Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-61-300-007 Outer Combustion Chamber Liner - Replace The Access Cover, Fuel Nozzle Guide And The Fuel Nozzle Guide Retainer, Repair-007 (VRS3095)

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-501 | 2A0550-01 |

01-501 | 2A1383 |

01-501 | 2A1385 |

01-501 | 2A1399 |

01-501 | 2A1618 |

01-501 | 2A1620 |

01-501 | 2A1666 |

01-501 | 2A2013 |

01-501 | 2A2032 |

01-501 | 2A2723-01 |

01-501 | 2A2837-01 |

01-501 | 2A3345-01 |

01-501 | 2A3345-001 |

01-501 | 2A3345-002 |

01-501 | 2A3345-003 |

01-501 | 2A3345-004 |

01-501 | 2A3347-01 |

01-501 | 2A3347-001 |

01-501 | 2A3347-002 |

01-501 | 2A3347-003 |

01-501 | 2A3347-004 |

01-501 | 2A3347-005 |

01-501 | 2A3439-01 |

01-501 | 2A3439-001 |

01-501 | 2A3439-002 |

01-501 | 2A3439-003 |

01-501 | 2A3439-004 |

01-501 | 2A3439-005 |

01-501 | 2A3439-006 |

01-501 | 2A3439-007 |

01-501 | 2A3439-008 |

01-501 | 2A3440-01 |

01-501 | 2A3440-001 |

01-501 | 2A3440-002 |

01-501 | 2A3440-003 |

01-501 | 2A3440-004 |

01-501 | 2A3440-005 |

01-501 | 2A3440-006 |

01-501 | 2A3440-007 |

01-501 | 2A3441-01 |

01-501 | 2A3441-001 |

01-501 | 2A3441-002 |

01-501 | 2A3441-003 |

01-501 | 2A3441-004 |

01-501 | 2A3441-005 |

01-501 | 2A3441-006 |

01-501 | 2A3441-007 |

01-501 | 2A3441-008 |

01-501 | 2A3442-01 |

01-501 | 2A3442-001 |

01-501 | 2A3442-002 |

01-501 | 2A3442-003 |

01-501 | 2A3442-004 |

01-501 | 2A3442-005 |

01-501 | 2A3442-006 |

01-501 | 2A3442-007 |

01-501 | 2A3442-008 |

01-501 | 2A4284-01 |

01-501 | 2A4309-01 |

01-501 | 2A4312-01 |

01-501 | 2A4314-001 |

01-501 | 2A4314-01 |

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

Combustion chamber outer liner | - | Corrosion and heat resistant |

alloy | ||

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 3X magnifier | LOCAL | 3X magnifier | ||

| Fastener | LOCAL | Fastener | ||

| Pliers | LOCAL | Pliers | ||

| Pneumatic or electric hand grinder | LOCAL | Pneumatic or electric hand grinder | ||

| Rivet head pulling tool | LOCAL | Rivet head pulling tool | ||

| Rivet installation tool | LOCAL | Rivet installation tool | ||

| Rotary filing bit | LOCAL | Rotary filing bit | ||

| White light | LOCAL | White light | ||

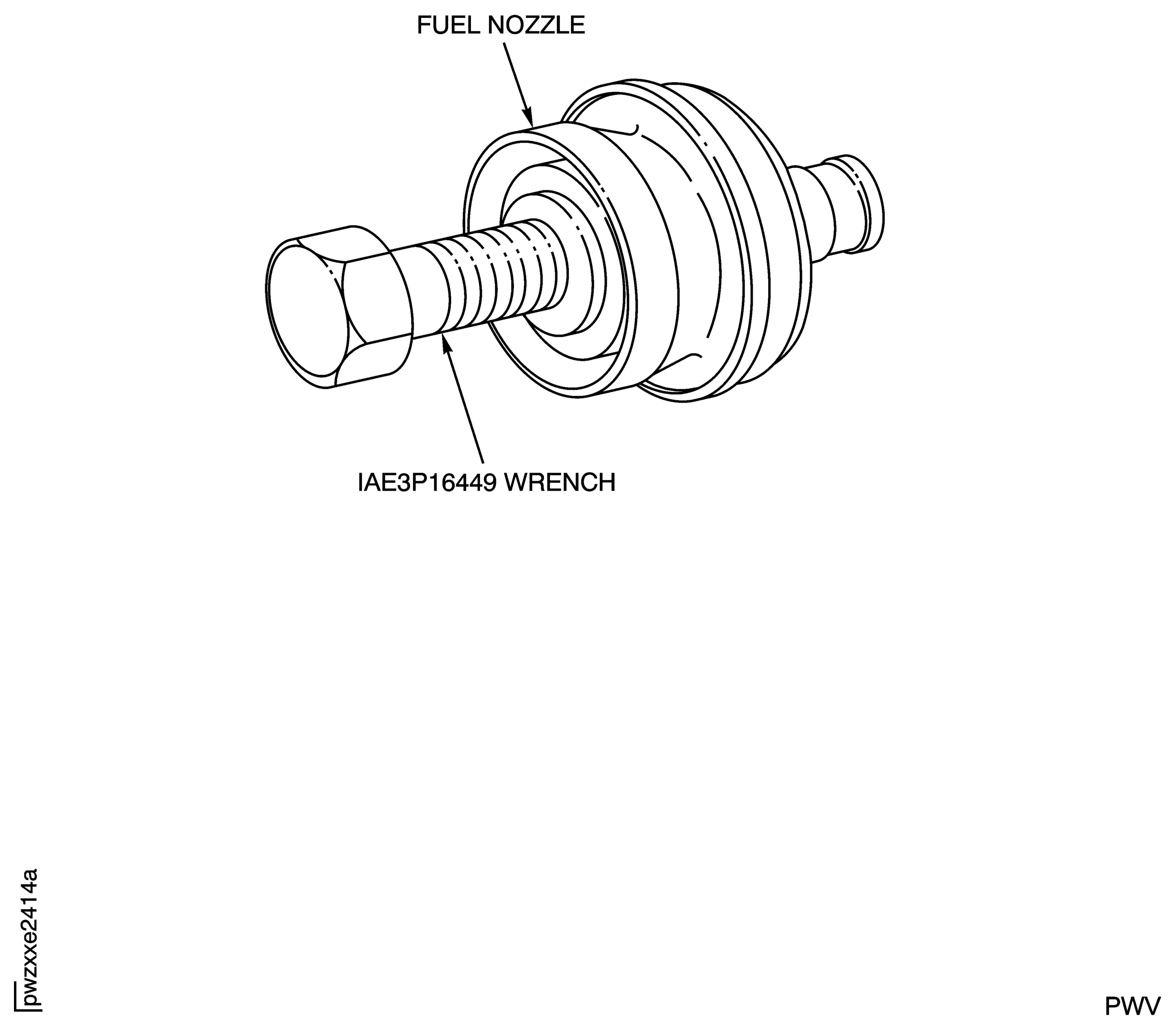

| IAE 3P16449 Wrench | 0AM53 | IAE 3P16449 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-243 WELDING FILLER WIRE | LOCAL | CoMat 03-243 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

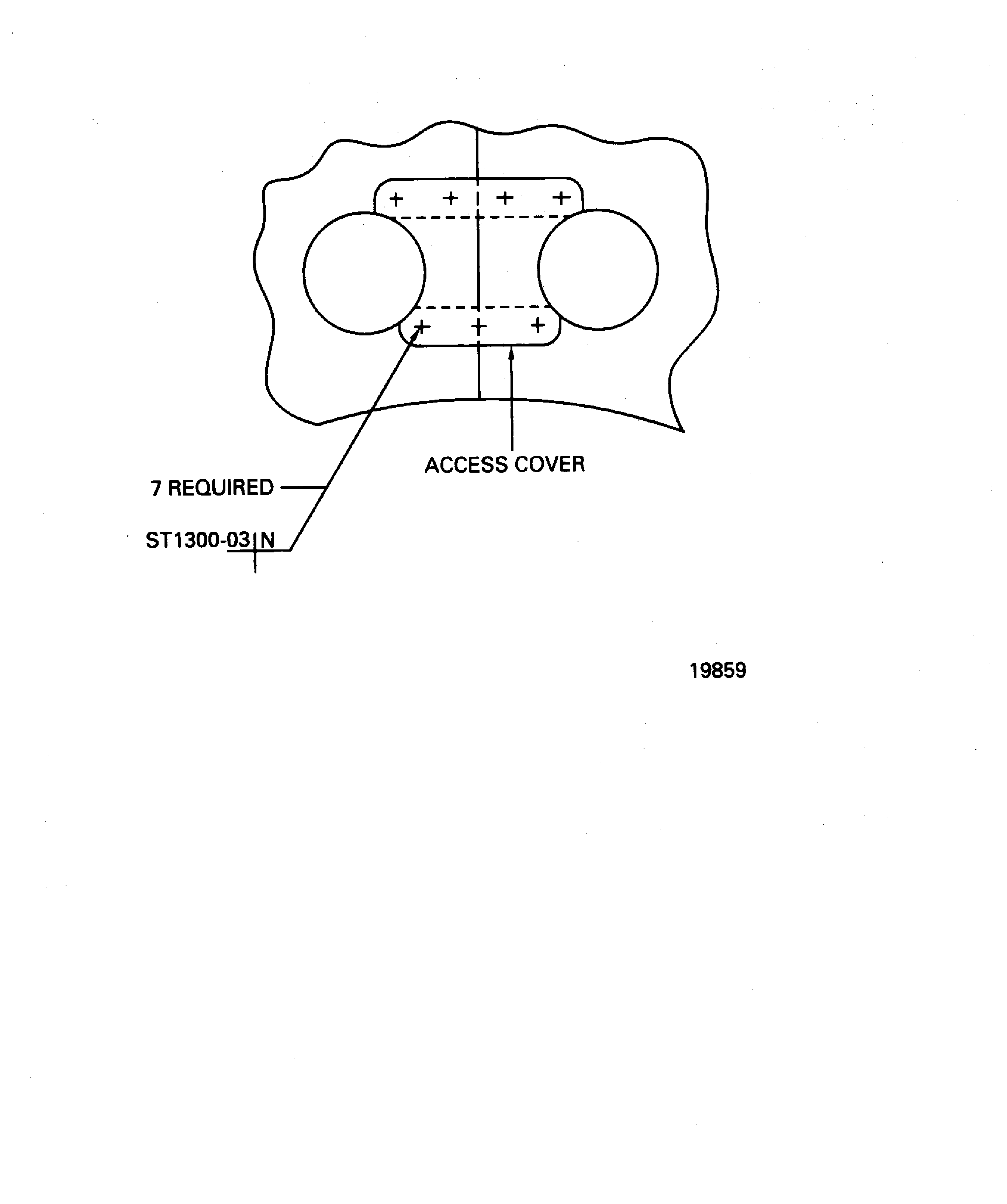

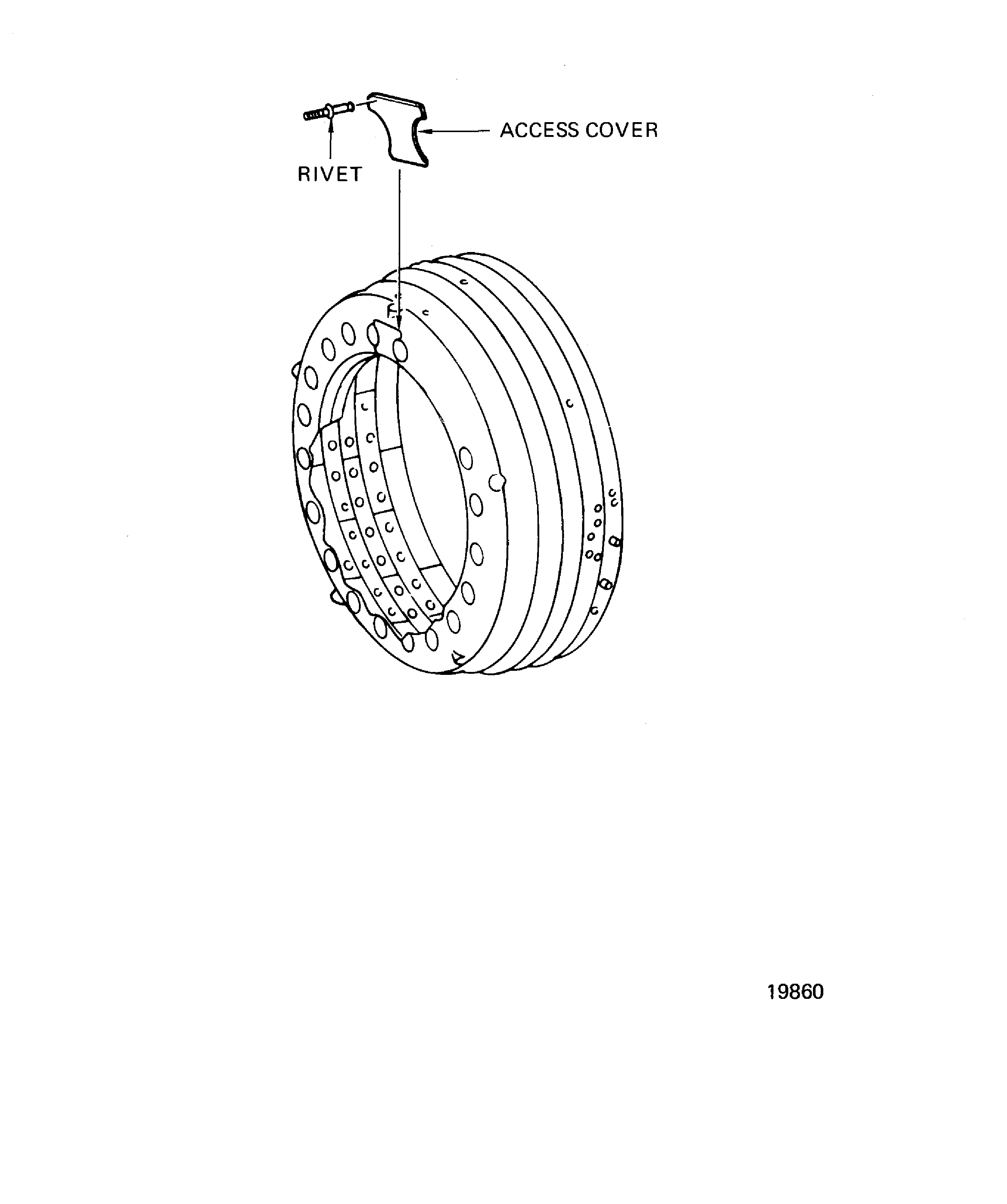

| RIVET - SOLID, UNIVERSAL HEAD | 77445 | ST1300-03 | ||

| Fuel nozzle guide | 2A0959 | 20 | ||

| Fuel nozzle guide retainer | 2A0960 | 20 | ||

| Access cover | 2A0962 | 1 | ||

| Fuel nozzle guide | 2A3325 | 20 | ||

| Fuel guide | 2A3340 | 20 | ||

| Fuel guide | 2A3341 | 20 | ||

| Fuel nozzle guide | 2A3350 | 20 | ||

| Fuel nozzle guide | 2A2380 | 20 |

Safety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-42-61-350-071 Remove the Access Cover

NOTE

It is not necessary to remove the access cover if the fuel nozzle guide retainers are not being replaced.Refer to Fig. 72-42-61-900-042. Install the base detail from the rear of the fuel nozzle guide with the 15 pins. (The pins are installed in the 15 guide cooling air holes). Attach the conical-shaped end plate to the base detail from the front of the fuel nozzle guide with a standard bolt. Torque the bolt to 144 to 192 lbfin (16.270 to 21.693 Nm).

Attach the IAE 3P16449 Wrench 1 off to the fuel nozzle guide.

Use a 1/4 inch diameter ball and a rotary filing bit to remove a minimum of guide material. Be careful to grind only the tack weld. It is not permitted to grind more than 1.00 in. (25.4 mm) cicumferentially at one of the tack weld locations. If you grind too much, the parts cannot be reassembled and will have to be replaced. Grind a little at a time, then try to remove the guide. Grind only enough to permit removal of the guide. Remove the guide from the rear with the 3/8 inch drive adapter (thread is left hand). Use a maximum torque of 600 lbfin (67.791 Nm). Too much torque to remove the guide from the retainer can cause damage to the bulkhead segment anti-rotation stud and/or the retainer clocking tangs. Set the guide towards the bulkhead anti-rotation stud while you remove the guide.

Grind the two tack welds which lock the retainer to the guide.

SUBTASK 72-42-61-350-072 Remove the Fuel Nozzle Guide

Refer to TASK 72-42-61-200-000 (INSPECTION/CHECK-000).

Use a white light and 3X magnification.

If the cracks or burns are more than what is permitted in TASK 72-42-61-200-000 (INSPECTION/CHECK-000 Page-801), refer to Repair, VRS3096 TASK 72-42-61-300-008 (REPAIR-008) to replace the bulkhead segment.

If you used more than 600 lbfin (67.791 Nm) of torque to remove the fuel nozzle guide, refer to Repair, VRS3096 TASK 72-42-61-300-008 (REPAIR-008) to remove and inspect the bulkhead segments.

Examine the bulkhead segment for cracks and burns.

Refer to TASK 72-42-61-200-000 (INSPECTION/CHECK-000).

There must be a minimum of two complete threads.

Replace guides that have less than two complete threads. A complete thread means the thread is continuous for 360 degrees. You can chase the threads to repair the guide so it can be assembled again with the correct torque.

Blending of tack weld locations is limited to 1.000 in. (25.44 mm) circumferentially at each location. The areas where you removed the tack weld must be blended smoothly with adjacent surfaces and you must remove burrs and sharp edges. If all four tack weld locations were blended, the fuel nozzle guide must be rejected.

Examine the fuel nozzle guide for thread damage.

If there are cracks or burns, or if an area is less than 0.030 in. (0.76 mm) thick and there is a step that is more than 0.005 in. (0.13 mm), replace the retainer.

There must be a minimum of three complete threads.

Replace retainers that have less than three complete threads. A complete thread means it is continuous for 360 degrees. You can chase the threads to repair the guide so it can be assembled again with the correct torque.

Blending of tack weld locations is limited to 1.000 in. (25.44 mm) circumferentially at each location. The areas where you removed the tack weld must be blended smoothly with adjacent surfaces and you must remove burrs and sharp edges. If all four tack weld locations were blended, the fuel nozzle guide must be rejected.

Examine the fuel nozzle guide retainer for cracks, burns, wear or thread damage.

SUBTASK 72-42-61-220-128 Examine the Liner (Bulkhead) Segment, the Fuel Nozzle Guide and the Fuel Nozzle Guide Retainer for Damage

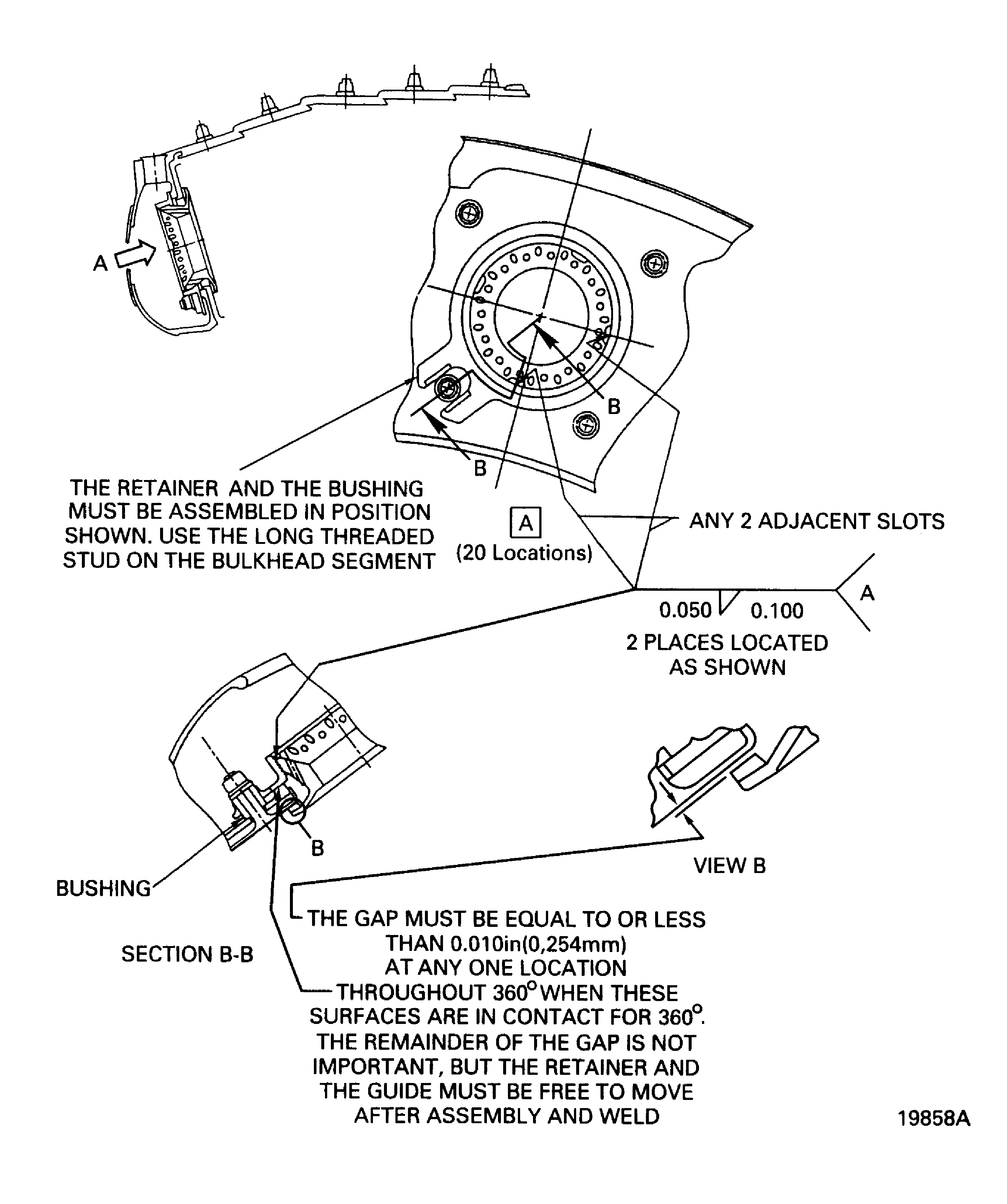

Refer to Figure.

Do not use more than 240 lbfin (27.116 Nm) of torque to turn the guide into the retainer. If you need to use more than 240 lbfin (27.116 Nm) of torque, clean or chase the threads of the guide and/or the retainer before you assemble them again.

Get the correct clearance between the guide and the bulkhead segment.

Turn the guide into the retainer.

SUBTASK 72-42-61-350-073 Install New Fuel Nozzle Guides and Retainers

Refer to Figure.

SUBTASK 72-42-61-220-129 Examine the Fuel Nozzle Guide for Clearance

Refer to Figure.

Refer to the SPM TASK 70-39-03-390-501.

Replace the cover with a new one if there are dents deeper than 0.050 in. (1.27 mm) or if it is visually cracked.

Install the access cover.

SUBTASK 72-42-61-350-074 Replace the Access Cover

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions