Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-50-300-007 HPC Rear Static Seal - Replace The Balance Tube(s), Repair-007 (VRS6639)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-100 | 6A3306 | Assembly A |

01-100 | 6A3932 | Assembly A |

01-100 | 6A4806 | Assembly A |

01-100 | 6A4447 | Assembly B |

01-100 | 6B1412 | Assembly C |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Rear Static Seal Asssembly A | QAL or QAW | Nickel alloy |

HP Compressor Rear Static Seal Asssembly B | QZZ or QAW | Nickel alloy |

HP Compressor Rear Static Seal Asssembly C | QMR | Nickel alloy |

Balance Tube | QCS | Nickel alloy |

Rivets | QBE | Nickel alloy |

General

This repair must only be done when instructed to do so as given in TASK 72-42-50 Inspection/Check.

The practices and processes referred to in the procedures by the TASK/SUBTASK numbers are used in SPM.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all cleaning and inspection procedures are performed before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | LOCAL | DELETED | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| RIVET - SOLID, COUNTERSUNK HEAD | U1653 | AS16689 | 24 A/R | |

| RIVET - SOLID, COUNTERSUNK HEAD | U1653 | AS16730 | 24 A/R | (oversize) |

| Balance tube | 77445 | 6A1576 | 6 A/R | |

| RIVET - SOLID, COUNTERSUNK HEAD | U1653 | AS16689 | 8 A/R | |

| RIVET - SOLID, COUNTERSUNK HEAD | U1653 | AS16730 | 8 A/R | (oversize) |

| Balance tube | 77445 | 6A1576 | 2 A/R |

Safety Requirements

NONEProcedure

Refer to SPM TASK 70-11-03-300-503.

Chemically clean the rear static seal assembly.

SUBTASK 72-42-50-110-058 Clean the HP Compressor Rear Static Seal Assembly

Refer to SPM TASK 70-09-01-400-501.

Identify any damaged holes.

If the rivet holes are within the limits given go to Step.

If you find that the rivet holes are too large go to Step.

SUBTASK 72-42-50-220-082-A00 Examine the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly A

Refer to SPM TASK 70-09-01-400-501.

Identify any damaged holes.

If the rivet holes are within the limits given go to Step.

If you find that the rivet holes are too large go to Step.

SUBTASK 72-42-50-220-082-B00 Examine the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly B

Refer to SPM TASK 70-09-01-400-501.

Identify any damaged holes.

If the rivet holes are within the limits given go to Step.

If you find that the rivet holes are too large go to Step.

SUBTASK 72-42-50-220-082-C00 Examine the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly C

Use 6A1576 01-180, 6 off as required, with locally made location clamp.

Temporarily install the balance tube(s) on to the rear static seal assembly.

SUBTASK 72-42-50-323-055-A00 Drill the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly A

CAUTION

YOU MUST ONLY DO THIS SUBTASK IF THE RIVET HOLES ARE TOO LARGE, REFER TO Step.Use 6A1576 01-180, 2 off as required, with locally made location clamp.

Temporarily install the balance tube(s) on to the rear static seal assembly.

SUBTASK 72-42-50-323-055-B00 Drill the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly B

CAUTION

YOU MUST ONLY DO THIS SUBTASK IF THE RIVET HOLES ARE TOO LARGE, REFER TO Step.Use 6A1576 01-180, 2 off as required, with locally made location clamp.

Temporarily install the balance tube(s) on to the rear static seal assembly.

SUBTASK 72-42-50-323-055-C00 Drill the Rivet Hole(s) on the HP Compressor Rear Static Seal Assembly, Assembly C

Use AS16689 RIVET - SOLID, COUNTERSUNK HEAD 01-126, 24 off and/or AS16730 RIVET - SOLID, COUNTERSUNK HEAD 01-127, 24 off, as required and 6A1576 01-180, 6 off, as required.

Assemble the HP compressor rear static seal assembly, balance tube(s) and rivets.

Refer to SPM TASK 70-39-03-390-501.

Cold squeeze the rivets.

SUBTASK 72-42-50-390-055-A00 Assemble the Balance Tube(s) to the HP Compressor Rear Static Seal Assembly, Assembly A

Use AS16689 RIVET - SOLID, COUNTERSUNK HEAD 01-126, 8 off and/or AS16730 RIVET - SOLID, COUNTERSUNK HEAD 01-127, 8 off as required, and 6A1576 01-180, 2 off as required.

Assemble the HP Compressor rear static seal assembly, balance tube(s) and rivets.

Refer to SPM TASK 70-39-03-390-501.

Cold squeeze the rivets.

SUBTASK 72-42-50-390-055-B00 Assemble the Balance Tube(s) to the HP Compressor Rear Static Seal Assembly, Assembly B

Use AS16689 RIVET - SOLID, COUNTERSUNK HEAD 01-126, 8 off and/or AS16730 RIVET - SOLID, COUNTERSUNK HEAD 01-127, 8 off as required, and 6A1576 01-180, 2 off as required.

Assemble the HP Compressor rear static seal assembly, balance tube(s) and rivets.

Refer to SPM TASK 70-39-03-390-501.

Cold squeeze the rivets.

SUBTASK 72-42-50-390-055-C00 Assemble the Balance Tube(s) to the HP Compressor Rear Static Seal Assembly, Assembly C

Refer to SPM TASK 70-23-05-230-501. Cracks are not permitted.

Do a penetrant crack test on the rivets.

SUBTASK 72-42-50-230-072 Do a Crack Test

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-501.

Vibro peen VRS6639 adjacent to the assembly number.

SUBTASK 72-42-50-350-076 Identify the Repair

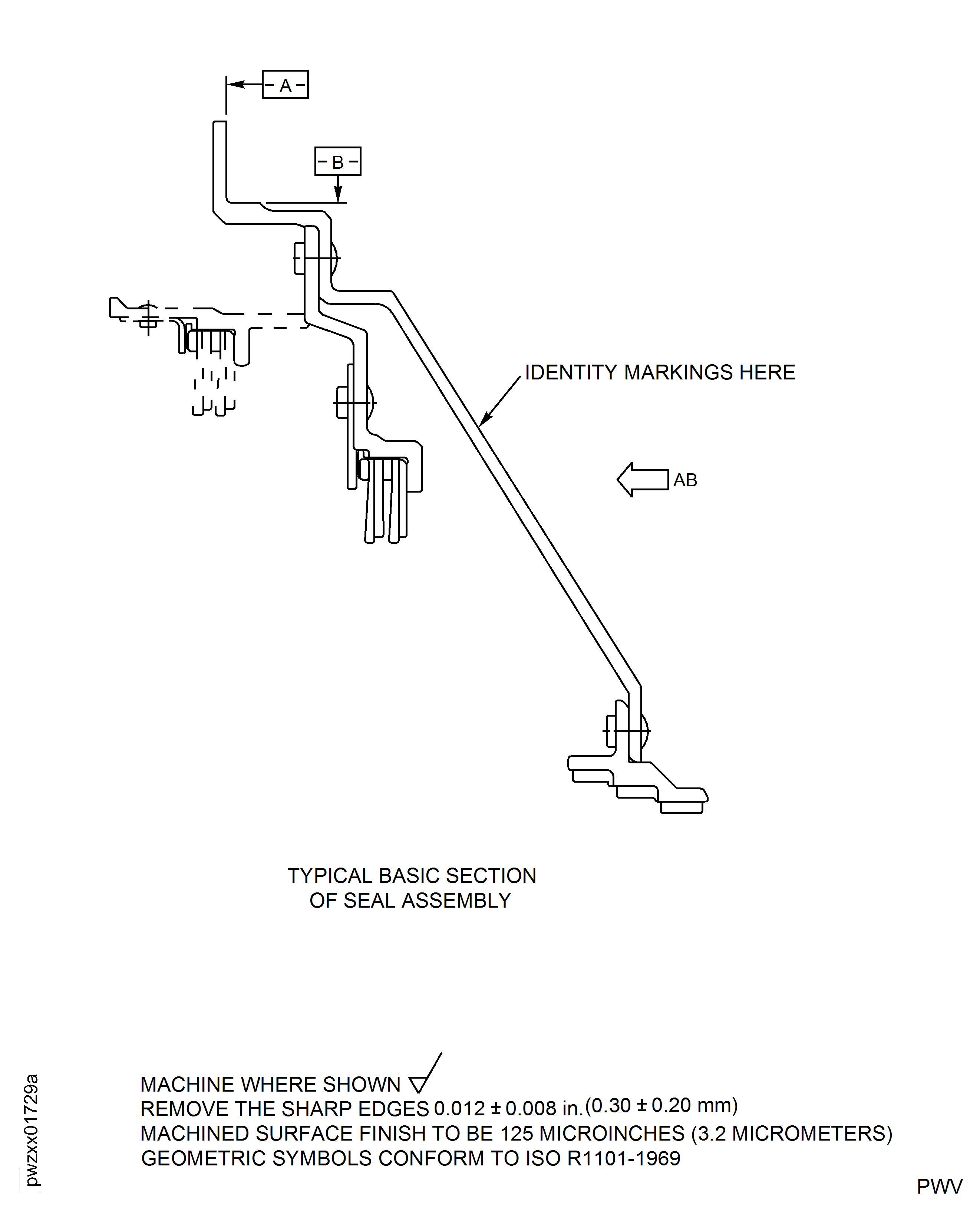

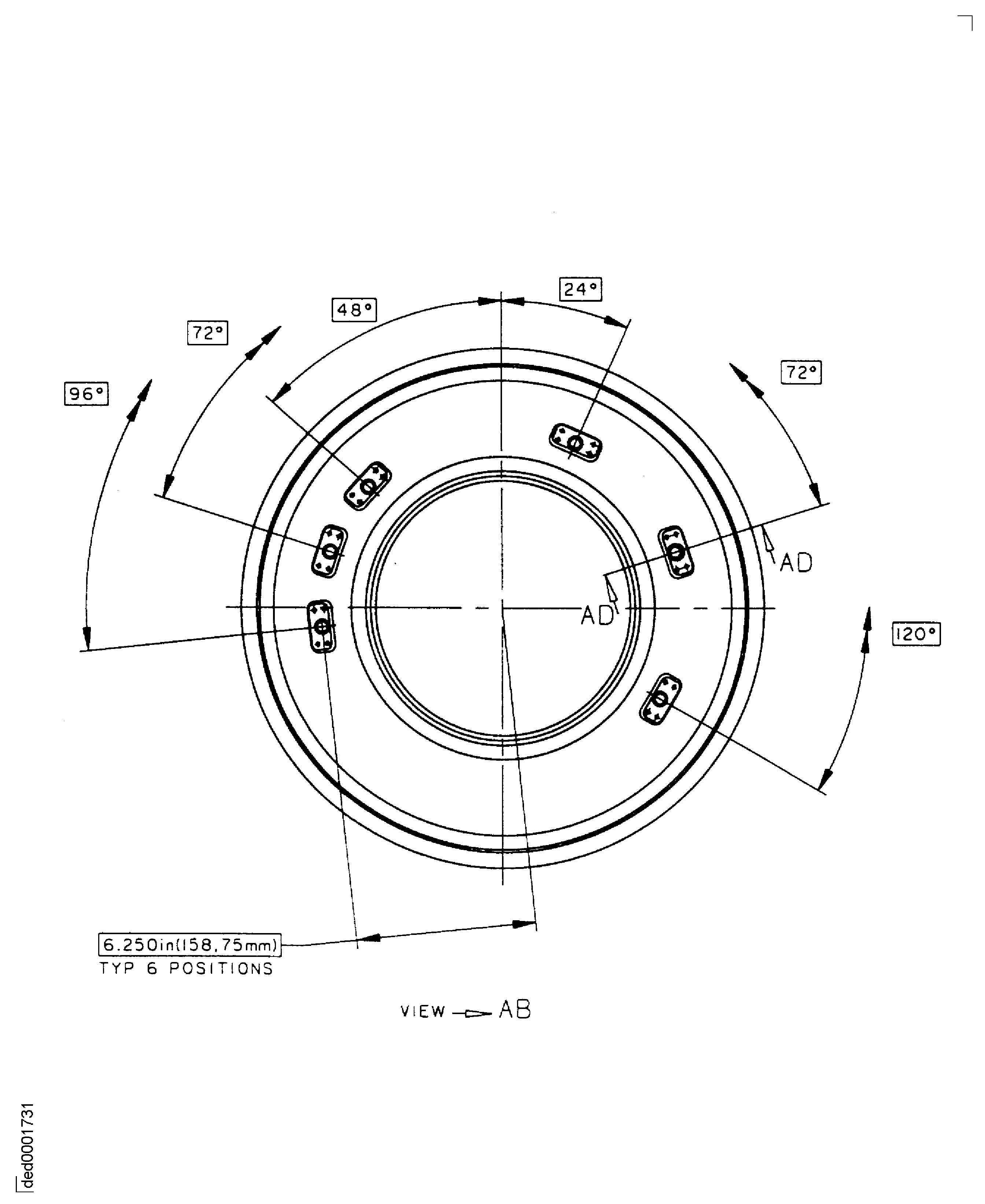

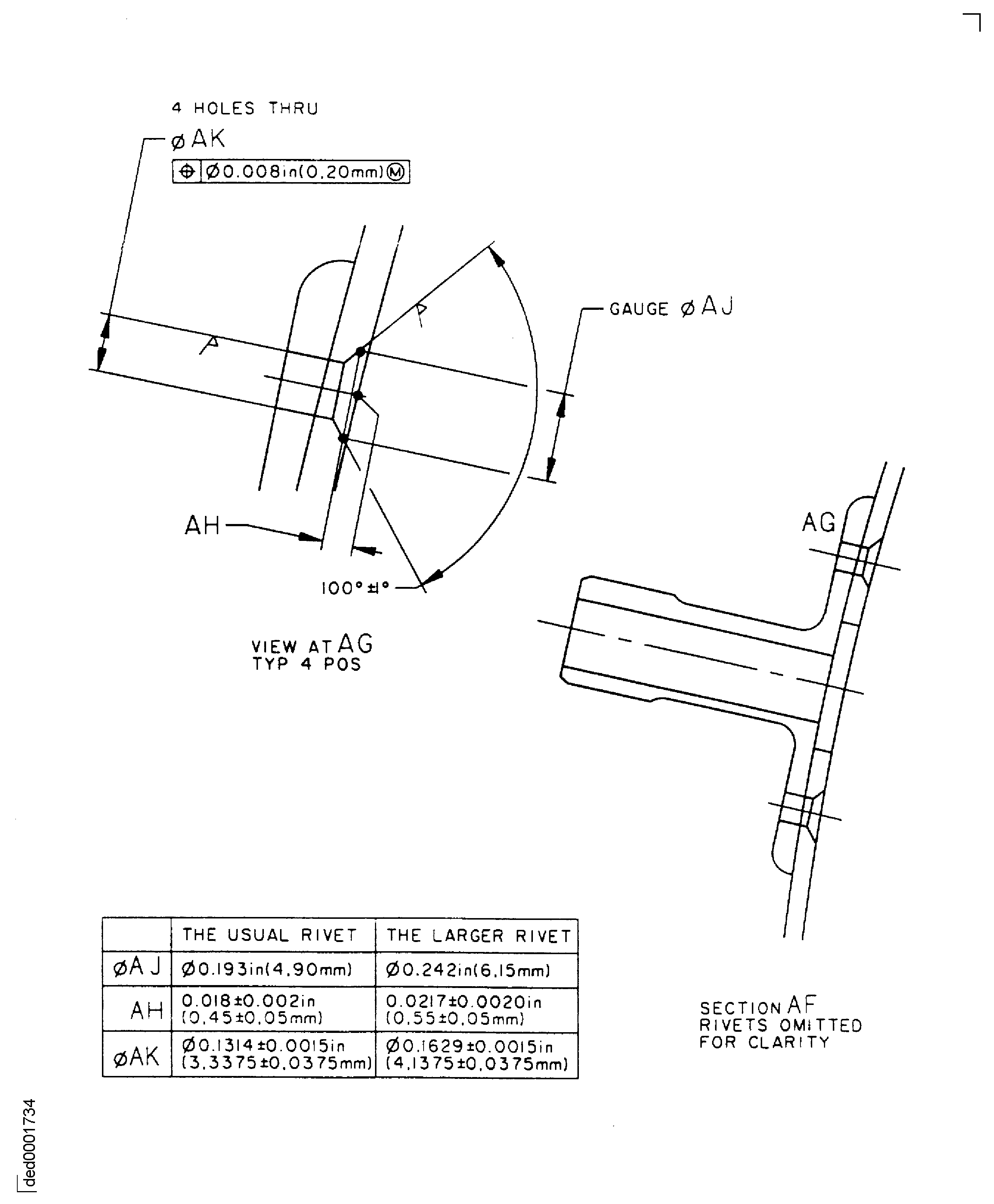

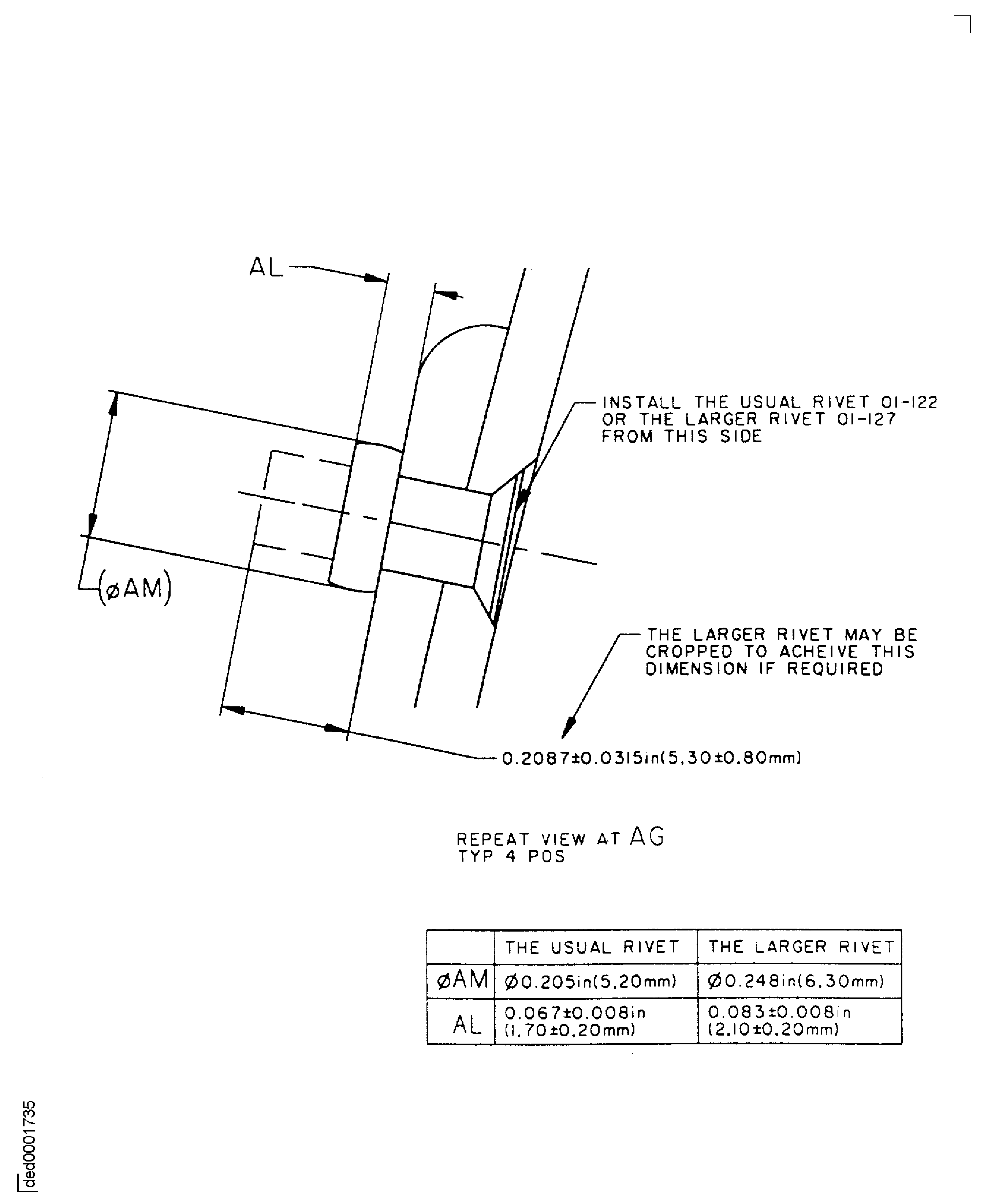

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

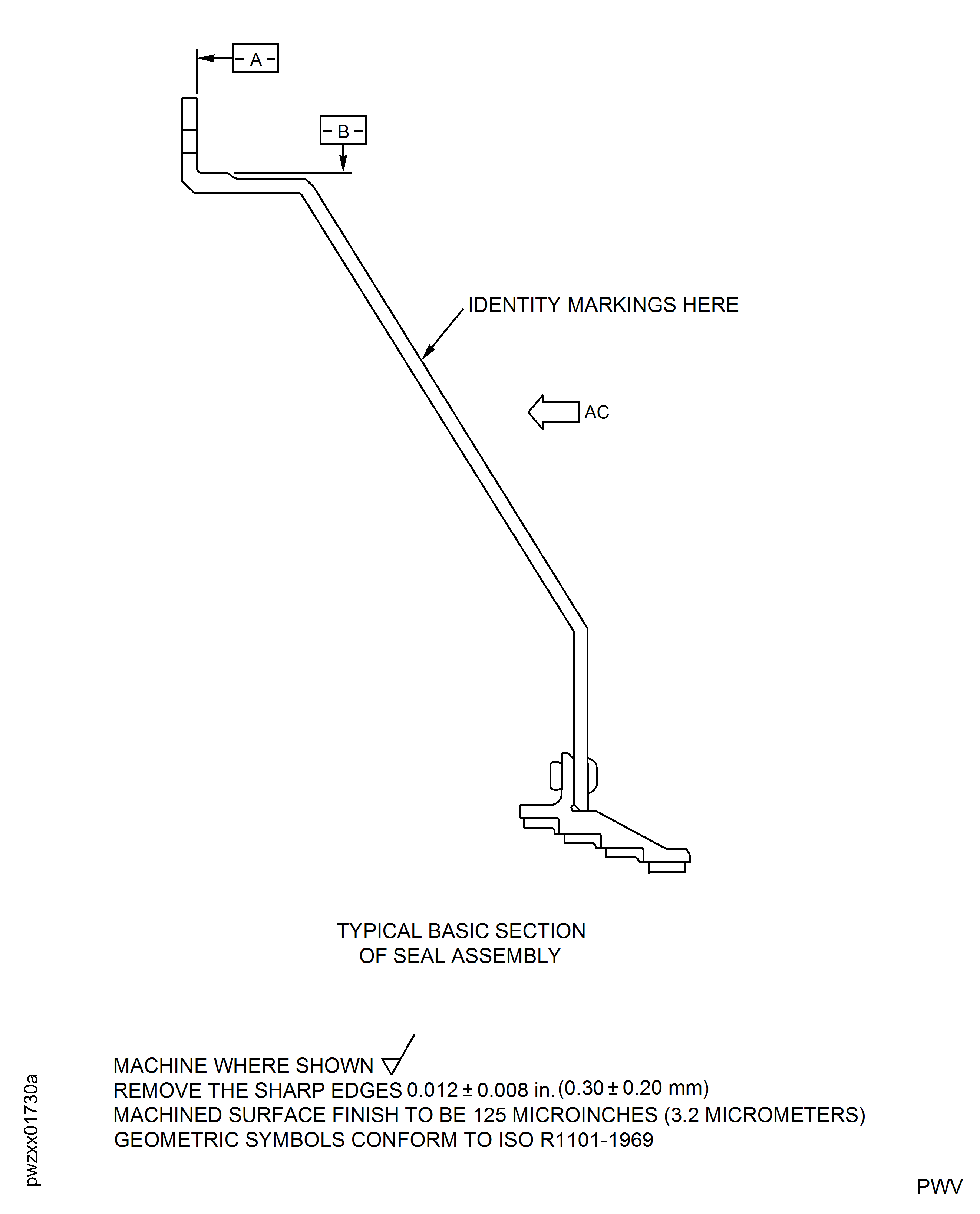

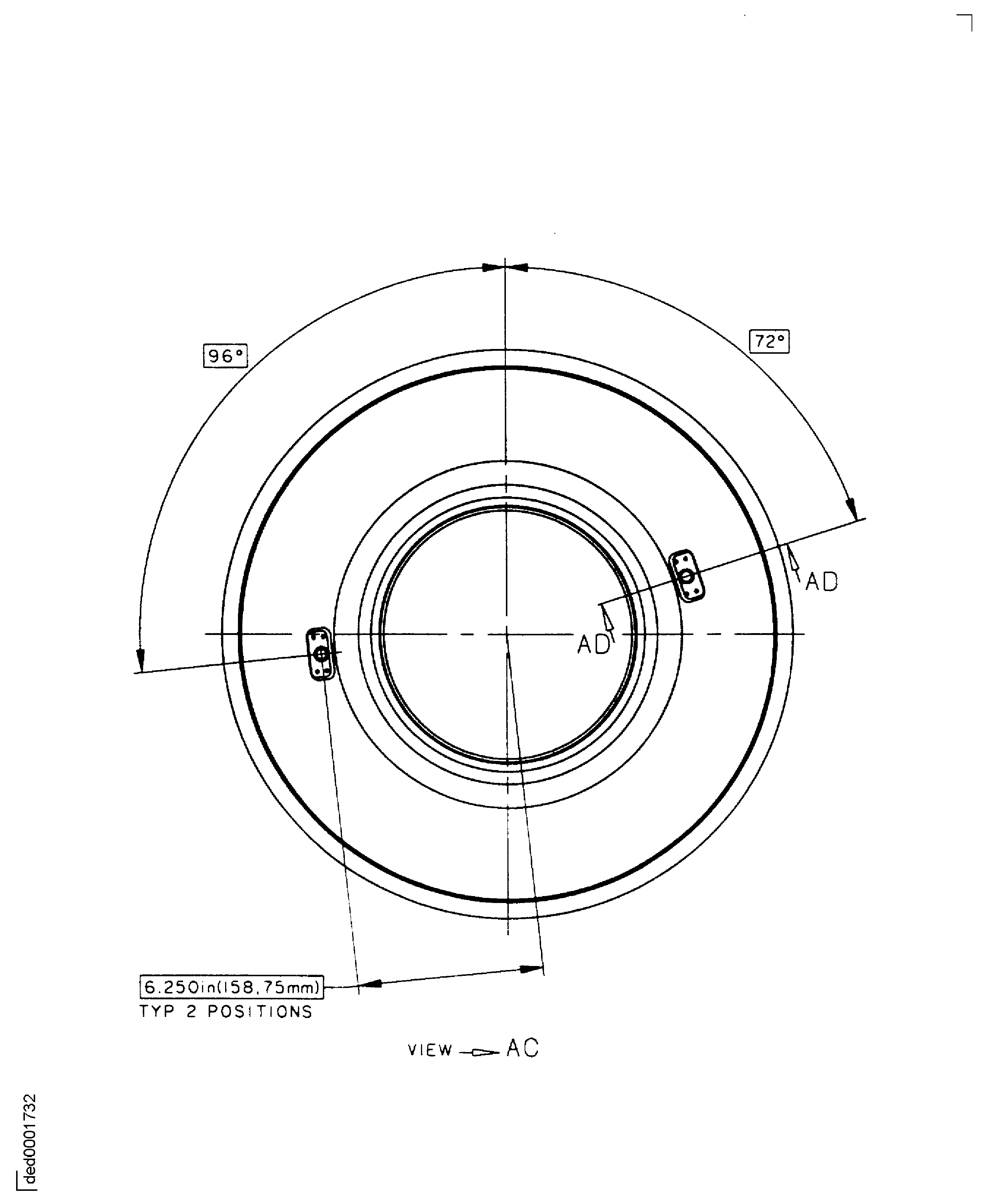

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

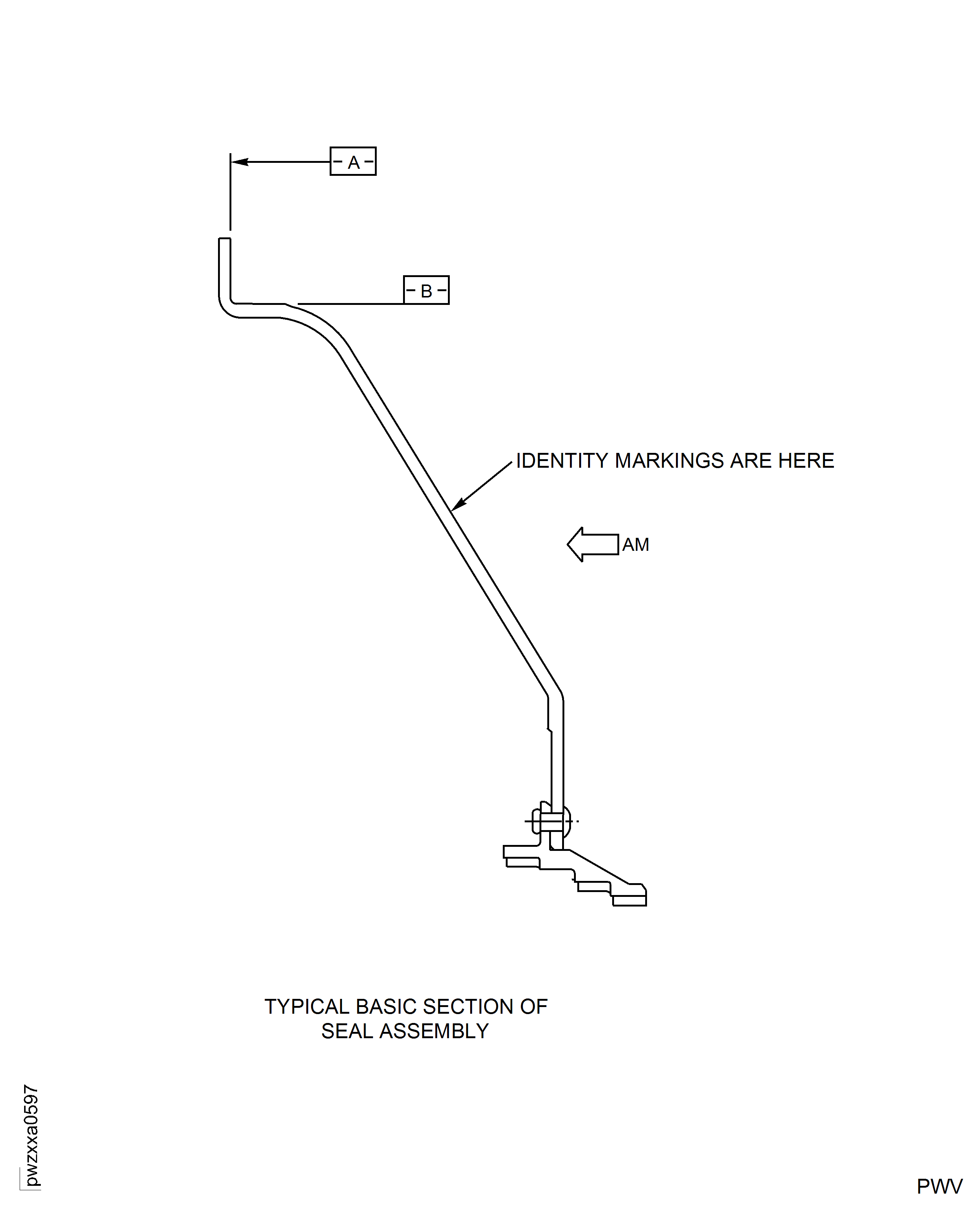

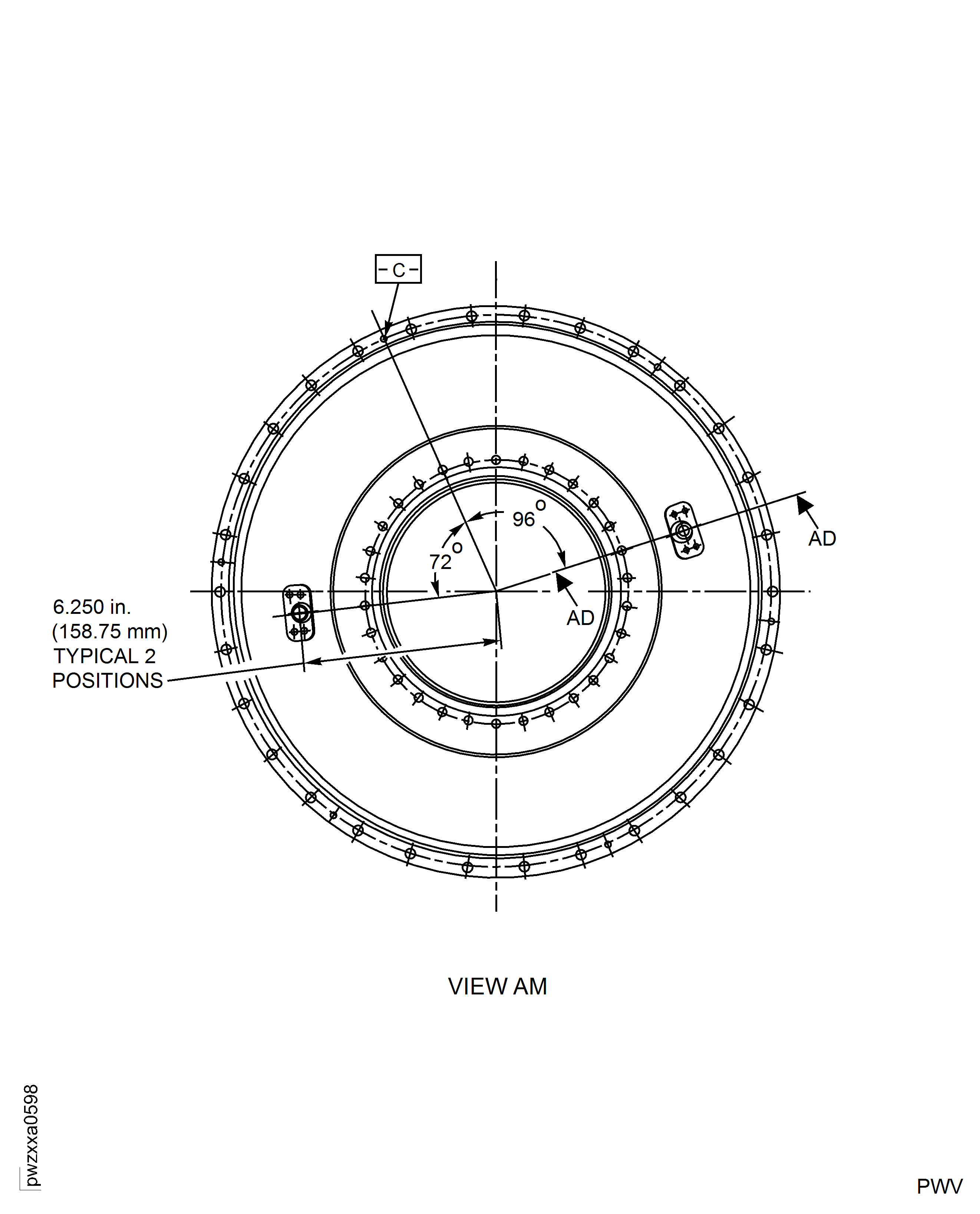

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

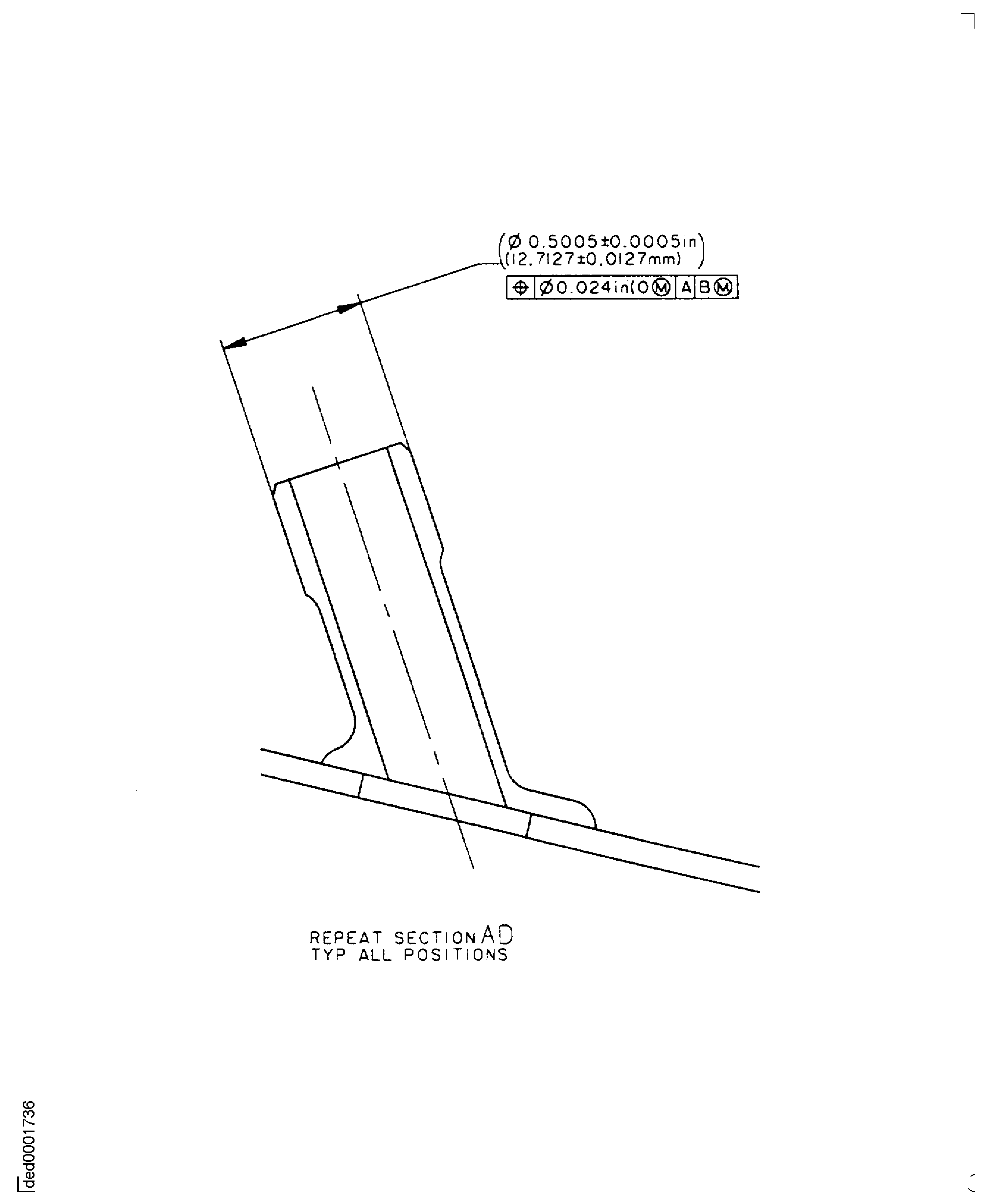

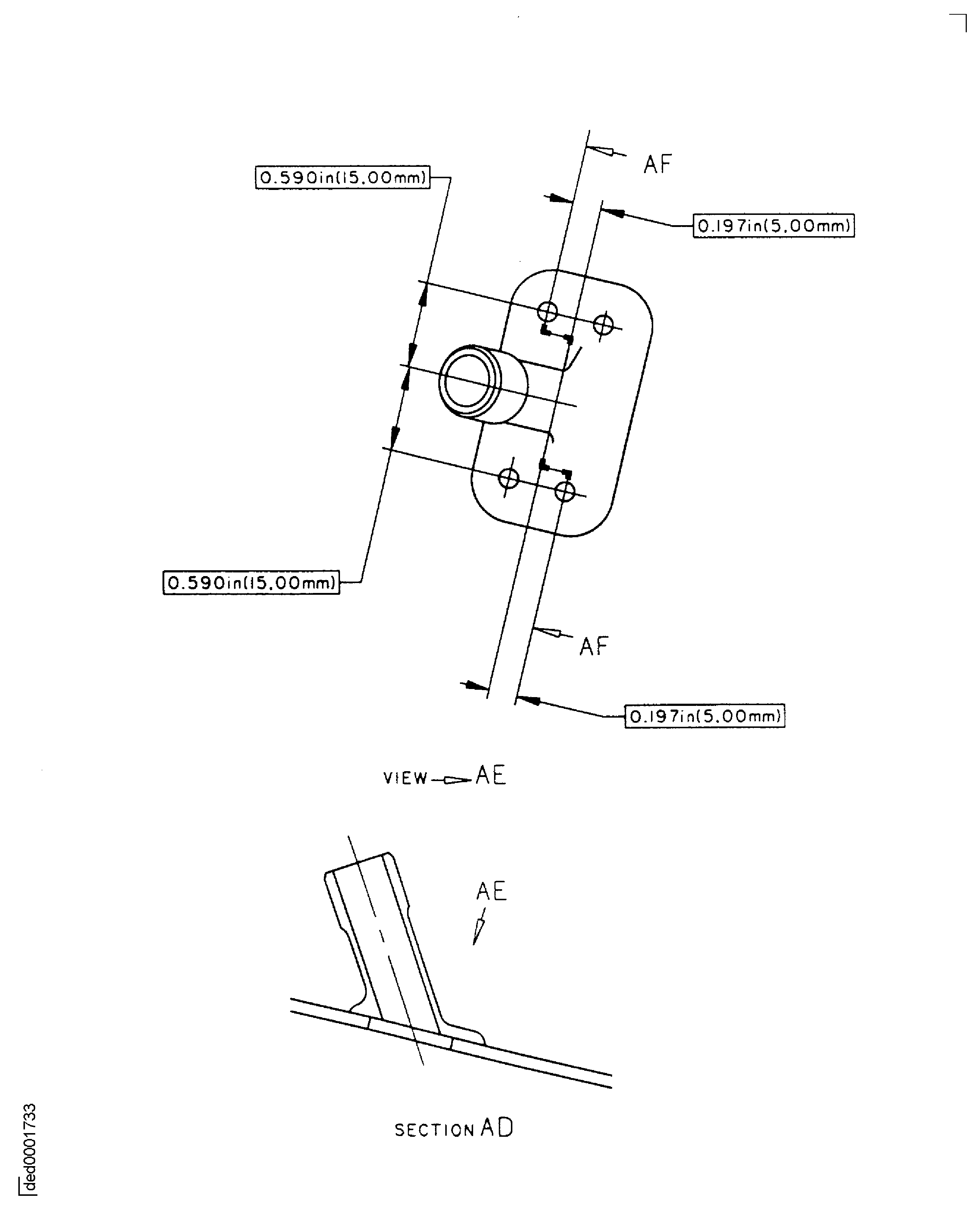

Figure: Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B, and Assembly C