Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-50-300-009 HPC Rear Static Seal - Repair The Spigot Diameter By Metal Spray, Repair-009 (VRS9493)

General

This repair must only be done when the instruction to do so is given in TASK 72-42-50-200-000 (INSPECTION-000).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | 00BB6 | CoMat 03-038 |

Spares

NONESafety Requirements

NONEProcedure

Remove the inner seal carrier.

Refer to Repair, VRS6203 TASK 72-42-50-300-002 (REPAIR-002).

SUBTASK 72-42-50-350-068 Remove the Inner Seal Carrier

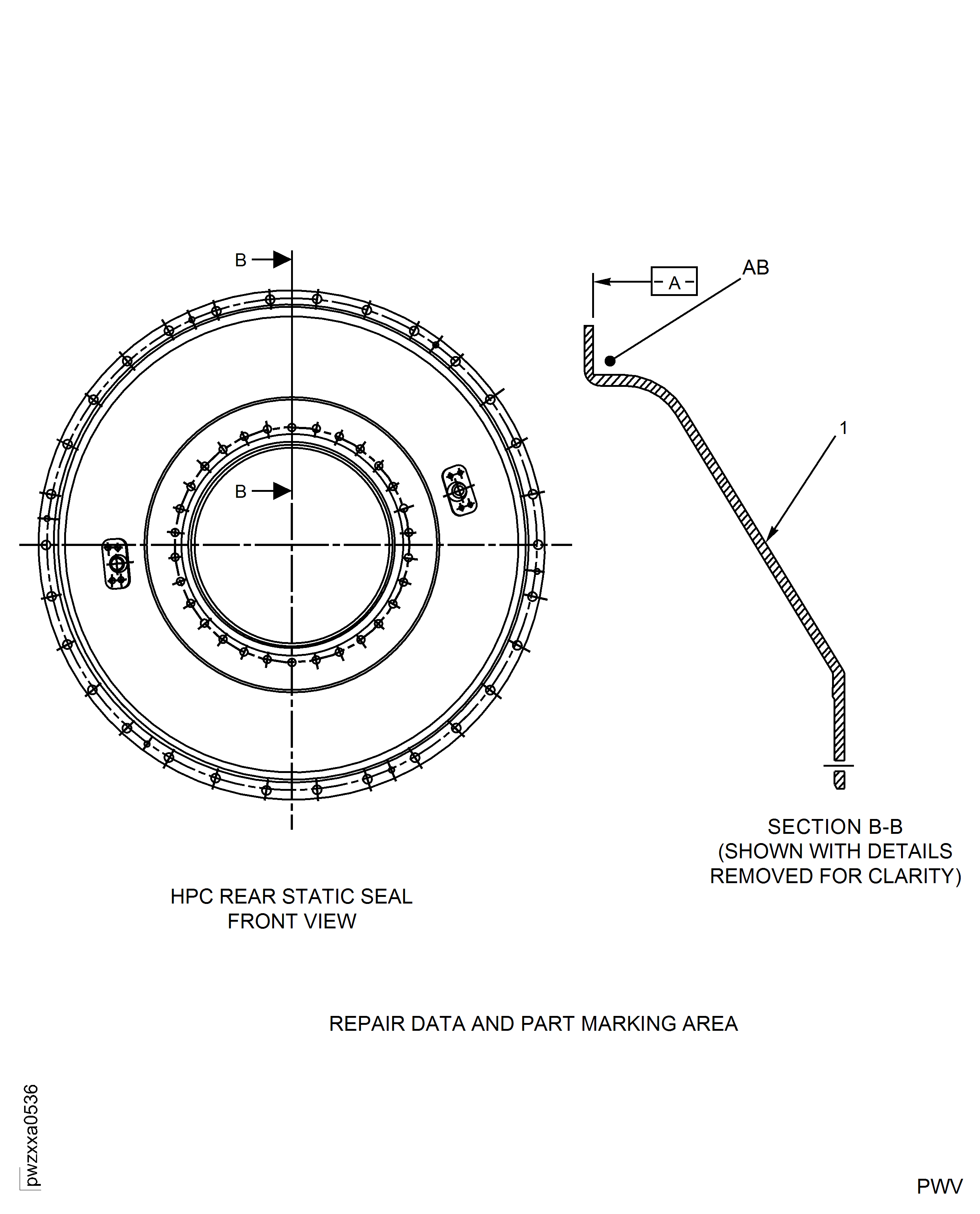

Refer to Figure.

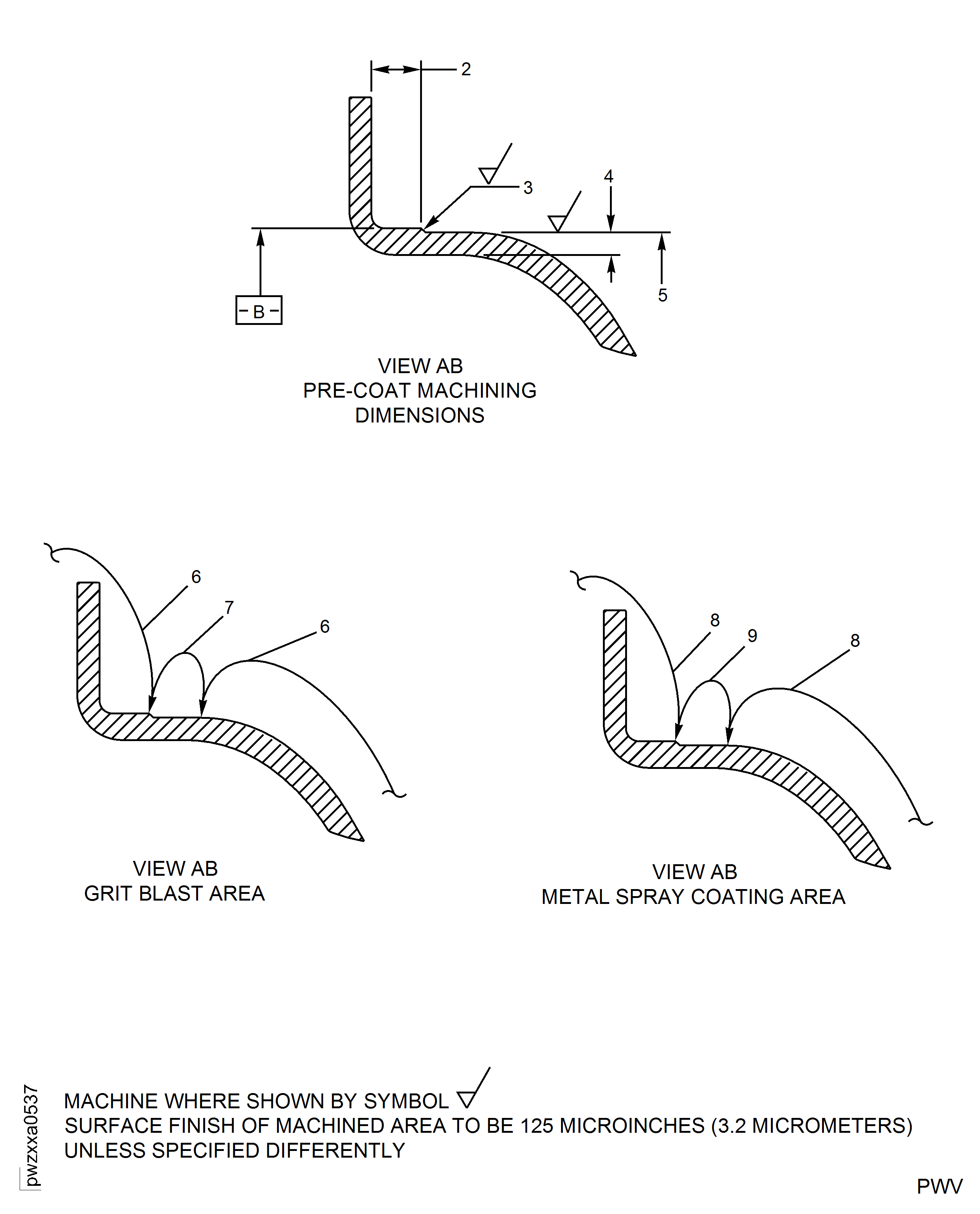

Machine only the minimum quantity of material to remove scores or coating. Break sharp edges 0.003 in. - 0.015 in. (0.077 mm - 0.381 mm).

If a metal spray layer has been applied before, make sure all metal spray is removed.

Machine the spigot diameter to remove all damage to the limit shown in Figure.

SUBTASK 72-42-50-320-001 Turn the HPC Rear Static Seal

Refer to the SPM TASK 70-11-03-300-503.

Chemically clean the HPC Rear Static Seal.

SUBTASK 72-42-50-110-061 Clean the HPC Rear Static Seal

Refer to the SPM TASK 70-23-03-230-501 or TASK 70-23-08-230-501.

No cracks are permitted.

Do a penetrant crack test of the repair area.

SUBTASK 72-42-50-230-075 Do a Crack Test

Refer to Figure.

Measure the dimension of the spigot diameter.

SUBTASK 72-42-50-220-086 Examine the HPC Rear Static Seal

Refer to Figure.

Excessive abrasive blast can cause deterioration of the prepared surface condition and must be prevented.

Grit blast out of the repair area shown is not permitted. Use masks or maskants.

Refer to the SPM TASK 70-34-18-380-501.

SUBTASK 72-42-50-340-001 Prepare the Part for Coat

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025.

Apply sufficient metal spray to obtain sufficient coating thickness when final machined, refer to Step.

Coat out of the repair area is not permitted. Use masks or maskants.

Apply metal spray.

Remove masks or maskants masking tape. Refer to the SPM TASK 70-34-18-380-501.

SUBTASK 72-42-50-340-055 Metal Spray the Spigot Diameter

Refer to Figure.

Make sure that the coating thickness is within the requirements. Refer to the SPM TASK 70-34-01-340-501, except minimum coating thickness waived at fillets and break edges within coated areas.

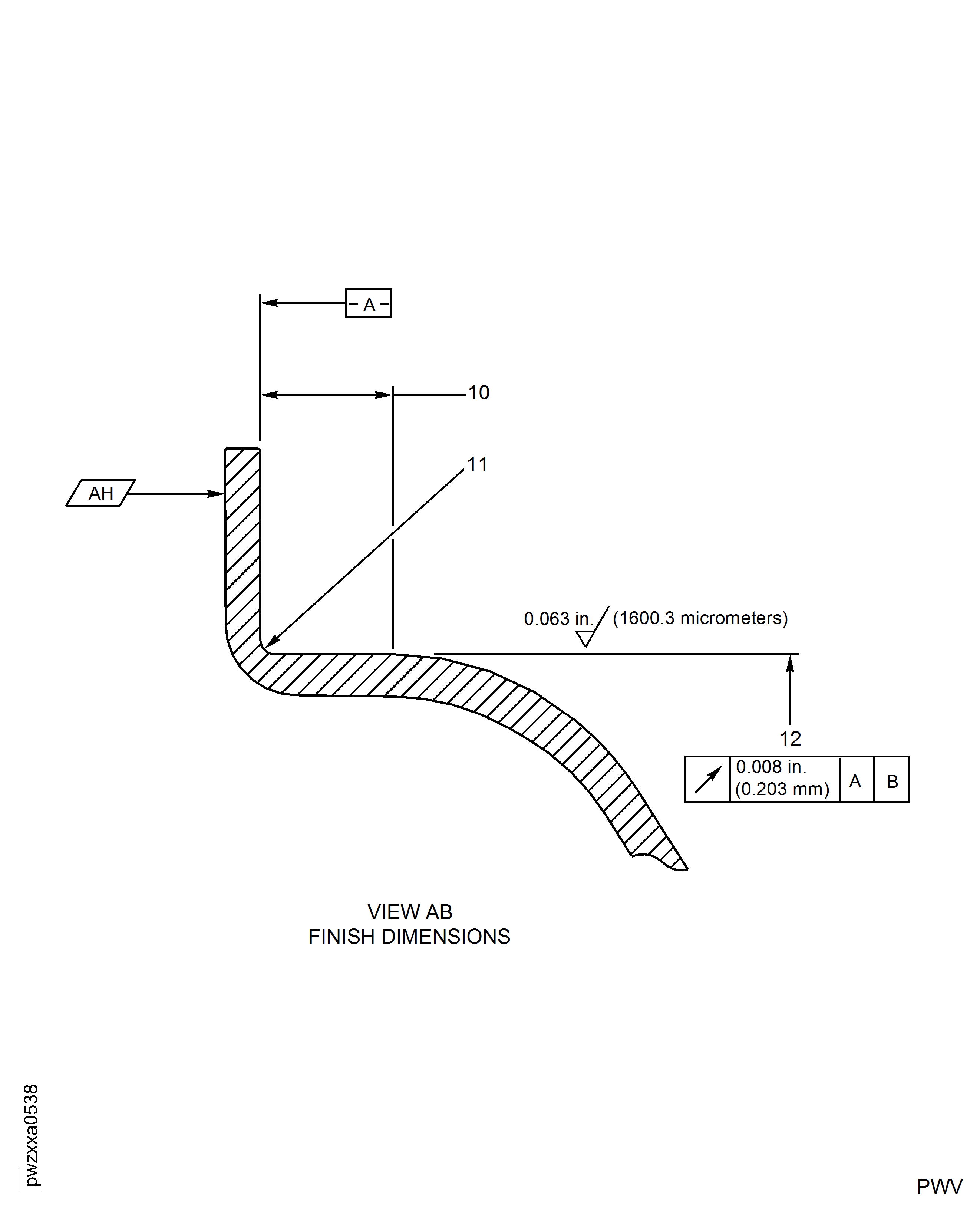

Finish the spigot diameter to the limit shown in Figure.

SUBTASK 72-42-50-320-002 Finish the HPC Rear Static Seal

Chemically clean the HPC Rear Static Seal.

Refer to the SPM TASK 70-11-03-300-503.

SUBTASK 72-42-50-110-062 Clean the HPC Rear Static Seal

Refer to Figure.

Examine the coating. Refer to the SPM TASK 70-34-01-340-501.

Visually examine and measure the dimensions.

SUBTASK 72-42-50-220-089 Examine the HPC Rear Static Seal

Vibro-engrave VRS9493 adjacent to the part number.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-90-00-400-001.

SUBTASK 72-42-50-350-080 Identify the Repair

Install the inner seal carrier.

Refer to Repair, VRS6203 TASK 72-42-50-300-002 (REPAIR-002).

SUBTASK 72-42-50-420-001 Install the Inner Seal Carrier

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions