Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-50-300-002 HPC Rear Static Seal - Replace The Inner Seal Carrier, Repair-002 (VRS6203)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

Support cone | QAW or | Nimonic 80A |

QAL | ||

Inner seal carrier | QAH or | C263 |

QAU | ||

Rivets | QBE | Nimonic 75 |

General

This repair must only be done when the instruction to do so is given in TASK 72-42-50 Inspection.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs

None

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand grinder | LOCAL | Hand grinder | ||

| Vertical drilling machine | LOCAL | Vertical drilling machine | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Special container for liquid nitrogen | LOCAL | Special container for liquid nitrogen | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Hot squeeze riveting electrodes | LOCAL | Hot squeeze riveting electrodes | ||

| Resistance welding machine | LOCAL | Resistance welding machine | ||

| Lathe | LOCAL | Lathe | ||

| Dial indicator | LOCAL | Dial indicator | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| IAE 3R18736 Turning fixture | 0AM53 | IAE 3R18736 | 1 | |

| IAE 3R18749 Tool holder | 0AM53 | IAE 3R18749 | 1 | |

| IAE 3R18750 Insert use with | 0AM53 | IAE 3R18750 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

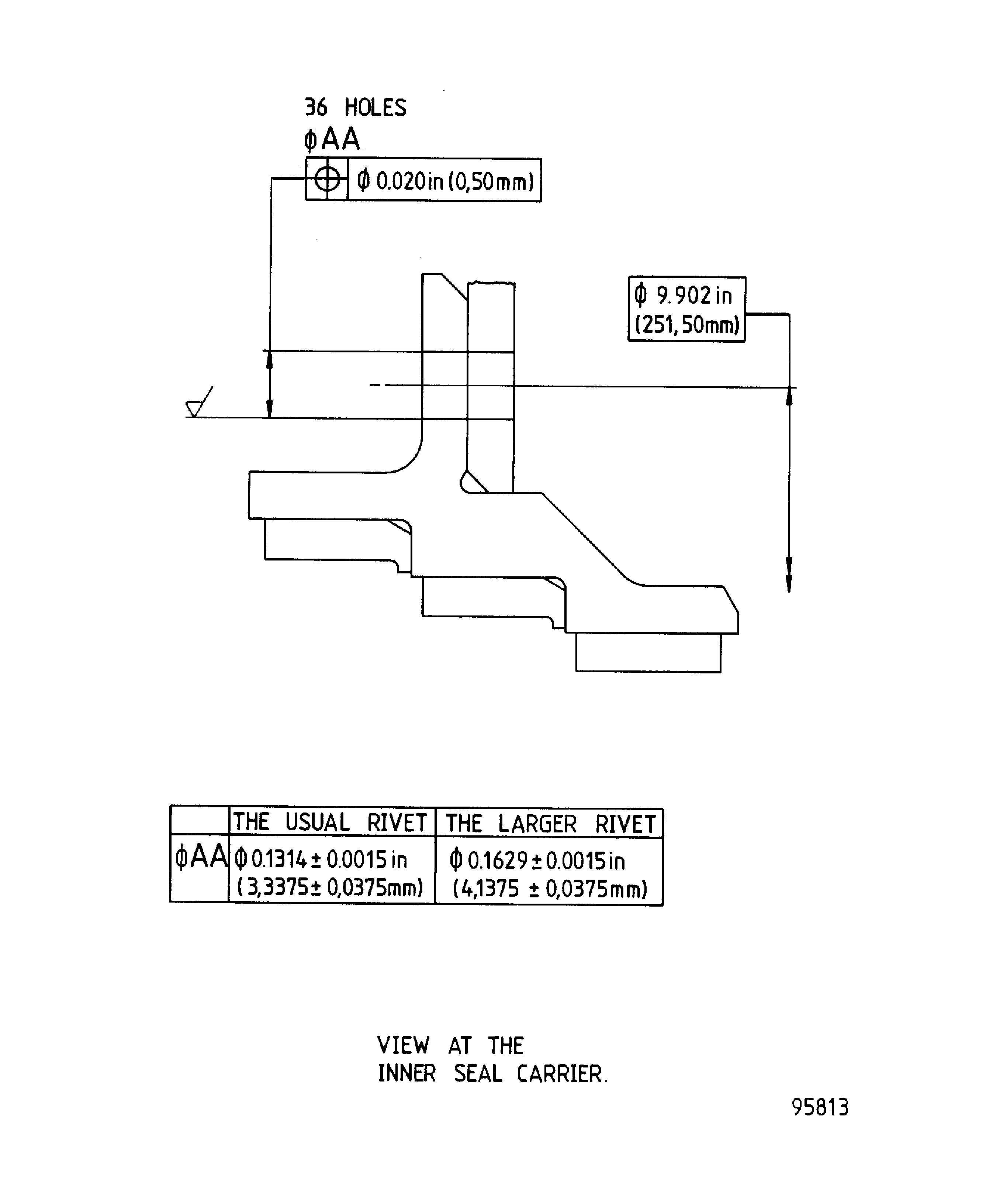

| Seal, assembly of inner carrier (Assembly A and Assembly B) | 6A4143 | 1 | ||

| Rivet, solid, universal head (Assembly A and Assembly B) | AS16289 | 36AR | ||

| Rivet, solid, universal head (Assembly A and Assembly B) | AS16330 | 36AR | ||

| Seal, assembly of inner carrier (Assembly C) | 6A5943 | 1 | ||

| Rivet, solid, universal head (Assembly C) | AS16289 | 30AR | ||

| Rivet, solid, universal head (Assembly C) | AS16330 | 30AR |

Safety Requirements

NONEProcedure

Refer to Figure

SUBTASK 72-42-50-323-051-A00 Drill Damaged Rivet Holes, Assembly A and Assembly B

Refer to Figure

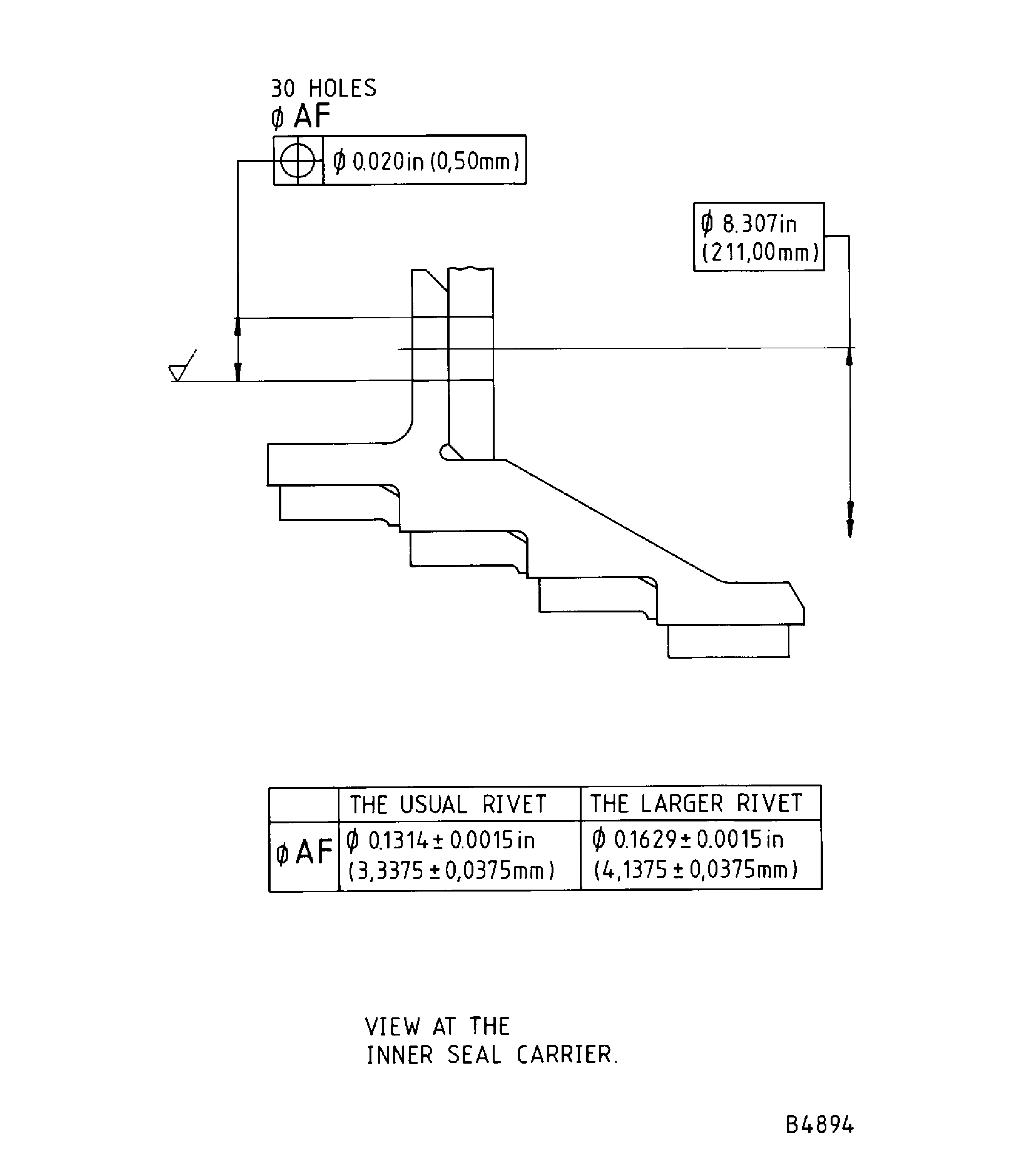

SUBTASK 72-42-50-323-051-B00 Drill Damaged Rivet Holes, Assembly C

Refer to SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test of the drilled hole(s).

SUBTASK 72-42-50-230-060 Do a Crack Test

Use, seal, assembly of, inner carrier 1 off, 01-160, with CoMat 03-026 LIQUID NITROGEN put in a suitable container for liquid nitrogen.

Use protective gloves.

Freeze the inner seal carrier.

SUBTASK 72-42-50-350-056-A00 Drill the Rivet Holes in the Inner Seal Carrier, Assembly A

Use seal, assembly of, inner carrier 1 off, 01-160, with CoMat 03-026 LIQUID NITROGEN put in a suitable container for liquid nitrogen.

Use protective gloves.

Freeze the inner seal carrier.

SUBTASK 72-42-50-350-056-B00 Drill the Rivet Holes in the Inner Seal Carrier, Assembly B

Use seal, assembly of, inner carrier 1 off, 01-160, with CoMat 03-026 LIQUID NITROGEN put in a suitable container for liquid nitrogen.

Use protective gloves.

Freeze the inner seal carrier.

SUBTASK 72-42-50-350-056-C00 Drill the Rivet Holes in the Inner Seal Carrier, Assembly C

Repair, VRS9205 TASK 72-42-50-300-008 (REPAIR-008).

Repair inner seal feltmetal.

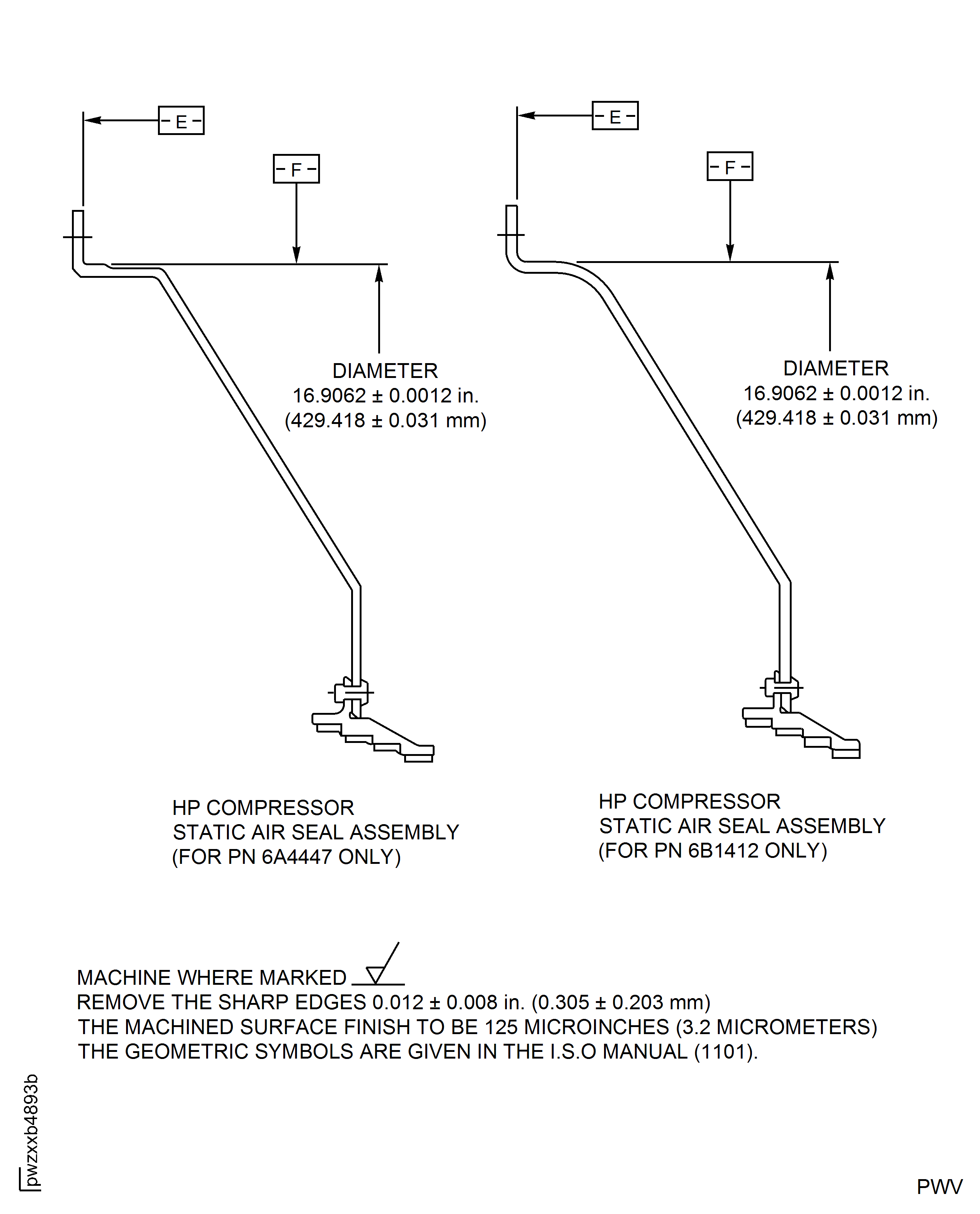

Use replacement part 6A4447 or 6B1412.

Replace inner seal carrier.

SUBTASK 72-42-50-350-067 Repair or Replace the Inner Seal Carrier

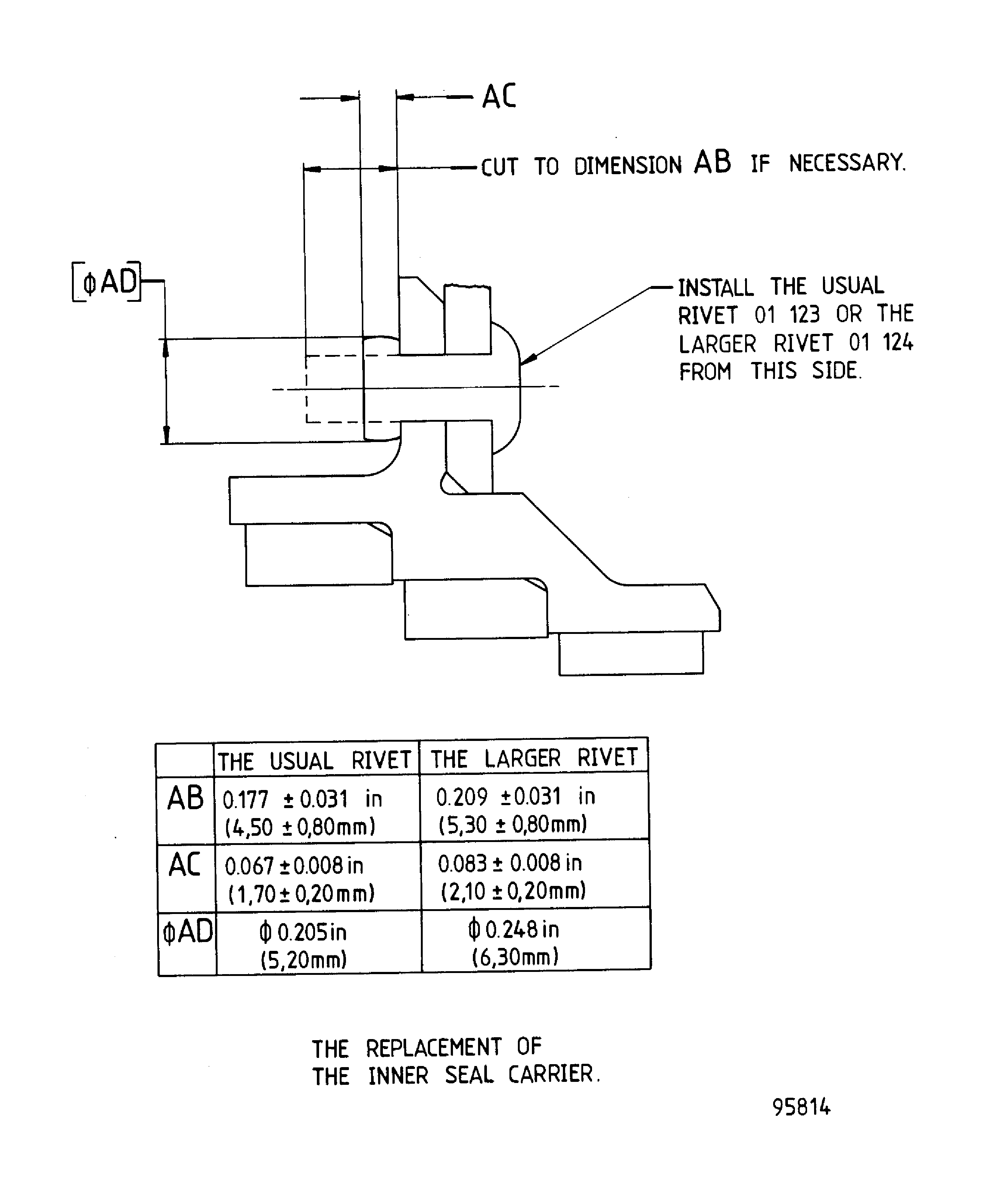

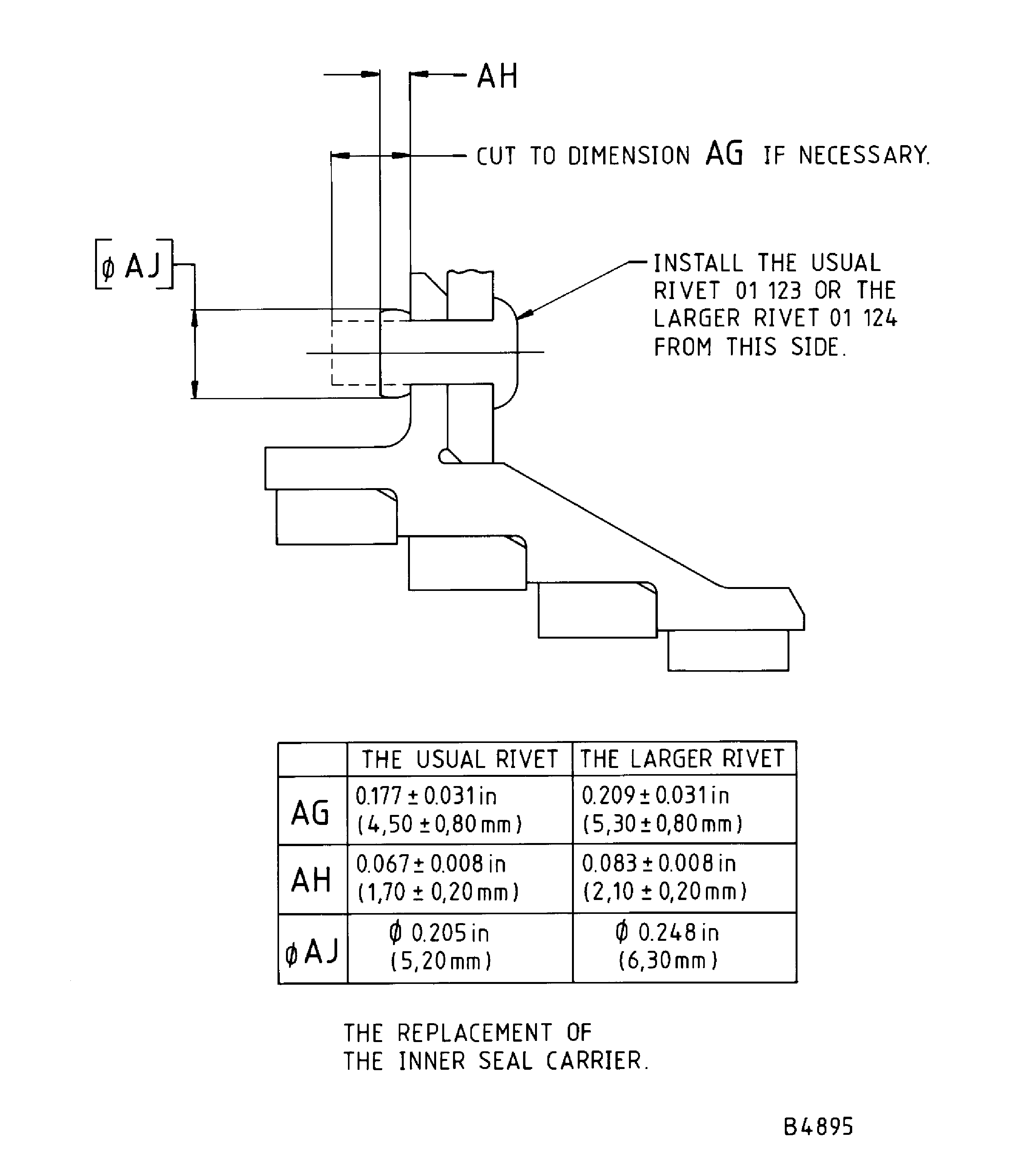

Refer to Figure

Refer to SPM TASK 70-39-02-390-501.

Use hot squeeze riveting electrodes, with resistance welding machine.

NOTE

The machine settings must be established by trial using suitable test pieces. Use a low voltage setting and the minimum amount of heat required to make the rivet force over.

Hot squeeze the rivets.

SUBTASK 72-42-50-390-051-001-A00 Secure the Inner Seal Carrier, Assembly A and Assembly B

Refer to Figure

Refer to SPM TASK 70-39-02-390-501.

Use hot squeeze riveting electrodes, with resistance welding machine.

NOTE

The machine settings must be established by trial using suitable test pieces. Use a low voltage setting and the minimum amount of heat required to make the rivet force over.

Hot squeeze the rivets.

SUBTASK 72-42-50-390-051-001-B00 Secure the Inner Seal Carrier, Assembly C

Refer to Figure

Refer to SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivets.

SUBTASK 72-42-50-390-051-002-A00 Secure the Inner Seal Carrier, Assembly A and Assembly B

Refer to Figure

Refer to SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivets.

SUBTASK 72-42-50-390-051-002-B00 Secure the Inner Seal Carrier, Assembly C

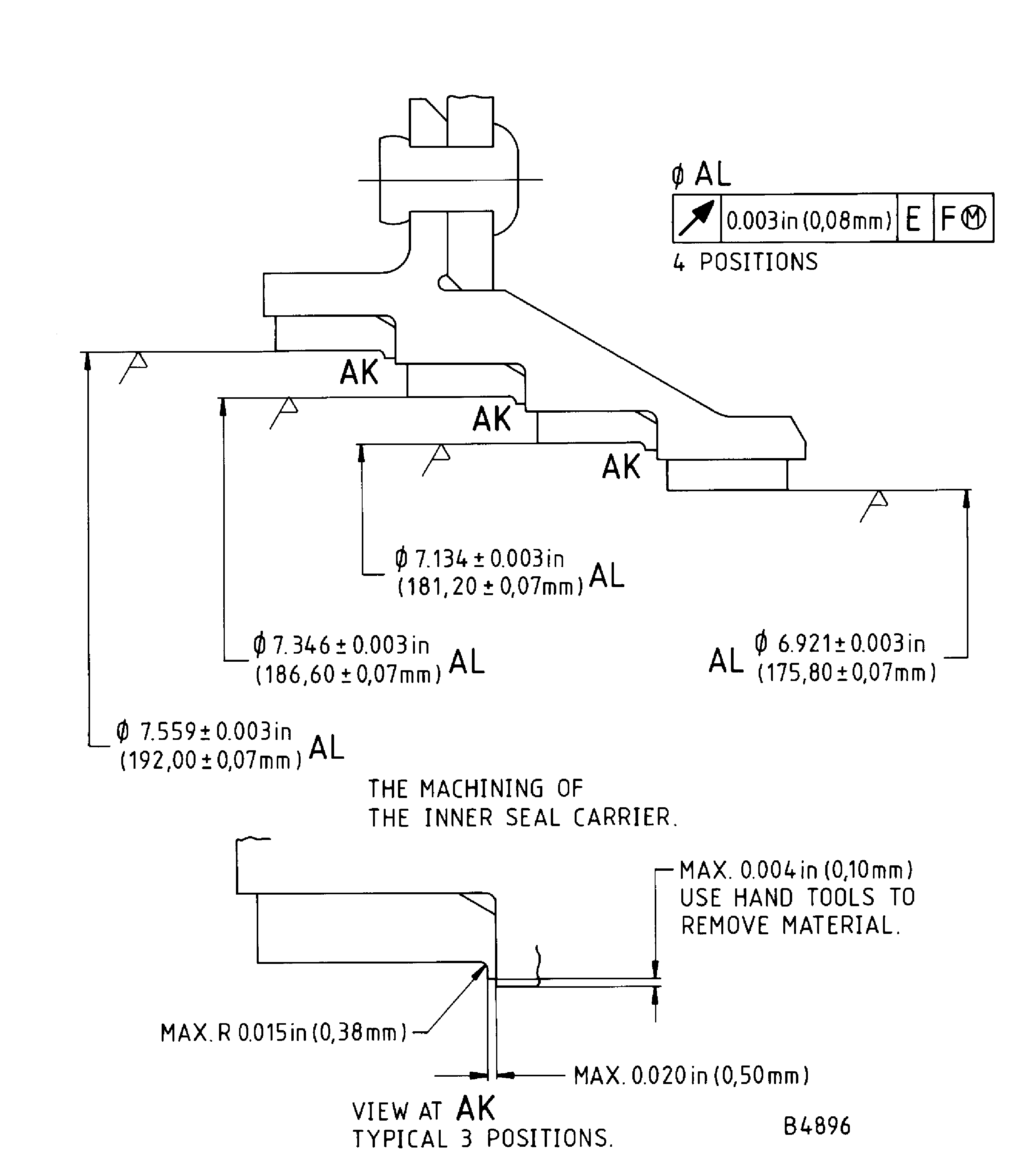

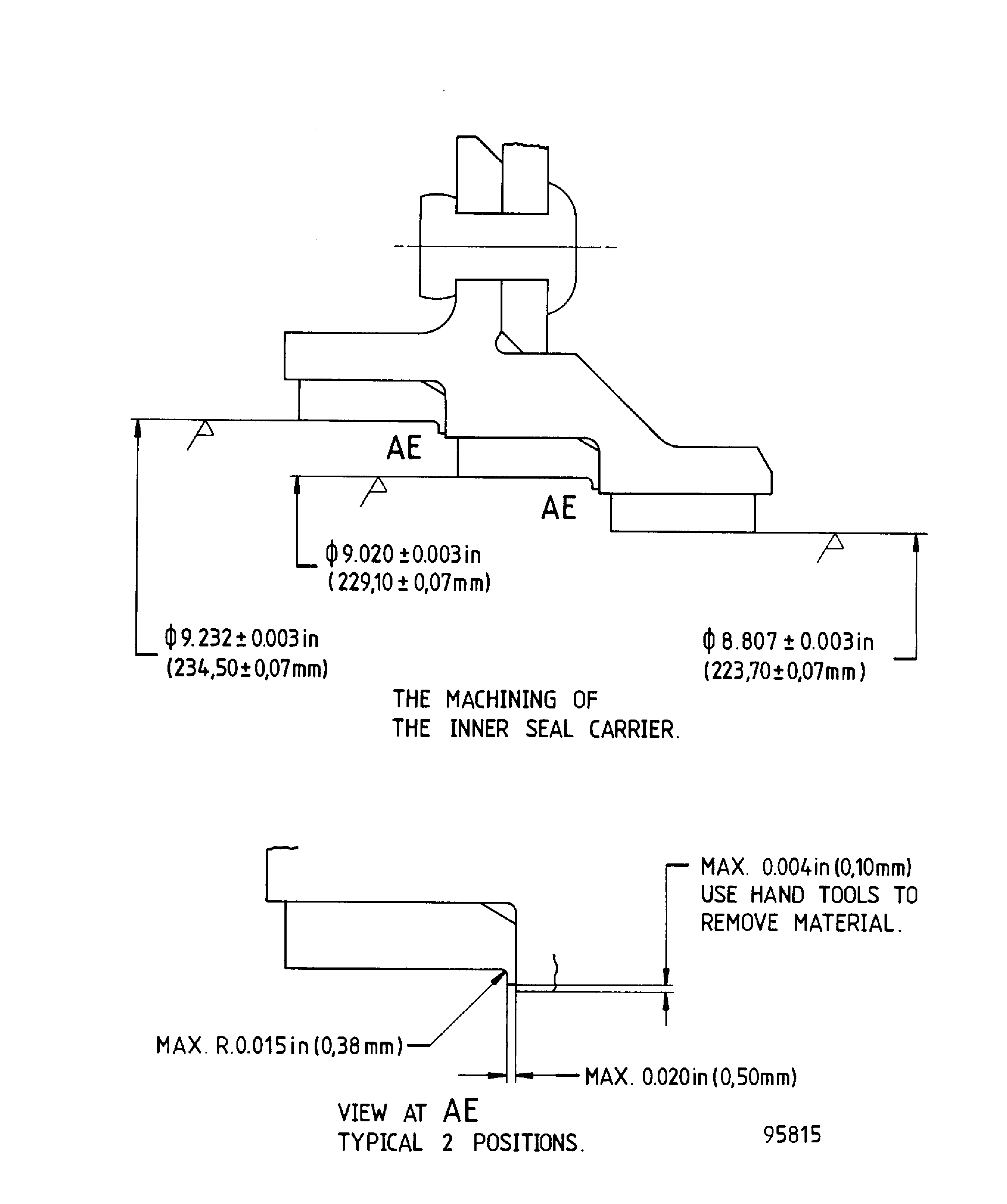

Refer to Figure

Use IAE 3R18736 Turning fixture 1 off, with a lathe and dial test indicator.

Set up the turning fixture on the lathe and set to run true.

Use IAE 3R18749 Tool holder 1 off, with IAE 3R18750 Insert use with 1 off.

Machine data:

Speed

470 surface feet (143 metres) per minute.

Feed

0.005 in. (0.127 mm) per rev.

Depth of cut:

Rough

0.010 in. to 0.030 in. (0.25 mm to 0.75 mm).

Finish

0.001 in. to 0.010 in. (0.025 mm to 0.25mm)

NOTE

Use a higher feed rate and a higher cutting speed for finishing cuts. Machine dry, and keep a sharp cutting tool.

Machine the three seals.

SUBTASK 72-42-50-325-052-A00 Machine the Seals in the Inner Carrier Ring, Assembly A and Assembly B

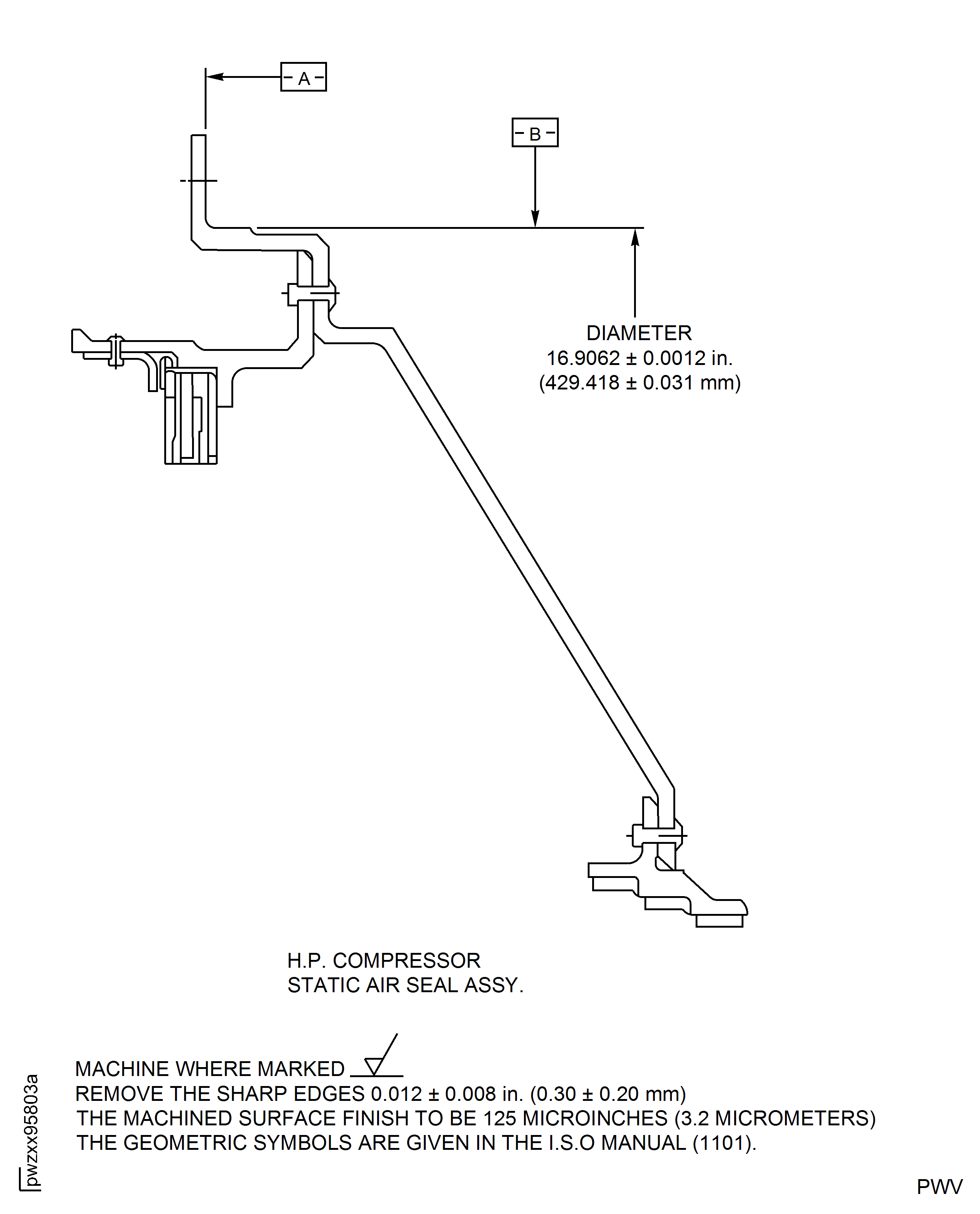

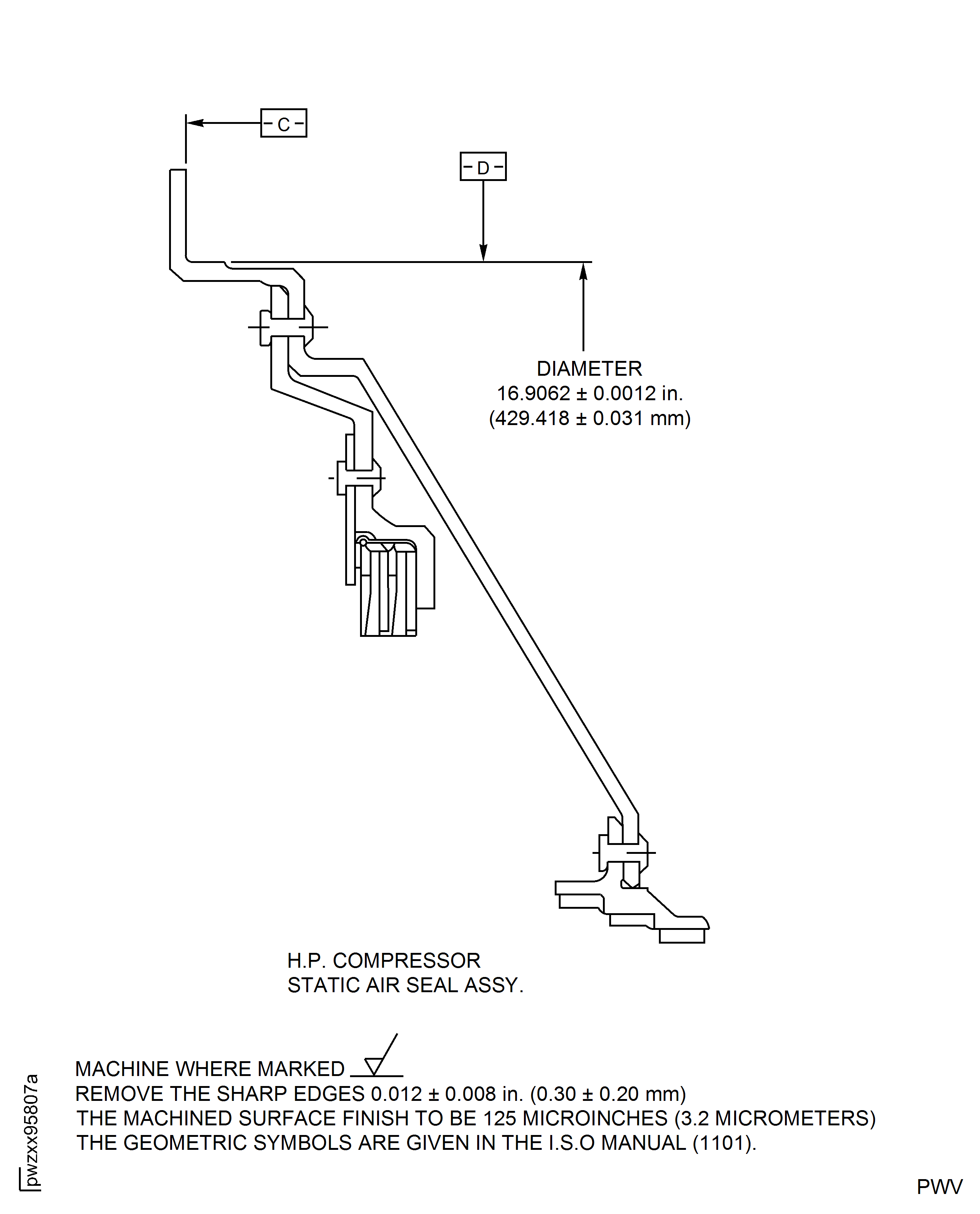

Refer to Figure

Use IAE 3R18736 Turning fixture 1 off, with a lathe and dial test indicator.

Set up the turning fixture on the lathe and set to run true.

Use IAE 3R18749 Tool holder 1 off, with IAE 3R18750 Insert use with 1 off.

Machine data:

Speed

470 surface feet (143 metres) per minute.

Feed

0.005 in. (0.127 mm) per rev.

Depth of cut:

Rough

0.010 in. to 0.030 in. (0.25 mm to 0.75 mm).

Finish

0.001 in. to 0.010 in. (0.025 mm to 0.25 mm)

NOTE

Use a higher feed rate and a higher cutting speed for finishing cuts. Machine dry, and keep a sharp cutting tool.

Machine the four seals.

SUBTASK 72-42-50-325-002-B00 Machine the Seals in the Inner Carrier Ring, Assembly C

Refer to Figure

SUBTASK 72-42-50-220-067-A00 Examine the Assembly, Assembly A and Assembly B

Refer to Figure

SUBTASK 72-42-50-220-067-B00 Examine the Assembly, Assembly C

Refer to TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Make a mark VRS6203 adjacent to the part number on the support cone.

SUBTASK 72-42-50-350-057 Identify the Repair

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C