Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-052 LPT Inner Diffuser Duct Support Ring - Weld Repair Cracks, Repair-052 (VRS4498)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

If required remove the locating key before repair and replace after repair. Replace the locating key before heat treatment Step if brazing method is used. Refer to Repair, VRS4130 TASK 72-50-24-300-024 (REPAIR-024).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 72-50-24-320-072 Remove the Coating

NOTE

If the part was repaired per VRS4129 before, remove the build up coating per VRS4129 TASK 72-50-24-300-023 (REPAIR-023).Keep material to a minimum to remove cracks.

Use hand held grinder.

Refer to the SPM TASK 70-31-13-310-501 and Figure.

If crack goes through, V-groove to half depth and weld up.

After this, V-groove from other surface until weld seam as necessary.

Weld other side as usual.

Completely V-groove the full length of the crack.

SUBTASK 72-50-24-350-097 Prepare the Cracks Before Welding

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-160 Clean the Support Ring Assembly

Refer to Figure and the SPM TASK 70-31-13-310-501.

For welding up through cracks refer to SUBTASK 72-50-24-350-001.

Gas tungsten arc weld the cracks.

SUBTASK 72-50-24-310-072 Weld Repair the Cracks

Refer to the SPM TASK 70-37-00-370-501.

Put the support ring assembly in an oven for eight hours at 1450 to 1500 deg F (788 to 816 deg C).

Use argon or vacuum.

Cooling rate equivalent to air cooling.

Heat treat the support ring assembly.

SUBTASK 72-50-24-370-067 Heat Treatment after Weld Repair

Refer to Figure.

Welded areas must be equal to the original contours and must be flush with the adjacent surfaces.

Use hand held grinder.

Dress the welds.

SUBTASK 72-50-24-320-073 Dress the Welded Areas

CAUTION

DO NOT OVERHEAT THE AREAS TO BE DRESSED.Refer to VRS4466 TASK 72-50-24-300-053 (REPAIR-053).

Restore the wear protective coating.

SUBTASK 72-50-24-350-098 Do the Post Repair

NOTE

Restore the build up coating. Refer to VRS4129 TASK 72-50-24-300-023 (REPAIR-023) if it was removed before.

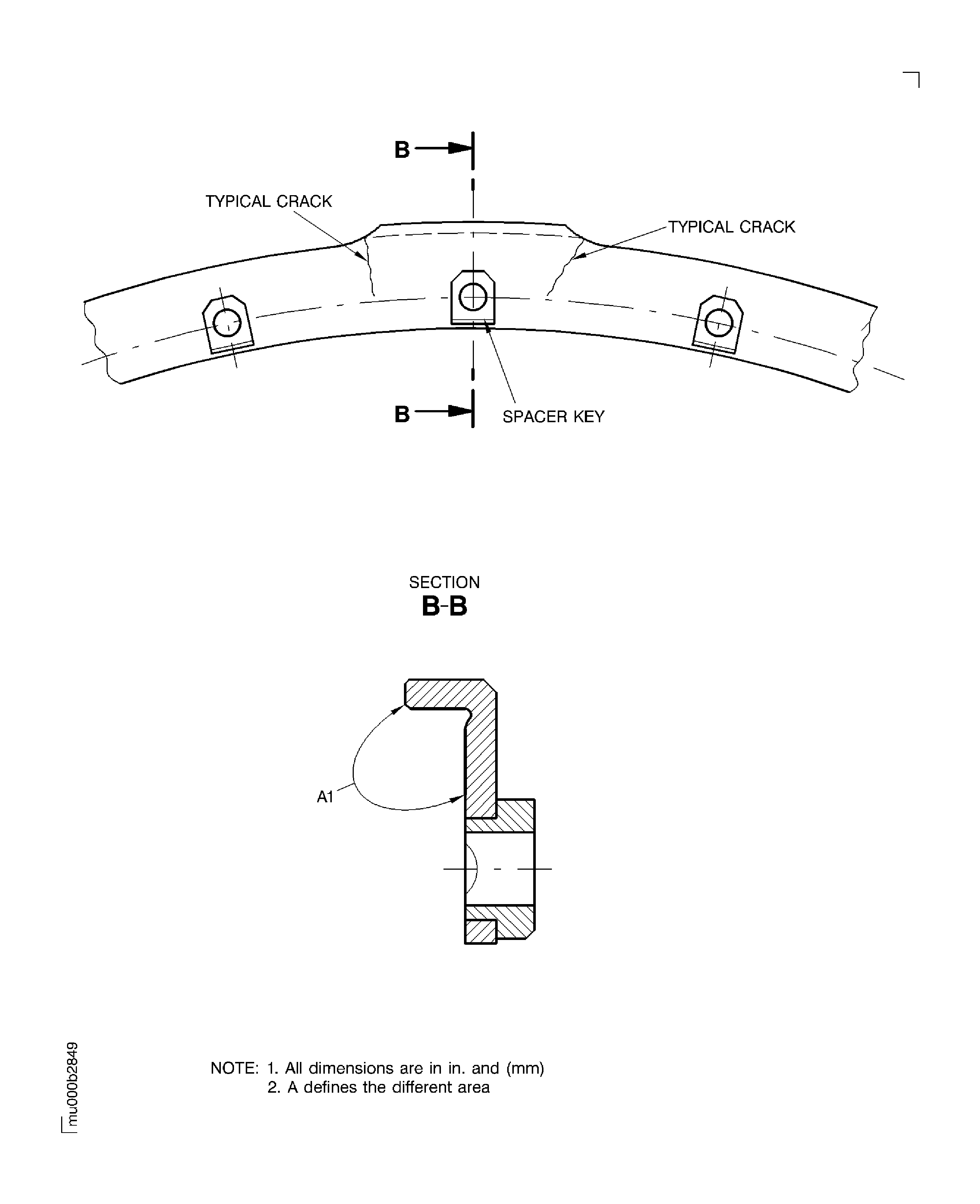

Figure: Weld repair cracks on the support ring assembly

Weld repair cracks on the support ring assembly