Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-00-430-001 LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit - Assemble The LPT Shaft To The LPT Case And Rotor Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Refer to TASK 72-50-00-990-501 for a sectional view of the LP turbine module.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10049 Vertical stand | 0AM53 | IAE 1F10049 | 1 | |

| IAE 1F10101 Counter weights kit | 0AM53 | IAE 1F10101 | 1 | |

| IAE 1J12201 Front sling | 0AM53 | IAE 1J12201 | 1 | |

| IAE 1J12202 Rear sling | 0AM53 | IAE 1J12202 | 1 | |

| IAE 1J12283 Expanding heater | 0AM53 | IAE 1J12283 | 1 | |

| IAE 1M14000 Lifting fixture | 0AM53 | IAE 1M14000 | 1 | |

| IAE 1M14001 Support fixture | 0AM53 | IAE 1M14001 | 1 | |

| IAE 1M14007 Hydraulic puller- pusher | 0AM53 | IAE 1M14007 | 1 | |

| IAE 1M14009 Storage stand | 0AM53 | IAE 1M14009 | 1 | |

| IAE 1M14057 Hydraulic basic fixture | 0AM53 | IAE 1M14057 | 1 | |

| IAE 1M14082 Protective cover | 0AM53 | IAE 1M14082 | 1 | |

| IAE 1M14125 Guide pin | 0AM53 | IAE 1M14125 | 1 | |

| IAE 1M14127 Support plate | 0AM53 | IAE 1M14127 | 2 | |

| IAE 1M14146 Support plate | 0AM53 | IAE 1M14146 | 2 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-149 DRY ICE | LOCAL | CoMat 02-149 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 72-50-00-220-051-A00 V2500-A1: Make sure that the Fits and Clearances of the LP Turbine Shaft and the Bolt are in the Limits Given at Location 3390 (Pre SBE 77-0001)

This subtask has been deleted.

SUBTASK 72-50-00-220-051-B00 V2500-A1: Make sure that the Fits and Clearances of the LP Turbine Shaft and the Bolt are in the Limits Given at Location 3400 (SBE 77-0001)

This subtask has been deleted.

Refer to: Figure.

Calculate the interference of the LP turbine shaft LPT Shaft And Related Parts (72-50-41,01-001) and the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) at location 3392.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3392

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

8.9803

8.9783

Intf

0.0039

Intf

0.0039

Shaft flange diameter

8.9776

8.9764

0.0007

0.0000

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3392

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

228.1000

228.0500

Intf

0.1000

Intf

0.1000

Shaft flange diameter

228.0320

228.0000

0.0180

0.0000

SUBTASK 72-50-00-220-053-A00 V2500-A1: Make Sure that the Fits and Clearances of the LP Turbine Shaft and the Stage 6 Turbine Disk are in the Limits Given at Location 3392 (Pre SBE 77-0001)

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.SBE 77-0001: Replacement of Turbine Exhaust Case and Installation of a Revised EGT Bracket Configuration

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.Refer to Figure.

Calculate the interference of the LP turbine shaft LPT Shaft And Related Parts (72-50-41,01-001) and the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) at location 3402.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3402

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

8.9803

8.9783

Intf

0.0039

Intf

0.0039

Shaft flange diameter

8.9776

8.9764

0.0007

0.0000

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3402

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

228.1000

228.0500

Intf

0.1000

Intf

0.1000

Shaft flange diameter

228.0320

228.0000

0.0180

0.0000

SUBTASK 72-50-00-220-053-B00 V2500-A1: Make Sure that the Fits and Clearances of the LP Turbine Shaft and the Stage 6 Turbine Disk are in the Limits Given at Location 3402 (SBE 77-0001)

Refer to: Figure.

Calculate the interference of the LP turbine shaft LPT Shaft And Related Parts (72-50-41,01-001) and the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) at location 3782.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3782

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

8.9803

8.9783

Intf

0.0039

Intf

0.0039

Shaft flange diameter

8.9776

8.9764

0.0007

0.0000

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3782

Stage 6 turbine disk, abutment

face LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-050) to

LP turbine shaft

LPT Shaft And Related Parts (72-50-41,01-001)

Disk abutment diameter

228.1000

228.0500

Intf

0.1000

Intf

0.1000

Shaft flange diameter

228.0320

228.0000

0.0180

0.0000

SUBTASK 72-50-00-220-053-C00 V2500-A5: Make Sure that the Fits and Clearances of the LP Turbine Shaft and the Stage 6 Turbine Disk are in the Limits Given at Location 3782

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.SUBTASK 72-50-00-220-054-A00 V2500-A1: Make Sure that the Fits and Clearances Between the Stage 6 Disk Bore and the Bolt are in the Limits Given at Location 3391 (Pre SBE 77-0001)

This subtask has been deleted.

SUBTASK 72-50-00-220-054-B00 V2500-A1: Make Sure that the Fits and Clearances Between the Stage 6 Disk Bore and the Bolt are in the Limits Given at Location 3401 (SBE 77-0001)

This subtask has been deleted.

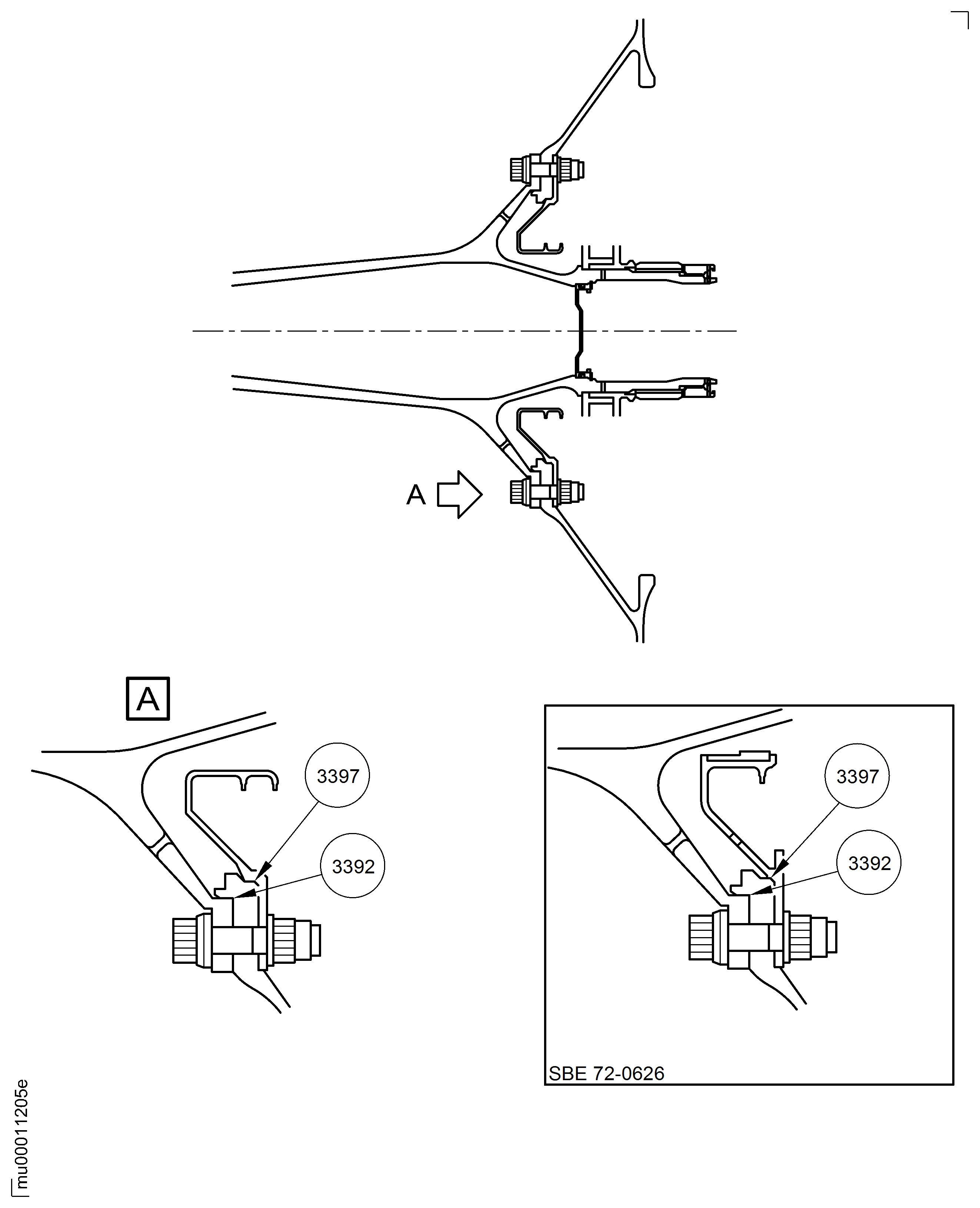

Refer to: Figure.

Calculate the interference of the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) and the stage 6 inner turbine air seal LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240) at location 3397.

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3397

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

8.3496

Intf

inner diameter

8.3465

0.0079

Stage 6 inner turbine

8.3543

0.0016

air seal outer diameter

8.3512

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3397

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

212.080

Intf

inner diameter

212.000

0.200

Stage 6 inner turbine

212.200

0.040

air seal outer diameter

212.120

SUBTASK 72-50-00-220-055-A00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 6 Inner Turbine Air Seal are in the Limits Given at Location 3397 (Pre SBE 77-0001)

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.SBE 77-0001: Replacement of Turbine Exhaust Case and Installation of a Revised EGT Bracket Configuration

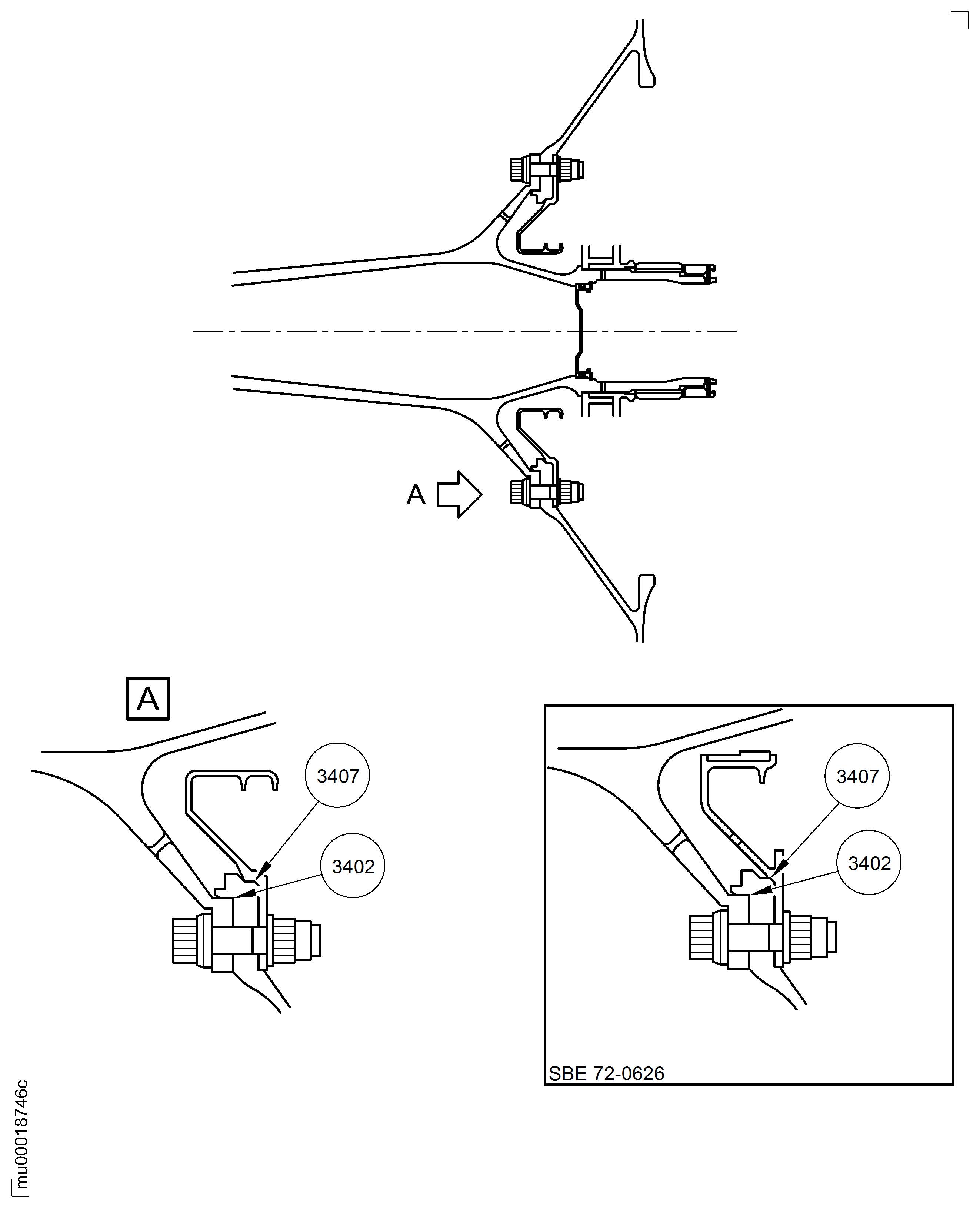

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.Refer to Figure.

Calculate the interference of the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) and the stage 6 inner turbine air seal LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240) at location 3407.

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3407

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

8.3496

Intf

inner diameter

8.3465

0.0079

Stage 6 inner turbine

8.3543

0.0016

air seal outer diameter

8.3512

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3407

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

212.080

Intf

inner diameter

212.000

0.200

Stage 6 inner turbine

212.200

0.040

air seal outer diameter

212.120

SUBTASK 72-50-00-220-055-B00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 6 Inner Turbine Air Seal are in the Limits Given at Location 3407 (SBE 77-0001)

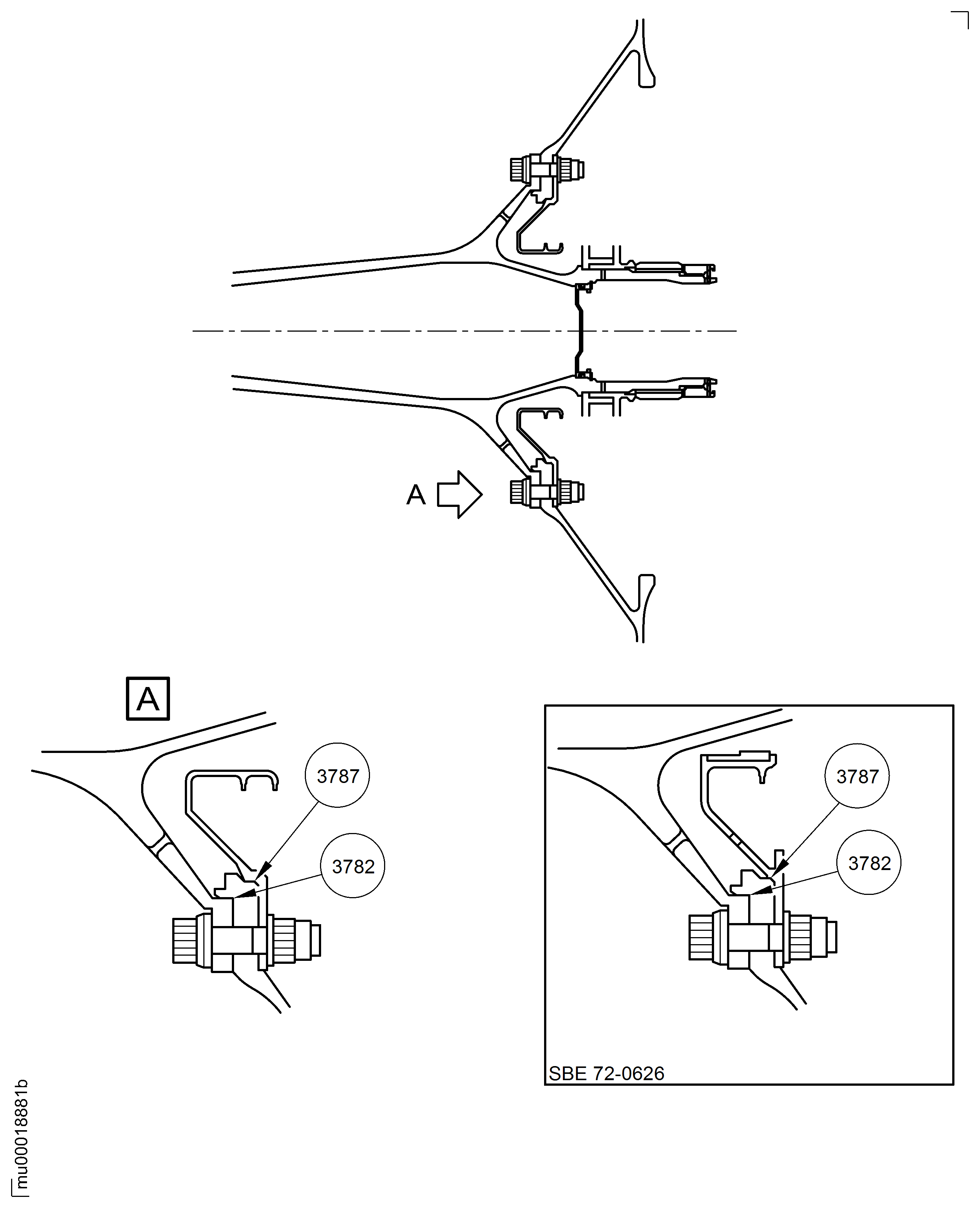

Refer to: Figure.

Calculate the interference of the stage 6 turbine disk LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) and the stage 6 inner turbine air seal LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240) at location 3787.

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3787

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

8.3496

Intf

inner diameter

8.3465

0.0079

Stage 6 inner turbine

8.3543

0.0016

air seal outer diameter

8.3512

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 3787

Stage 6 turbine disk

inner diameter

LPT Stage 3, 4, 5, 6, 7 Disks (72-50-31,01-150) to

stage 6 inner turbine

air seal outer diameter

LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit (72-50-00,01-240)

Stage 6 turbine disk

212.080

Intf

inner diameter

212.000

0.200

Stage 6 inner turbine

212.200

0.040

air seal outer diameter

212.120

SUBTASK 72-50-00-220-055-C00 V2500-A5: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 6 Inner Turbine Air Seal are in the Limits Given at Location 3787

NOTE

During assembly, it is not necessary to measure, calculate and record the fits and clearances if both parts are new.SUBTASK 72-50-00-220-056-A00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Inner Turbine Air Seal and the Bolt are in the Limits Given at Location 3398 (Pre SBE 77-0001)

This subtask has been deleted.

SUBTASK 72-50-00-220-056-B00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Inner Turbine Air seal and the Bolt are in the Limits Given at Location 3408 (SBE 77-0001)

This subtask has been deleted.

Install the IAE 1J12201 Front sling 1 off to the front thread of the LP turbine shaft. Attach hoist equipment to the sling.

Install the IAE 1J12202 Rear sling 1 off to the rear thread of the LP turbine shaft. Attach a second hoist equipment to the rear sling.

Remove the LP turbine shaft from the storage stand as follows:

Install the LP turbine shaft to the IAE 1F10049 Vertical stand 1 off as follows:

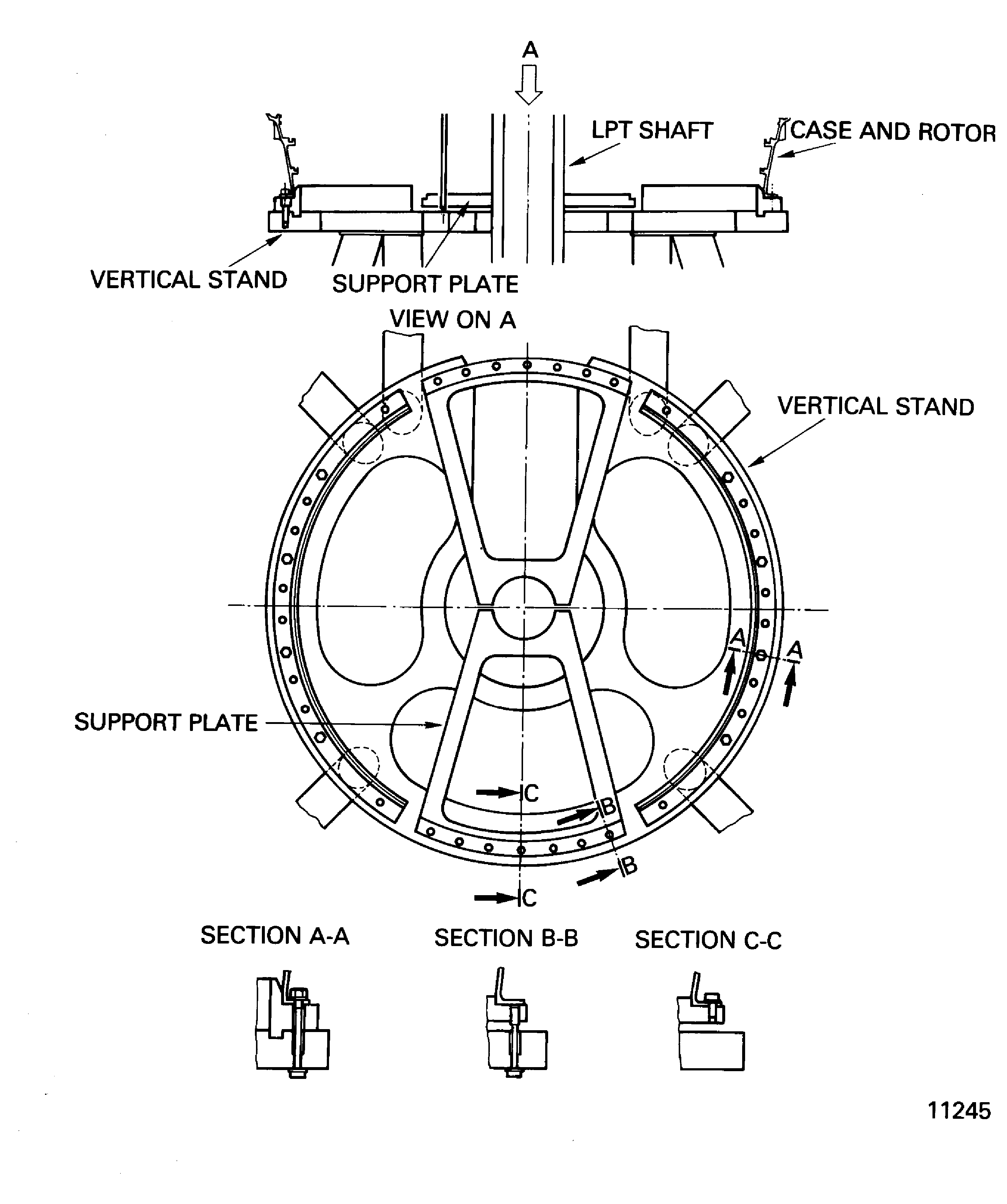

Attach the IAE 1M14127 Support plate 2 off with the four head capscrews to the vertical stand. Tighten the screws.

SUBTASK 72-50-00-430-051-A00 V2500-A1: Install the LP Turbine Shaft to the Vertical Stand

NOTE

Make sure that the IAE 1F10101 Counter weights kit 1 off is installed on the IAE 1F10049 Vertical stand 1 off. Do not move the stand with the installed LP turbine case and rotor without the counterweight kit.Install the IAE 1J12201 Front sling 1 off to the front thread of the LP turbine shaft. Attach hoist equipment to the sling.

Install the IAE 1J12202 Rear sling 1 off to the rear thread of the LP turbine shaft. Attach a second hoist hoist equipment to the rear sling.

Remove the LP turbine shaft from the storage stand as follows:

Install the LP turbine shaft to the IAE 1F10049 Vertical stand 1 off as follows:

Attach the IAE 1M14146 Support plate 2 off with the four head capscrews to the vertical stand. Tighten the screws.

SUBTASK 72-50-00-430-051-B00 V2500-A5: Install the LP Turbine Shaft to the Vertical Stand

NOTE

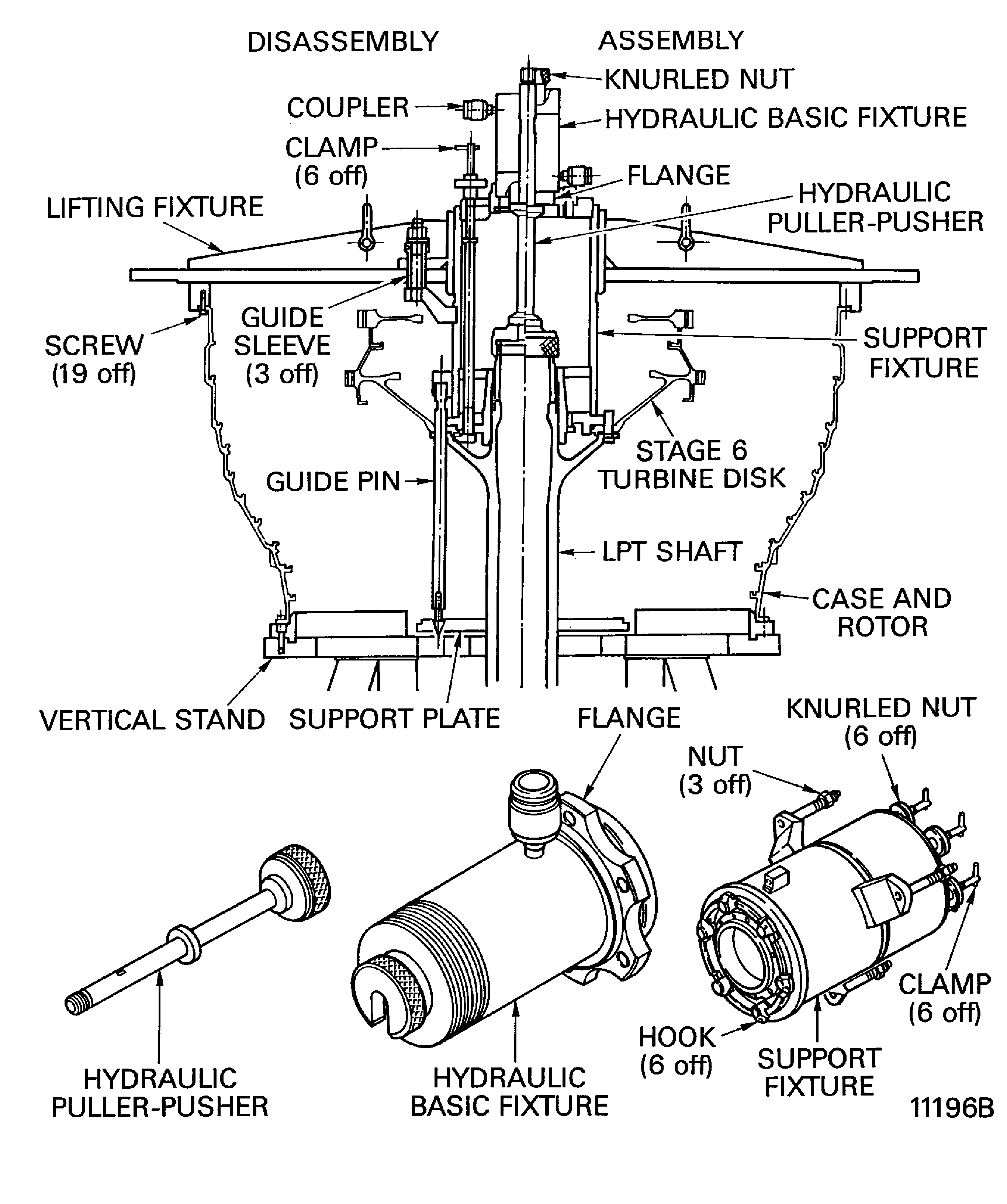

Make sure that the IAE 1F10101 Counter weights kit 1 off is installed on the IAE 1F10049 Vertical stand 1 off. Do not move the stand with the installed LP turbine case and rotor without the counterweight kit.Refer to: Figure

Install the IAE 1M14007 Hydraulic puller- pusher 1 off to the rear end of the LP turbine shaft.

SUBTASK 72-50-00-430-052 Install the Hydraulic Puller-Pusher

Install the IAE 1J12283 Expanding heater 1 off to the rear face of the LP turbine shaft.

SUBTASK 72-50-00-430-053 Heat the Rear Face of the LP Turbine Shaft

Engage the IAE 1M14000 Lifting fixture 1 off on to the IAE 1M14001 Support fixture 1 off. Turn back the three guide sleeves, part of the lifting fixture, until the support fixture touches the lifting fixture.

SUBTASK 72-50-00-430-072 Install the Support Fixture in to the Lifting Fixture

Refer to: Figure

Release the eight bolts and nuts which attach the IAE 1M14082 Protective cover 1 off to the turbine case. Remove the cover.

Install the IAE 1M14125 Guide pin 1 off to the support fixture.

NOTE

Make sure that the IAE 1M14001 Support fixture 1 off is installed to the lifting fixture.Install the IAE 1M14000 Lifting fixture 1 off to the rear flange of the LP turbine case as follows.

SUBTASK 72-50-00-430-054 Install the Lifting Fixture

Refer to: Figure

NOTE

The word "assembly" on the flange must be in the top position.Attach the flange (part of IAE 1M14057 Hydraulic basic fixture 1 off) to the IAE 1M14001 Support fixture 1 off.

SUBTASK 72-50-00-430-055 Install the Hydraulic Basic Fixture

Remove the IAE 1J12283 Expanding heater from the rear flange of the LP turbine shaft.

SUBTASK 72-50-00-430-056 Remove the Heater

Release the four clamp straps and the wing nuts that attach the LP turbine case to the IAE 1M14009 Storage stand 1 off.

SUBTASK 72-50-00-430-057 Install the LP Turbine Case and Rotor to the LP Turbine Shaft

Turn the lockring, part of the IAE 1F10049 Vertical stand 1 off until the connecting flange of the LP turbine shaft touches the flange of the stage 6 turbine disk.

Attach the IAE 1M14057 Hydraulic basic fixture 1 off to the IAE 1M14007 Hydraulic puller- pusher 1 off with the knurled nuts.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the hydraulic basic fixture.

SUBTASK 72-50-00-430-058 Connect the LP Turbine Case and Rotor to the LP Turbine Shaft

Disconnect the IAE 1F10026 Hydraulic hand pump from the IAE 1M14057 Hydraulic basic fixture 1 off.

Loosen the knurled nut to release the hydraulic basic fixture from the IAE 1M14007 Hydraulic puller- pusher 1 off.

Remove the hydraulic cylinder and the flange from the IAE 1M14001 Support fixture 1 off.

Remove the 19 screws which attach the IAE 1M14000 Lifting fixture 1 off to the rear flange of the LP turbine case.

Remove the IAE 1M14125 Guide pin from the support fixture.

SUBTASK 72-50-00-430-059 Remove the Tools from the LP Turbine

Decrease the temperature of the stage 6 LP turbine inner air seal. Use the CoMat 02-149 DRY ICE. Decrease the temperature to get a minimum temperature differential of 180.0 deg F (100.0 deg C) between the stage 6 disk and the stage 6 inner air seal.

SUBTASK 72-50-00-430-073-A00 V2500-A1: Install the Stage 6 LP Turbine Inner Air Seal (Pre SBE 72-0626)

Refer to: Figure.

Decrease the temperature of the stage 6 LP turbine inner air seal. Use CoMat 02-149 DRY ICE. Decrease the temperature to get a minimum temperature differential of 180.0 deg F (100.0 deg C) between the stage 6 disk and the stage 6 inner air seal.

SUBTASK 72-50-00-430-073-B00 V2500-A5: Install the Stage 6 LP Turbine Inner Air Seal (Pre SBE 72-0626)

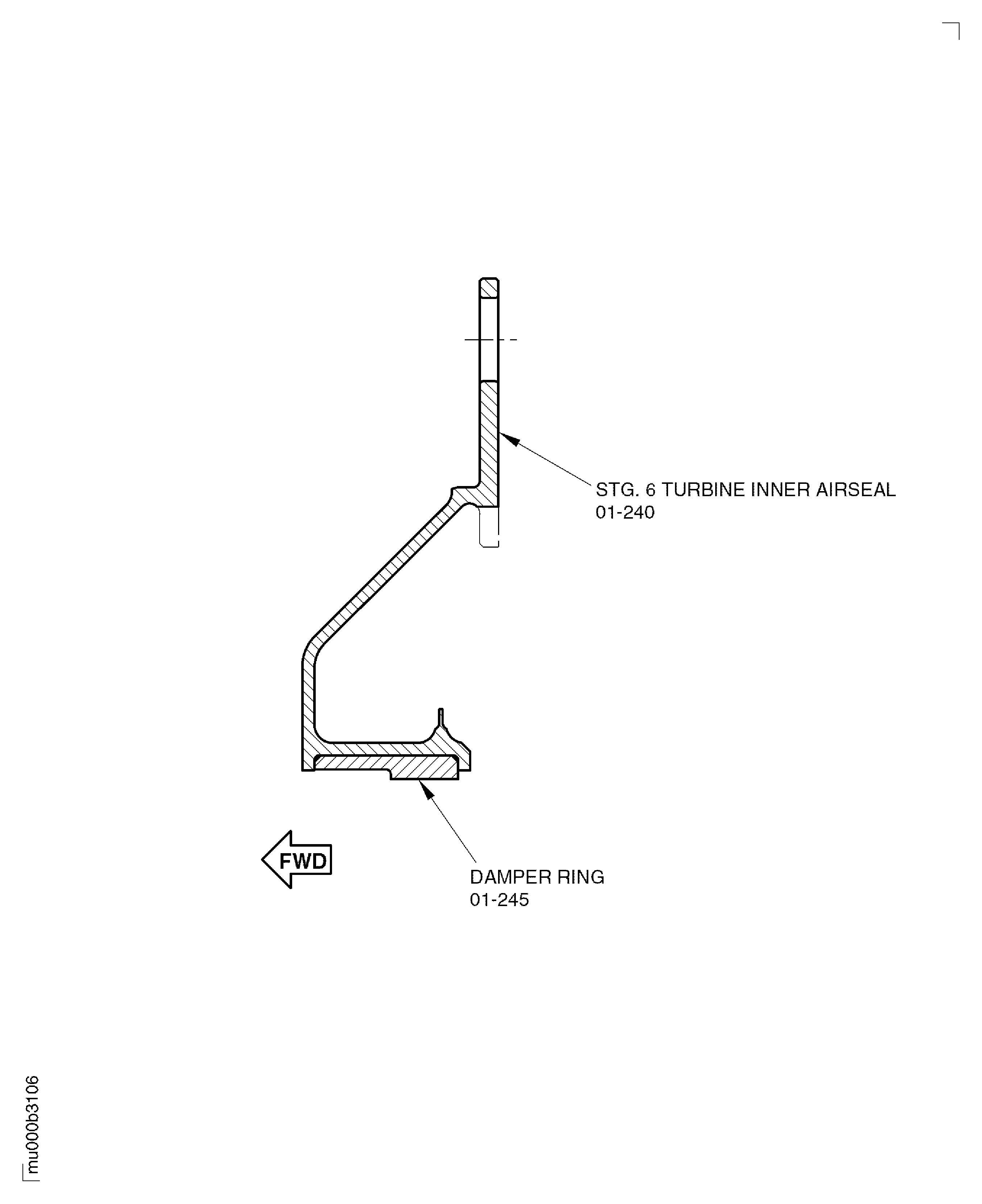

Install the inner damper ring on to the stage 6 turbine inner airseal. Use circlip pliers to compress the damper ring. Make sure that the damper ring is correctly installed on to the stage 6 turbine inner airseal. Refer to Figure.

Decrease the temperature of the stage 6 LP turbine inner air seal. Use the CoMat 02-149 DRY ICE. Decrease the temperature to get a minimum temperature differential of 180.0 deg F (100.0 deg C) between the stage 6 disk and the stage 6 turbine inner air seal.

SUBTASK 72-50-00-430-073-C00 V2500-A1: Install the Stage 6 LP Turbine Inner Air Seal (SBE 72-0626)

Refer to Figure.

Install the inner damper ring on to the stage 6 turbine inner airseal. Use circlip pliers to compress the damper ring. Make sure that the damper ring is correctly installed on to the stage 6 turbine inner airseal. Refer to Figure.

Decrease the temperature of the stage 6 LP turbine inner air seal. Use the CoMat 02-149 DRY ICE. Decrease the temperature to get a minimum temperature differential of 180.0 deg F (100.0 deg C) between the stage 6 disk and the stage 6 turbine inner air seal.

SUBTASK 72-50-00-430-073-D00 V2500-A5: Install the Stage 6 LP Turbine Inner Air Seal (SBE 72-0626)

CAUTION

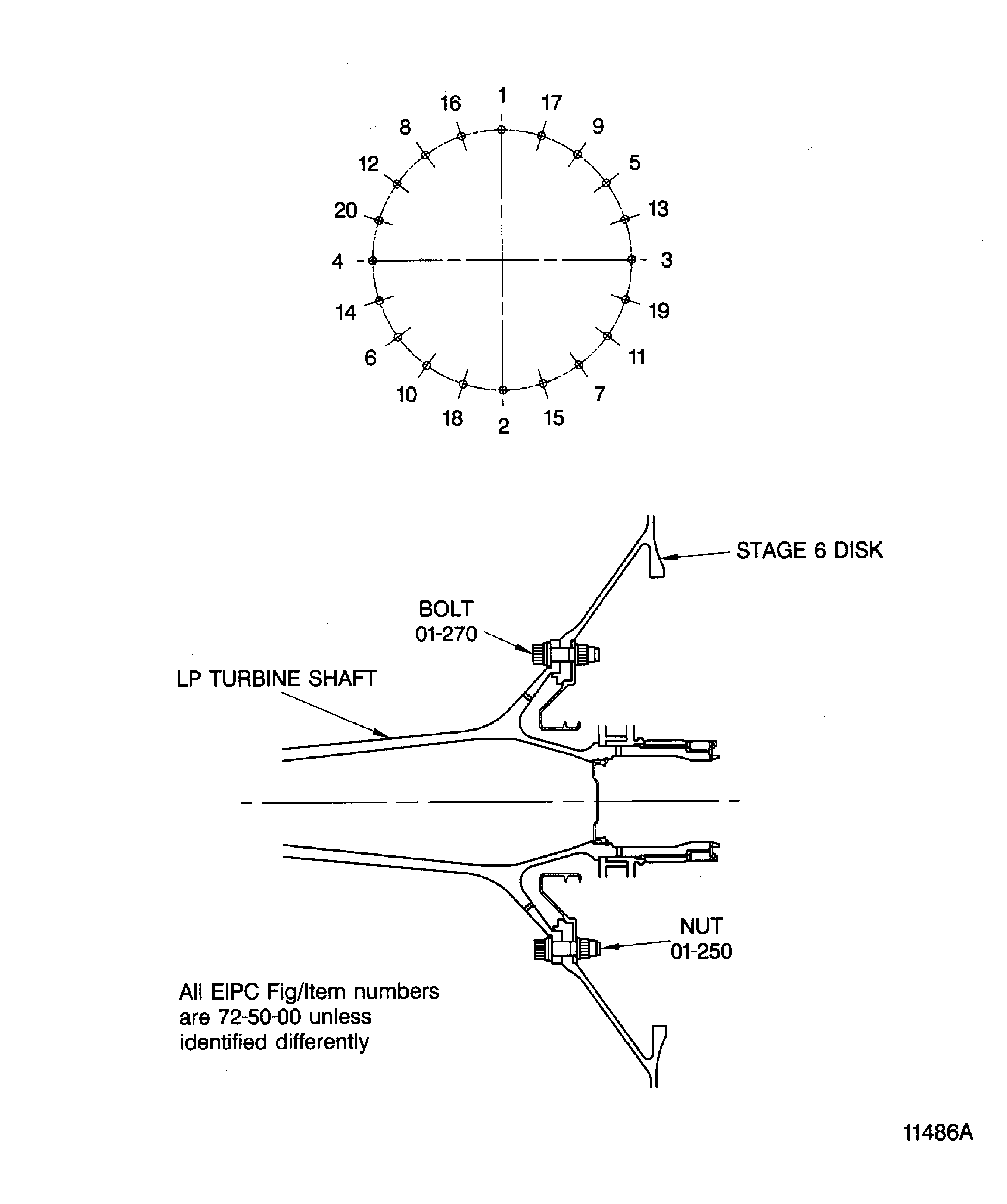

HOLD THE BOLTS IN THEIR POSITION WHEN YOU INSTALL THE NUTS ON TO THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE SHAFT/DISK FLANGE AND/OR THE BOLTS CAN BE DAMAGED BY SCORES.Install the other 16 more bolts and nuts which lock the rear flange of the LP turbine shaft to the stage 6 turbine disk.

NOTE

The tightening torque value includes the self locking torque value.Torque the nuts in two steps. For the torque sequence, refer to Figure.

SUBTASK 72-50-00-430-060 Install the Bolts

Refer to: Figure

Attach the IAE 1M14127 Support plate 2 off to the LP turbine case front flange with 10 head capscrews.

SUBTASK 72-50-00-430-074-A00 V2500-A1: Attach the Support Plates to the LP Turbine Case

Refer to: Figure

Attach the IAE 1M14146 Support plate 2 off to the LP turbine case front flange with 10 head capscrews.

SUBTASK 72-50-00-430-074-B00 V2500-A5: Attach the Support Plates to the LP Turbine Case

Install the turbine exhaust case. Refer to TASK 72-50-00-430-002 (Assembly-002).

SUBTASK 72-50-00-430-061 Install the Turbine Exhaust Case

Figure: V2500-A1: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk

V2500-A1: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk

Figure: V2500-A1: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk (SBE 77-0001)

V2500-A1: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk (SBE 77-0001)

Figure: V2500-A5: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk

V2500-A5: Fits and Clearances at the Rear Flange of the LP Turbine Shaft and the Stage 6 Turbine Disk

Figure: Install the LP Turbine Shaft

Install the LP Turbine Shaft

Figure: Install the Support Plates

Install the Support Plates

Figure: Torque Sequence of the Nuts which Attach the Stage 6 Turbine Disk and the LP Turbine Shaft

Torque Sequence of the Nuts which Attach the Stage 6 Turbine Disk and the LP Turbine Shaft

Figure: Installation of the Damperring

Installation of the Damperring