Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-40-300-004 HPT Stage 1 Outer Seal - Repair Wear On The Tab, Repair-004 (VRS3523)

General

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Austenitic stainless wire brush | LOCAL | Austenitic stainless wire brush |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-44-40-100-001 (CLEANING-000).

Clean the outer seal assembly.

SUBTASK 72-44-40-120-052 Clean the Stage 1 HPT Outer Seal Assembly

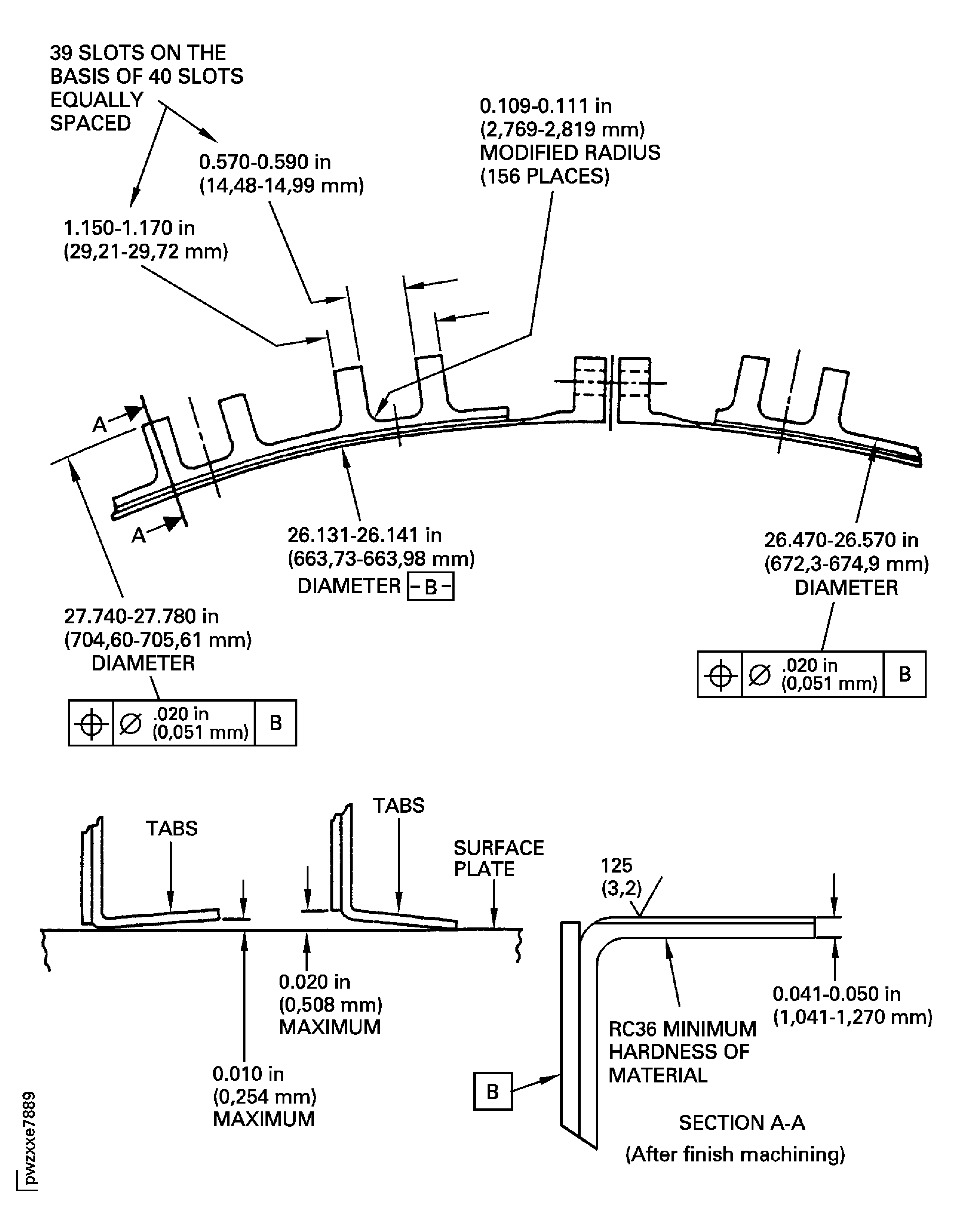

Refer to Figure for the flange thickness and width limit.

Machine the flange tabs of the outer seal assembly to remove wear.

SUBTASK 72-44-40-320-052 Machine the Flange Tabs of the Stage 1 HPT Outer Seal Assembly to Remove Wear

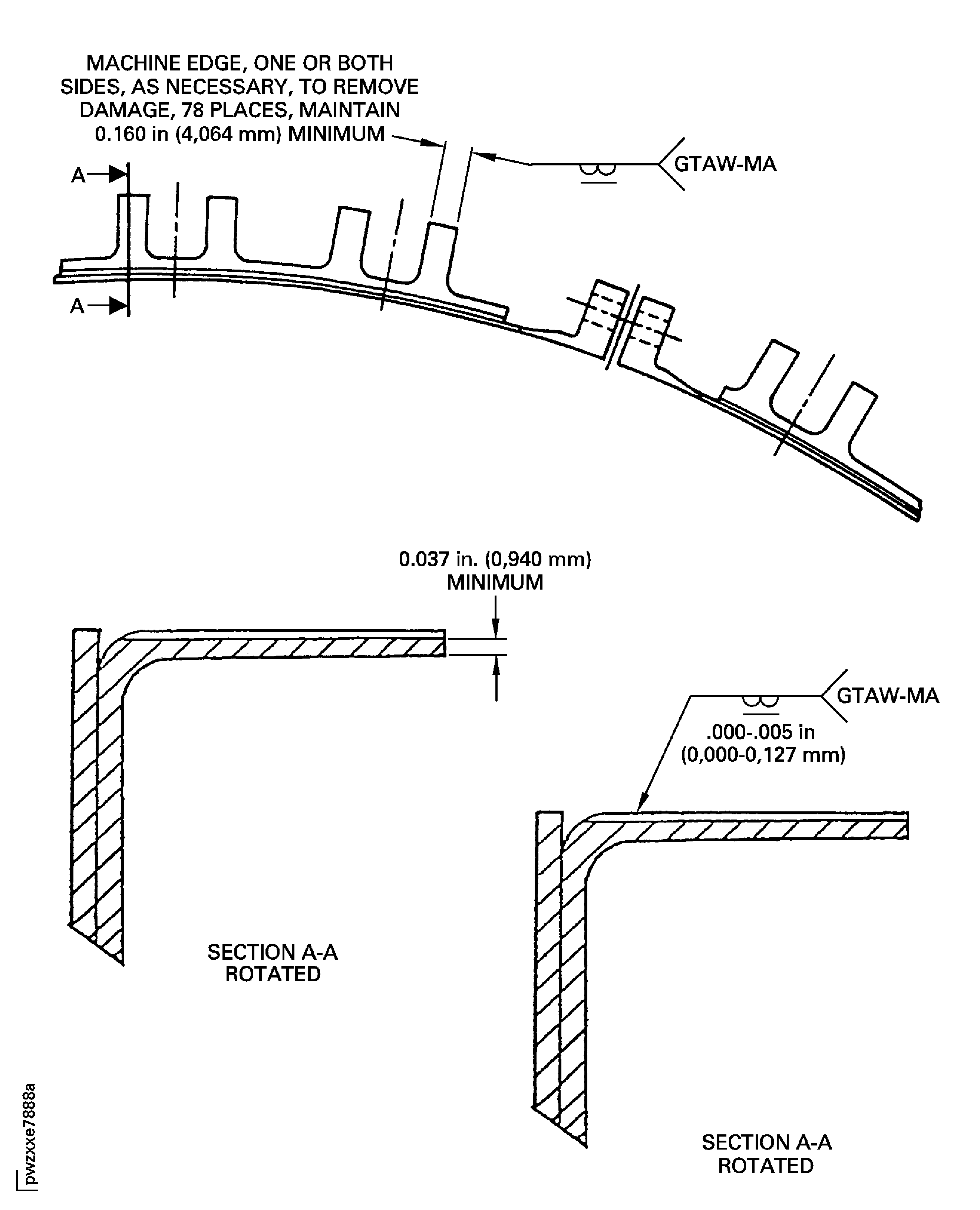

Refer to the SPM TASK 70-31-13-310-501 and Figure.

Refer to Figure for the tab thickness and width after finish machining.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE and the GTAW-MA method.

Weld to build up the tabs to a sufficient thickness and width to permit finish machining.

SUBTASK 72-44-40-310-051 Weld to Build Up the Tabs of the Stage 1 HPT Outer Seal Assembly

Use a surface plate and the limits as shown in Figure to check for distortion.

Inspect the tabs for distortion.

SUBTASK 72-44-40-220-063 Inspect the Tabs of the Stage 1 HPT Outer Seal Assembly for Distortion

Refer to the SPM TASK 70-37-01-370-501, Cycle 12A.

Stress relieve the outer seal assembly.

SUBTASK 72-44-40-370-051 Stress Relieve the Stage 1 HPT Outer Seal Assembly

Refer to Figure for final dimensions, surface finish and material hardness.

Machine the tab surfaces.

SUBTASK 72-44-40-320-053 Finish Machine the Stage 1 HPT Outer Seal Assembly

No cracks are permitted.

Local fluorescent penetrant inspection by the SPM TASK 70-23-05-230-501 is permissible.

Refer to the SPM TASK 70-23-02-230-501.

Fluorescent penetrant inspect the machined surfaces.

SUBTASK 72-44-40-230-053 Fluorescent Penetrant Inspect the Machined Surfaces of the Stage 1 HPT Outer Seal Assembly

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS3523 adjacent to the part number.

SUBTASK 72-44-40-350-052 Identify the Repair

Figure: Stage 1 HPT outer seal assembly tab buildup by welding

Stage 1 HPT outer seal assembly tab buildup by welding

Figure: Stage 1 HPT outer seal assembly tab repair

Stage 1 HPT outer seal assembly tab repair