Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-023 LPT Inner Diffuser Duct Support Ring - Plasma Spray The Rear Face, Repair-023 (VRS4129)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Turning lathe | LOCAL | Turning lathe | ||

| Grinding machine | LOCAL | Grinding machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-047 TAPE, HEAT REFLECTIVE | 52152 | CoMat 02-047 | ||

| CoMat 02-050 HIGH TEMPERATURE GLASS CLOTH TAPE | 76381 | CoMat 02-050 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 | ||

| CoMat 05-046 ALUMINUM OXIDE GRIT | 62596 | CoMat 05-046 |

Spares

NONESafety Requirements

NONEProcedure

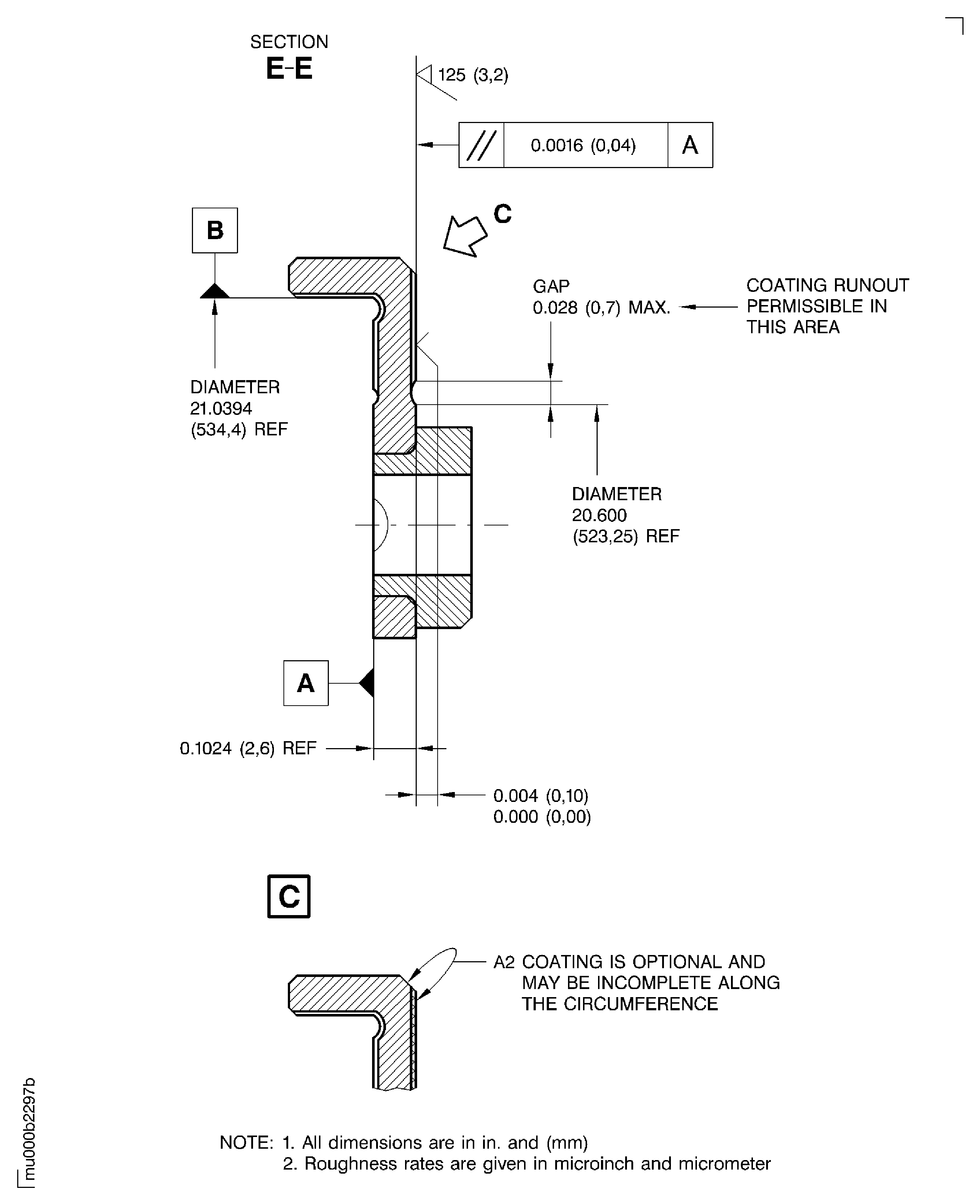

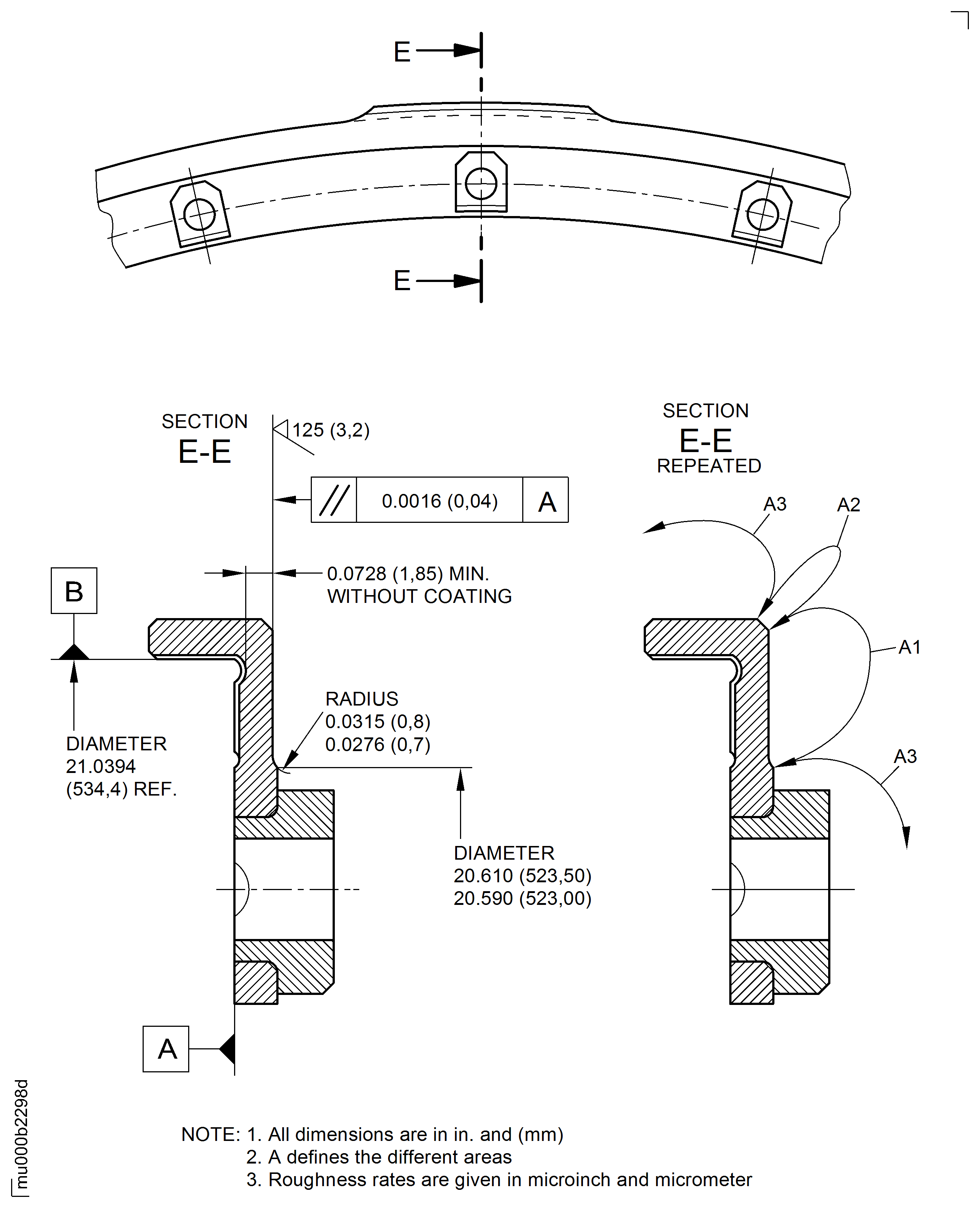

Refer to Figure.

Remove the old coating and damage fully.

Keep material removal to a minimum. Use turning lathe or grinding machine.

Machine to remove the old coating.

SUBTASK 72-50-24-325-076 Machine the Rear Face

Refer to Figure for dimensions.

Examine dimensionally.

SUBTASK 72-50-24-220-142 Examine Machined Areas

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-106 Clean the Support Ring Assembly

Mask the areas A3.

Surface texture must be 120 to 200 microinch RMS (3.0 to 5.0 micrometer Ra).

Blasting in area A2 is permitted.

Refer to Figure and the SPM TASK 70-34-03-340-501.

Grit blast the area A1.

SUBTASK 72-50-24-340-078 Prepare Surfaces for the Plasma Spray Procedure

Refer to Figure.

Coating in area A2 is permitted if it was blasted before.

Make sure that there is sufficient material to do last machining.

Refer to the SPM TASK 70-34-03-340-501.

In area A1 minimum coating thickness is 0.0039 in. (0.10 mm) after machining and maximum coating thickness is 0.030 in. (0.75 mm) before machining.

Plasma spray the area A1.

Refer to the SPM TASK 70-34-03-340-501-002 for Acceptance Standards.

Examine the coating.

SUBTASK 72-50-24-340-079 Plasma Spray the Prepared Surfaces

Refer to Figure and the SPM TASK 70-34-03-340-501. Use turning lathe or grinding machine.

Machine the coated area.

SUBTASK 72-50-24-325-077 Machine the Coated Areas

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-108 Clean the Support Ring Assembly

Refer to Figure.

Examine machined areas dimensionally.

Refer to the SPM TASK 70-34-03-340-501.

Examine the coating visually.

SUBTASK 72-50-24-220-143 Do the Post Repair Inspection

Refer to the SPM TASK 70-09-00-400-501.

Vibropeen VRS4129 and applicable beehive symbol adjacent to the part number.

SUBTASK 72-50-24-350-073 Make a Mark to Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions