Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-24-300-026 HPT Stage 2 Ring Segment And Vane Cluster - Plasma/Weld Repair, Repair-026 (VRS3570)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-050 | 2A4462 |

02-120 | 2A0088-01 |

02-320 | 2A0088-01 |

02-120 | 2A1106-01 |

02-260 | 2A4562 |

02-320 | 2A1106-01 |

02-120 | 2A3431-01 |

General

Price and Availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fusion welding equipment | LOCAL | Fusion welding equipment | ||

| Grinding equipment | LOCAL | Grinding equipment | ||

| Penetrant inspection equipment | LOCAL | Penetrant inspection equipment | ||

| Plasma spray equipment | LOCAL | Plasma spray equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-197 WELDING FILLER WIRE | LOCAL | CoMat 03-197 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-12-09-120-501 or SPM TASK 70-12-02-120-501.

Grit blast worn flange area to be repaired.

SUBTASK 72-45-24-120-001 Grit Blast the Repair Area

Refer to SPM TASK 70-34-03-340-501.

For wear up to a maximum depth of 0.030 in. (0.76 mm), plasma coat the area.

Refer to SPM TASK 70-31-13-310-501.

For wear up to a maximum depth of 0.030 in. (0.76 mm), weld build up the area by the Manual Gas Tungsten Arc method. Use CoMat 03-197 WELDING FILLER WIRE. Use of cooled cooper chill block during the welding process is recommended to minimize flange distortion during welding.

Stress relieve the air sealing ring segment at 1800 deg F (982.2 deg C) plus or minus 25 deg F (14 deg C) for one hour in a protective atmosphere or vacuum.

NOTE

You can do the stress relief after you blend or machine the air sealing ring segment by Step.NOTE

The stress relief may be concurrent with Repair, VRS3380 TASK 72-45-24-300-016 (Repair 016), braze cycle, SUBTASK 72-45-24-310-053.

SUBTASK 72-45-24-350-091 Repair the Worn Surface Area on the Ring Segment Flange by one of the following methods:

Refer to Figure or TASK 72-45-24-300-026.

SUBTASK 72-45-24-350-092 Mark the Ring Segment with the Repair Symbol

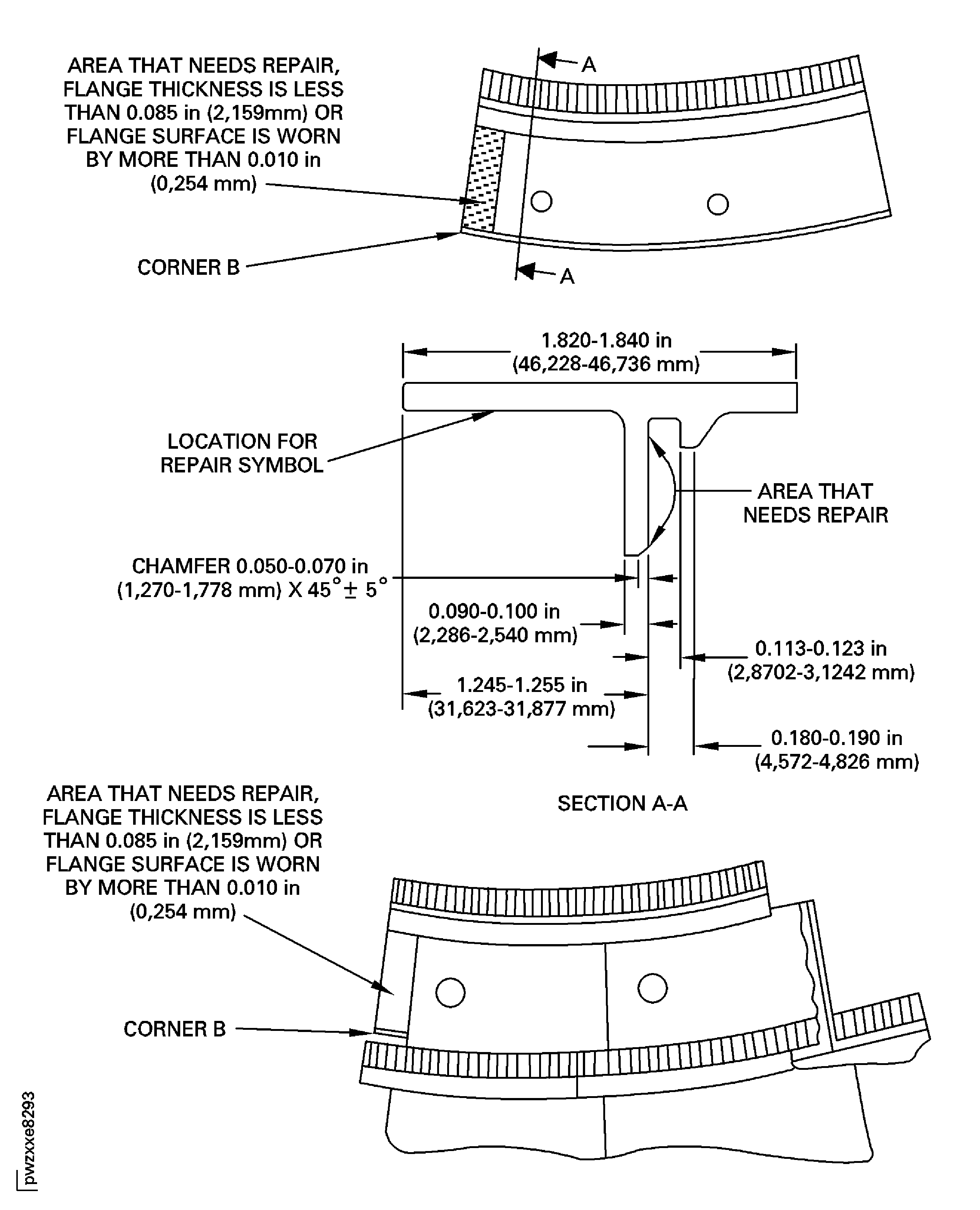

Figure: Repair Details and Dimensions (PN2A0088-01)

Repair Details and Dimensions (PN2A0088-01)

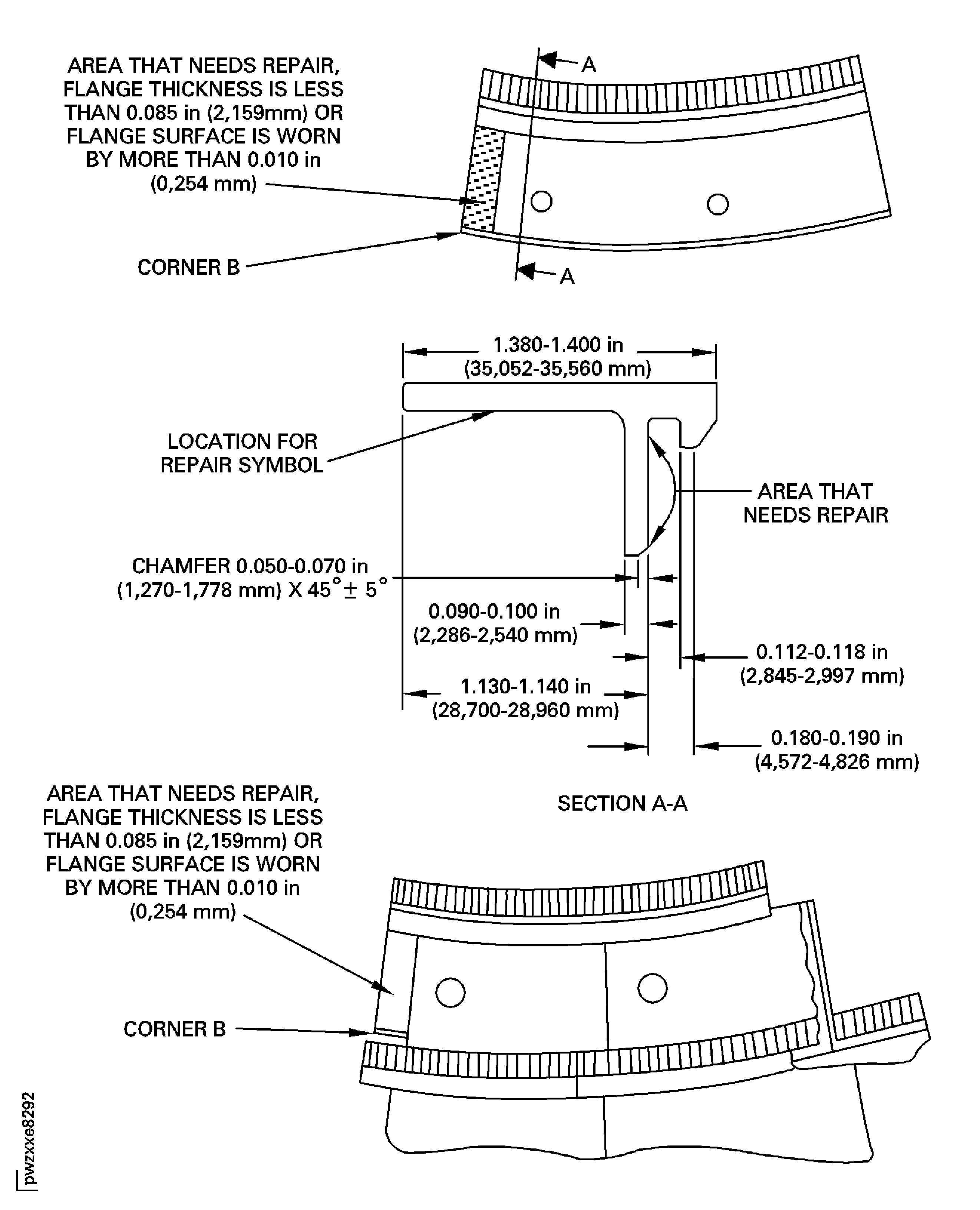

Figure: Repair Details and Dimensions (PN2A1106-01 and 2A3431-01)

Repair Details and Dimensions (PN2A1106-01 and 2A3431-01)