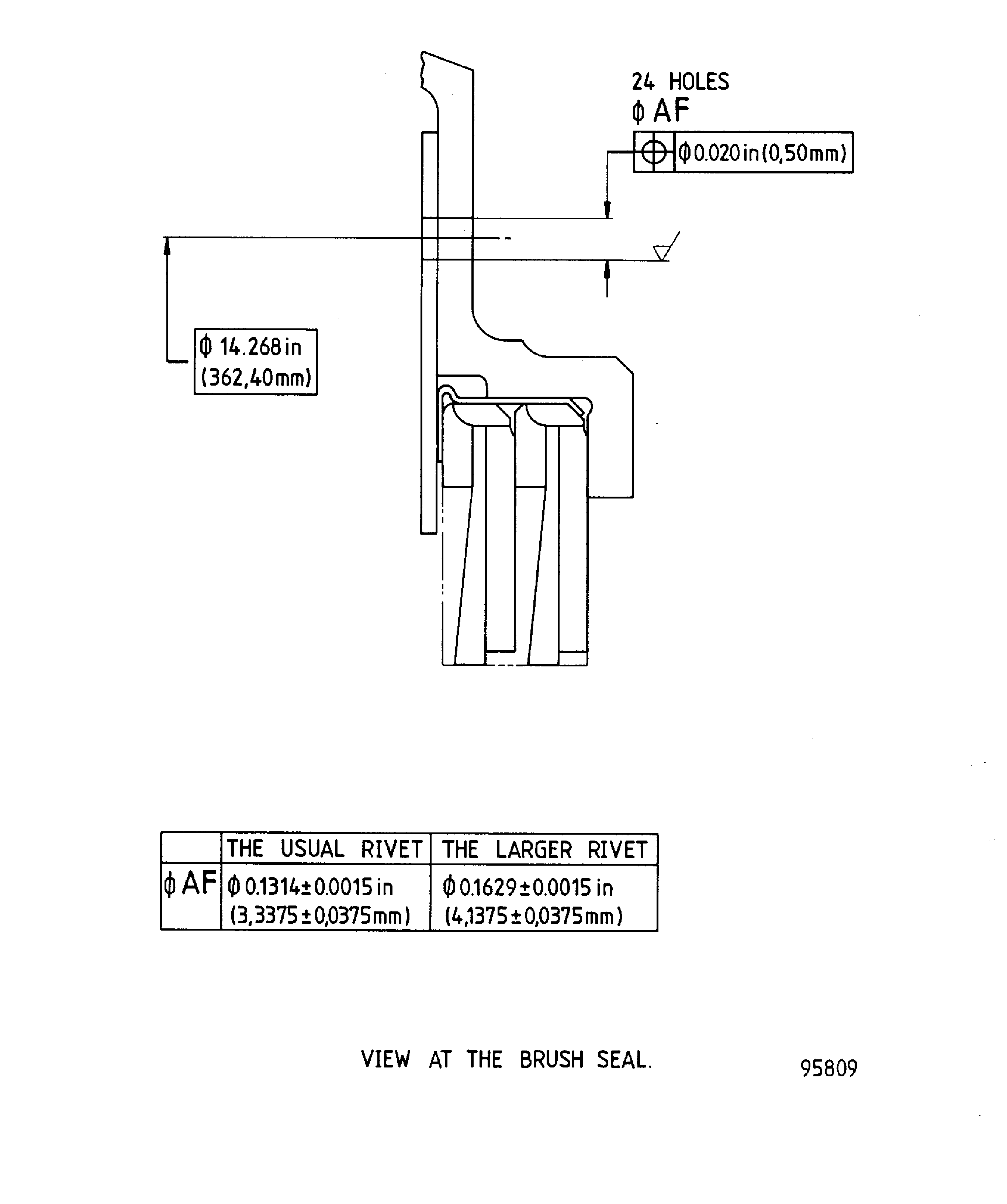

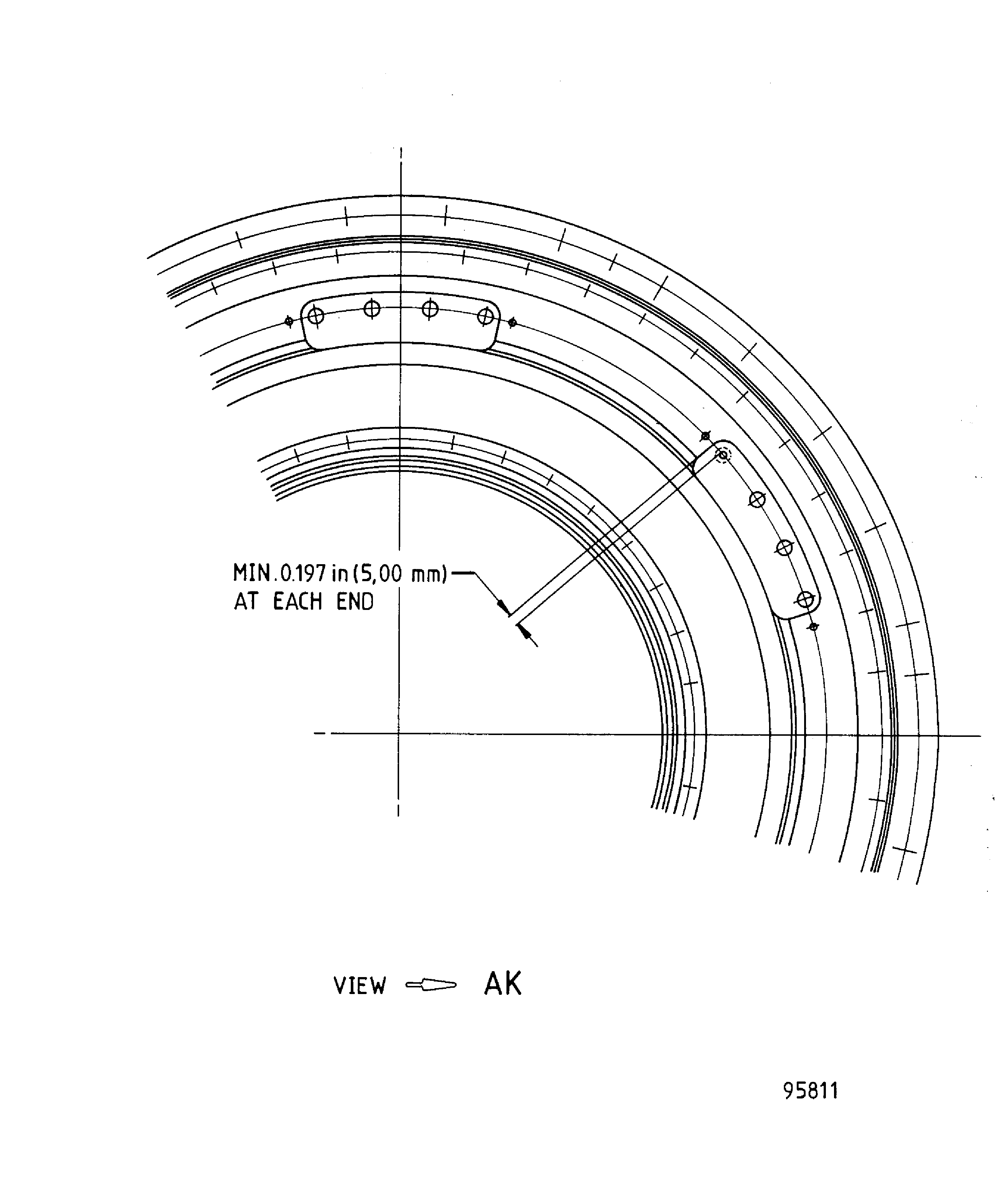

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

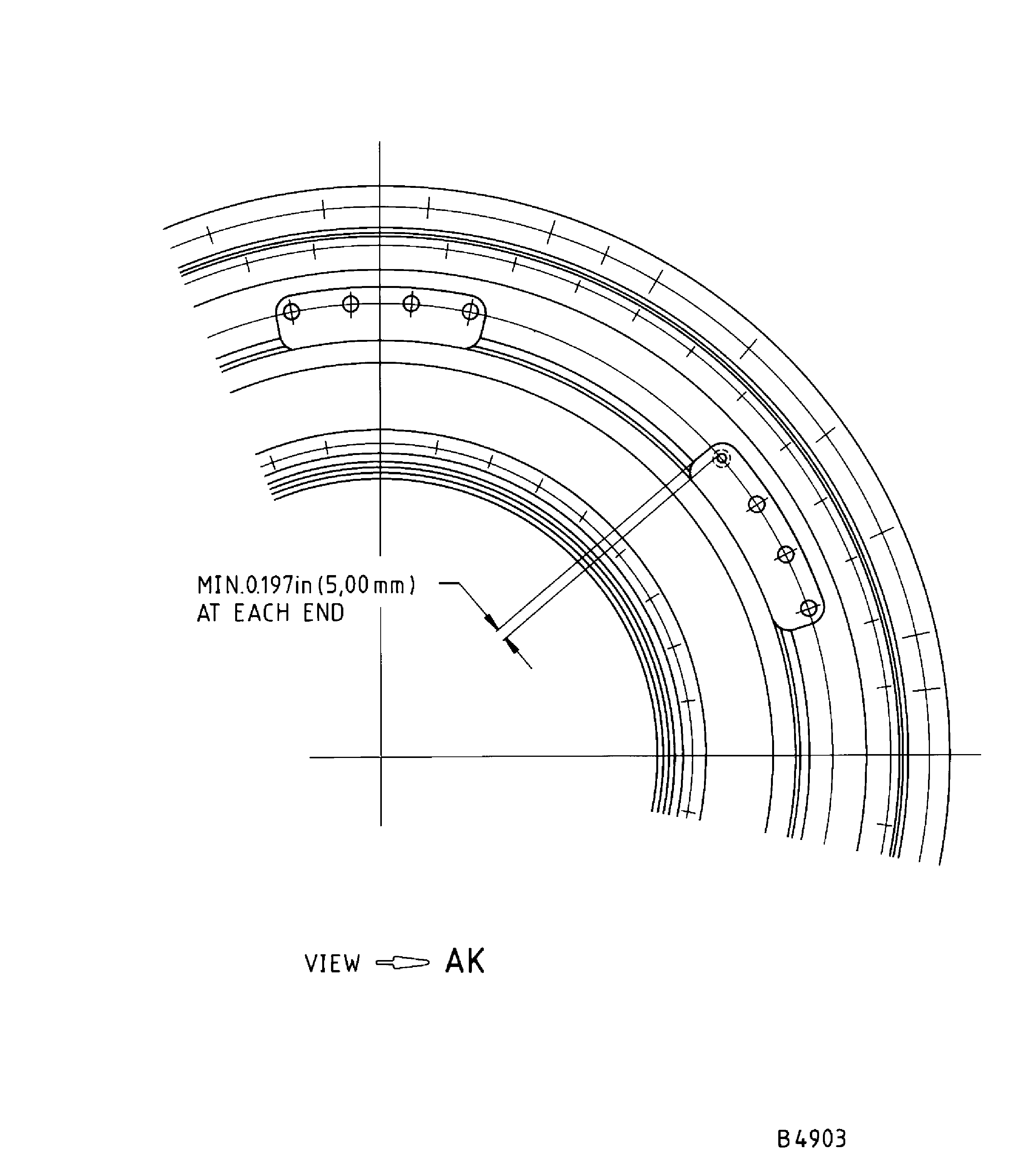

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions

Repair Details and Dimensions