Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-21-300-009 LPT Case - Weld Repair Cracks Adjacent To The Borescope Hole, Repair-009 (VRS4012)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Before start of repair, remove borescope boss (refer to TASK 72-50-21-300-010, VRS4013). If in good condition, retain boss for later use. After completion of repair, install boss again (refer to TASK 72-50-21-300-010, VRS4013).

If oven stress relieving method is used, remove screw inserts (refer to TASK 72-50-21-300-026, VRS4049). After repair replace screw inserts (refer to TASK 72-50-21-300-026, VRS4049).

In Step, all equipment and material required for local stress relieving method will be of local purchase, with exception of coil. Trials should be carried out on discard components to make sure the success of local stress relieving before try to repair on case.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| File | LOCAL | File | ||

| Various stones | LOCAL | Various stones | ||

| Hand held grinder | LOCAL | Hand held grinder | ||

| Welding equipment | LOCAL | Welding equipment | ||

| Oven | LOCAL | Oven | ||

| Thermocouple | LOCAL | Thermocouple | ||

| Standard induction heater | LOCAL | Standard induction heater |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-23-05-230-501. Use medium sensitivity level.

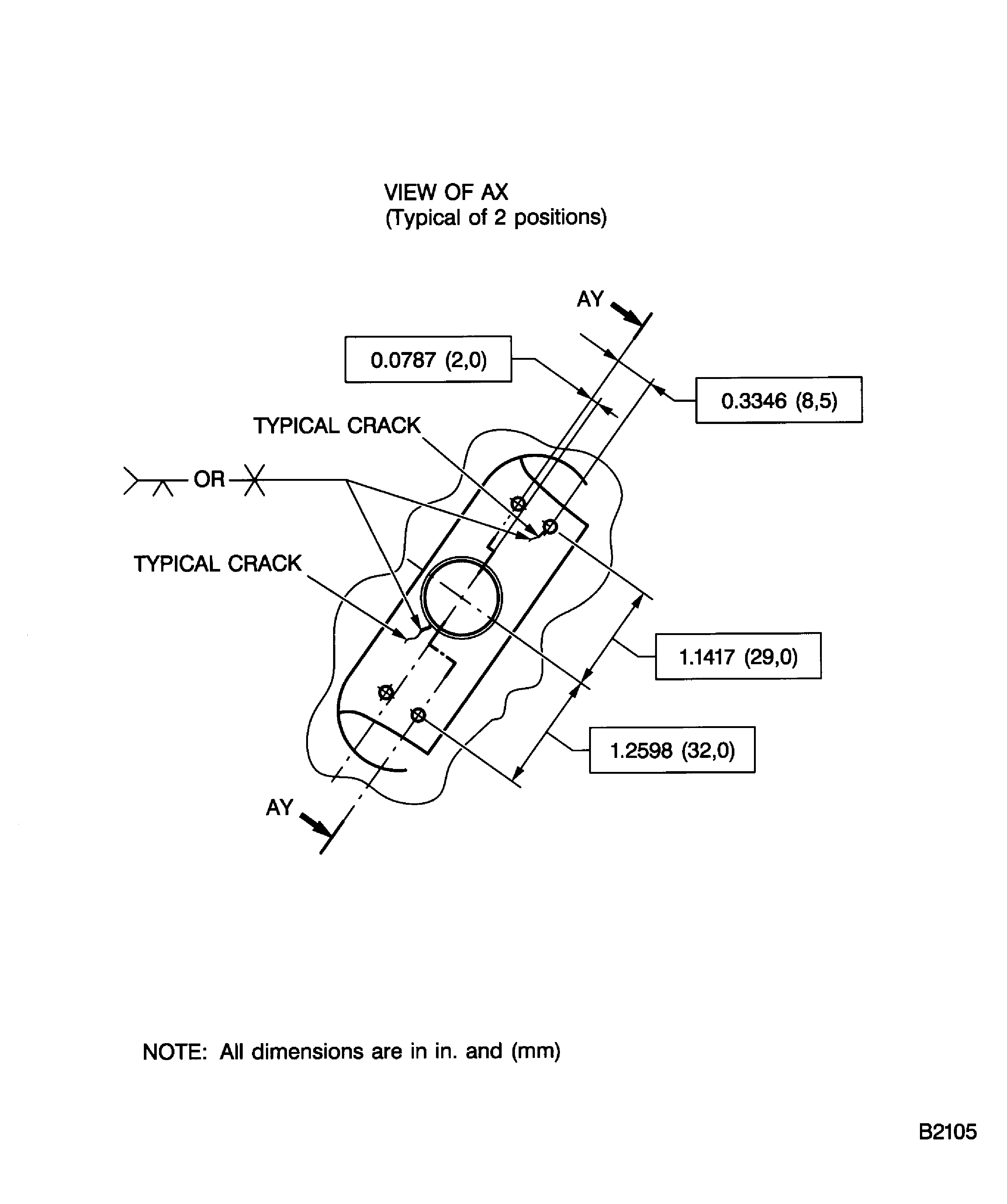

Repair cracks which begin only from borescope hole or rivet holes and are not more than 0.700 in. (17.8 mm) in length.

Do the test for cracks locally.

SUBTASK 72-50-21-230-081 Determine Location and Length of Cracks

Refer to the SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-50-21-110-080 Clean the LP Turbine Case

Refer to Figure and the SPM TASK 72-31-13-310-501. Use CoMat 03-284 WELDING FILLER WIRE, NiBASE.

Refer to Step for welding up of through-cracks.

Weld up prepared areas. Use manual tungsten inert gas technique.

SUBTASK 72-50-21-310-052 Weld up Prepared Surfaces

Refer to the SPM TASK 70-37-00-370-501 and SPM TASK 70-37-01-370-501.

Heattreat component.

SUBTASK 72-50-21-370-054 Heattreat Component in an Oven after Welding

NOTE

This process is alternative to local stress relief method in SUBTASK 72-50-21-370.This process is alternative to oven stress relief method in SUBTASK 72-50-21-370-.

Use one of the methods given in step C, step D and step E. It is necessary for this methods that the stress relief temperature is carefully monitored and kept within given limits. Therefore, thermocouples must be attached to the weld area repaired and coupled to accurate readout equipment. Chromel/Alumel (Ni-Cr-Ni) thermocouple wire is recommended for this repair.

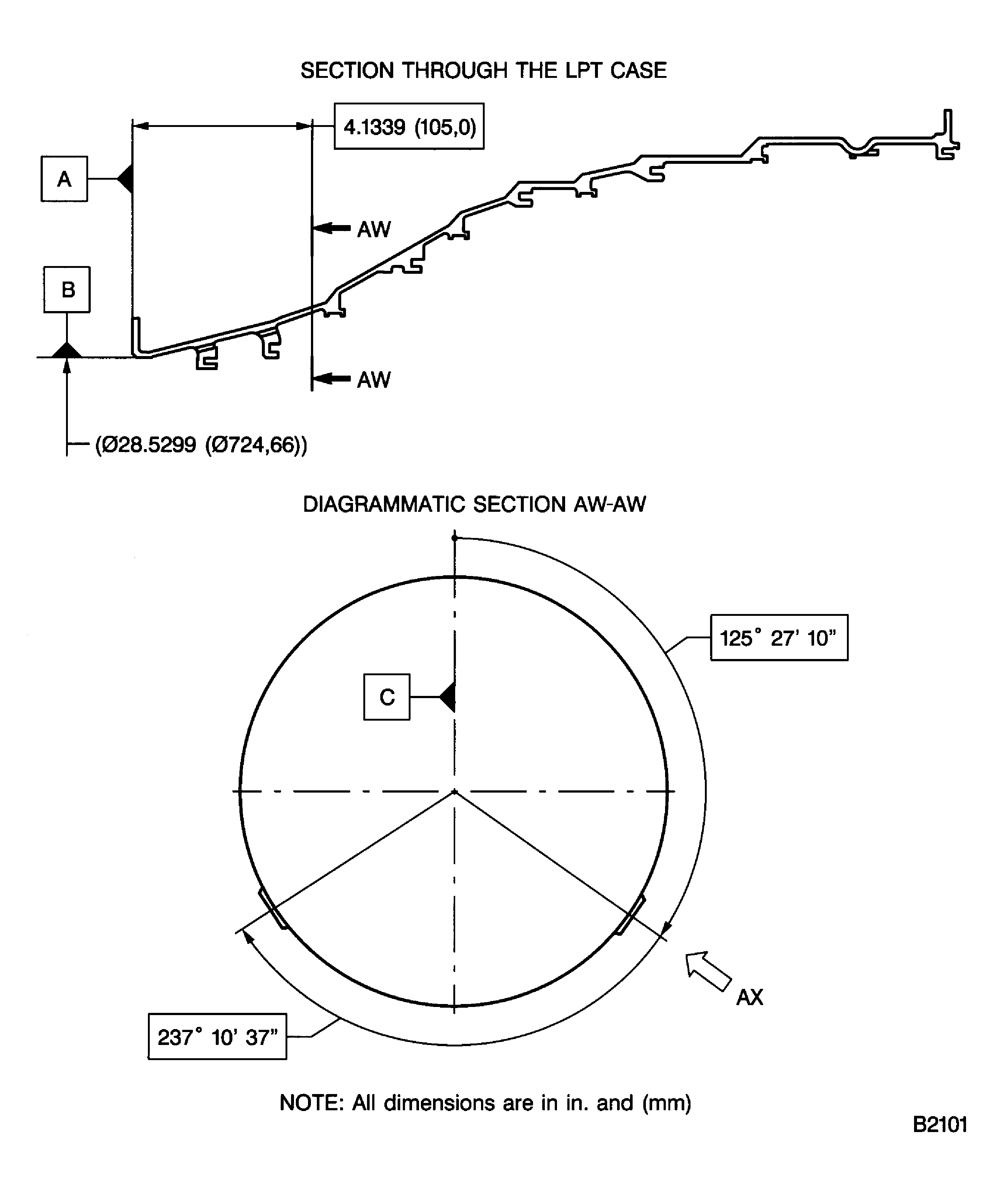

Refer to the SPM TASK 70-37-01-370-501 without item (a) for heattreatment cycle or heat to 1335 to 1365 deg F (724 to 740 deg C) with a heating rate not faster than 54 deg F (30 deg C) per min. and hold for 4 hours. For cool down refer to cycle in SPM TASK 70-37-01-370-501.

Heattreat component.

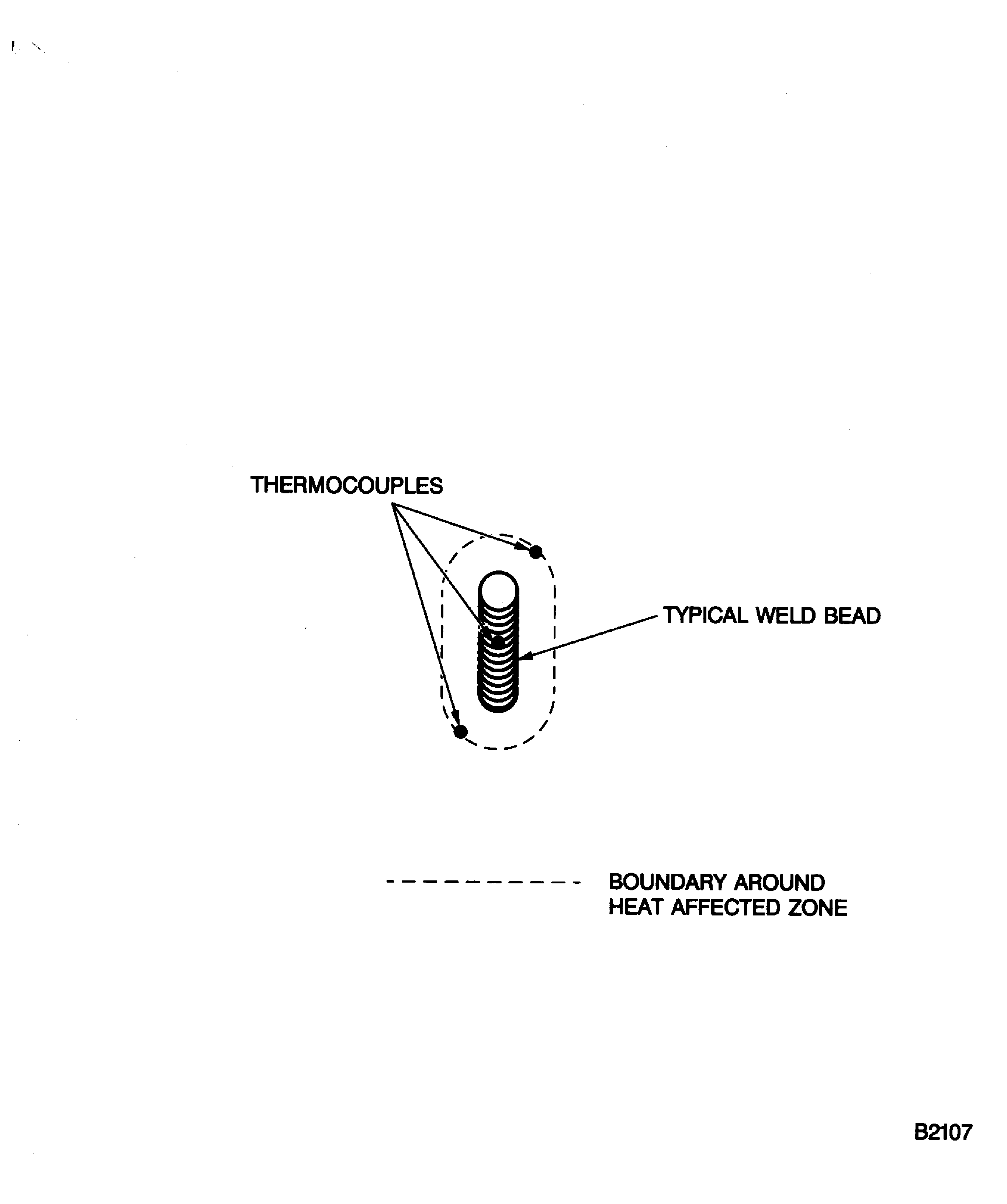

The thermocouples must be attached to the same side of the case that the source heat is supplied from. Deterioration of thermocouples can occur. Use standard capacitance discharge weld equipment to tack weld thermocouple wire to weld bead. Do not use too much power, which causes pits in the repair area. Outer thermocouples must always be attached at the limits of the heat affected zone. Attach thermocouples as shown in Figure.

Attach thermocouple.

To give an equal temperature distribution, the blanket must be installed tight and flat to the case surface. Use kaopak, or equivalent insulating blanket on the resistance blanket and also on adjacent areas (if weld repairing the inside surface, insulate local outer case surfaces also) keep heat loss to a minimum.

Use resistance heated blanket method.

Connect coil to standard induction heater. The placement height of the coil above the part surface affects the strength of the magnetic field inducted in the case and consequently the heat generated in the case. A test is required to achieve the correct height of the coil such that heat is sufficient to stress relieve the area. On no account must the coil be set closer than 0.125in. (3.18 mm) to the case surface.

Use induction coil method.

SUBTASK 72-50-21-370-055 Heattreat Component using Local Stress Relief Method after Welding

NOTE

Refer to the SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-50-21-110-081 Clean the LP Turbine Case

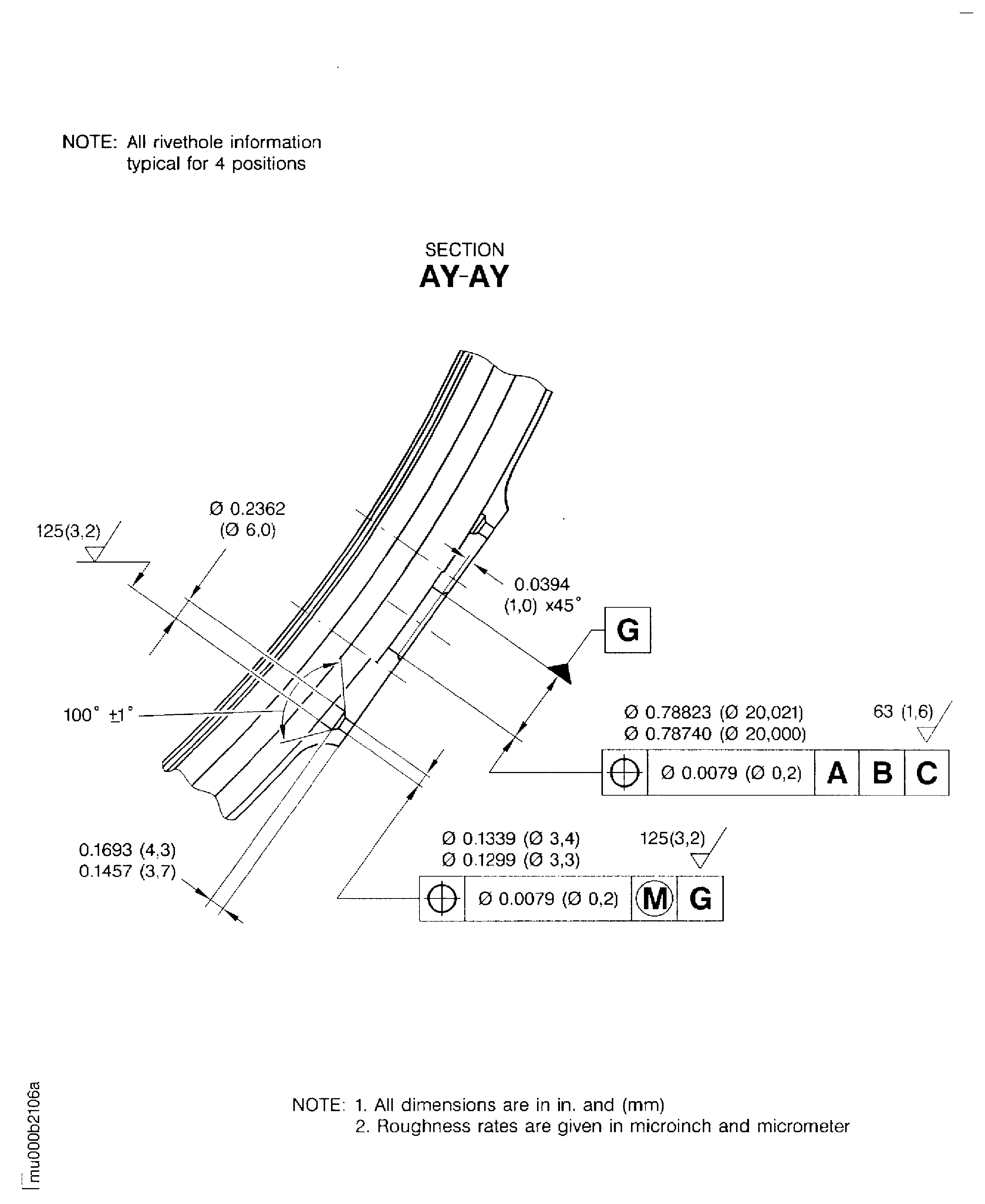

For actual dimensions refer to Figure.

Machine borescope hole and/or affected rivet holes.

SUBTASK 72-50-21-320-058 Restore Borescope Hole and/or Rivet Hole Diameters

Refer to the SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-50-21-110-082 Clean the LP Turbine Case

For actual dimensions refer to Figure.

Dimensionally examine the machined areas.

SUBTASK 72-50-21-220-135 Do the Post Repair Inspection

Figure: Weld repair of cracks adjacent to borescope hole

Weld repair of cracks adjacent to borescope hole

Figure: Weld repair of cracks adjacent to borescope hole

Weld repair of cracks adjacent to borescope hole

Figure: Weld repair of cracks adjacent to borescope hole

Weld repair of cracks adjacent to borescope hole

Figure: Typical layout of thermocouples for local heattreatment method

Typical layout of thermocouples for local heattreatment method