Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

2A0549-01 2A1374 2A1398 2A1617 2A2034 2A2034-001 2A2722-012A2838-01 2A3344-001 2A3344-002 2A3344-003 2A3344-004 2A3344-005 2A3344-0062A3344-007 2A3344-01 2A3351-003 2A3351-004 2A3351-01 2A4283-01 2A4311-012A4313-01 2A4315-001 2A4315-01

Common Information

TASK 72-44-30-300-004 Inner Combustion Chamber Liner - Repair The Plasma Coat on The Rear Mount Flange, Repair-004 (VRS3170)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-401 | 2A0549-01 |

01-401 | 2A1374 |

01-401 | 2A1398 |

01-401 | 2A1617 |

01-401 | 2A2034 |

01-401 | 2A2034-001 |

01-401 | 2A2722-01 |

01-401 | 2A2838-01 |

01-401 | 2A3344-01 |

01-401 | 2A3344-001 |

01-401 | 2A3344-002 |

01-401 | 2A3344-003 |

01-401 | 2A3344-004 |

01-401 | 2A3344-005 |

01-401 | 2A3344-006 |

01-401 | 2A3344-007 |

01-401 | 2A3351-01 |

01-401 | 2A3351-003 |

01-401 | 2A3351-004 |

01-401 | 2A4283-01 |

01-401 | 2A4311-01 |

01-401 | 2A4313-01 |

01-401 | 2A4315-01 |

01-401 | 2A4315-001 |

01-420 | 2A2718-01 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Combustion Chamber - | Wrought non-hardable | |

Inner liner | nickel base alloy |

General

Price and availability - refer to IAE

A ** following SPM TASK referenced in this repair indicates that the Process is not yet published in the current revision of the SPM manual. Contact IAE for additional information concerning the Process.

The practices and processes referred to in the procedure by the TASK number are in SPM.

Prerequisites

Make sure that the cleaning and inspection procedures are done before this repair

Refer to Engine Manual, PN E-V2500-1IA, Section 72-44-30 and SPM Manual, PN SPM-V2500-1IA Section 70-11-00

Remove the liner segments and the gang nut channels

Refer to Repair 001, VRS3173 TASK 72-44-30-300-001 and Repair 003, VRS3264 V2500-A0-72-44-3001-00A-920A-C

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-066 METAL SPRAYING POWDER, 75 CHROMIUM CARBIDE/25 (80 NICKEL - 20 CHROMIUM ALLOY), FINE | DK026 | CoMat 03-066 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 |

Spares

NONESafety Requirements

NONEProcedure

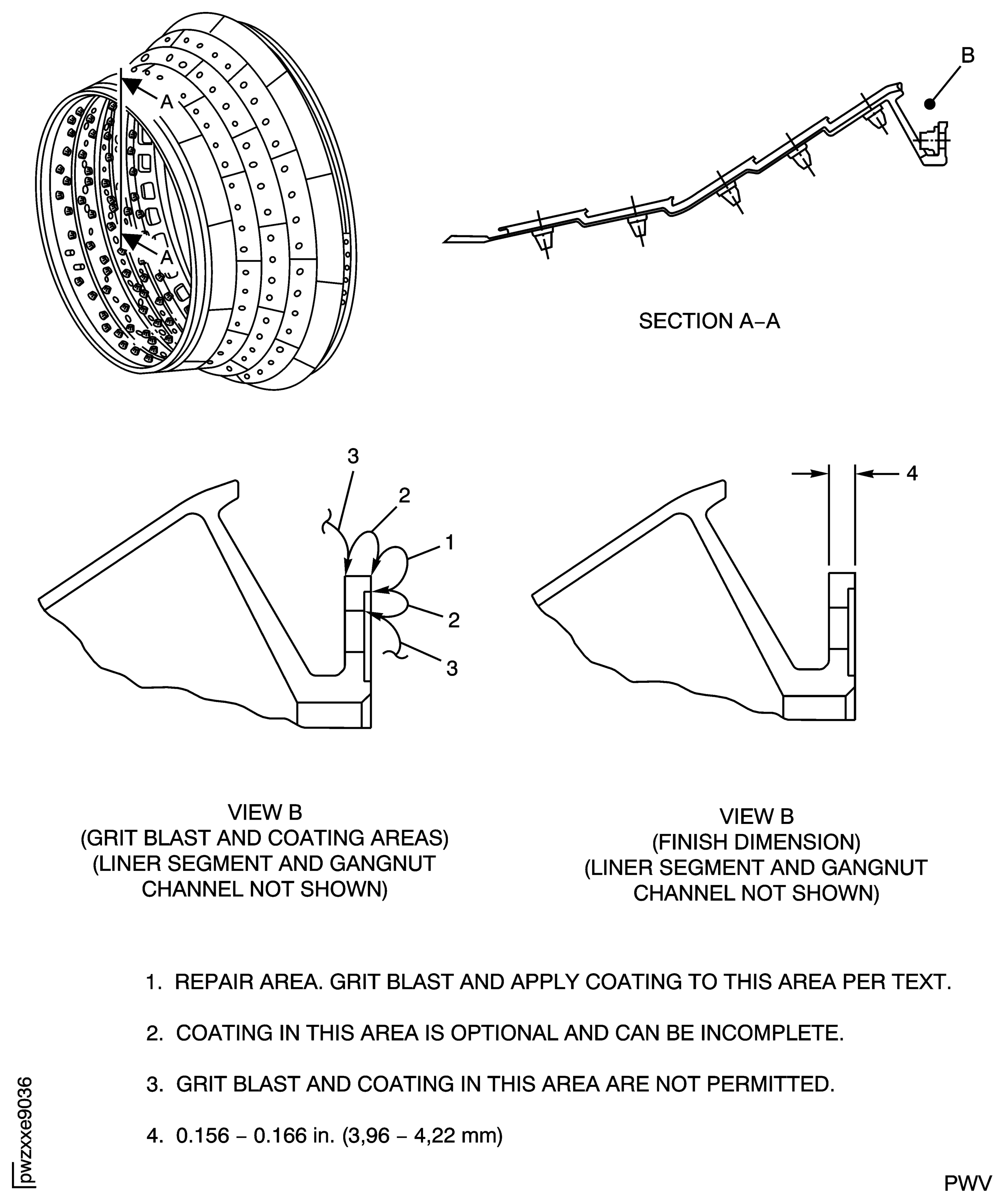

Refer to Figure.

SUBTASK 72-44-30-330-001 Remove Wear and/or Existing Coating from the Rear Mount Flange

Refer to SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-44-30-110-058 Clean the Combustion Chamber Inner Liner Assembly

Refer to SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501 or SPM TASK 70-23-05-230-501. Use high sensitivity. No cracks permitted.

Do a fluorescent penetrant inspection of the repair area.

SUBTASK 72-44-30-230-069 Do a Fluorescent Penetrant Inspection of the Repair Area

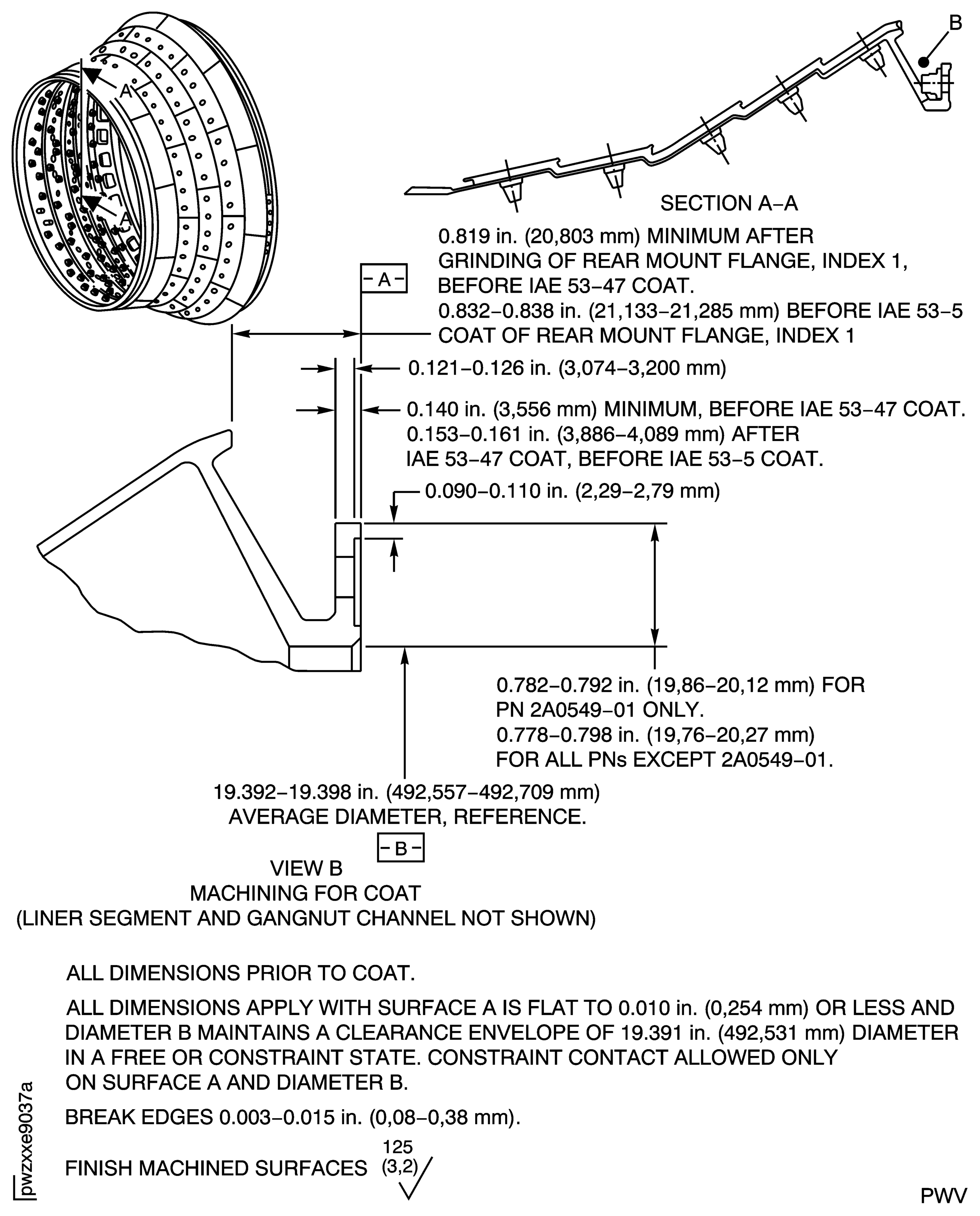

Refer to Figure.

SUBTASK 72-44-30-220-098 Do a Dimensional Inspection of the Combustion Chamber Inner Liner Assembly

Refer to Figure.

Refer to SPM TASK 70-34-18-380-501.

Shotpeen is not required. Grit blast out of the repair area is not permitted. Use masks.

Prepare the combustion chamber inner liner assembly for base coat.

SUBTASK 72-44-30-380-006 Prepare the Combustion Chamber Inner Liner Assembly for Base Coat

Refer to Figure.

Use CoMat 03-096 PLASMA SPRAY POWDER. Refer to theSPM TASK 70-34-03-340-501 and Fig.72-44-300-990-013-001.

Unless otherwise specified, coat out of the repair area is not permitted. Coat to a sufficient thickness to permit finishing.

Coat the repair area by IAE 53-47.

Finish coat thickness must be 0.003 to 0.021 in. (0.08 to 0.03 mm) thick. Refer to the SPM TASK 70-34-03-340-501 and Figure. No cutting fluids are permitted.

Dry machine or dry grind the base coat.

SUBTASK 72-44-30-340-052 Apply Base Coat to the Rear Mount Flange

Refer to SPM TASK 70-34-18-380-501 and Figure. Shotpeen is not required. Grit blast out of the repair area is not permitted. Use masks.

Prepare the combustion chamber inner liner assembly for top coat.

SUBTASK 72-44-30-380-009 Prepare the Combustion Chamber Inner Liner Assembly for Top Coat

Use CoMat 03-066 METAL SPRAYING POWDER, 75 CHROMIUM CARBIDE/25 (80 NICKEL - 20 CHROMIUM ALLOY), FINE. Refer to SPM TASK 70-34-03-340-501 and Figure.

Unless otherwise specified, coat out of the repair area is not permitted. Final coating thickness must be 0.003 to 0.005 in. (0.08 to 0.13 mm). Grinding to achieve finish dimensions is not permitted.

Coat the repair area by IAE 53-5.

SUBTASK 72-44-30-340-060 Apply Top Coat to the Rear Mount Flange

Refer to SPM TASK 70-11-26-300-503.

Remove the tape residue.

SUBTASK 72-44-30-110-059 Remove Masks and Tape Residue from the Combustion Chamber Inner Liner Assembly

Refer to SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-44-30-110-060 Clean the Combustion Chamber Inner Liner Assembly

Refer to Figure.

SUBTASK 72-44-30-220-099 Do a Dimensional Inspection of the Combustion Chamber Inner Liner Assembly

Refer to SPM TASK 70-34-03-340-501.

Examine the coating after repair by IAE 53.

SUBTASK 72-44-30-220-077 Examine the Plasma Coating on the Rear Mount Flange

Refer to SPM TASK 70-09-00-400-501.

Vibropeen mark "VRS3170" adjacent to the part number.

Refer to Repair 001, VRS3173 TASK 72-44-30-300-001 and Repair 003, VRS3264 V2500-A0-72-44-3001-00A-920A-C.

Install the liner segments and the gang nut channels.

SUBTASK 72-44-30-350-065 Postrequisites

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Repair Details and Dimensions